Week 13

Wildcard Week

Supersonically fast Zund & very slow-curing glass fibre composites

I wanted to dedicate this week to my final project where I will be actuating roses. My plan was to get the petals cut with the Zund, and to cast my torso with plaster so that I could make a composite out of it with glass fibre.

Composites

The composite training with Alfonso was very fun and we managed to successfully make a composite out of a 3D printed airplane cockpit that Alfonso designed.

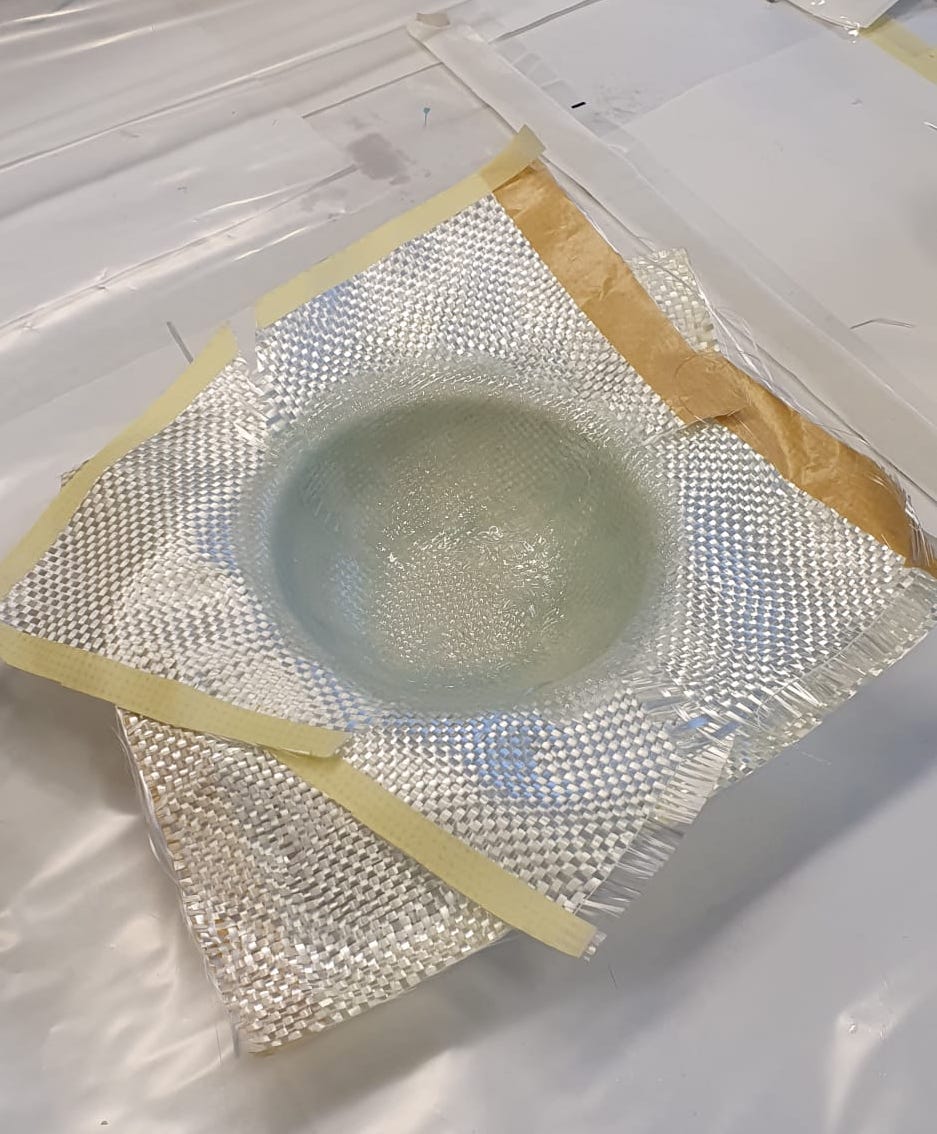

After that, I wondered how well we the glass fibre would work on larger curved areas so I went ahead and made a plaster cast out of a bowl I found in the lab. The composite process involves vaccuum sucking the entire structure in a plastic bag, so the cast needs to be very strong. When casting the bowl, I did some test with the number of layers of plaster bandage to test out its strength, and Alfonso and I decided that 4 layers of plaster bandage would be strong enough to endure the vaccuum. With my plaster cast in hand, I went to MIT's Mars lab.

