Introduction

For this week, I decided to make a mold for an ashtray. The process involves milling a wax mold, using that to cast a silicone mold, and finally casting parts with drystone.

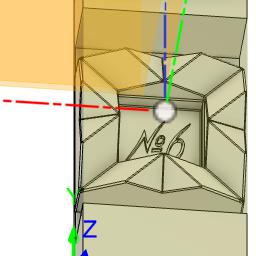

CAD Design

I started with an Ashtray design I liked from FreeCAD. I then adjusted it to my preferences and added a logo in the middle using Fusion 360. what follows

Wax Mold

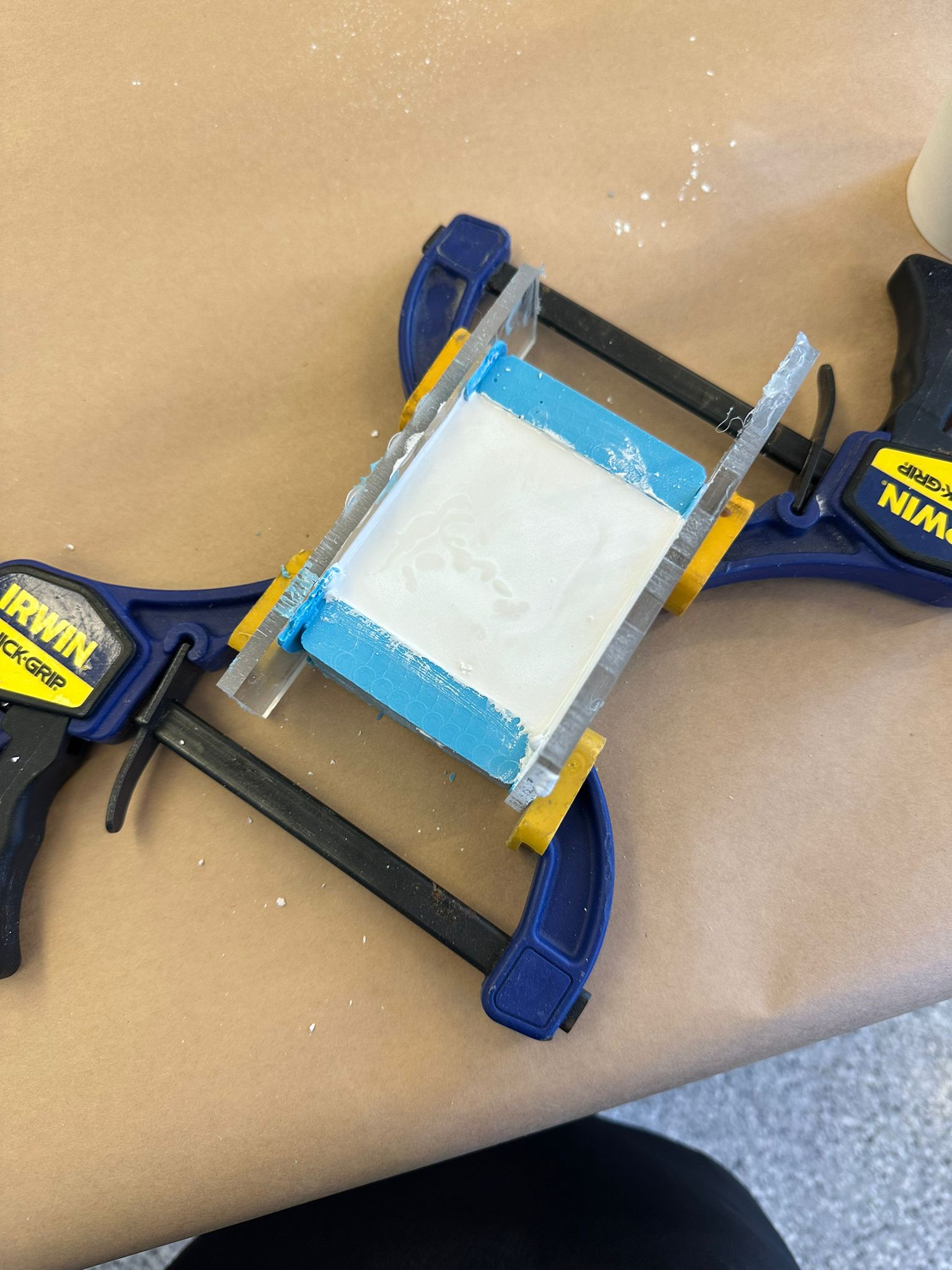

After consulting Anthony on how to maximize the size of the mold, We decided to mill the mold without boarders at the side and then hot glue acrylix at the side.

