Sound?

I find that in my daily life, I never leave time to relax and do nothing for the sake of doing nothing. All day long, I am doing something. Whether it is homework, driving, eating, sleeping, etc.. my mind is active and occupied. Humans are incredibly sensory creatures, constantly looking for inputs so that we understand the world. Sensory deprivation is an interesting concept for me for this reason.While obviously it is impossible to do absolutely nothing at a given moment, I'd like to explore the idea of doing SOMETHING that is NEXT to NOTHING. In my mind, this is listening. The intentional activation (or inactivaton) of hearing for the purpose of relaxation is effective for many people. ASMR, soundcapes, and even earplugs.

For my final project, I'd really like to make something to do with sound and its relationship to emotion and relaxation. Maybe the sound of human heartbeats. Maybe soundscapes. ASMR. Handheld devices. Distractions. Human connection through devices. I'm very interested in the concept of connecting two people through sound and relaxation as well.

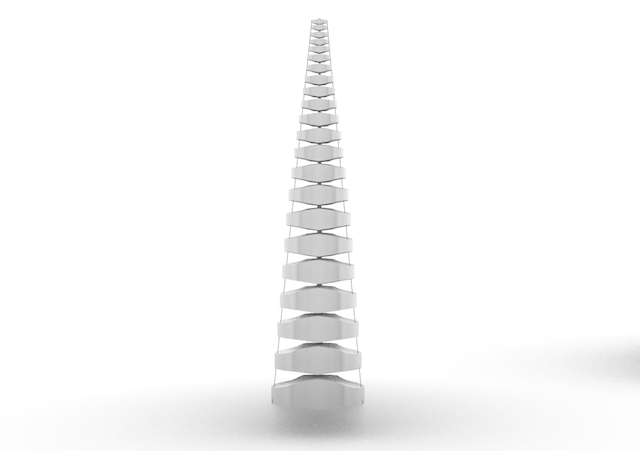

Here is a project I made that I'm taking inspiration from:

The devices play a soundscape of my design in each ear, simulating the Earth's heartbeat frequency (7.83Hz). The sound and tactile elements are meant to relax the user.

I want to explore the idea of relaxation through sound further, making a device that requires you focus your attention on the sound alone.

And since I am OCTOABBY, I wonder if I could make the device octopus-like, being able to mold to anyone's face, cover their eyes, and play sound into their ears......

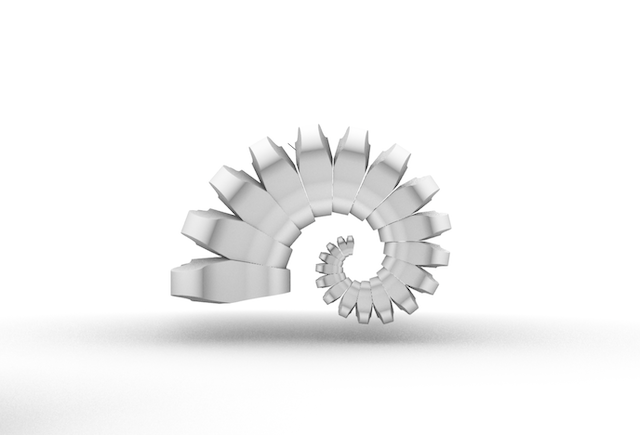

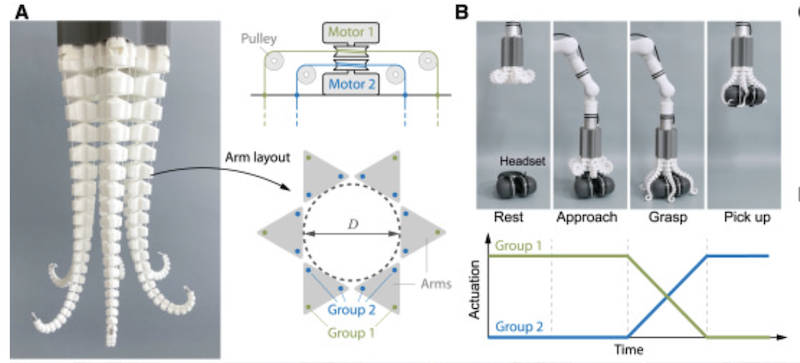

Tentacle Robot

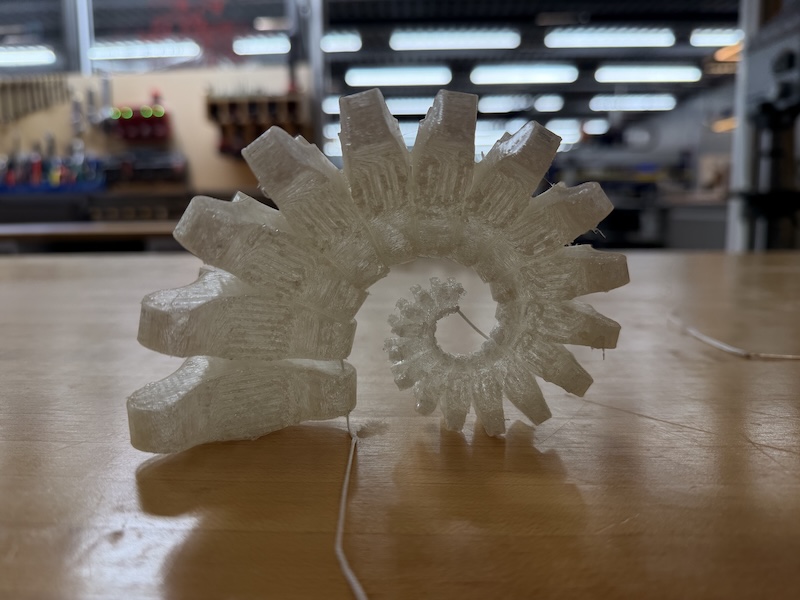

I was recently super inspired by SpiRobs, a logarithmic spiral shaped soft robot. It is inspired by octopi and elephants and other animals that have a natural spiral used for gripping things in nature. The paper is linked here.So, for 3D printing week, I modeled this tentacle somewhat after their tentacle in the paper. It is not a perfect logarithmic spiral (I am still figuring out grasshopper), but I just wanted to test if I could do it and if I could print with TPU.

