Accessibility in low resource contexts

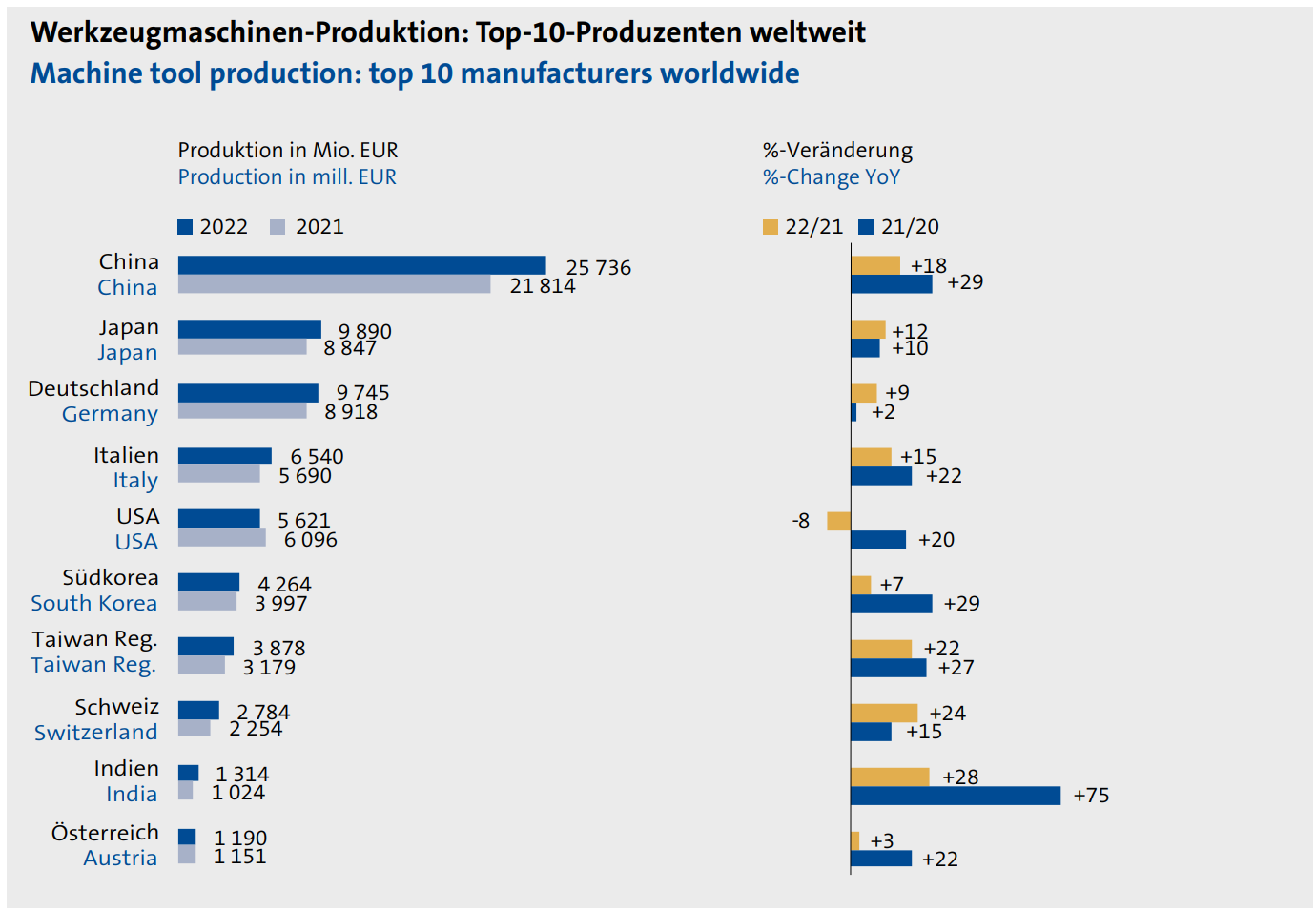

Importance of Manufacturing in Economic Development

- Manufacturing is a key driver for sustainable transformation

- Machine tools - also known as mother machines are the key enablers of manufacturing

- Technological developments in the manufacturing sector have spillover effects in various other industries

- Can directly contribute to SDG goals 8 Decent Work and Economic Growth and 9 Industry, Innovation and Infrastructure

- Creating jobs and income, directly contribute to reducing poverty, reducing inequalities and several others.

