Assignments

The individual assignments for this week are:

- Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to):

Waterjet

I decided that I wanted to try using a waterjet this week for wildcard week. Jen from the Architecture shops is leading this session, and she graciously offered to let us use the waterjet machine. The waterjet machine is capable of cutting through hard and thick objects and other objects that a laser cutter would have trouble cutting through, such as glass, tiles, metals, or other ceramics.

The first step is to come up with a design. I tried thinking of things that I could waterjet that would be useful for my final project, but I couldn’t really think of anything that would be 2D and useful for a climbing wall, besides making holds from a material like tile or metal that can be folded into a 3D shape. However, I figured that it would be quite difficult to make something that is strong, shaped like a climbing hold, and thick enough to work as a good climbing hold. There was also the issue that a waterjet has a large kerf and error on its precision, which meant that it wasn’t ideal for the small features of a climbing hold.

I decided that I would instead just make something decorative, which would be more material agnostic, as well as being potentially more fun/useful(?).

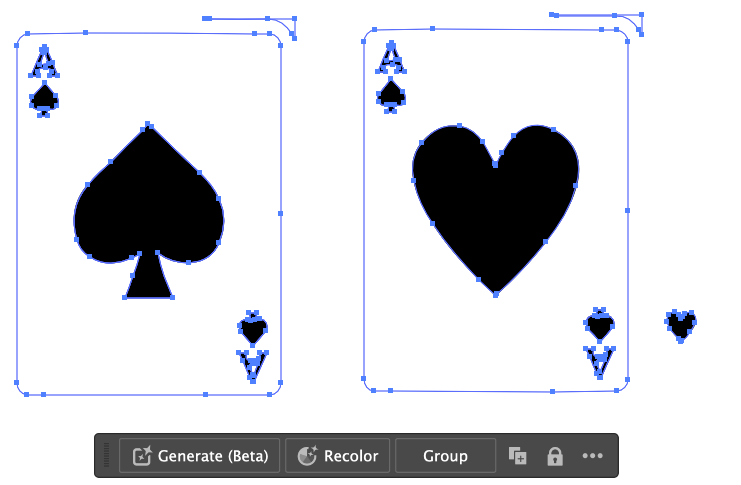

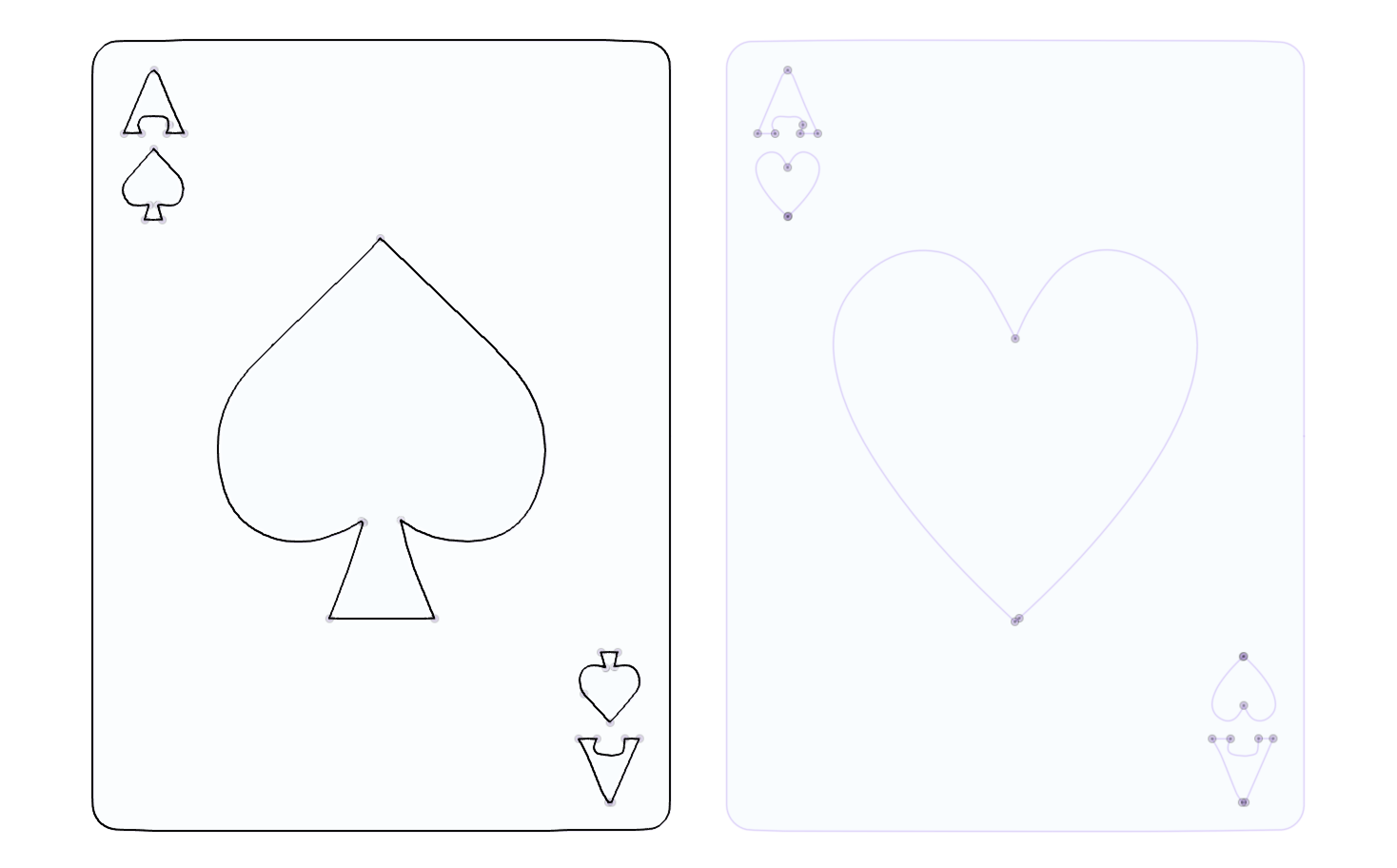

Since I like playing poker and other card games, I decided that I would make a couple of playing cards to use as a decoration. To do this, I looked up some images of poker cards, copied them and pasted them into Adobe Illustrator to turn them into a dxf file. I found an image that contained two aces overlapping which I liked. However, I also realized that I couldn’t just use the waterjet on them, since the card that was behind would be disconnected. Thus, I just cut out the card that was behind, and copied and pasted it. I then found an image of the heart, and replaced the spades in the copied card to make an ace of spades and an ace of hearts.

