Voxel assembly is often done manually from faces to a cuboctahedron. I want to explore a streamlined process for assembly, which ultimately enables the discrete assembly of large structures.

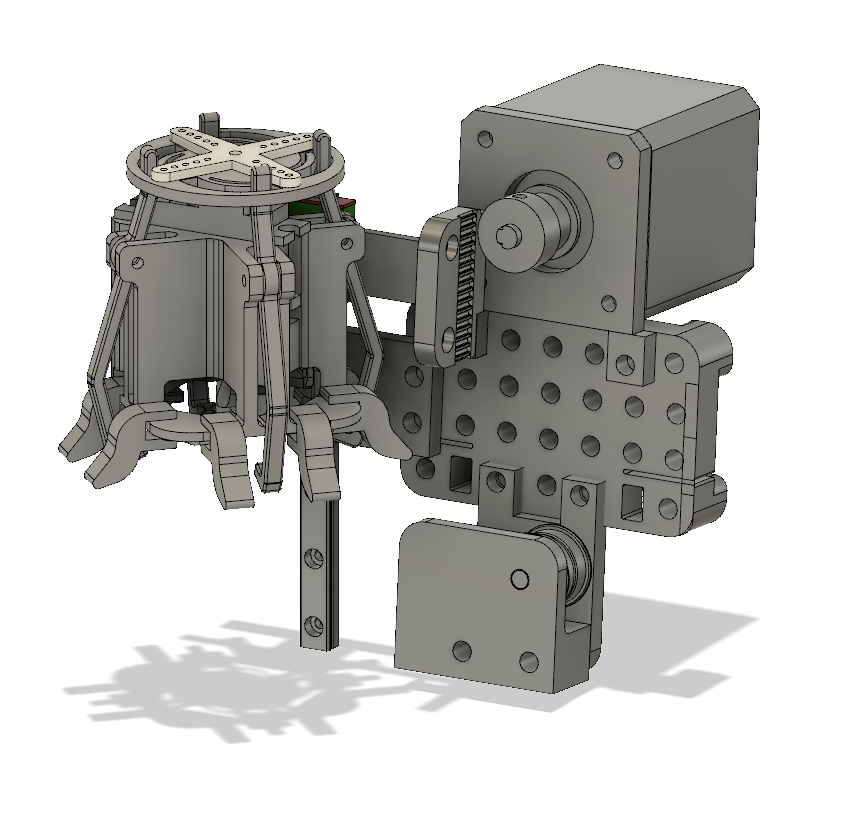

Resdesigning the end effector for the z-axis pick and place. Here, we add several mounts to the base-plate carriage in order to add a stepper, pulleys, a belted drive, and a servo-driven gripper.

