Week 13: Wildcard Week

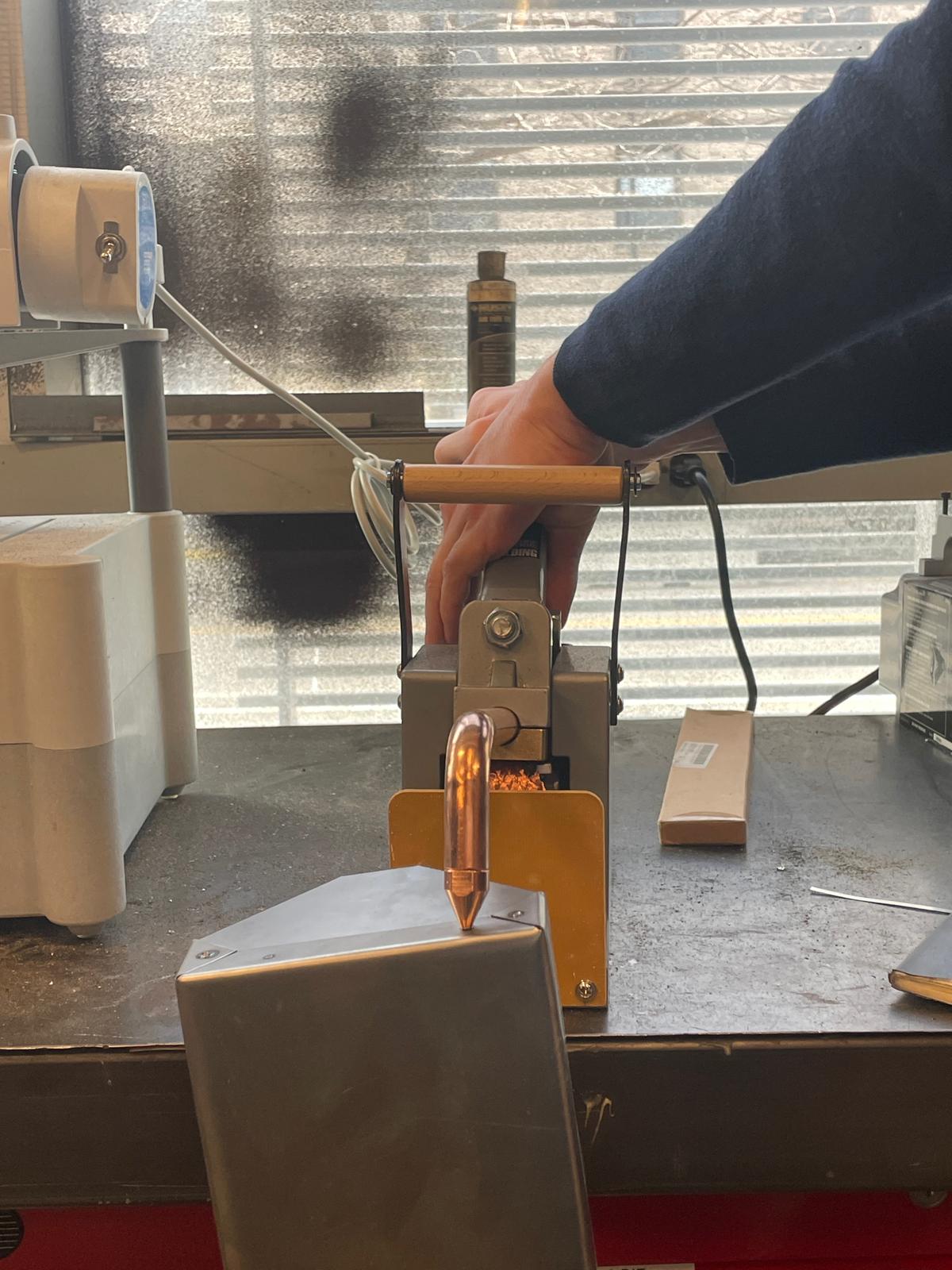

This week, we were given the opportunity to choose a topic amongst a list of 12 and learn a new method or tool from an expert. Although all topics looked appealing, I knew that I wanted to explore metals since the failure of my Glockenspiel. I therefore chose the topic taught by John on how to use sheet metal. I attended John's workshop where we went over using the FabLight fiber laser cutter to cut sheet metal, using the finger brake, as well as the anvil, to fold our pieces of metal, and using a few welders such as spot welders, MIG welders and TIG welders. It was very instructive to go over all of these methods and I had been wanted to hammer metal on an anvil for a long time, so that was fun to do.