I printed it out using TPU and the Prusa XL as an experiment of if it could actually work.

And it did! The holes were too small for cables.. so I will have to fix that for future. But I really enjoy the movement.

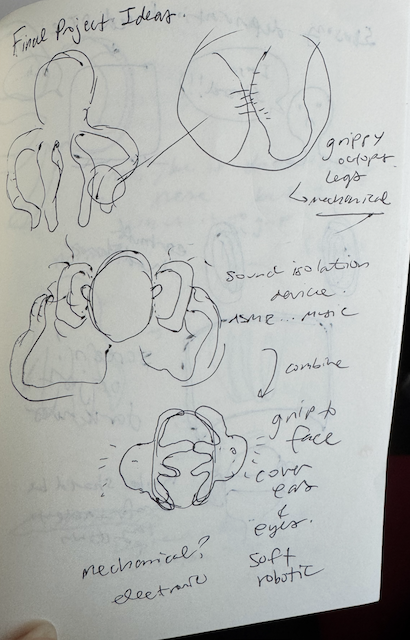

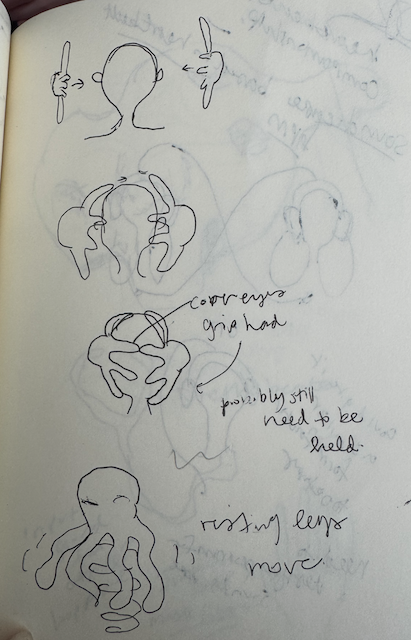

OctoPhone????

So... how do I combine these interests. I am very interested in soft robotics and sound so I definitely want to use both...I was thinking, what if I made headphones that were like the body of an octopus and the tentacles wrapped around my head??? Kind of crazy and maybe a little weird. But cool.

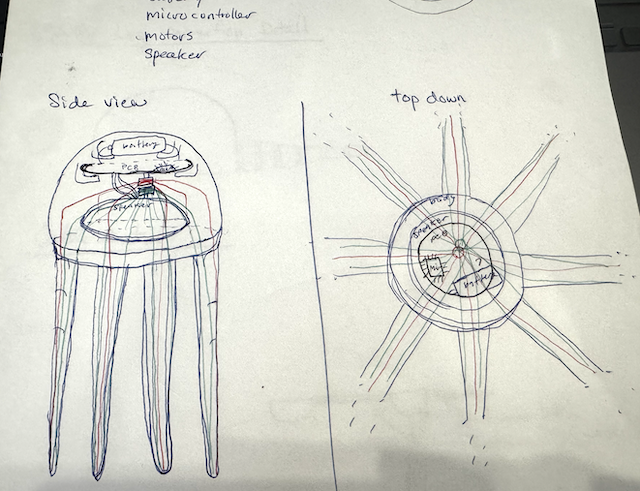

Here are some sketches I have for OctoPhone....

I think I'd like to have a sensor inside, so that when the octopus nears your head it will extend its arms. I also will design my own soundscape for the music that is played. The arms will likely need to operate via caple, rotating motor, and pulley, but I am still looking into this.

Here are some initial thoughts on how I'd sert everything up. For each octopus, I will generally need:

- a body

- eight tentacles (ideally)

- two? DC motors to pull cables

- a speaker + audio module - a distance sensor

- rotational sensor (maybe)

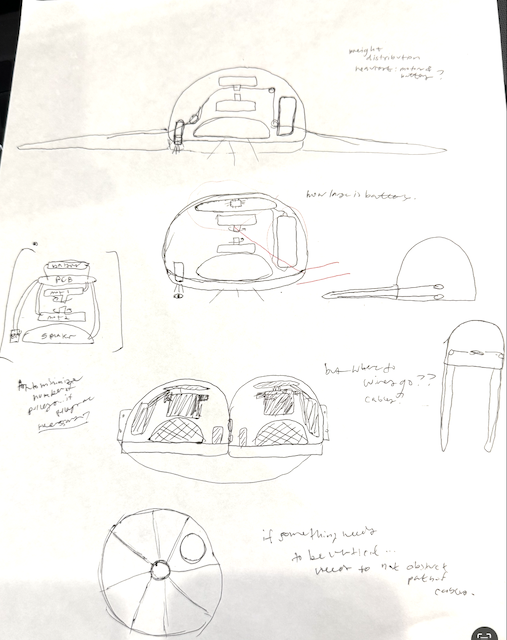

I will want to store all of the electronics and bits inside of the body, which is the headphone part. Here are some sketches of how I might go about it.. although I anticipate many challenges.

I also want to follow this scheme from SpiRobs - using the cables and two rotating motors to move the legs up and down.