One improvement would've been to add spacing between the wax mold and the acrylic so that the oomoo mold would have formed a boarder.

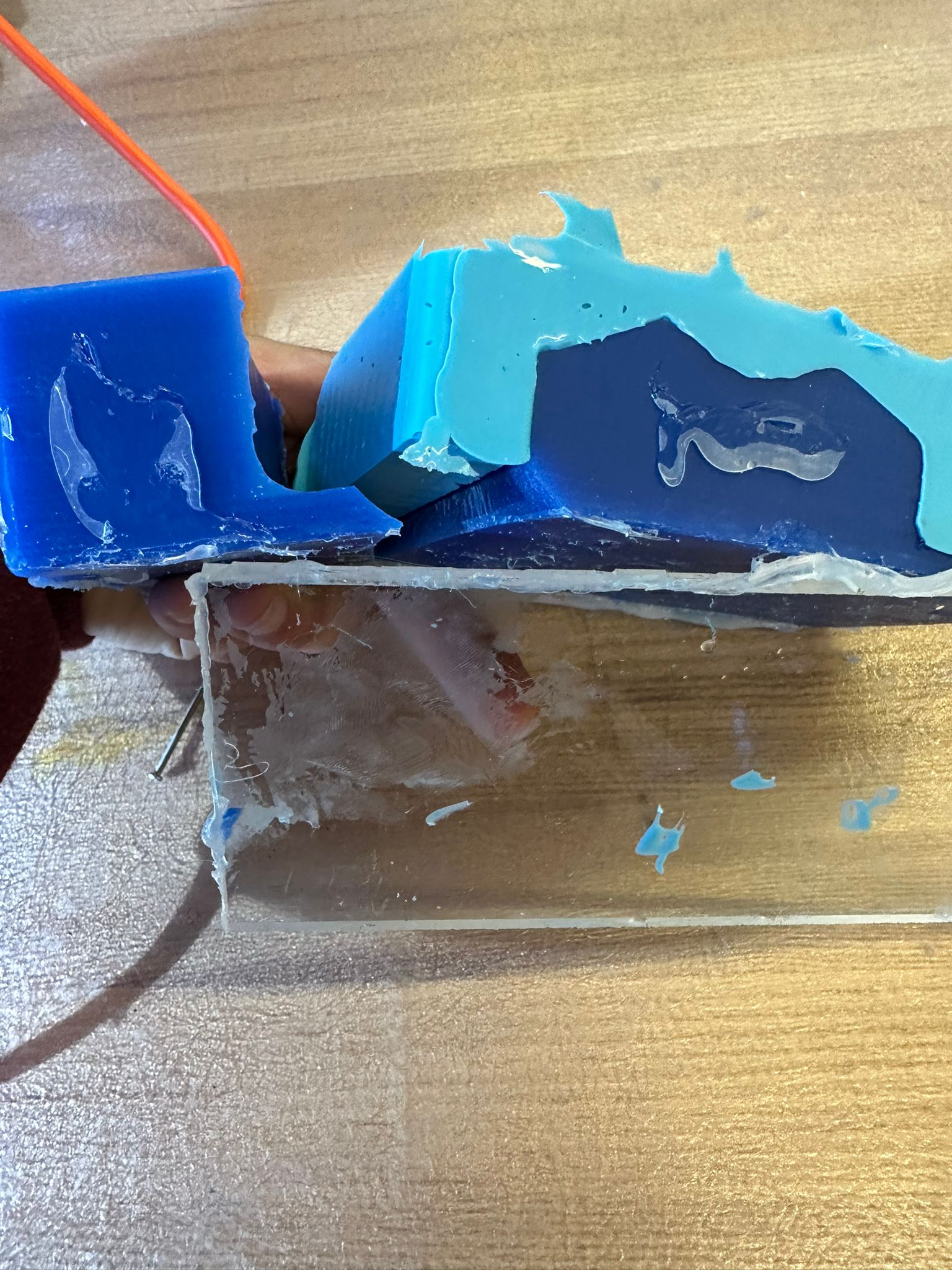

Silicone Mold

After milling the wax mold, I used it to cast a silicone mold. There was some water trapped between the silicone and the wax which affected the text in the middle.

There was a crack

Drystone Casting

Finally, I used the silicone mold for casting parts with drystone.