This week I made a simple bench with press-fit and wedge joints.

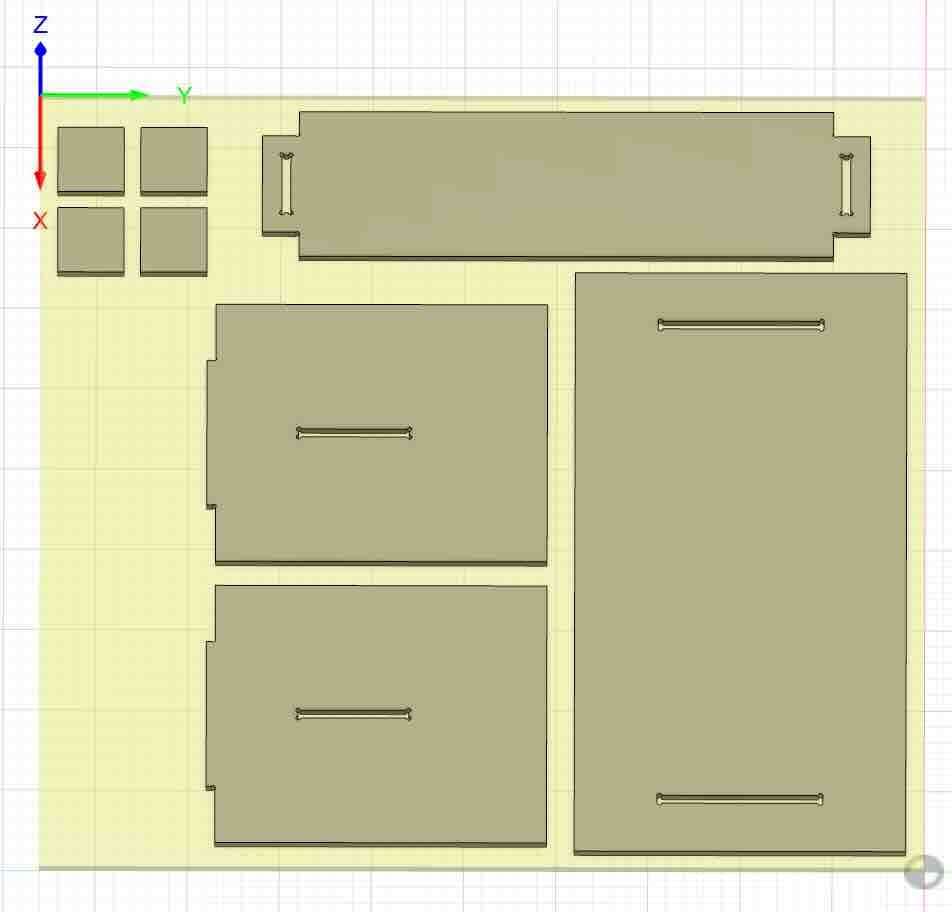

I prepared the CAD and Anthony walked me through the generation of g-code. It was important to add tabs to prevent the full release of parts from the board when CNC is operating, the tool rotates up to 15,000 rpm which can really send things flying!

Here is the shopbot cnc:

Here is my final bench and some of the tools I used.

Initially, I planned to make a footrest height version of this to use for storage under my desk. However, I embarassingly used a tape ruler that labels cm rather than in". The final result was 2.5x bigger than I expected so I need to add a support for the center. My plan for this is to cut two triangles with a wedge joint to slide over the center bar in the middle of the bench, for the bench top to rest on.

Thank you to Anthony for catching me up on this week!

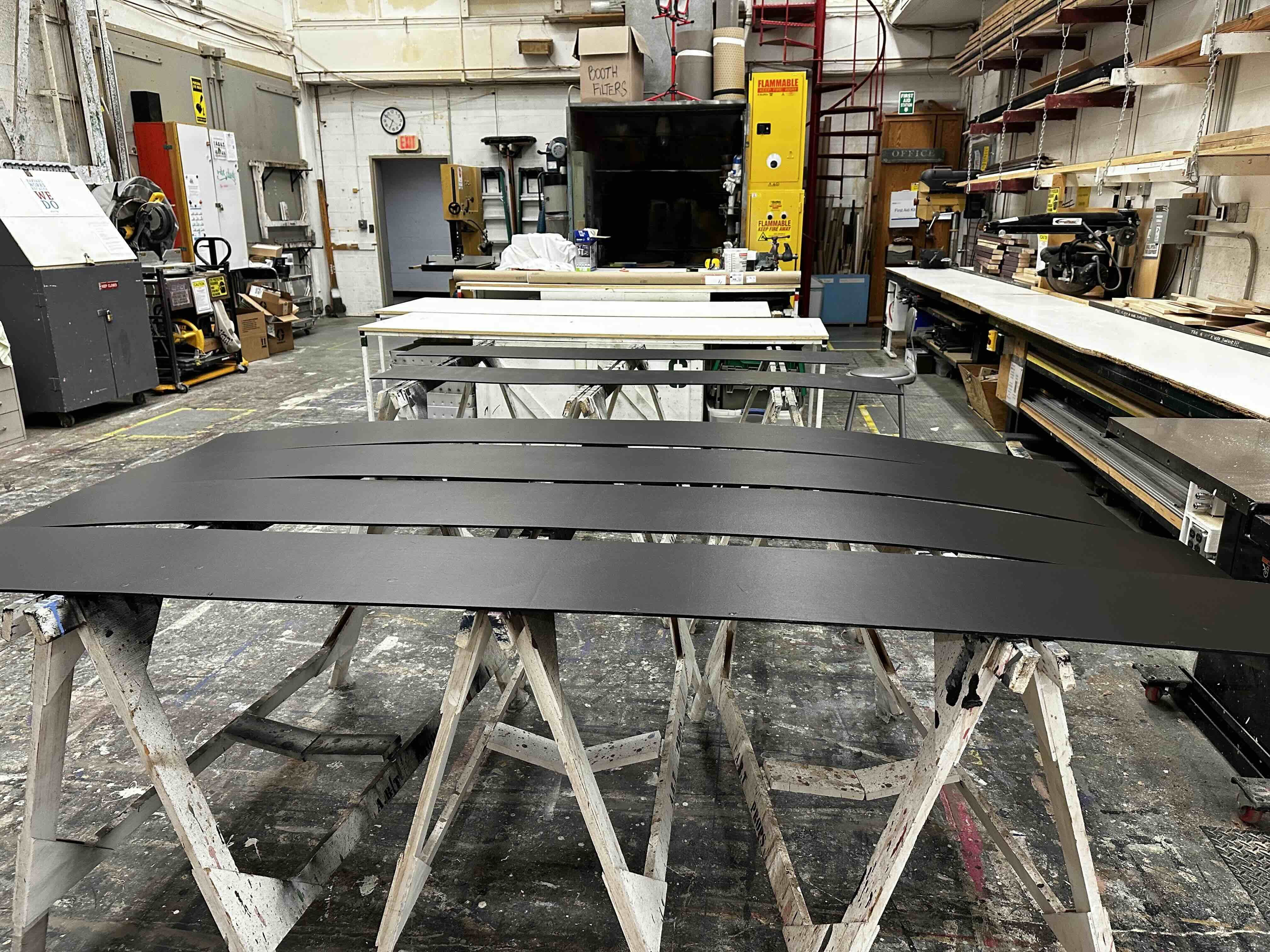

Before I got to the CNC, I made a 40 foot strip of wood to cover strip lights across the stage for Harvard Ballet! I used a table saw to cut large pieces of wood and a drill to attach them together.

get tickets to Harvard Ballet’s show!!