Design and Fab Plan

In order to actually make this, I think I will need a very secure plan to get me all the way there.I am writing this during PCB design week (week 5), and I will outline some following weeks with a tentative plan.

- Electronics Production (6): Make distance sensor PCB, attempt to design and make one for a rotating motor to test cables.

- Computer Controlled Machining (7): Design and fab final tentacles with cables. Start body design.

- Input Devices (8): Work on distance sensor.

- Output Devices (9): Work on motors.

- Molding and Casting (10): mold and cast a head.

I'll only go to there because I imagine I will not be able to follow this plan perfectly. But I have faith I will be able to do it and make it beautiful!!!!

Cables

Writing this during electronics production week, week 6. I decided to print a large tentacle this week and try to string a cable through it to see if it works. I used the Prusa Xl and clear TPU again.

And it did!!! Tada! Now I am going to prioritize getting a motor working so I can try to pull the cables automatically. The tentacle is also a little wide for my liking, so I will work on redesigning it to be a little smaller an thinner to fit the face better.

I used organic supports this time, which actually left a bunch of little bumps all over it and was more difficult to remove. So I'll go back to regular supports for next time!

Electronics Thoughts?

Ok so I am trying to fit my things into the shape of the head, and I realize that making octopus headphones is a little ambitious? So I may just make a robotic octpus that can hold onto anything without the sound component. I also want to mold and cast the head so it is squishy.Head Shell Sizing

