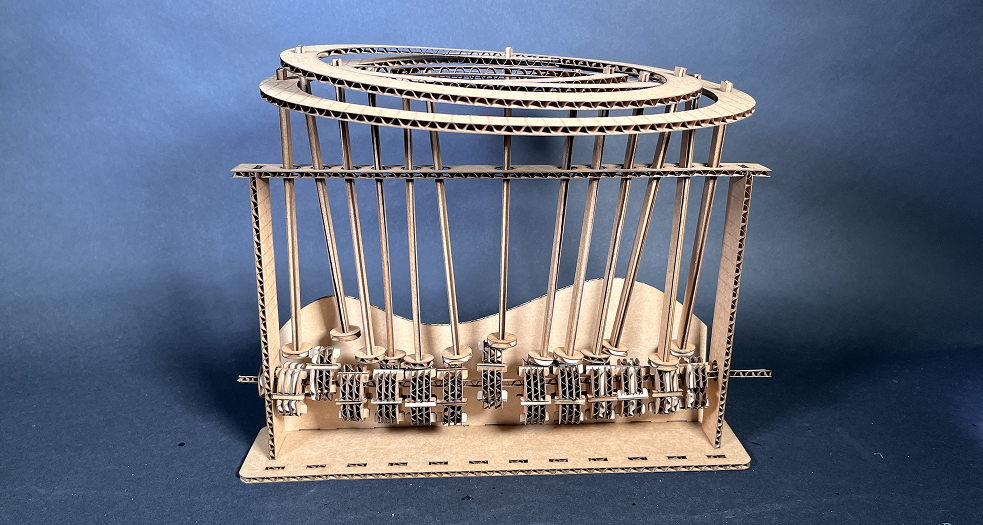

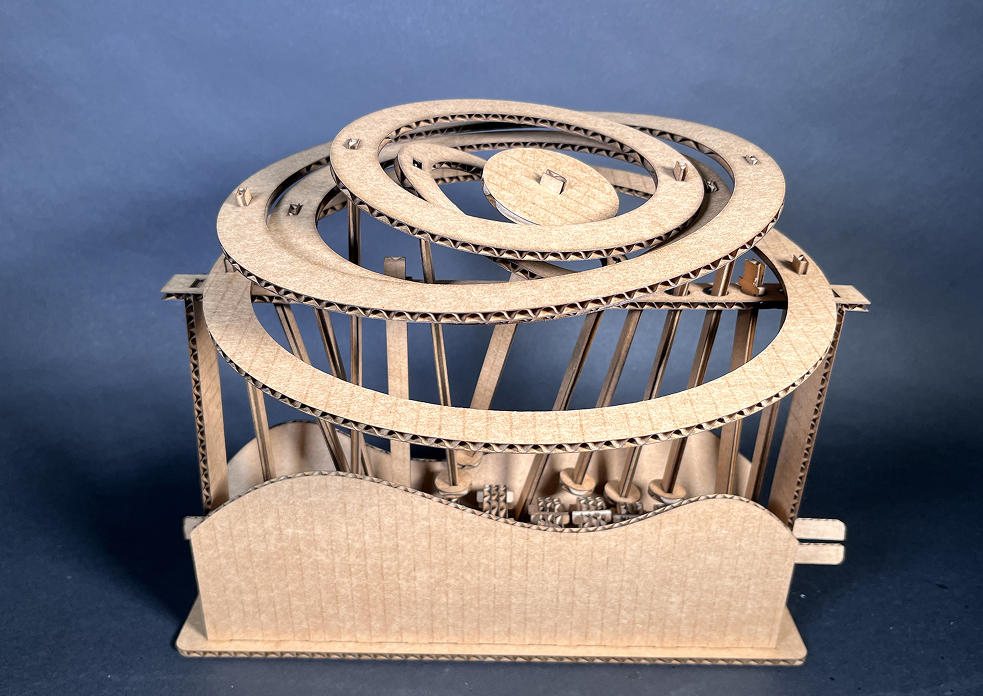

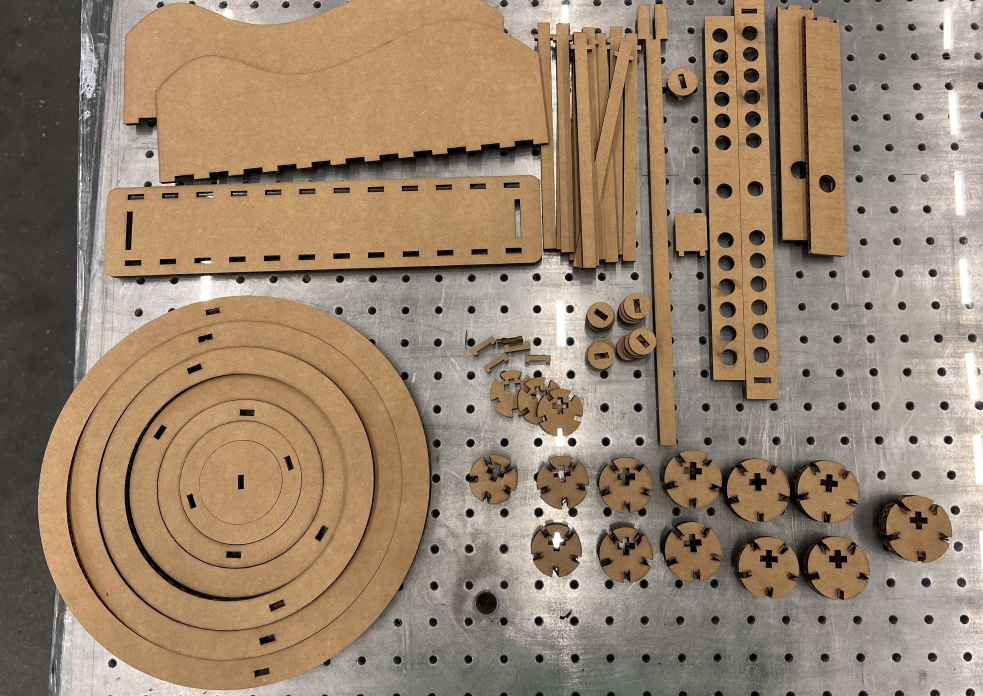

Result

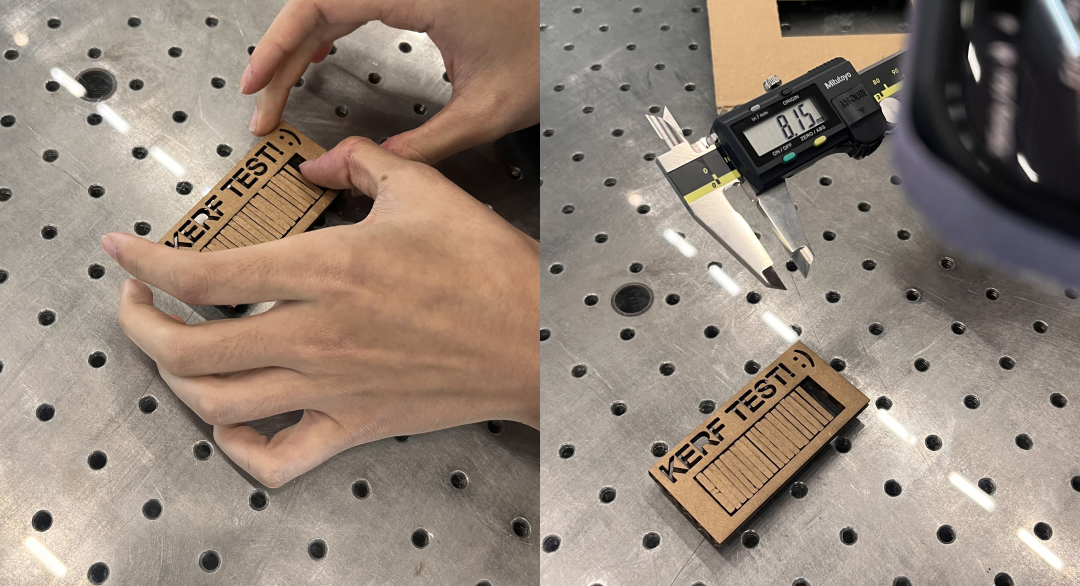

