Week 3 - 3D Printing and Scanning

# Goal

This week the assignment was to 3D print something small that cannot (or is too difficult to) make subtractively. I decided I wanted to make a toy for my pet mouse Goon. Initially, I wanted to 3D print a mini-trampoline, but after some research, I decided that the trampoline mesh net part would not be able to be 3D printed. I still wanted to design something with springs in it because Goon has lots of jumpy energy, so my inspiration landed on those playground rocker toys:

My goal was to make a small version for Goon that he can rock back-and-forth or even jump around on.

# 3D Printing

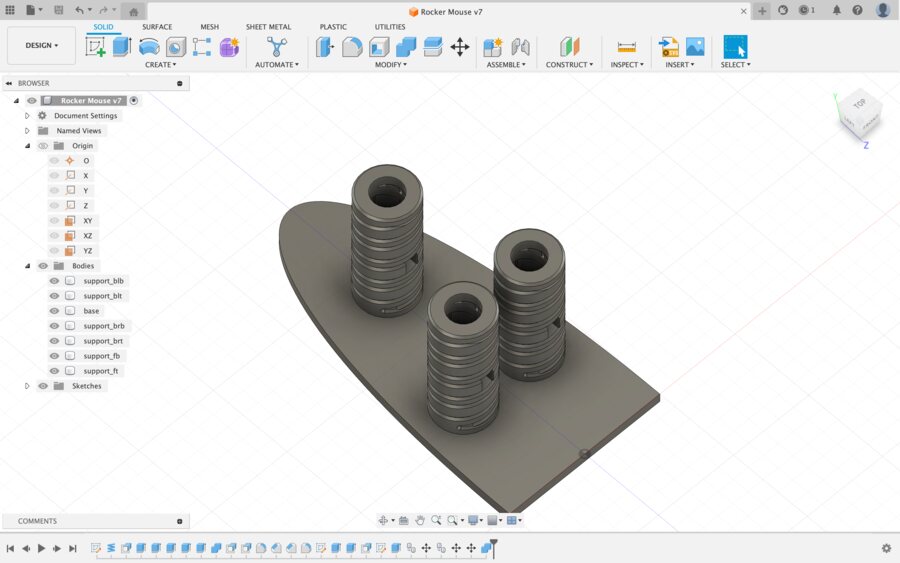

I looked around for some tutorials on 3D printing springs and found a lot of different approaches. I decided to follow this tutorial with designed supports. I modeled the rocker toy in Fusion360 with three springs for more stability for Goon. The tutorial was extremely helpful because its design was parametric, so I only had to change a few parameters in order to use it. Then, I attached the springs to an extruded base with a surfboard like shape:

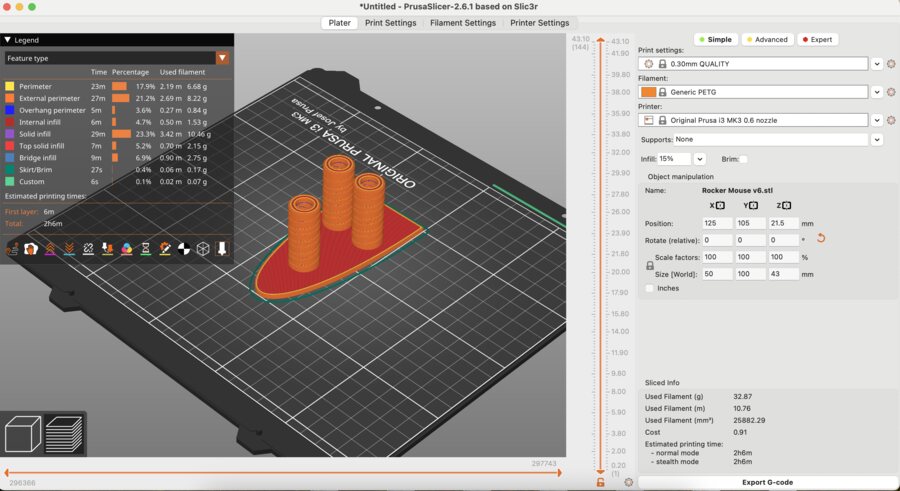

Onto slicing. I downloaded Prusa’s slicer software and sliced my model in their program.