Step 1

The first thing we did is prepare the plaster cast with some sealing agent to smooth out the plane.

Step 2

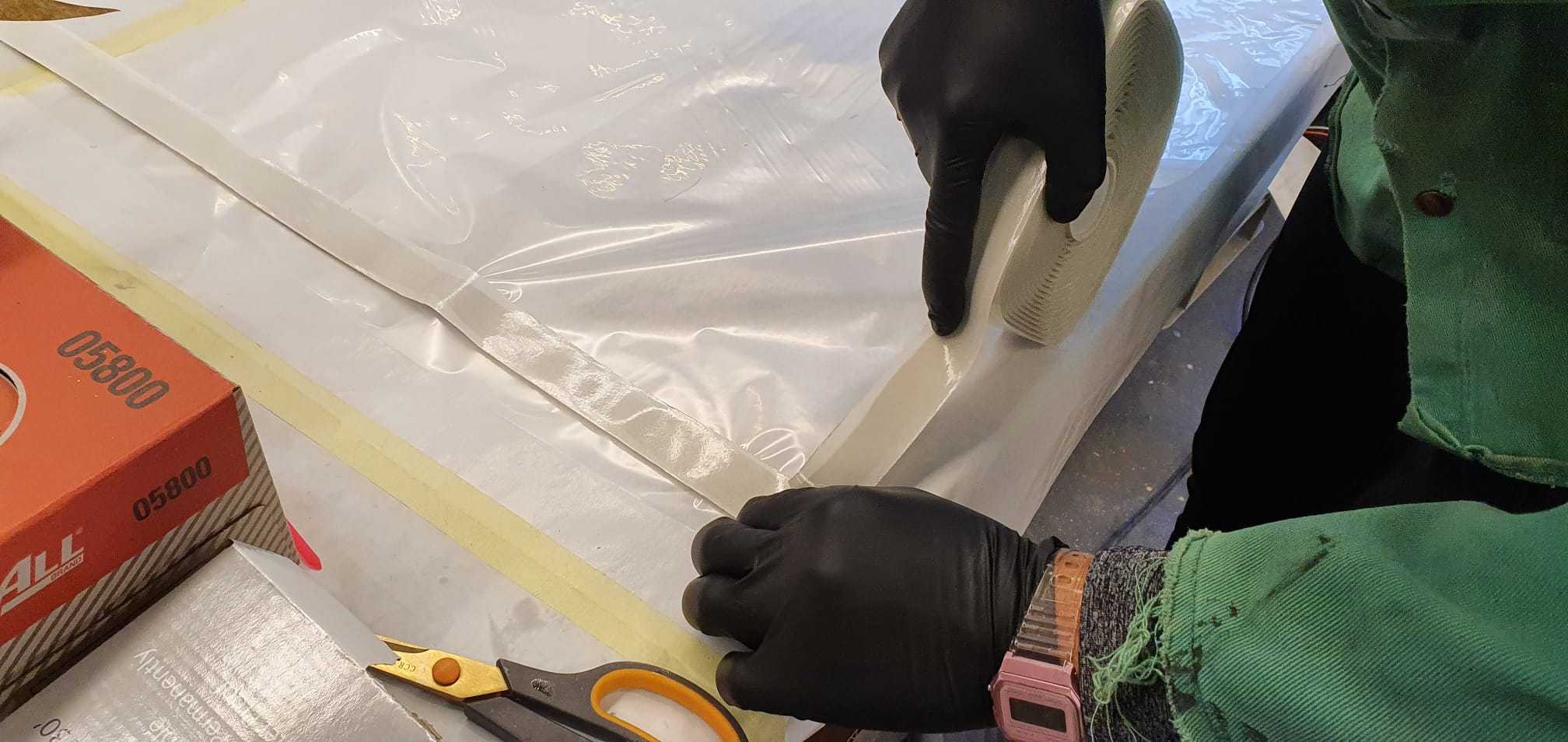

