Week13

WIDLCARD!!#

Unfortunately due to final project dominating my time I didn’t do anything too crazy but I did want to take the oppurtunity to learn some tools that I hadn’t been able to before.

My “defining my” own assignment: Design and produce something with a digital process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it.

My assignment is to use the waterjet to cut a material uncuttuable on anything else due to its hardness/thickness, and use it to make a fun lab decoration and/or musical implement if time permits!

My idea was that I really wanted to work with metals and other hard materials - I had initially wanted to do metal laser cutting, but I found that the depth was super limited and so I switched instead to waterjetting. I did at least get to be trained on the metal laser cutter so that was cool!

I was inspired by a previous student who made a kalimba. And so I set out to make some kind of metal musical instrument - I set out to do a glockenspiel, which, if you’re not familar is basically a small xylophone made out of metal. I had wanted to do something similar in molding and casting week, but I heard that that metal was very non resonant, so perhaps this time could be my time to shine.

The first step was research - it turns out that most of these are made of either metal or aluminum, I personally think that steel makes a nicer sound, but we only had alumnium, so I had to use that. Unfortunately, there was only a quite thin piece for me to use (at least compared to typical orchestral ones which have a thickness of 5-8 mm).

Training!!#

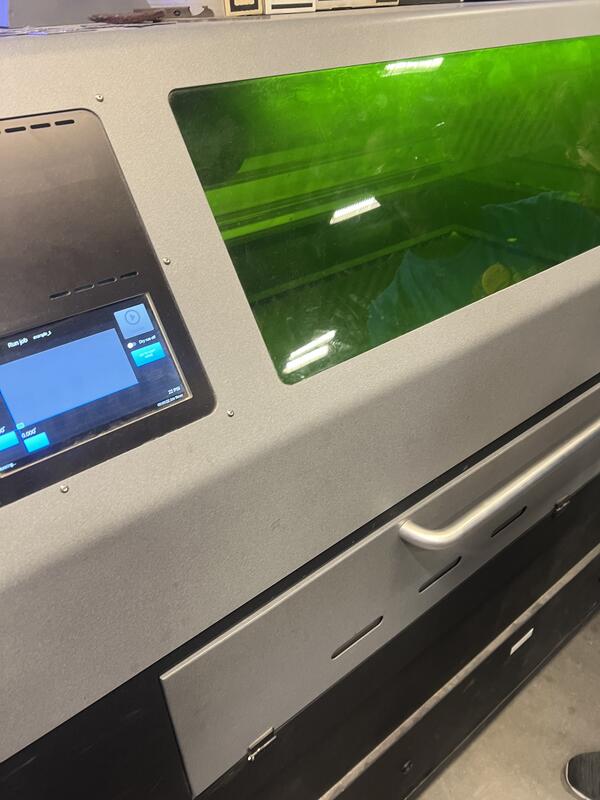

First up was being trained on the metal laser cutter.

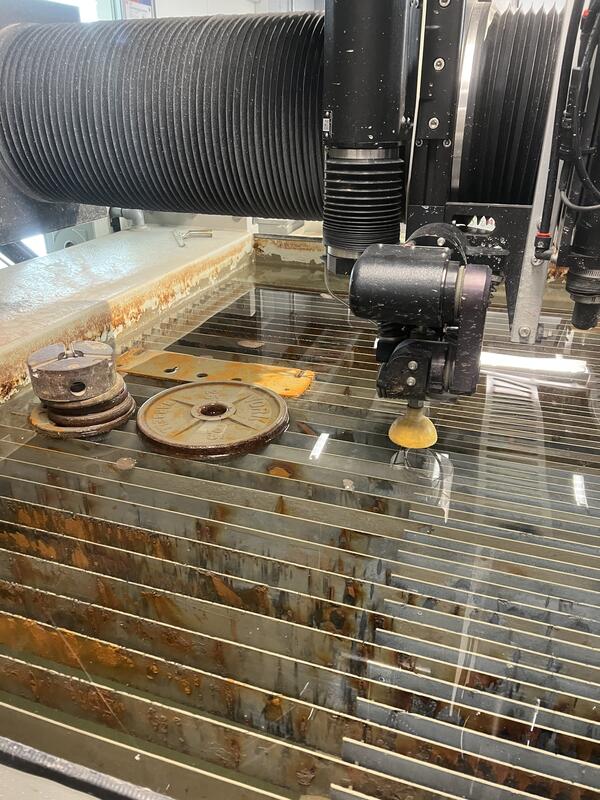

Followed by waterjet time - Dan said that it was quite a simple machine which it surprisingly was - the software/computer was as usual a bit old and finicky - it didn’t like my design for some reason and froze up.