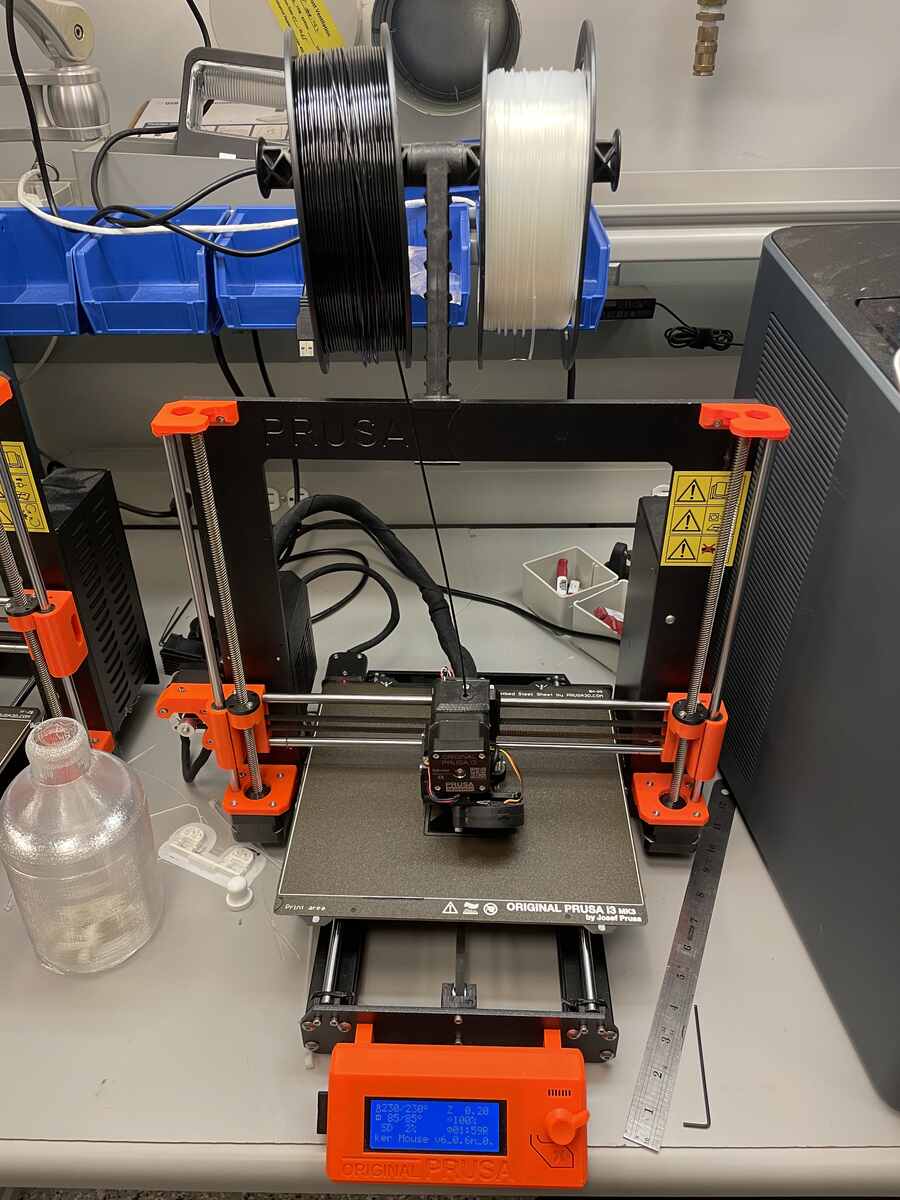

And… we’re off to printing!