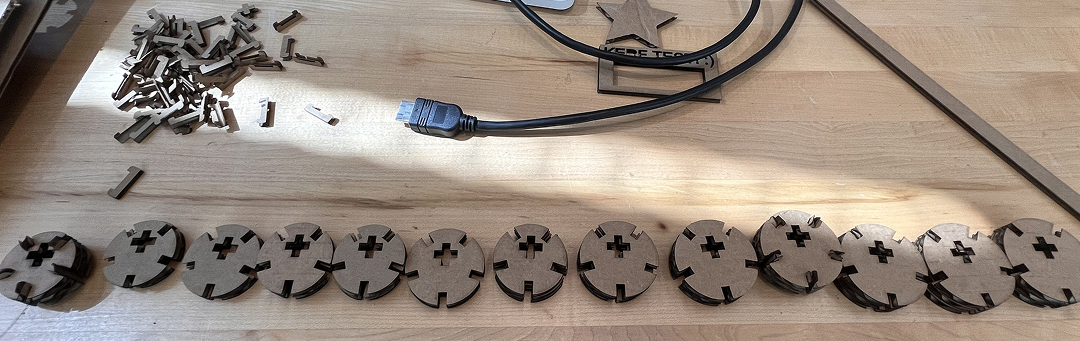

Group Assignment: Kerf Test

We tested the kerf using a 20mm width square cut. After laser cutting, the remaining inner square measured 8.15mm, indicating that the kerf was approximately 0.4mm in total.

This is a paragraph with a link. You can write more content here describing the project.