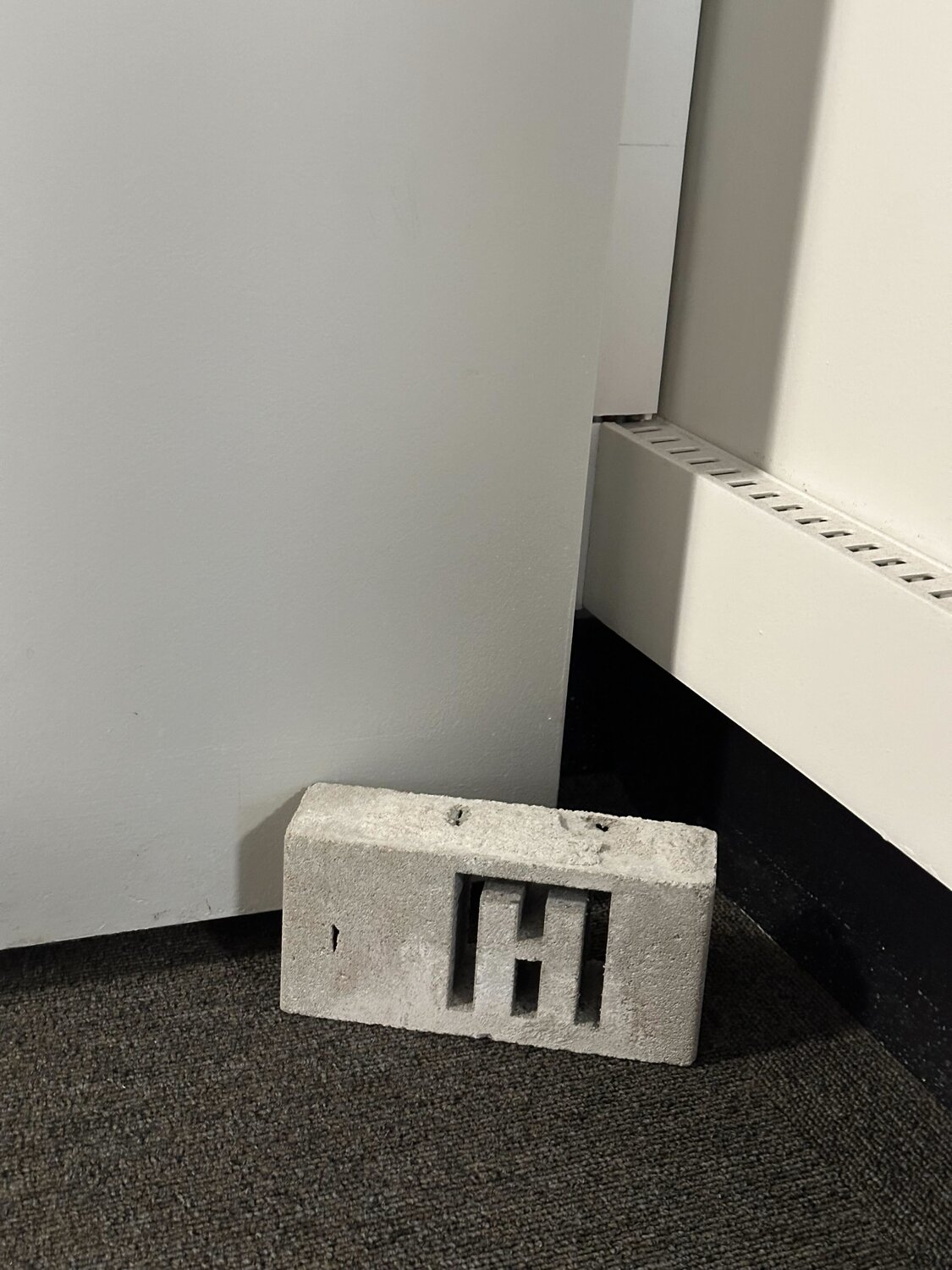

Before training I stopped by Home Depot and got a nice cement block which I wanted to cut:

My group shares a room with another lab that has this really cool cement doorstop with their logo cut out of it and I also wanted one of those. However, my attempt was foiled by the fact that it didn’t like my design and also I realized that doing this would take a super long time which this week I did not have.

Update: I went back and actually cut (part of the design!) It took some iteration and a few passes and a fair amount of time (~30 mins) but amazingly it managed to pierce through pure concrete which is really cool to me:

Overall, the waterjet was not what I expected - somehow I pictured something more like a really strong hose (which I guess it is), but instead it was a bit more “laser cutter in a fish tank” type vibe.