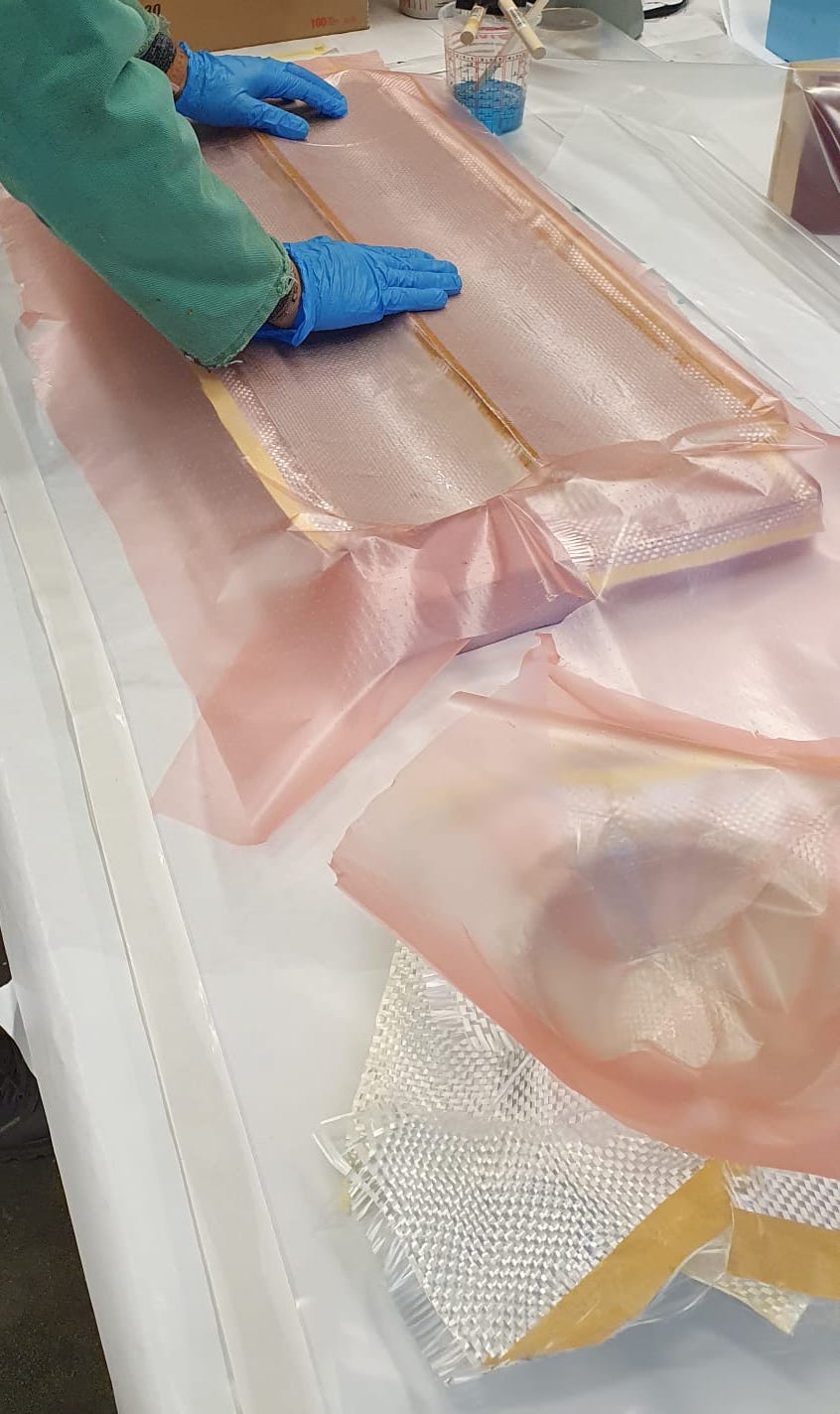

Next up, we prepared the plastic encasing by taping the edges with very thick tape:

Step 3

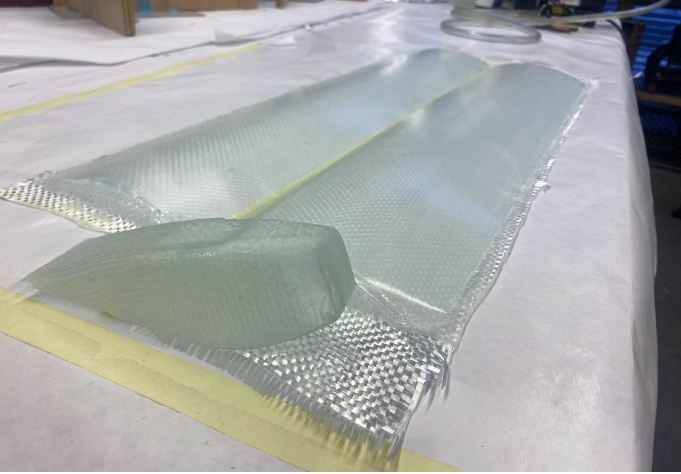

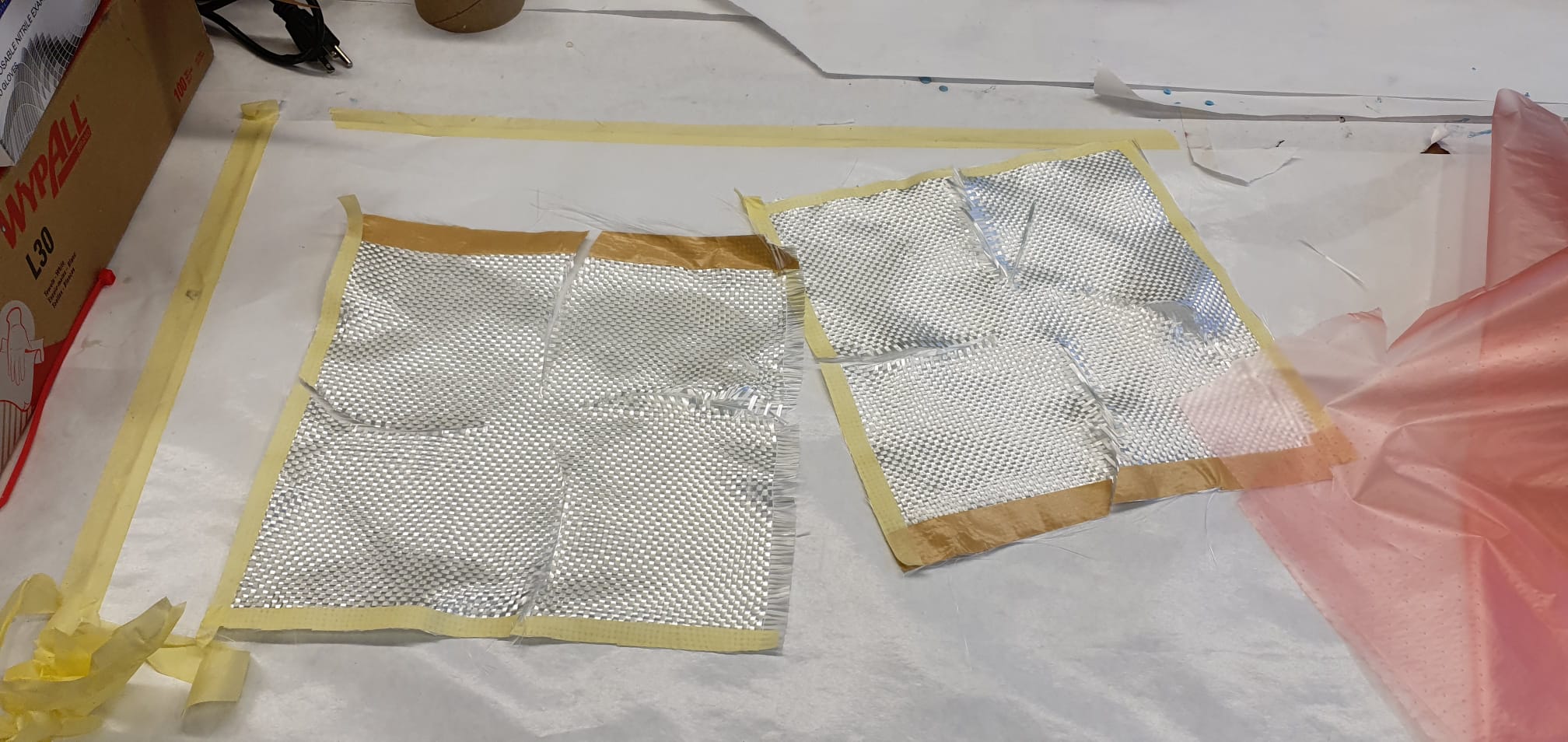

I then cut the glass fibre in the shape of the object that we will be 'casting'. Cutting glass fibre is very tricky because of how it is braided, but placing tape where you want to cut makes it much easier. Because I was using a curved object, I had to make curved cuts and it fit perfectly.

Step 4

The resin we used turned out to be quite ancient. 6 years old to be exact, but it worked like a charm. We mixed 2:1 of the two solutions and gave it a good mix. I then started to apply resin to the fibre using a sponge brush, making sure I don't apply any pressure to deform the fibre braid. I placed the second sheet on top of the first, and because I had quite a bit of resin on the first layer, I didn't have to apply much resin to the second layer.

Alfonso cut the edges off which was a bit tricky:

Step x

Once that was done, it was time to seal the deal (or bag). We placed another plastic sheet on top (it has a name, I will get back to this).

We then layered the whole lot with a felt-like fabric, which will soak up the excess resin.

Alfonso poked a tiny hole in the plastic and placed the vaccuum hose inside it.