The Accessibility Problem

- Machine tools and more specifically 'digital fabrication machines' are generally produced in a select few industrialized countries like the USA, Germany, China, Japan etc.

- Most developing countries do not produce any machine tools and therefore have to import them

- These machines are usually way too expensive for small microenterprises to purchase. Shipping costs and taxes further increase these costs along with increased adminstrative and beaurocratic complexity.

- With used machine tools being more affordable, they are still expensive for typical users in developing countries due to such machines still costing several thousand USD

- Lack of research capacities and human capital to invent machine tools

- Commercial machine tool technology hidden behind IPs and patents

The Open Source DIY movement: Hedonic vs Utilitarian

- Open source economics as an alternative bottom up approach

- Majority of users in the makerscene are generally categorized as white, male, middle-class with a degree in engineering or computer science.

- Most open source machine projects also originate from users based in the global north which are inevitably also catered to the needs, resources and backgrounds of users from similar demographics

- Digital fabrication in global north is often for hobbyist related purposes with motivations often being self-fulfillment,reputation, learning new skills, building reputation, being part of a community etc.

- In global south - DIY projects are more utilitarian i.e. with a focus on income generation or solving real world problems where they are often also cosidered frugal innovations, famously known in hindi as Jugaad.

Open source machine tools (OSMT)

- Open source machine tools (OSMT) i.e. a distinct subset of open source hardware (OSH) have been proposed as a solution to the problem

- The blueprints to reproduce OSMT are freely available for anyone to use, modify and sell.