Progress

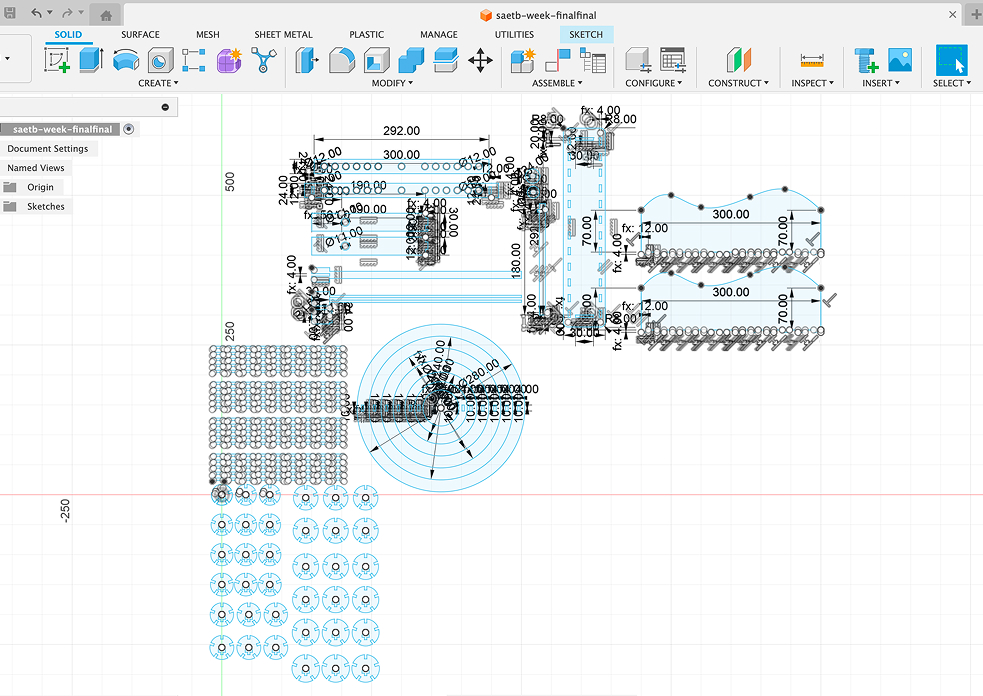

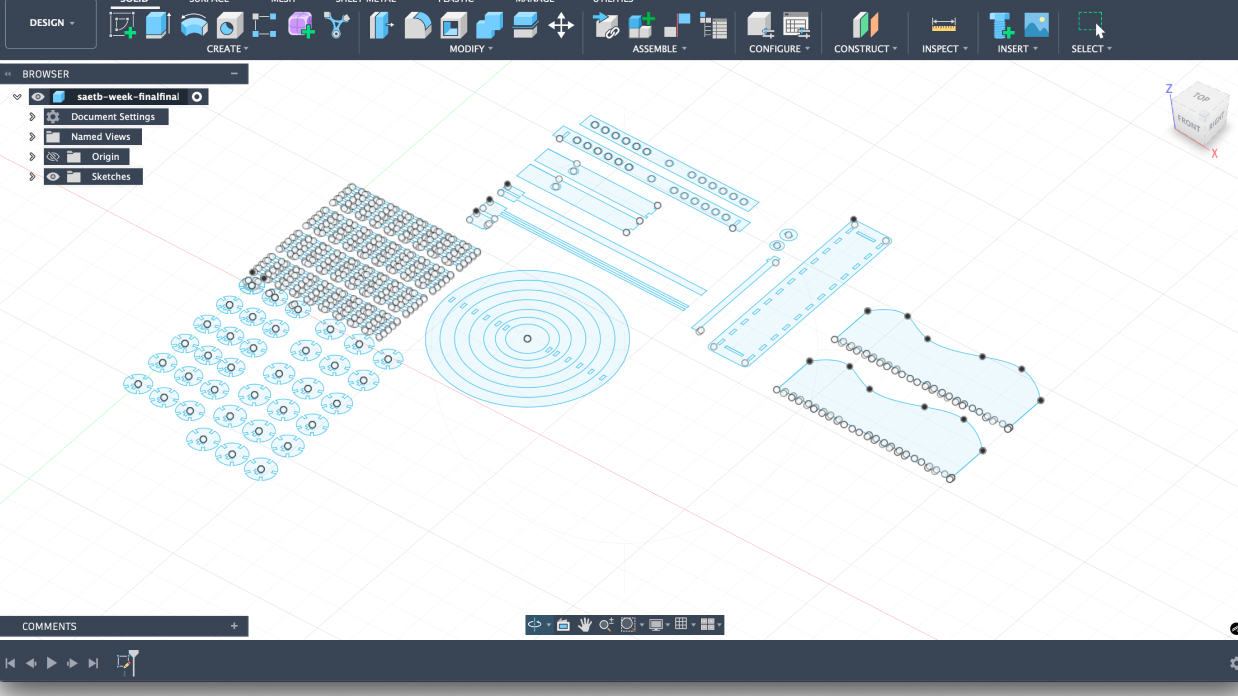

