Assignments

The individual assignments for this week are:

- make (design+mill+assemble) something big (~meter-scale)

- extra credit: don’t use fasteners or glue

Designing

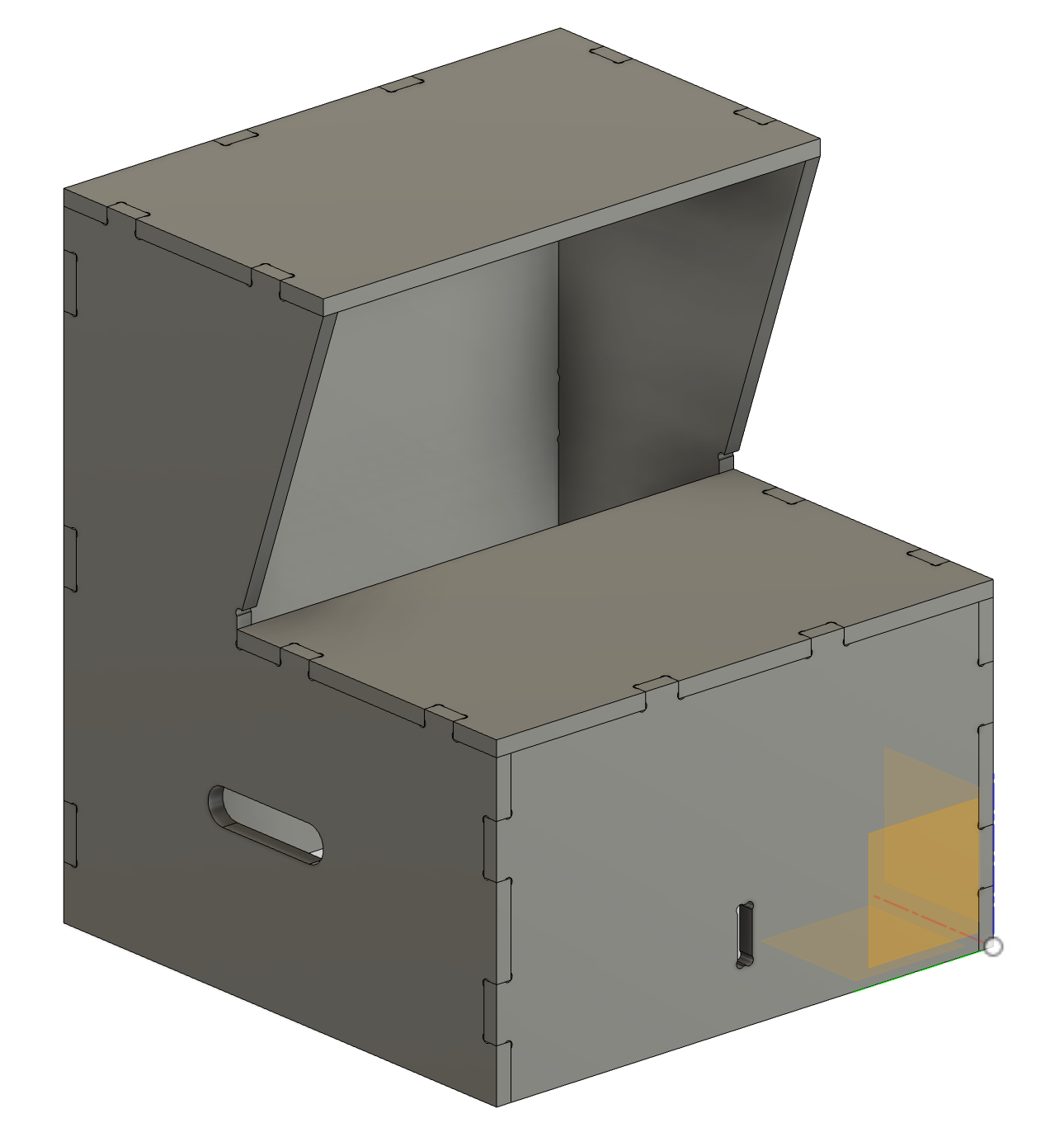

I wanted to make a couple of steps. This would help my girlfriend reach the higher shelves in her kitchen that she normally has trouble reaching.

After discussing what she wanted, I made each step have a depth of 9”, be 15” wide, and be at a height of 9” above the previous. To `save space, there is a 3” overlap between the steps.

I designed it in 3D, rather than making it in 2D and trying to get all of the pieces to fit together afterwards.

After the sketch was completed and the body created, I used the Nifty Dogbone extension (I am on the 60 day free trial) to add dogbones to all internal corners.