- Example project: Fabulaser mini

Pat Delaney's Open Source Machine Tools Project

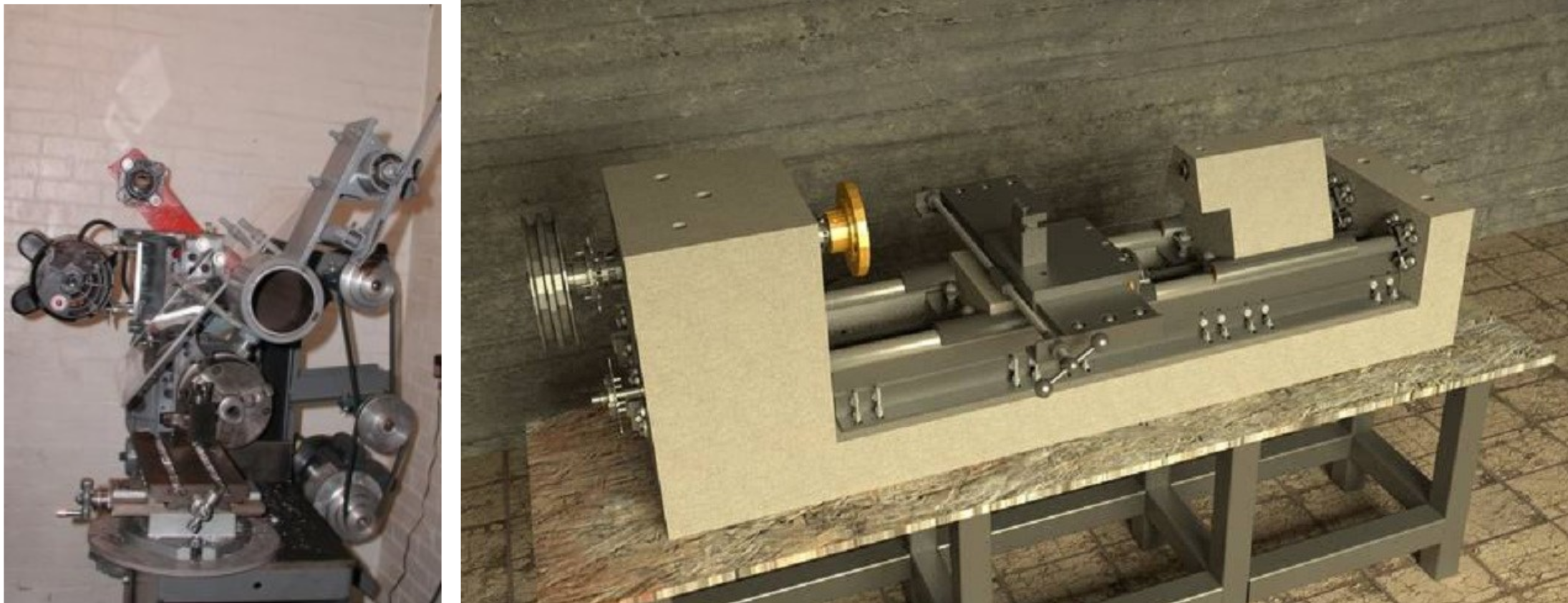

Left: Multimachine, Right: Concrete lathe

Left: Multimachine, Right: Concrete lathe

-

Pat Delaney's Open source machine tools project was basically a set of instructions to build manual machine tools from scratch from early 2000

-

Notably the multimachine and the concrete lathe (a more recent instructable of the concrete lathe build)

-

The multimachine cleverly reused scavenged automotive car engines to create a coombined milling and lathe machine. Engines already have precisely machined surfaces and therefore avoids the need to machine flat surfaces (difficult with no access to large industrial machine tools).

-

The project was specifically aimed at developing countries with a lack of precision manufacturing facilities and access to specilized components

-

However the project died out due to several reasons such as much too complicated instructions, complex modifications, need to source specifc types of engines etc.

Open Source Ecology's 'Civilization Starter Kit'

- Set of 50 machines that could be used for self-sufficinecy from macnufacturing and agricultural to baking machines.

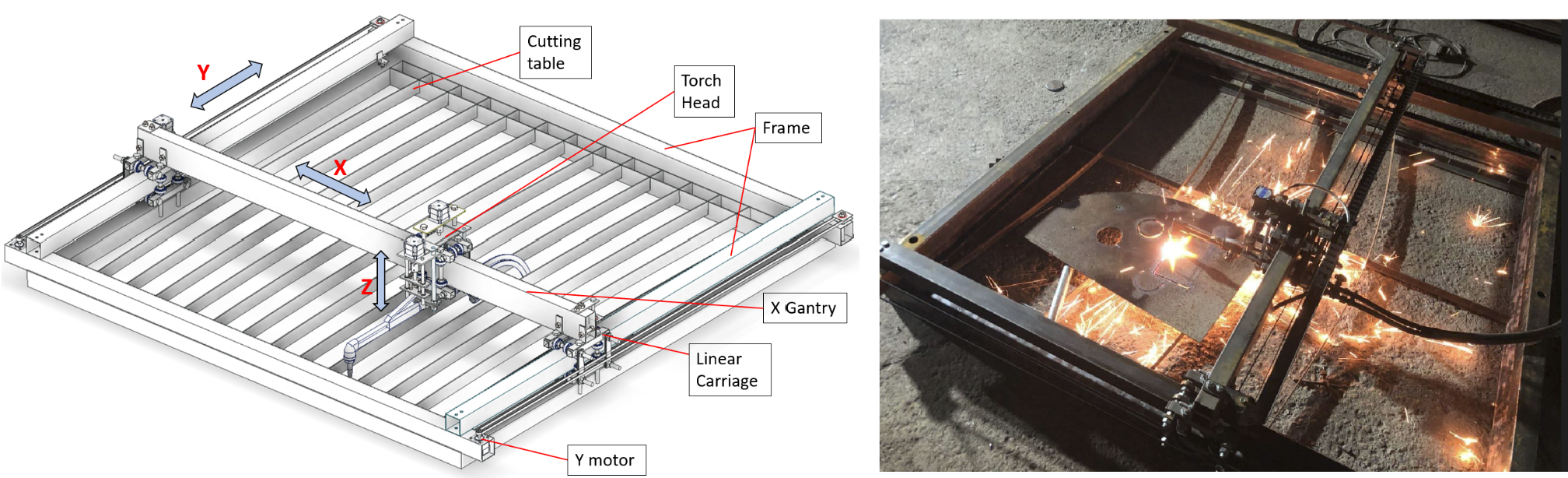

- Several CNC cable machines among the list of machines developed such as a CNC oxyfuel cutter, 3D printer etc.