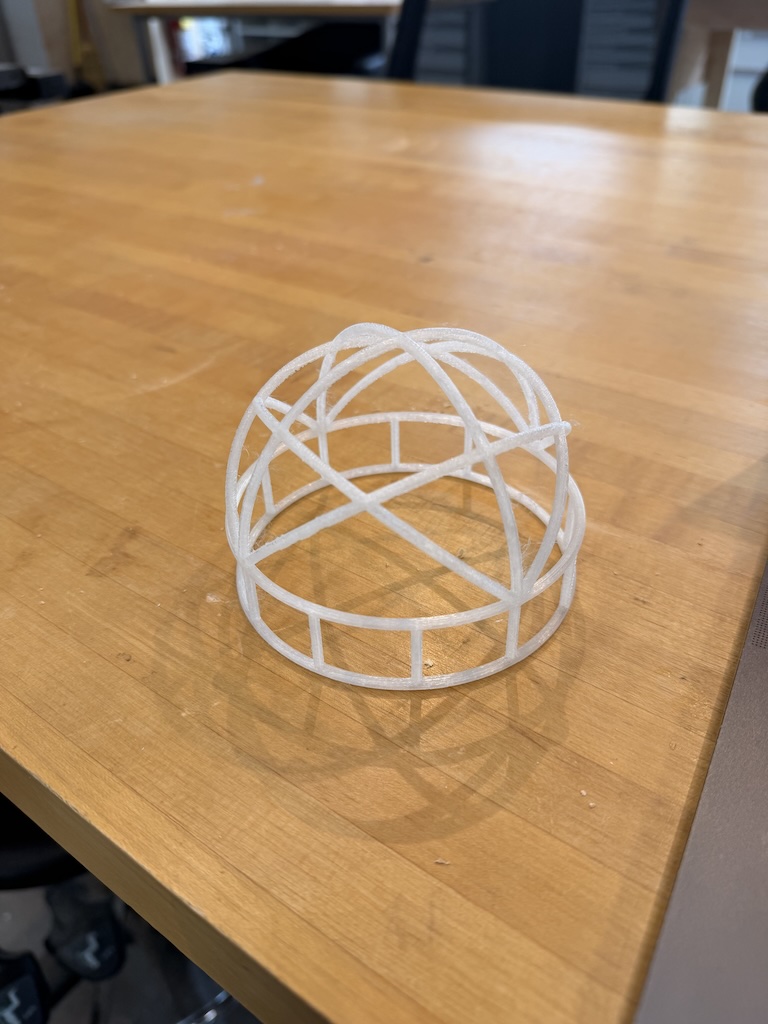

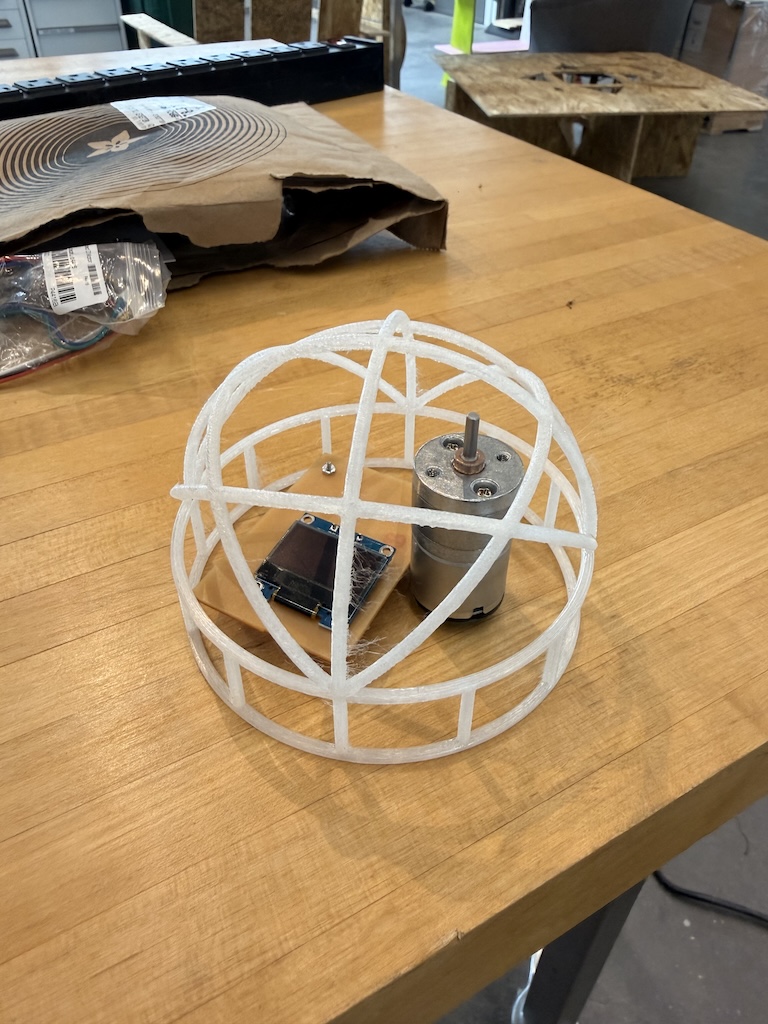

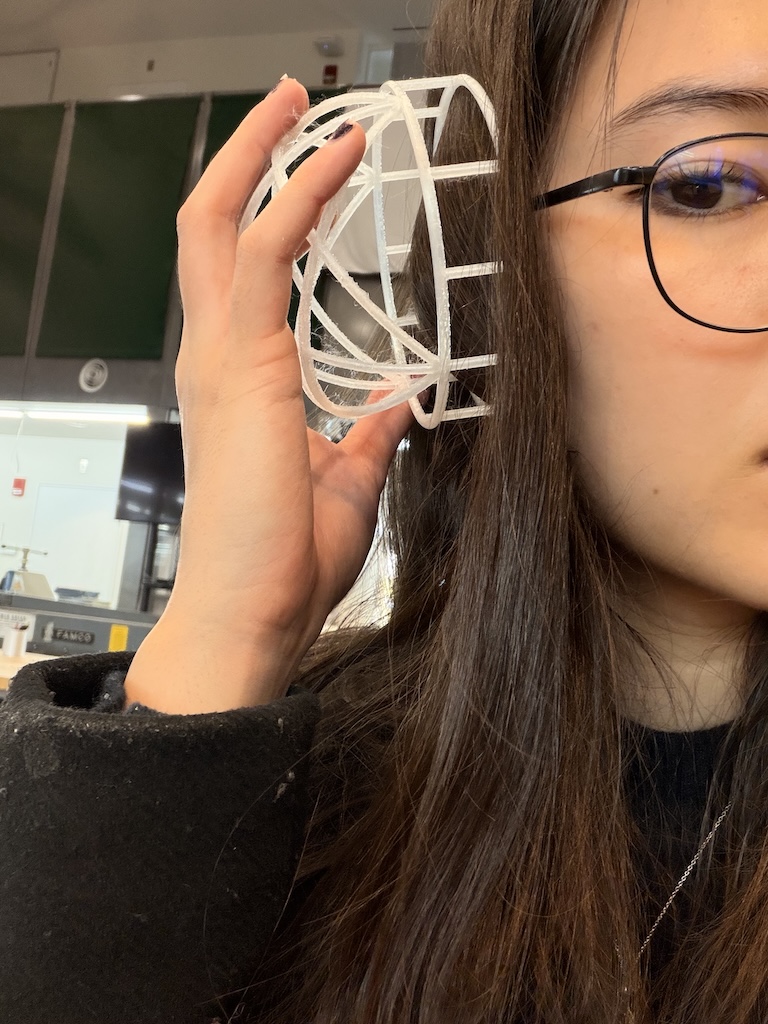

I also made a skeleton for the head during input week, to see if I can fit things into it and also prepare for molding and casating so I can stretch something squishy over it potentially.

I just put some things I already have inside to see if I can contain them.

And I also put it up to my head to see if it is adequate octopus size.

Which I think it is! Yay!

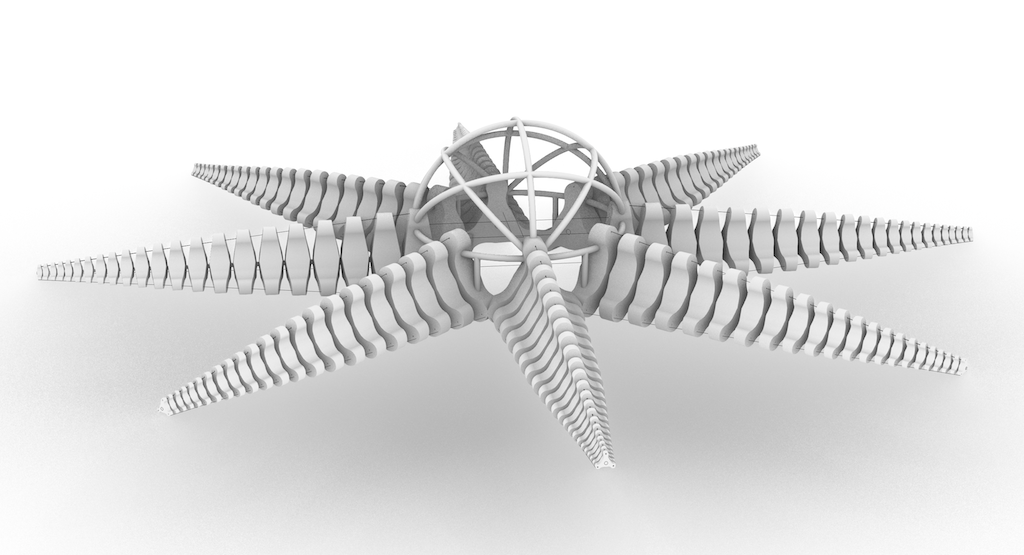

Here is a sketch of it all together:

So plan from now - during output devices I want to have several functioining TPU tentacles to see if they work with the little DC motor I have, and get better cables.