CAM

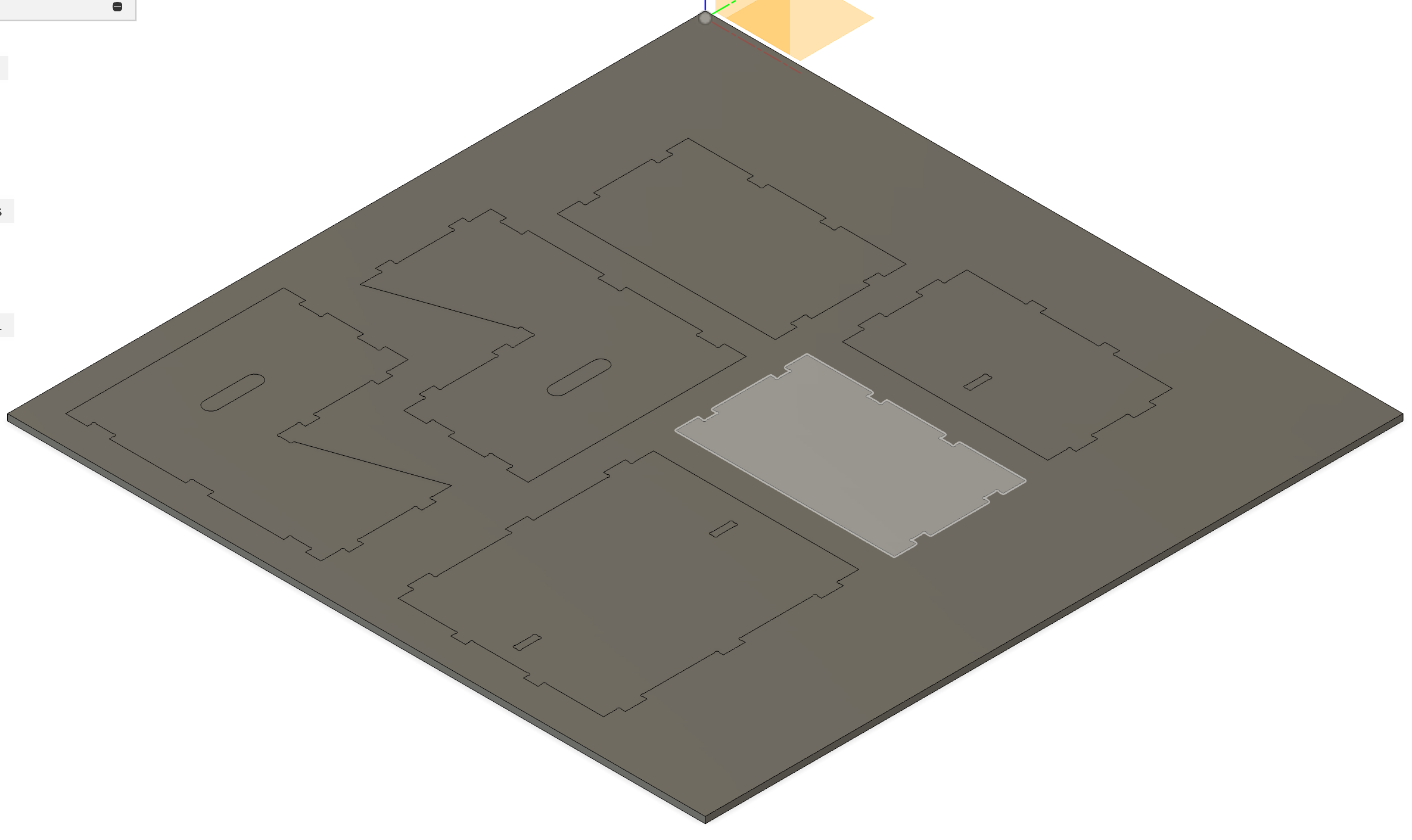

I used the arrange feature to put all of the pieces onto the 48” x 48” stock for milling.

I am using a 3/8” endmill for all of the cutting, except for the dogbones, which were done by the 1/4” endmill.

Machining

To prepare the stock, we used a nail gun to nail the stock to the bed using roughly plastic nails in a 5x5 grid.

I then set the X, Y, and Z axes using the zeroing tool.

After milling, the pieces looked like:

I used an oscillating tool to cut off all of the tabs left over from the mill, and used rasps to file down the remaining stubs of the tabs.

I tried putting the pieces together, but the edges of the fingers for the finger joints were a bit too rough and stuck out, so I ran the rasps on each side of every finger four times so that they would all fit together.

At this point, I would align the pieces and use the butt of the rasps or a rubber mallet to hammer the pieces together at the finger joints.

I first put together the frame of the steps, and it looked like this. All of these pieces were held together with use friction.

Anthony recommended I use glue to connect each step to the frame in addition to the finger joints, since body weight will make the steps tend to bow in the middle and hence pull away from the edges. I tested it without glue and it seemed to hold my weight fine with only slight bowing, but I ended up using a wood glue on all three sides that connect the steps to the frame.

I also used Anthony’s orbital sander to get rid of all of the rough edges and smooth down all of the corners. I also used some sandpaper to smooth the insides of the handles i added so that it is relatively easy to hold up.