|

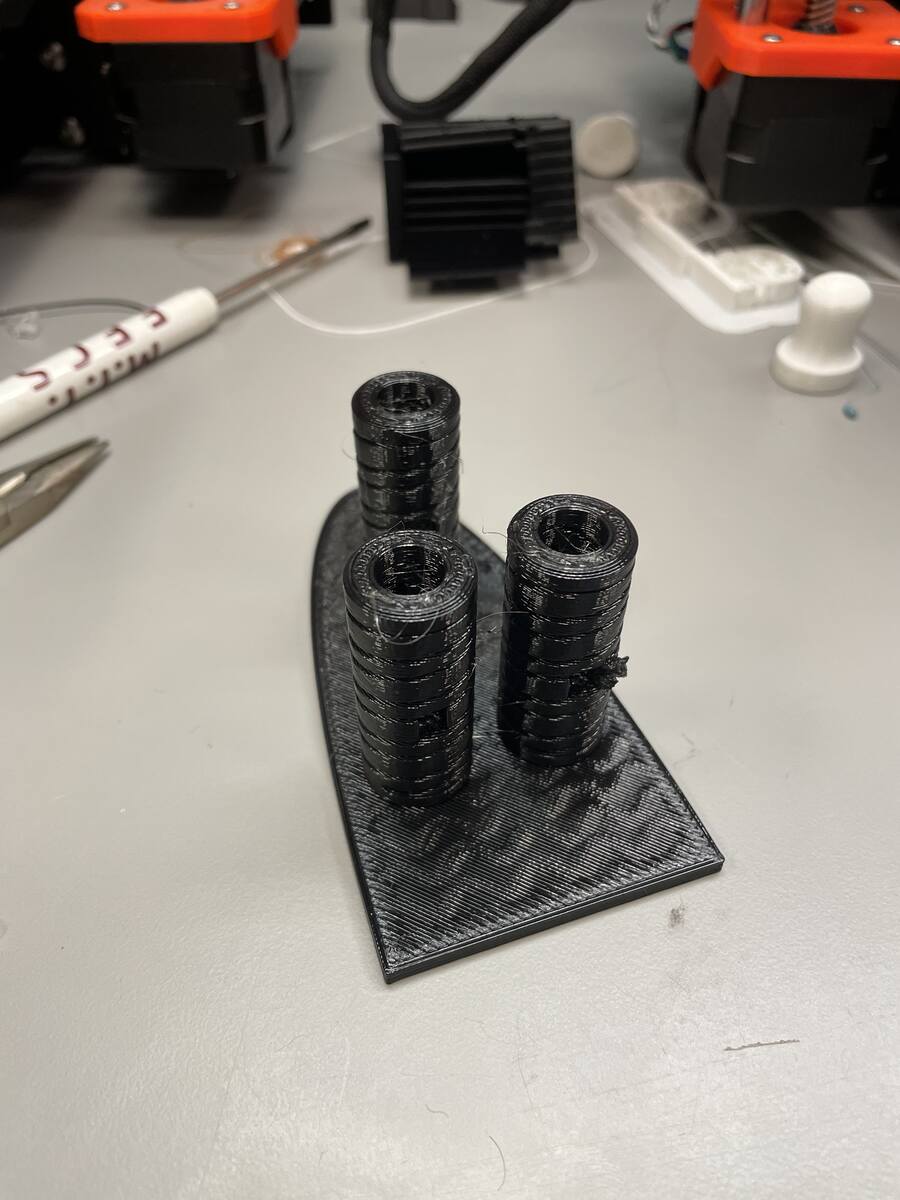

|

Unfortunately, while trying to cut the manually designed supports I used, I ran into several problems. For starters, the springs were placed too close to each other, so I wasn’t able to cut many parts of the support with the clippers. Also, the springs were a bit too thin and cracked easily.

Anthony suggested I increase the pitch and try printing a single spring with no supports. If the pitch is large enough, the spring should be able to print just fine without supports. However, the flat part of the spring at the top required supports in the slicer, so we ended up autogenerating supports for the whole piece for a run to see how those came out.