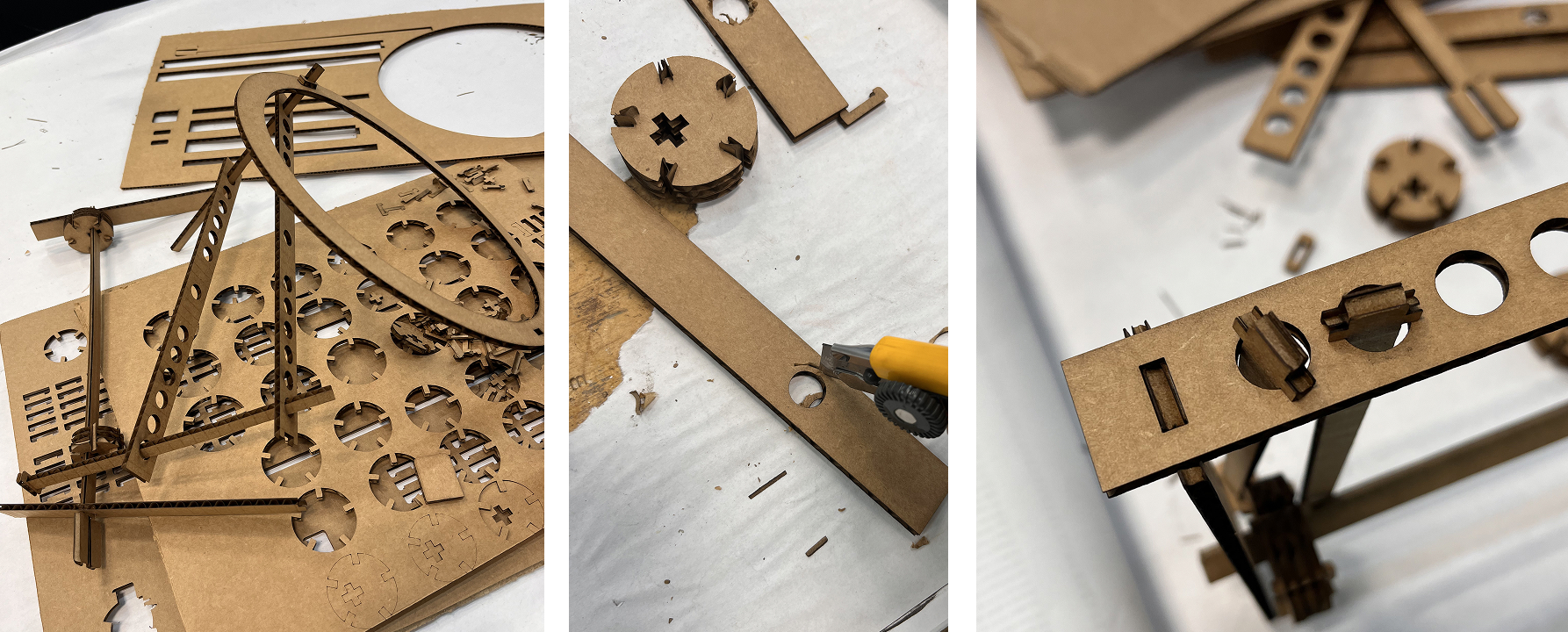

I designed parametric design sketch file with the fusion.