Tentacle Activation Attempt 1

I printed a larger tentacle and threaded it with black sewing thread. Here is a video of Dan as a pupeteer.Also during output devices week, I got a DC motor and used it to activate my tentacles. Here are some videos:

Here are my reflections:

- I need to get a more sturdy, smooth, almost frictionless cable to use instead of thread, as it frays and gets caught.

- I need to calculate the distance I need pulled.

- I think I will need to make the tentacle itself a little shorter, as it is difficutl to pull the tiny little modules at the bottom.

- I will want to try using two motors at the same time- one controlling top and one controlling bottom. But need to calculate load and coordinate the two.

- I want to get better at programming so will need to practice that.

- And maybe need to research SpiRobs a bit more.

Otherwise, I'm happy that this generally worked out!

molding and casting update

For molding and casting week, I attempted to cast a silicone head part for my octopus. It is not big enough, but it was to see if I like the color and consistency of the silicone.

Also, I got some new, much more durable thread that I will incorporate into my previous motor design.

Midterm Review

For the midterm review, I have constructed some diagrams and am figuring out how to get my project done in the time I have left.

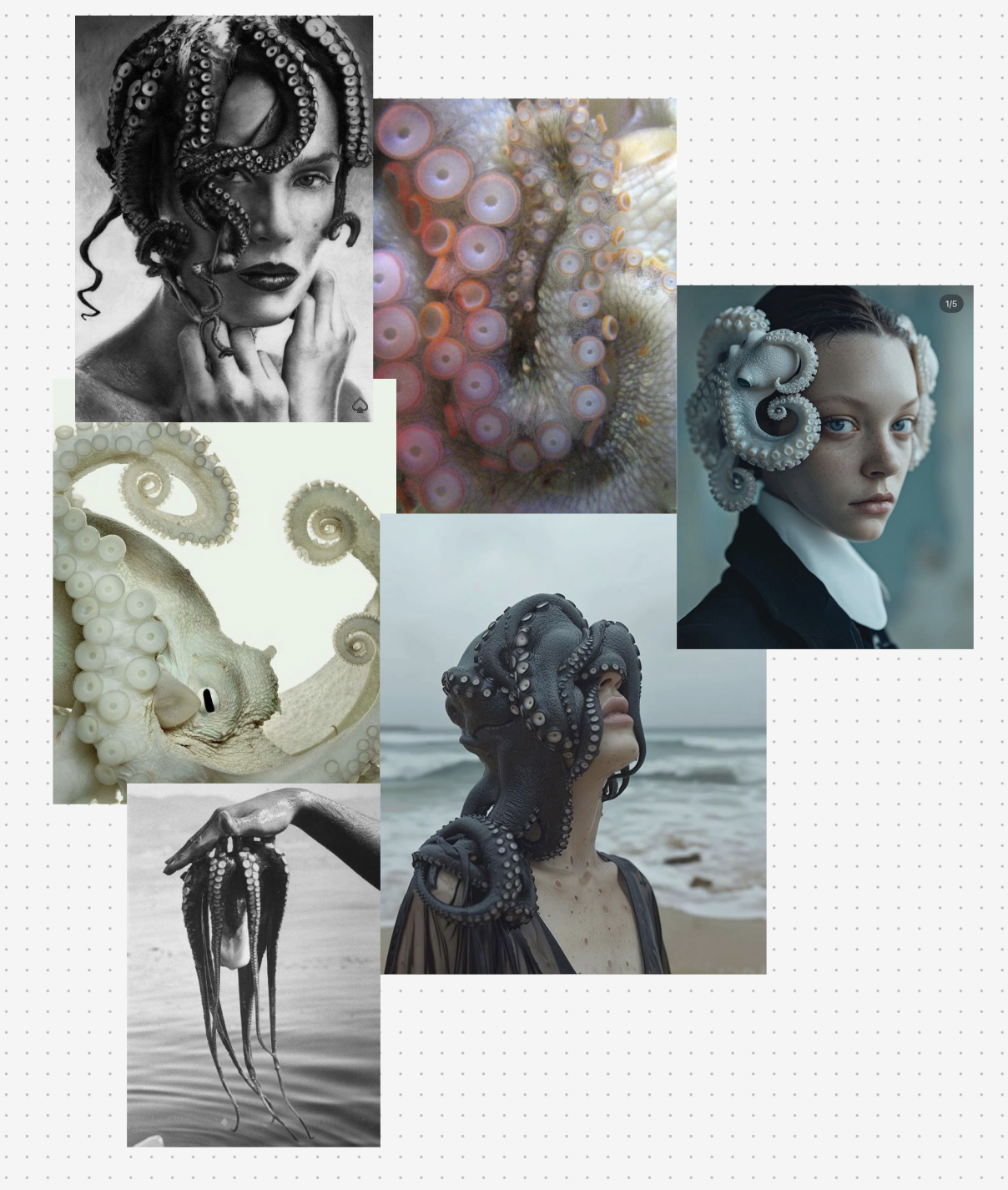

Firstly, here is a silly little moodboard for the vibe I am going for.