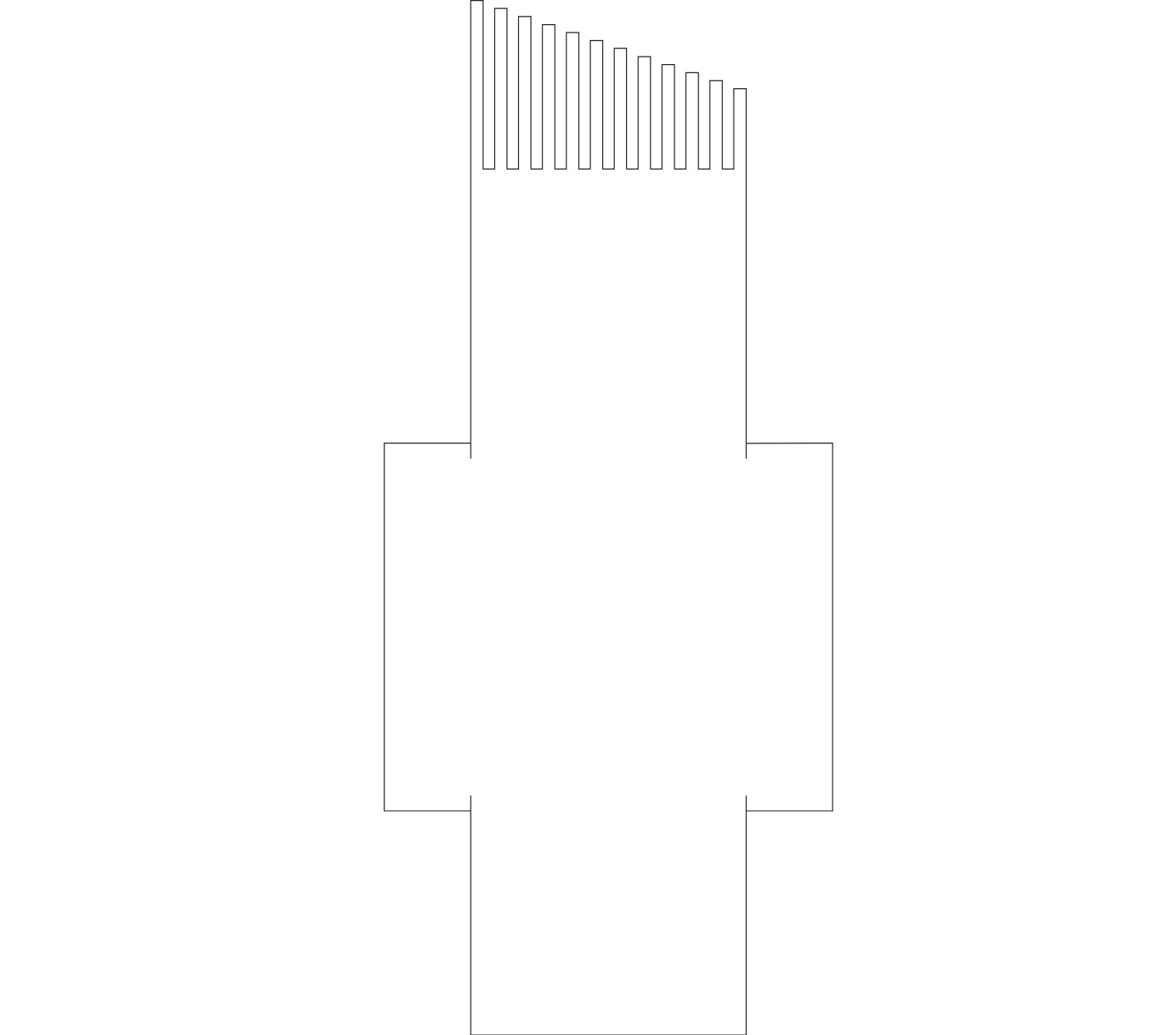

I looked at the sheets we had and discovered that they had a pretty nice spring quality, which could potentially made them fit to make metal tines that could resonate. I therefore decided to do a small kalimba (a.k.a thumb piano)-like instrument, and started designing the svg on Illustrator. I obtained the following design:

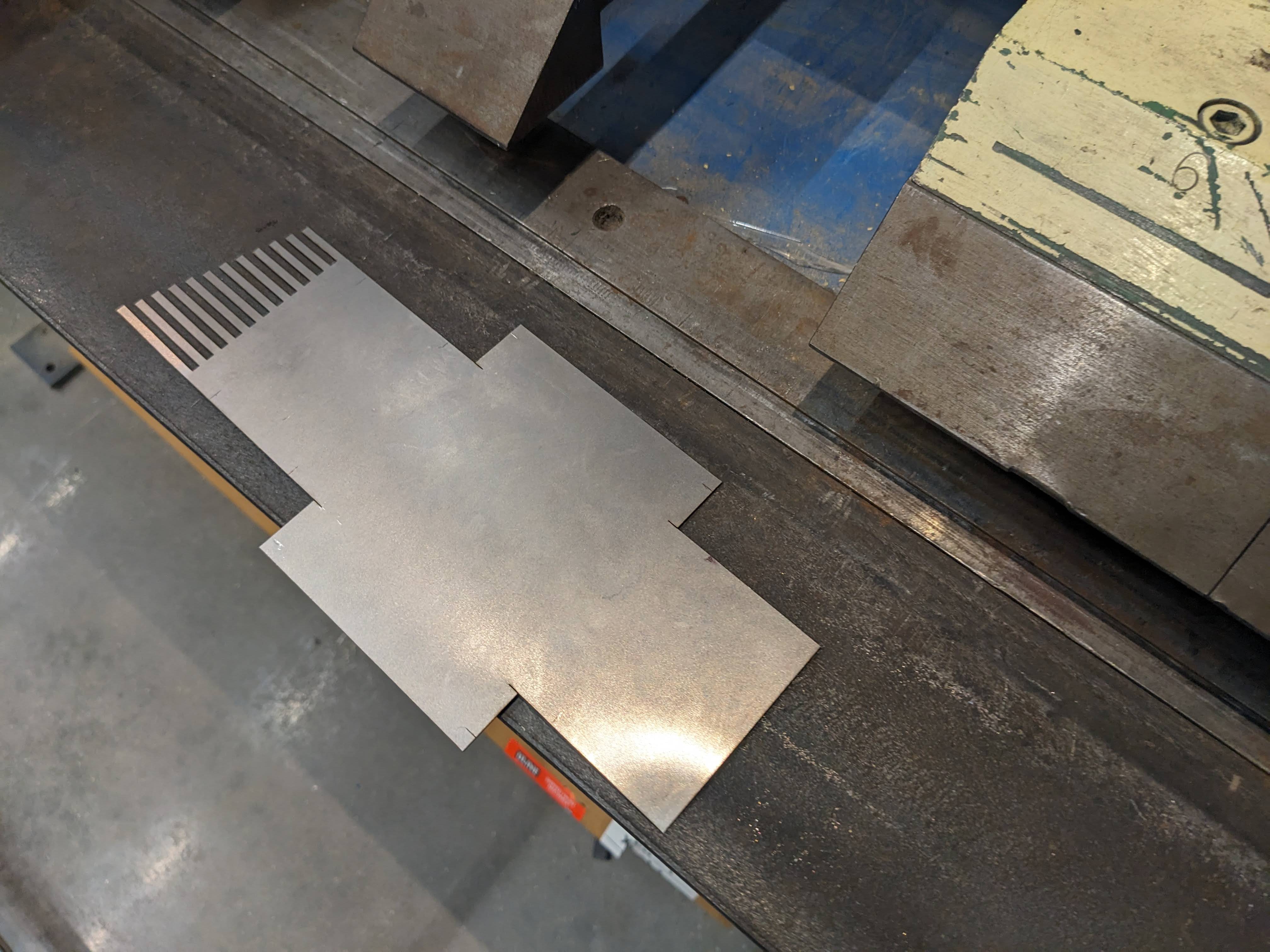

I then used the FabLight and cut out my template. I went on to use the finger brake to fold out the different parts of my design, but I had to fold some by hand because the features were too small. I also realized that properly thinking ahead of the order of the folds was more complicated than expected. I had to undo a few folds in order to fold more inner features a few times before obtaining a satisfying result.

I ended up not using any welding on this design, but I am still very glad to have learned the method. Although it looks tricky, I hope to be able to use it in another work soon. Eventually, I obtained a fun-looking kalimba which does make sound (!!) although not the most pleasing one. Obviously, a regular kalimba has its tines decoupled from the main body, which I did not do here. However, I enjoyed the final result for its aesthetics as well as the metalic fun sounds it produces.

Notes to a future me (learning outcomes):

- Making folds in metal in the proper order is challenging.

- There are many welding techniques, and some of them are more tricky than others.

- Metal is cool.