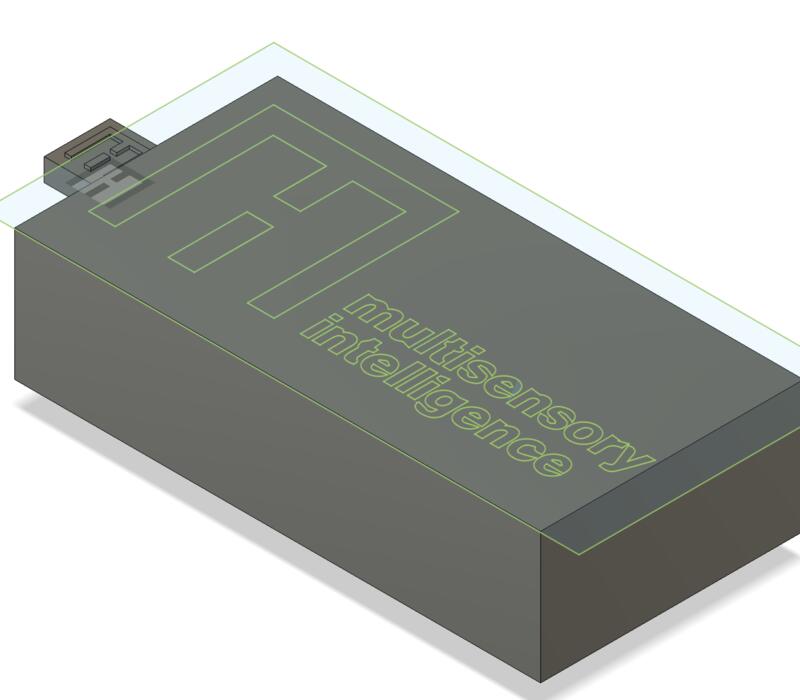

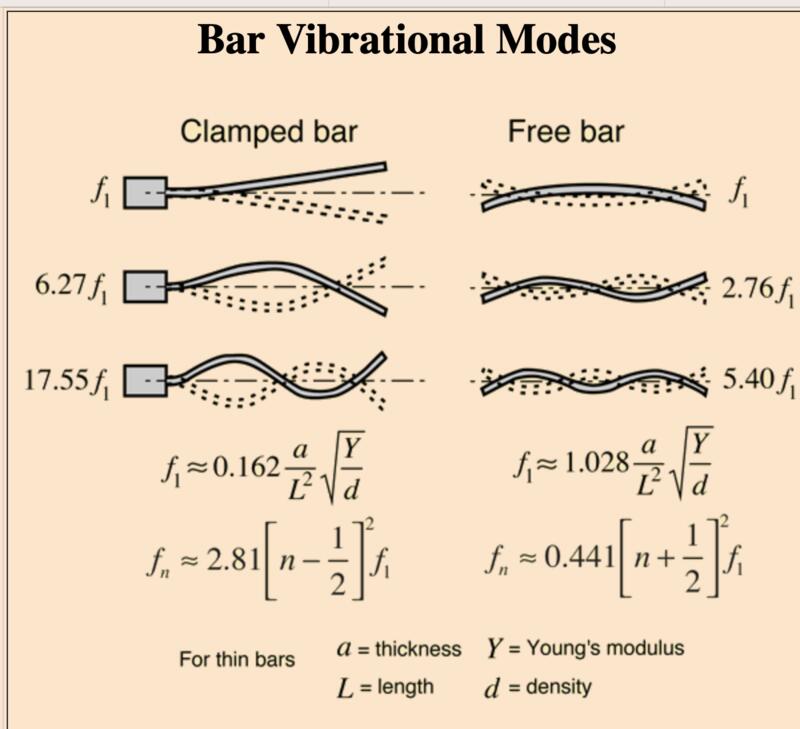

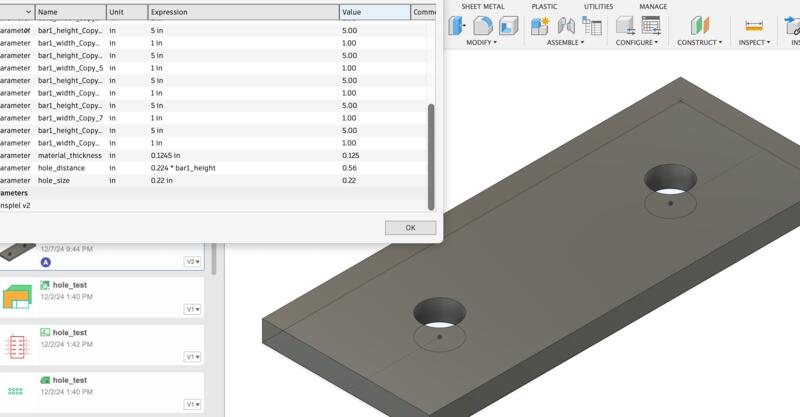

For the glockenspiel, I then spent some time thinking about the physics of how to get the resonant frequency of the bar I wanted, which is a number of interesting physical properties. First of all, the holes for fixturing the bars need to occur at “nodal points” where the resonance is at a minimum so as to not dampen the vibrations. Second of all, the resonant frequency depends a lot on the material, thickness, and resulting Young’s Modulus etc.

A really good resource for calculating these things was this. Overall, this modeling bit took me back to musical physics class and was also a good exercise in parameterizing in Fusion.

The actual job itself was really fast and easy - I just had to do it twice since the first time I didn’t put tabs and sadly my piece got lost to the waters of the waterjet.

I then tried this small one, but sadly it seemed to be very not resonant even so :( - it did produce a decent pitch but it wasn’t nearly as nicely sounding as I had hoped. My hypothesis was that it simply too thin a material and also possible a mallet issue (Dan very helpfully gave me a hammer to try, but perhaps I needed an actual felt tipped glockenspiel mallet).

I wanted to do more, and also get the cement block done, but sadly that was all for this week - hopefully I’ll be able to circle back later though!