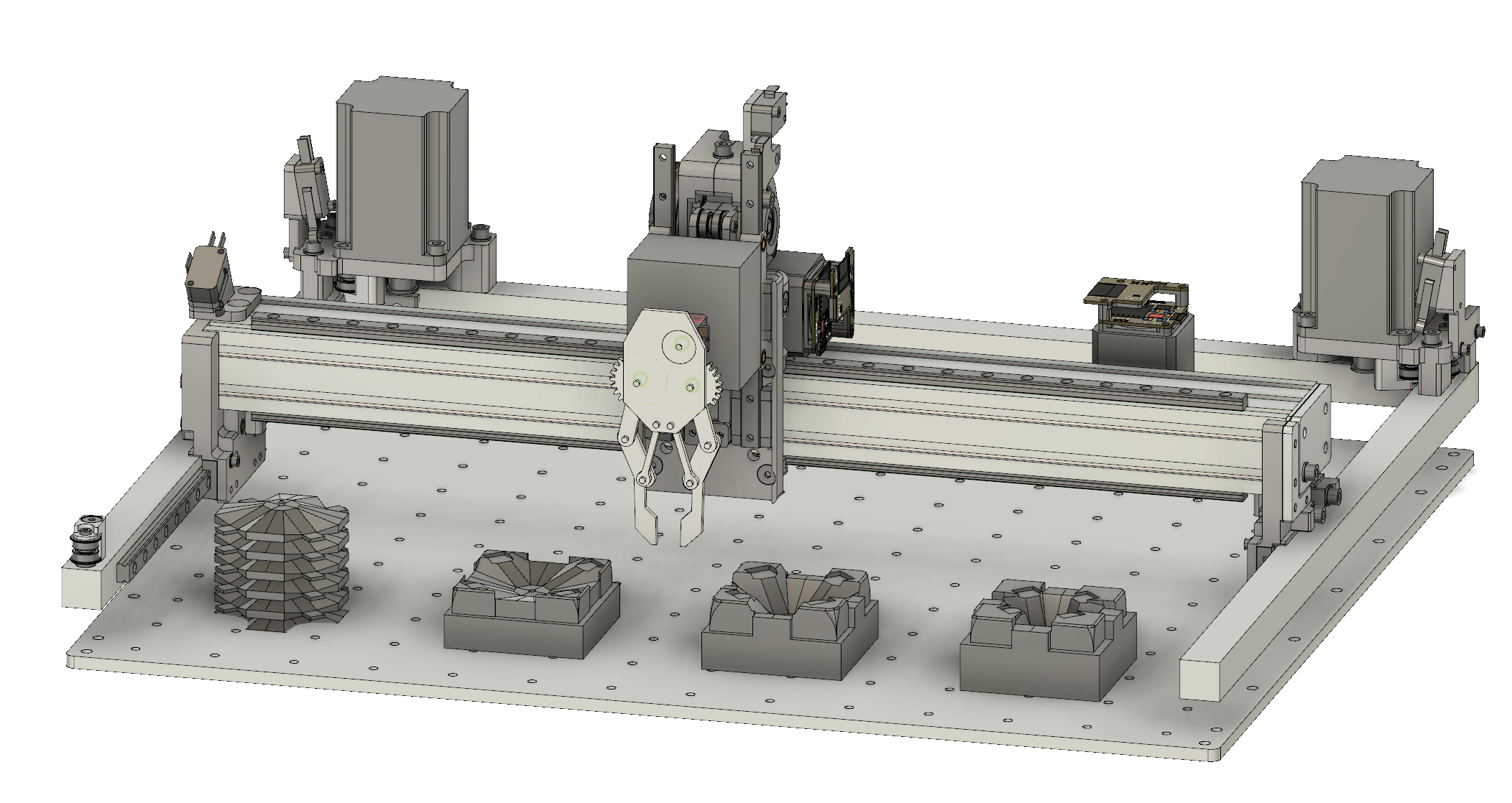

By modifying Jake's Clank, I plan on creating a pick and place machine with a robotic gripper that moves the 2D faces through every stage of the molds that Alfonso designed. There are 3-4 stages of the folding through custom molds, as well as a clamp press top (one-axis) that will be implemented. I need to modify the robotic gripper to have 4 fingers for gripping each side flap.