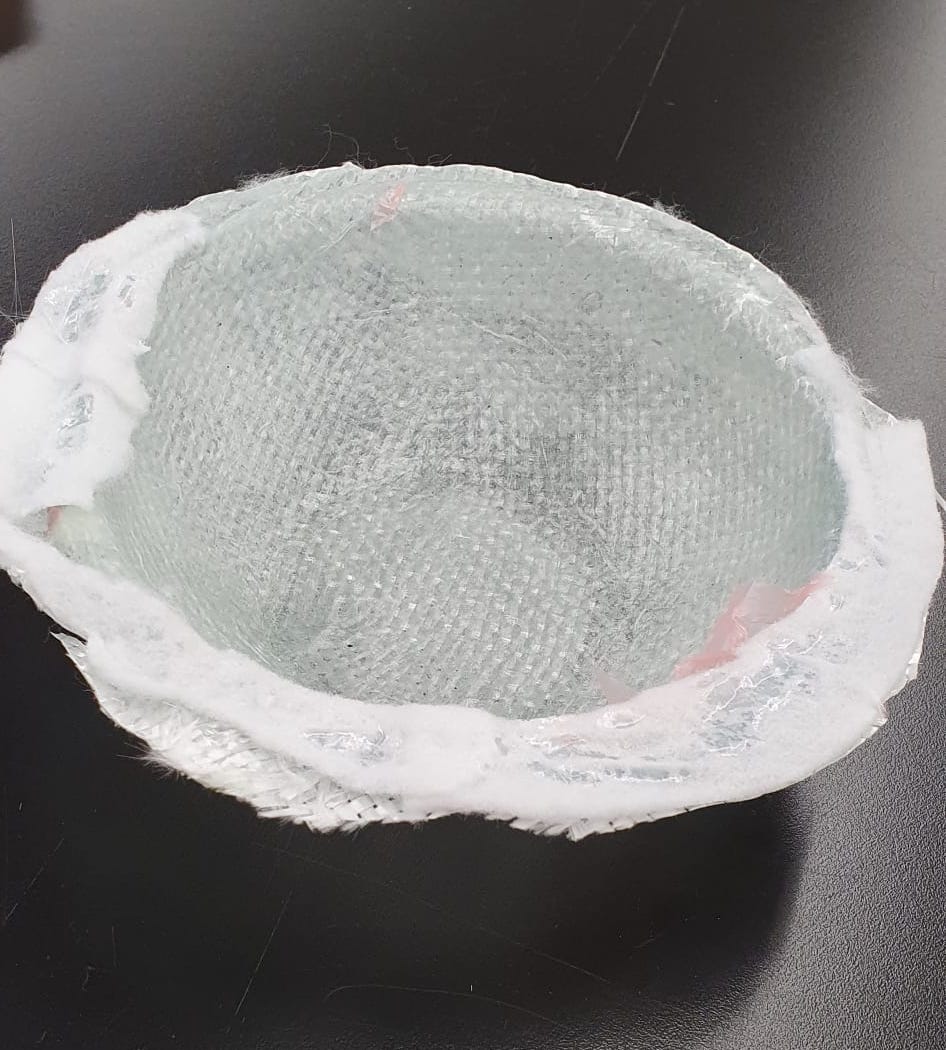

It has to be vaccuum sucked for at least 12 hours. I came in the next day and it came out pretty good.

The Zund

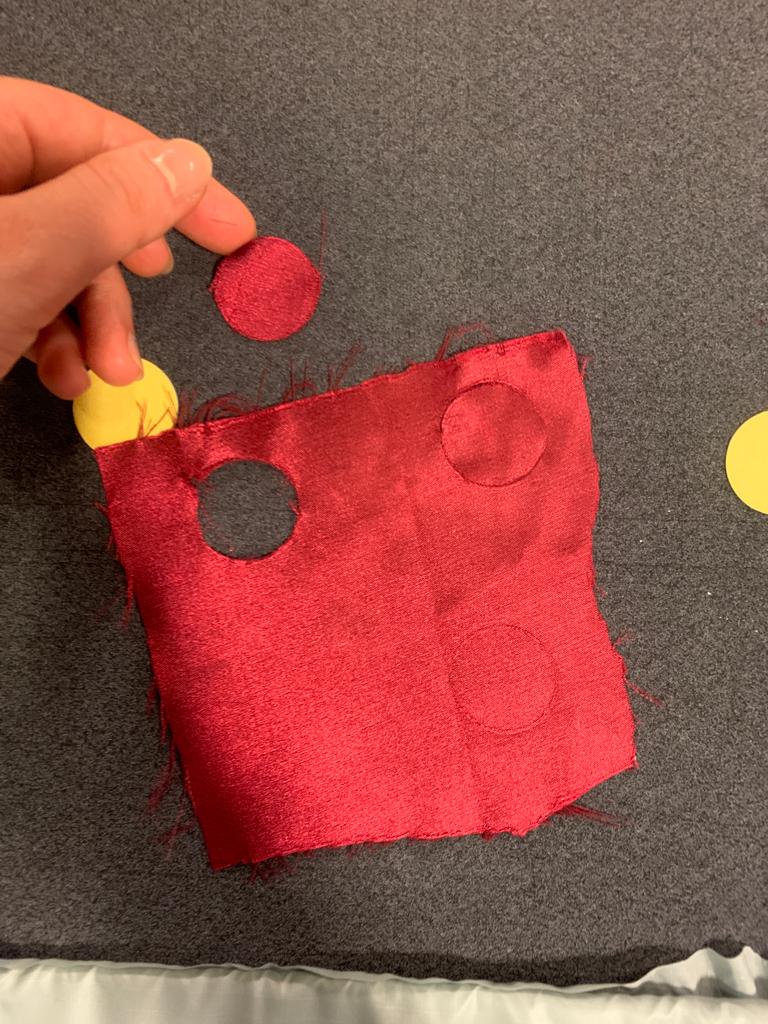

Because I want to make flowers out of fabric, I though it would be a good idea to cut the petals using the Zund, which was designed for cutting fabrics. The training was very interesting, and I was amazed it could cut sheets of metal into origami structures. We CAD'ed a quick design of a circle to test cut the satin fabric that I brought. It was a small piece, so Alfonso placed a sheet of thick paper of top of it so it wouldn't move mid-cut.

The first test cut we did didn't cut through, so we set it to cut twice. That also didn't cut all the way through. Alfonso then changed some of the settings and then it magically worked. However, it wasn't the best cut ever:

It also frayed which is not ideal. I decided to use the lasercutter instead to make the actual petals.