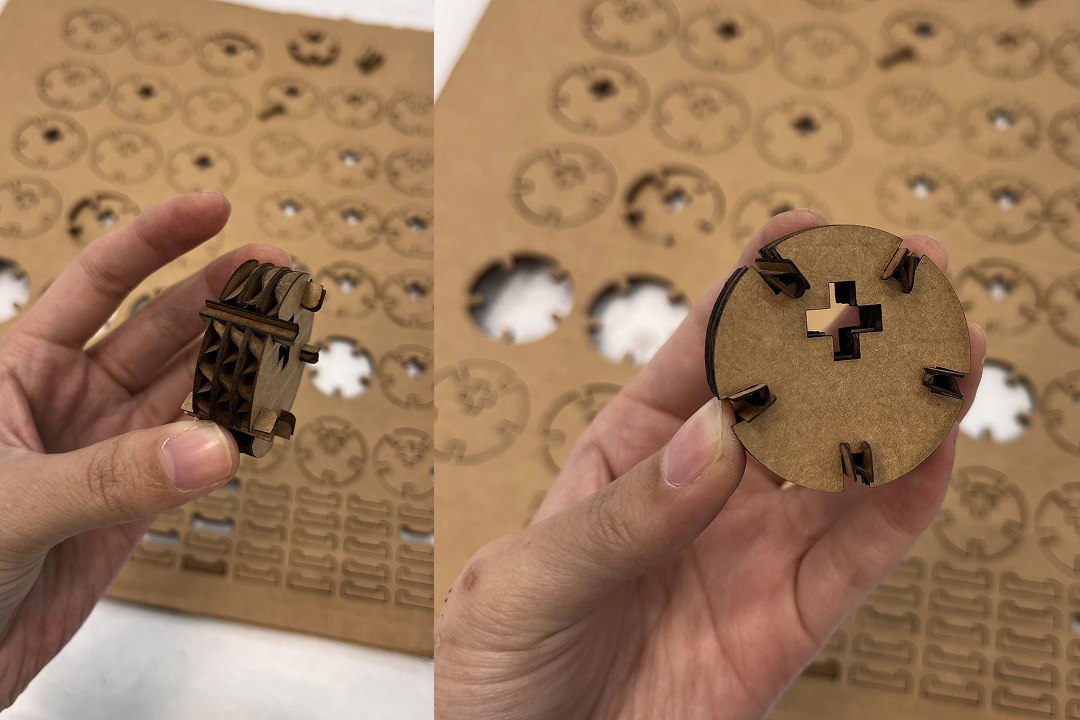

Experiment 1: Wheel Design

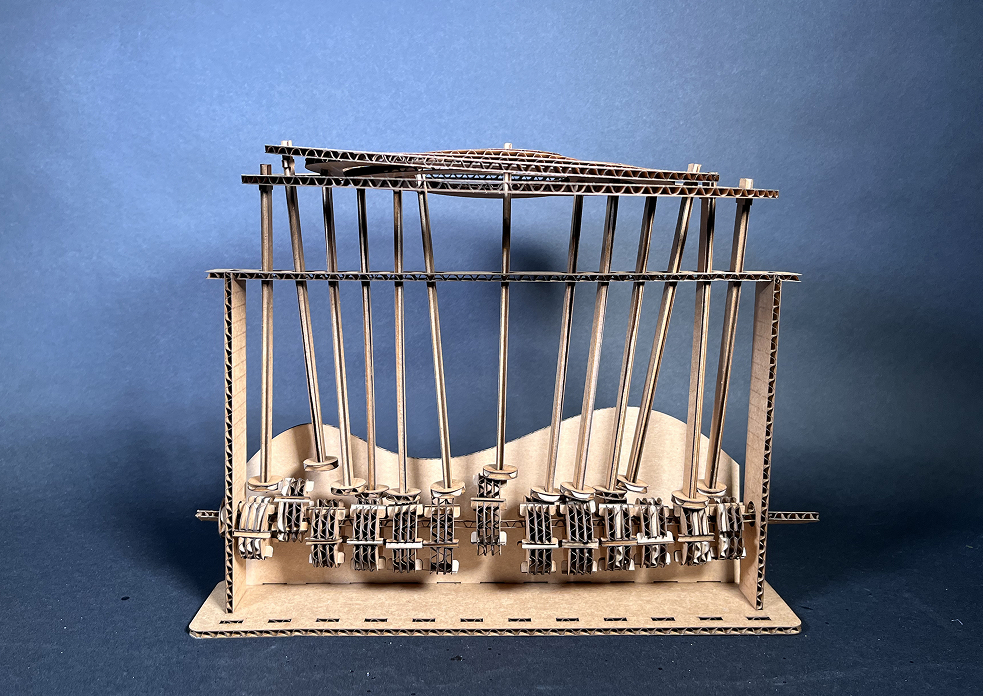

The first attempt used flexible joints on the wheel’s side panels to provide structural support. However, the slots were too narrow and unstable, causing the wheel to deform during rotation.

The wheel design was revised to use interlocking slots on the side panels, which significantly improved stability and allowed the wheel to roll smoothly.