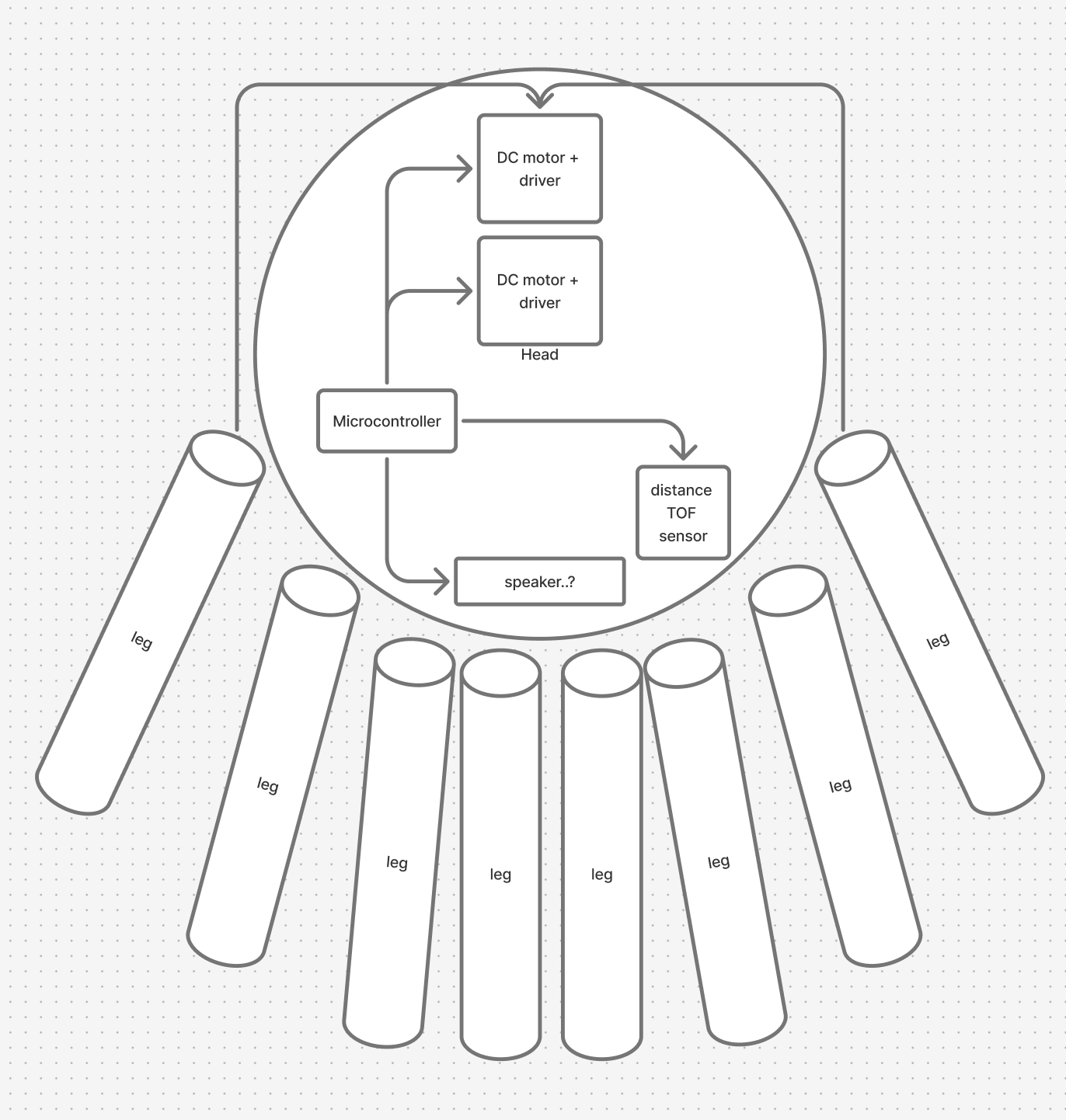

Here is a general diagram of what I need to make my octopus robot. I will need:

- a microcontroller

- 2 DC motors + drivers

- a distance sensor

- 8 tpu legs + cables

- a frame for the head/to hold legs

- a squishy silicone head

Put in a diagram, here are the key components and then some things if I have time. The speaker is iffy, because I haven't really looked into it yet. It would be super cool though if I could get it to work! I want to, but I guess I'll ask if it is feasible.