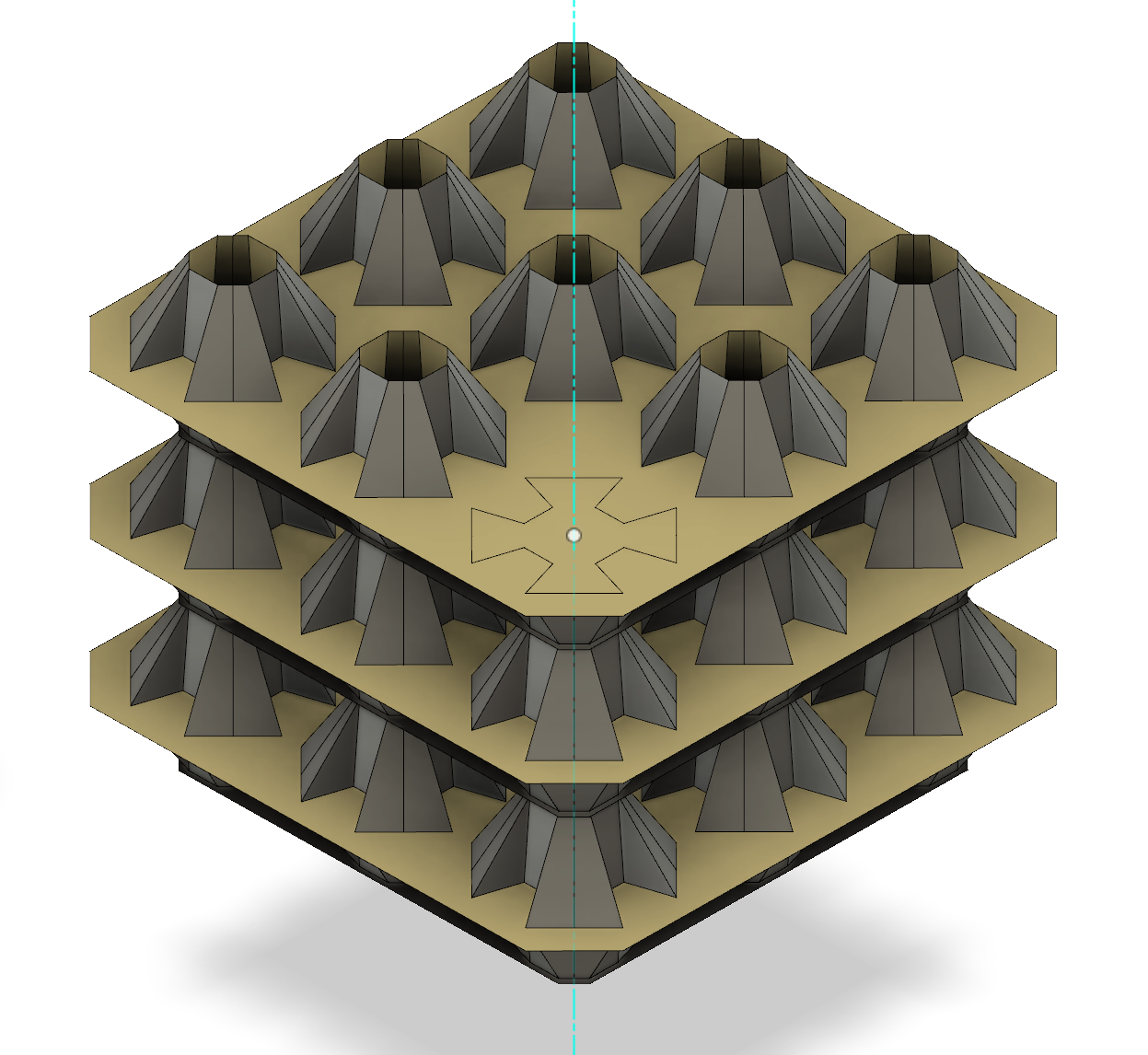

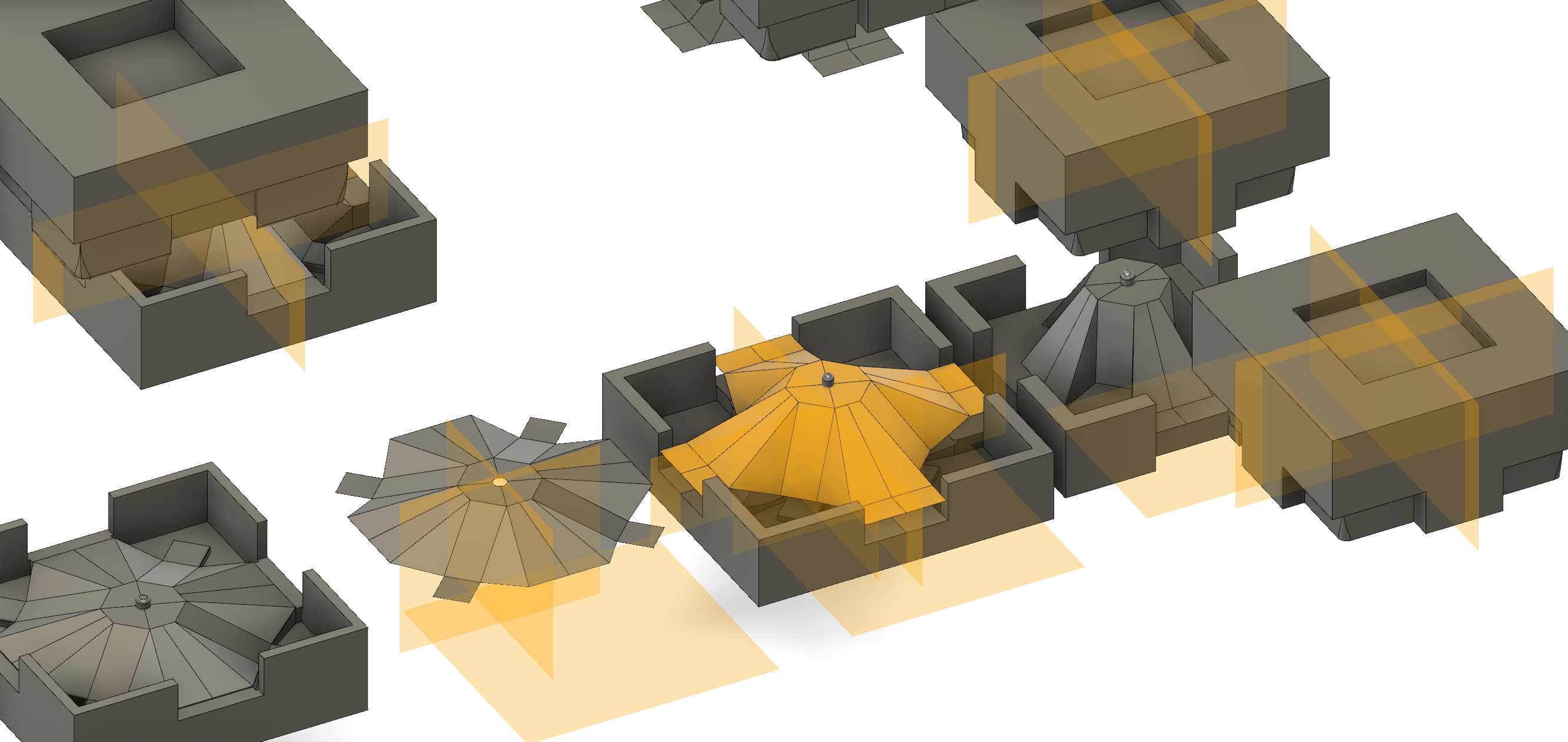

These are Alfonso's designs, which show the approximate layouts of a discrete grid of folded voxels.