Experiment 2: Joints

The joint connections were still unstable when supporting the full structure. Slot dimensions need to be refined to ensure a more secure fit between the walls and wave components.

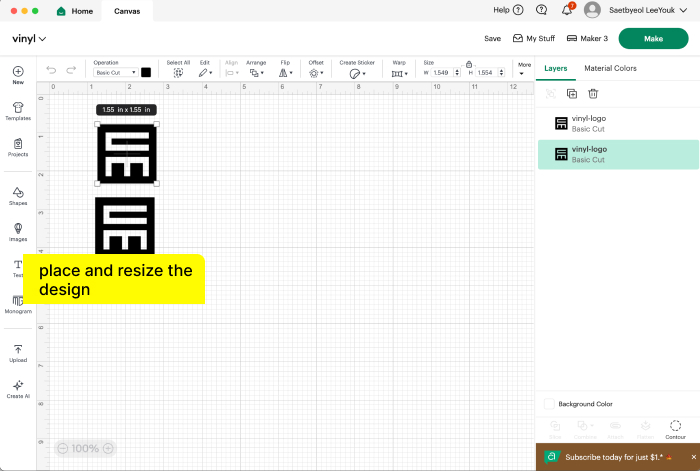

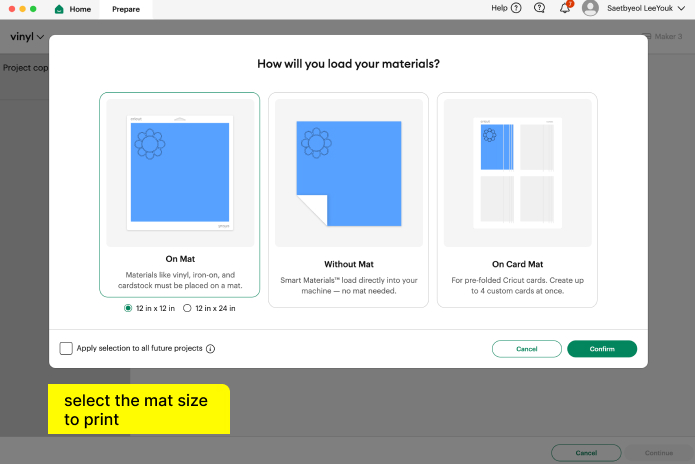

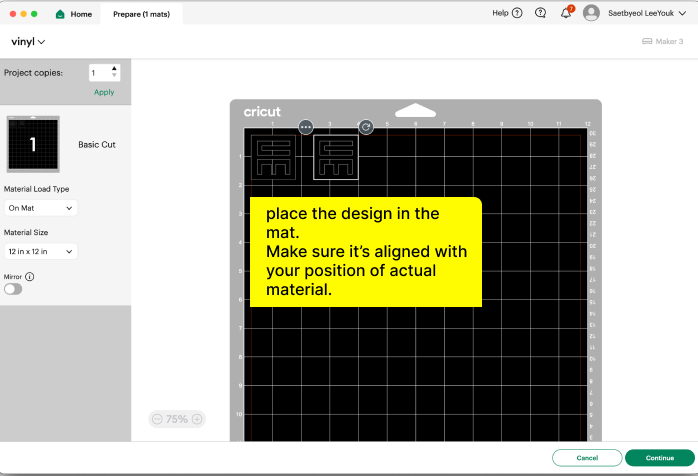

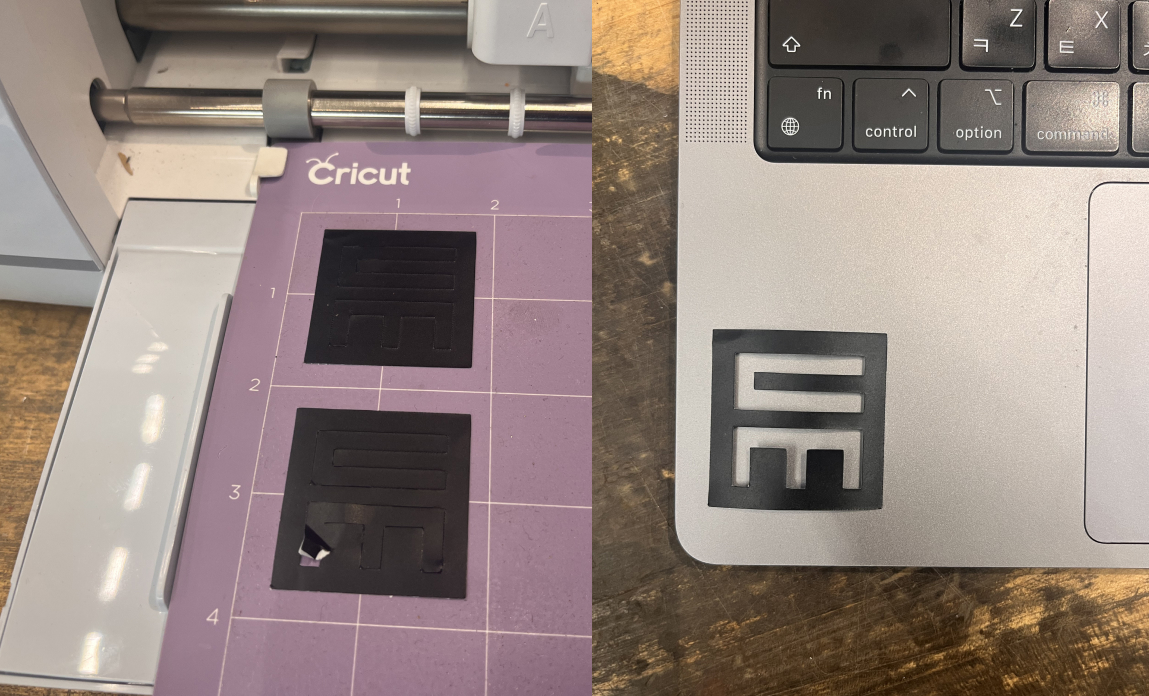

Vinyl Cutting

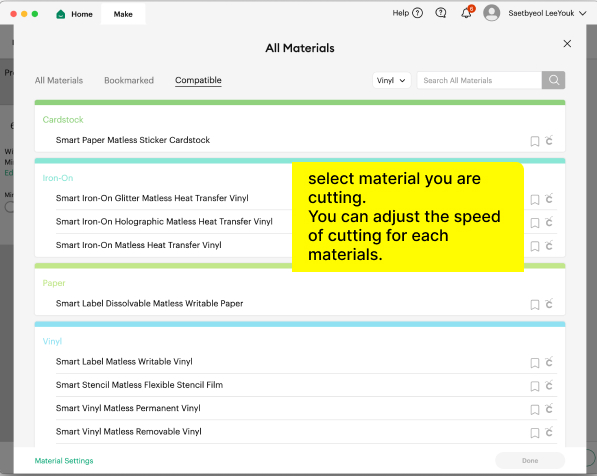

For vinyl cutting, I used Critical Matter logo. To run the vinyl cutting, you have to download the cricut software. Resize the design, align the cutting route with the actual position that you've putted the material on the pad. Then check the speed and material options. Cut!

The first version was destroyed during cutting. So I changed the speed of cutting, then the second round turned out perfect.

Appendix

Learning from Failures

- Material Matters: Cardboard surfaces generate too much friction when rotating against each other. It's crucial to evaluate the mechanical properties of materials for moving components.

- Parametric Design Matters: Use critical measurements, like kerf width, as base parameters. Designing components relative to these values makes the structure more consistent and easier to modify.

Files

- Fusion design file and .dxf file for laser cutting.

- To use the .dxf file in the CBA shop's laser cutter, you need to split into pieces and import the file, due to size limit.