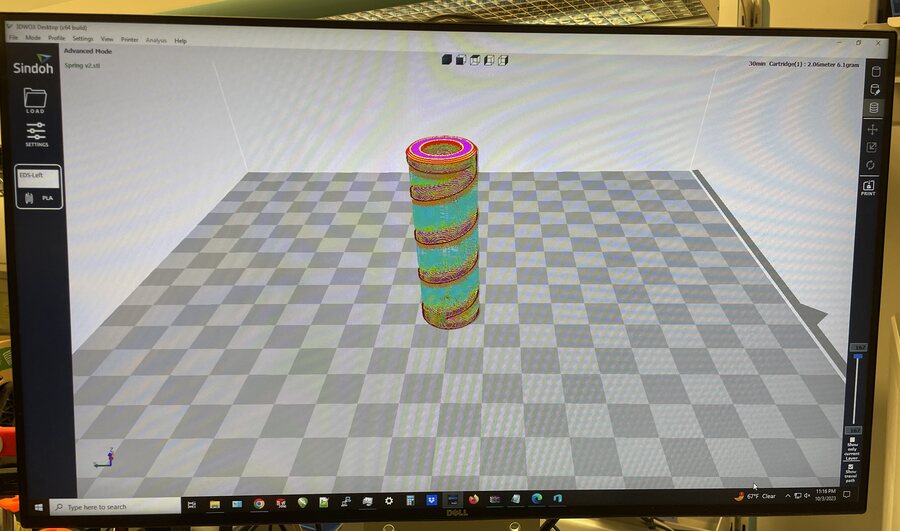

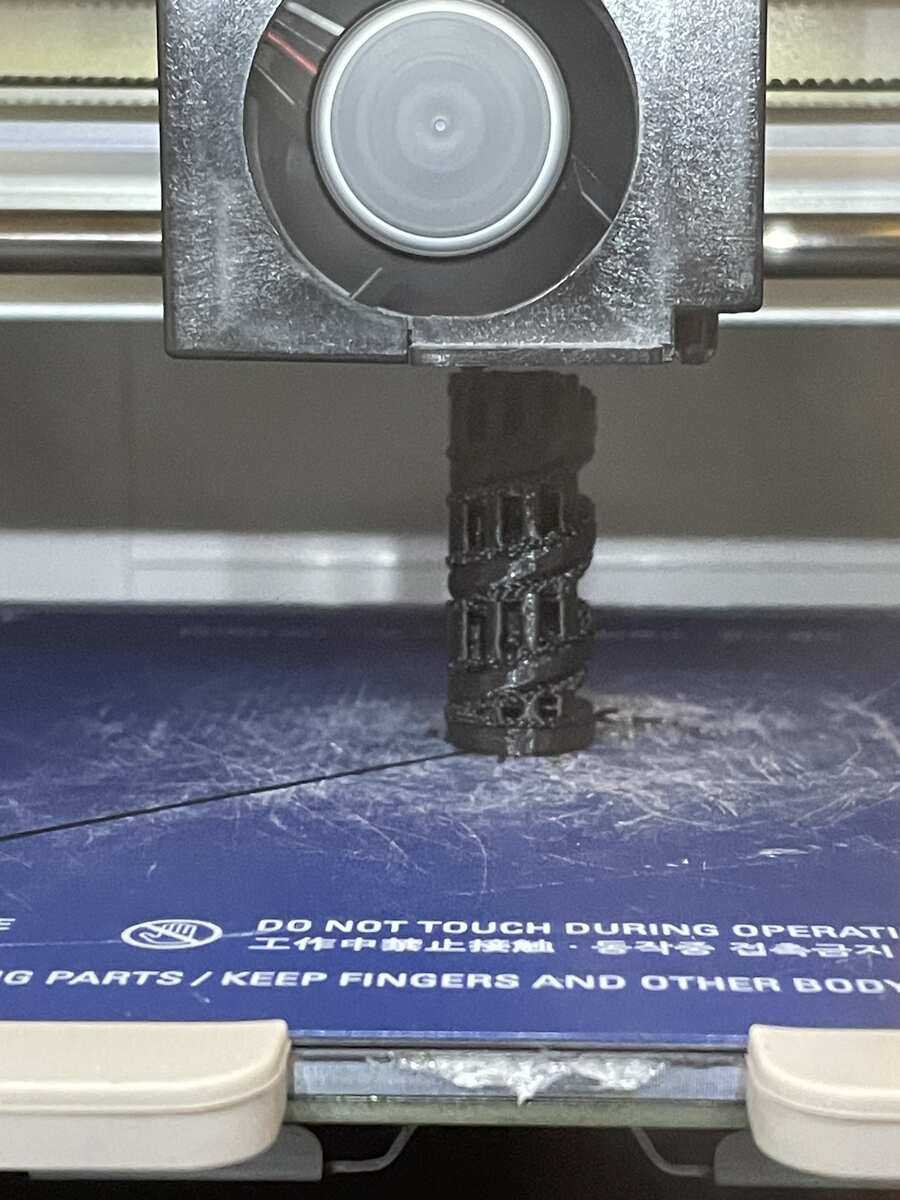

Try 2 on the Sindoh…

|

|

The supports were a total pain to cut, but the final spring was pretty solid!

This still wouldn’t work in the final version with three springs on the rocker toy because cutting would be impossible due to their proximity to each other. So we decided to send the full version off to the Stratsys so we could print it with autogenerated supports in dissolvable material. I adjusted the spring parameters one more time to add more springiness and sent it to the Stratsys to print overnight. In the morning I tossed it into the dissolving solution to get rid of the support material:

After a couple hours, I picked up the rocker toy and the supports were all dissolved!