- we will likely increase the overall pitch of these voxels to get up to 20 cm.

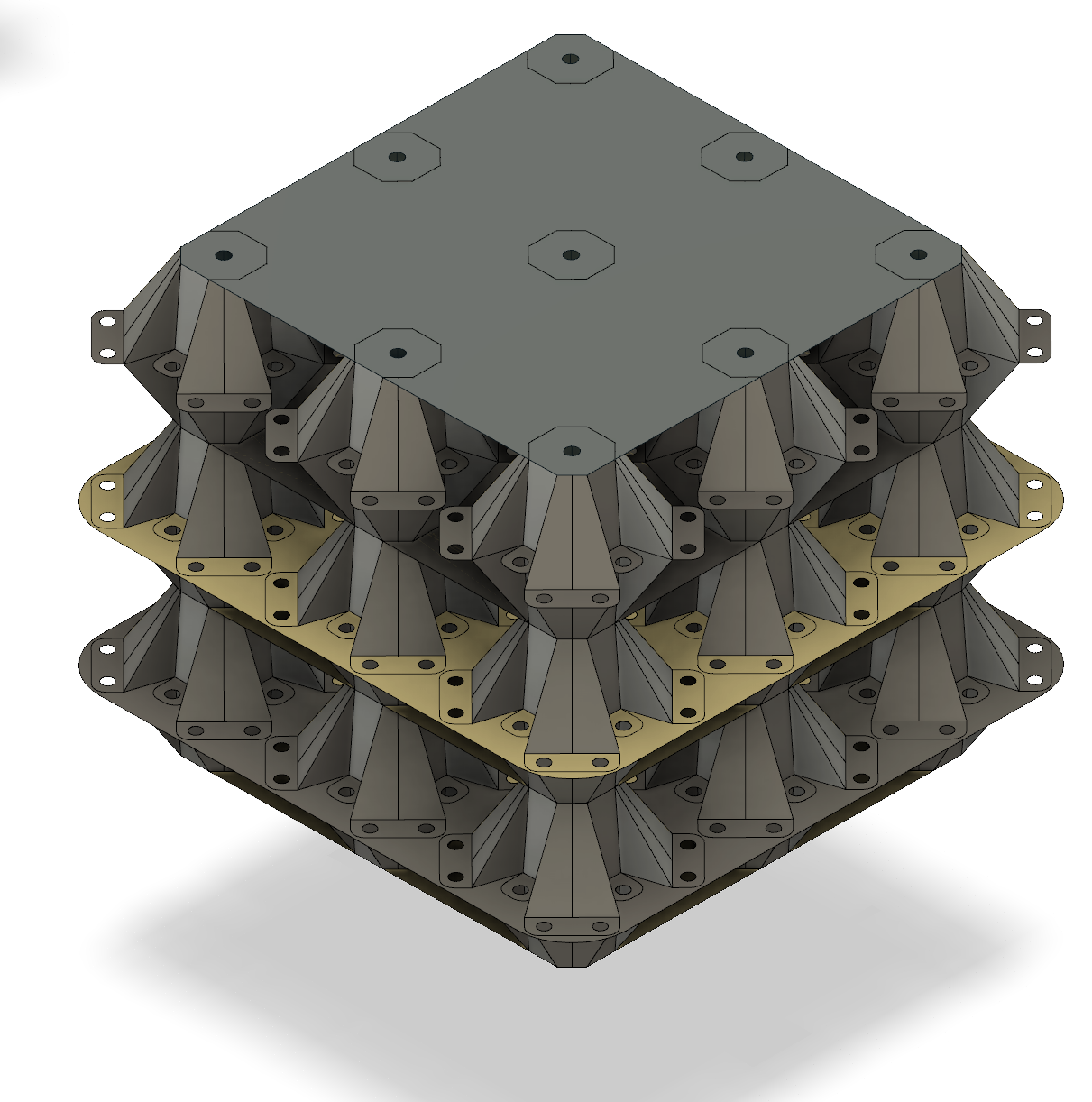

Again, Alfonso's designs showing an exemplar final structure. There is currently still a sheet between the faces for the riveted connections, but we are working to remove this step to make assembly less complex.

- Alfonso's molds. A kinematic mold would be ideal to reduce the number of stages ... will see how much time is available.