The process for this was relatively simple:

- Open an image that I want in Adobe Illustrator and select it

- Click on Object -> Image Trace -> Make

- Change settings like threshold if needed

- Press Expand.

- Delete the parts that I don’t care about.

- Make other changes to the image trace as desired

- Export as dxf

I then opened it in a Fusion sketch, since I was more comfortable with rearranging and making small changes in Fusion. I also rescaled the cards to be roughly 25cm tall. After making finishing touches, I exported this as another dxf from Fusion.

I then sent over the dxf over to Jen.

Waterjetting

The waterjet itself was this big machine that took up about half of the room. It is an OMAX waterjet.

I didn’t have any material to cut out, but luckily the shop had a big piece of scrap aluminum that had a big enough area that I could cut out two of my full size, 25cm cards.

The actual process for waterjetting was as follows.

Pick material. Measure thickness of material and input it and the material type into the computer controlling the OMAX. Prep the machine by homing the origin and setting the z height to the right height above the surface of the material. Put weights on the parts of the stock that aren’t getting cut so that the piece doesn’t move while it is getting cut. Inspect the generated gcode path. Importantly, the waterjet has to have a “lead in” for every cut, which is where it makes a tiny starter cut to the side of the actual cut. For example, when cutting out the outer edge of a card, it would start out by starting the waterjet something like an eigth of an inch outside of the edge, then move towards the path, and then continue through the entire path. Overall, it was quite a simple process, and was very similar to using a laser cutter.

Here are a few shots from the waterjetting.