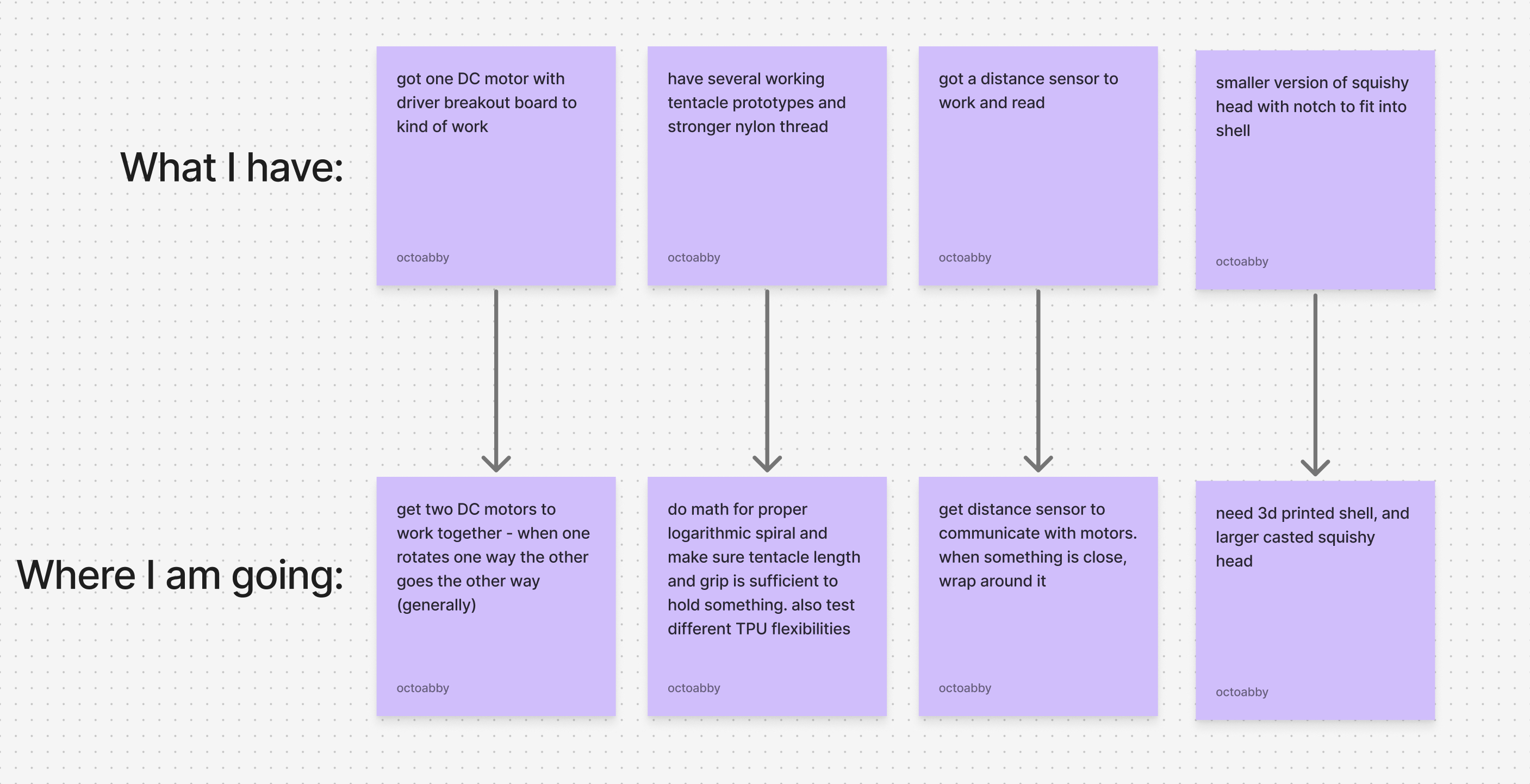

Here is a little chart of what I currently have and where I need to go. Here is what I plan to do before December 15th (aka 1 month from now).

- Fix tentacle geometry and settle on exact size and print 8 of them. Wire cables through. Test on a basic frame with a dowel to see analog movement.

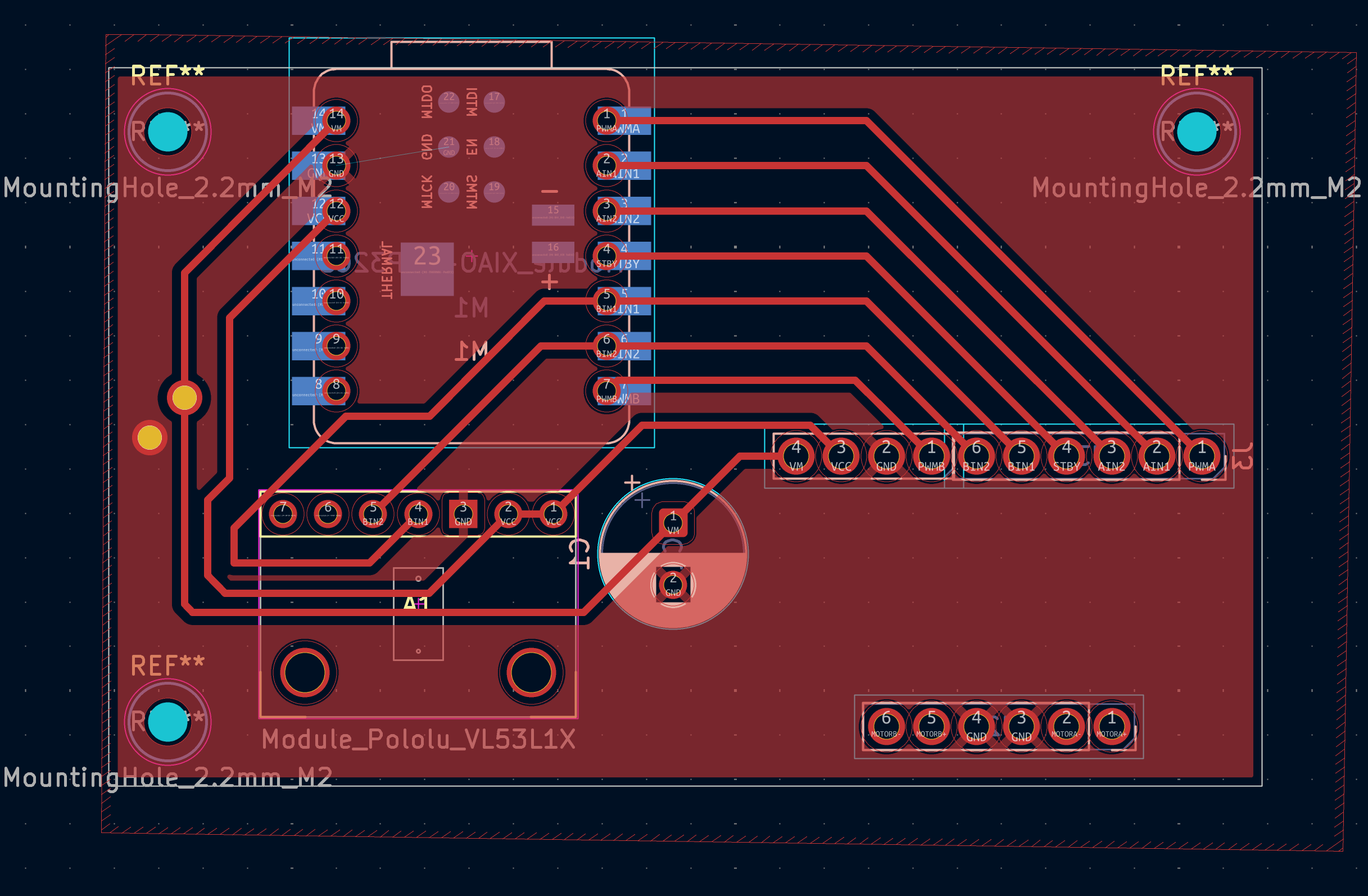

- Work on all electronics - create one main PCB with microcontroller, distance sensor, and motor drivers (and leave room for speaker stuff in case). Debug. make sure everything works properly and does what it is supposed to. get help.

- Integrate everything / overflow from previous week. Create frame for head to house the electronics and the tentacles. Debug. - Mold and cast head. Work on speaker stuff if time.

One thing I am grappling with is...do I make two..... I shall decide this soon. Because if I do, I will make everything together in parallel, not in series.

12/09 update

I got some new white 95A TPU and printed out 5 tentacles! The supports on these are exceptionally hard to remove....

I will try to find a better way to smooth it out. But I do think that the rough edge might actually be helpful if I am trying to grip onto things. So I may just leave it as the bottom part of the tentacle.

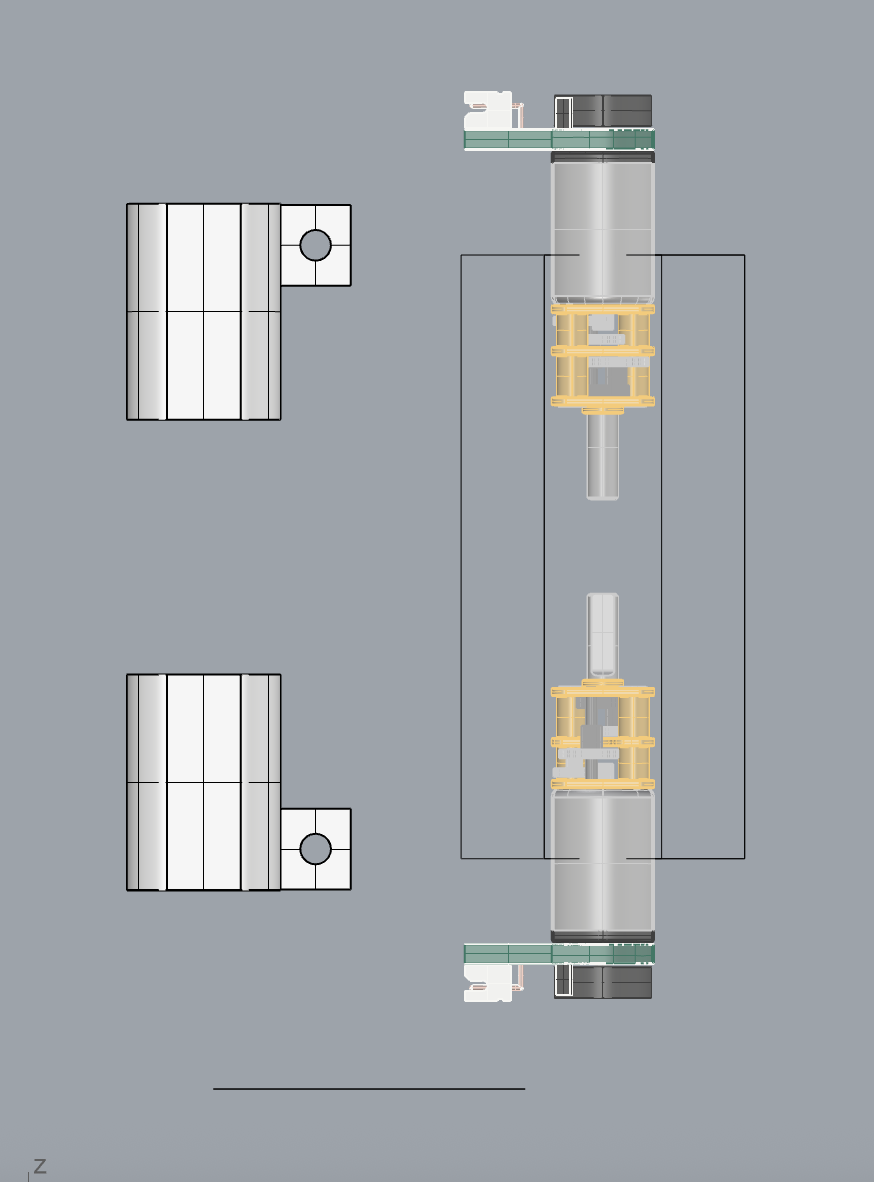

I also got new N20 DC motors, and decided to maybe not fit the speaker into the body because it is a little tight with all of the cables and stuff etc. I am currently working on ways to mount the motors like this:

So the top cables can connect to the top and bottom ones can connect to bottom and rotate to pull them.

HOME STRETCH! Final Information

It is Thursday, December 11th. I am now beginning my final documentations here!The electronic components I am using are:

- 2 N20 DC motors (link)

- 1 TB6612 DC driver breakout board (link)(I wanted to make my own dual H bridge driver, but unfortunately I did not get to it and used this as my backup)

- 1 Pololu VL53L5CX TOF distance sensor

- 1 Xiao ESP32C3

- 1 470 uF 16V capacitor

Here is my final PCB schematic and layout.

Today I am assembling my PCB and getting my motors to work. I have all of my tentacles printed, and then after this will need to create the house for the electronics, aka the head.