- Being developed in the US, still hard to translate 1:1 to other contexts with different resources and manufacturing capabilities

- Slow progress - Due to reasons such as lack of similar incentives for designers as seen in conventional industry projects, design and development done in free time, lack of resources etc.

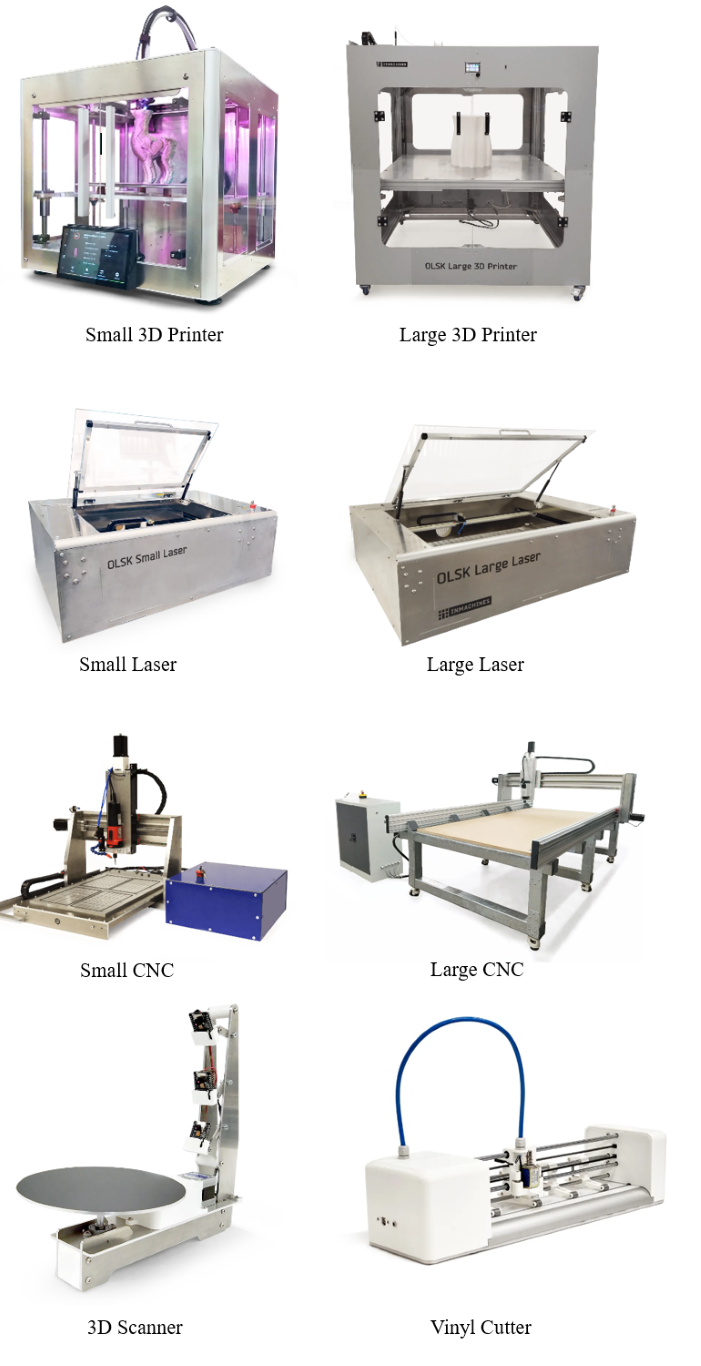

Open Lab Starter Kit (OLSK)

The 8 open source alternatives to the Fablab Inventory

- The OLSK project is an open source alternative to the commercial fablab machines

- Set of 8 open source machines - 3D printers, laser cutters, vinyl cutters and a 3D scanner.

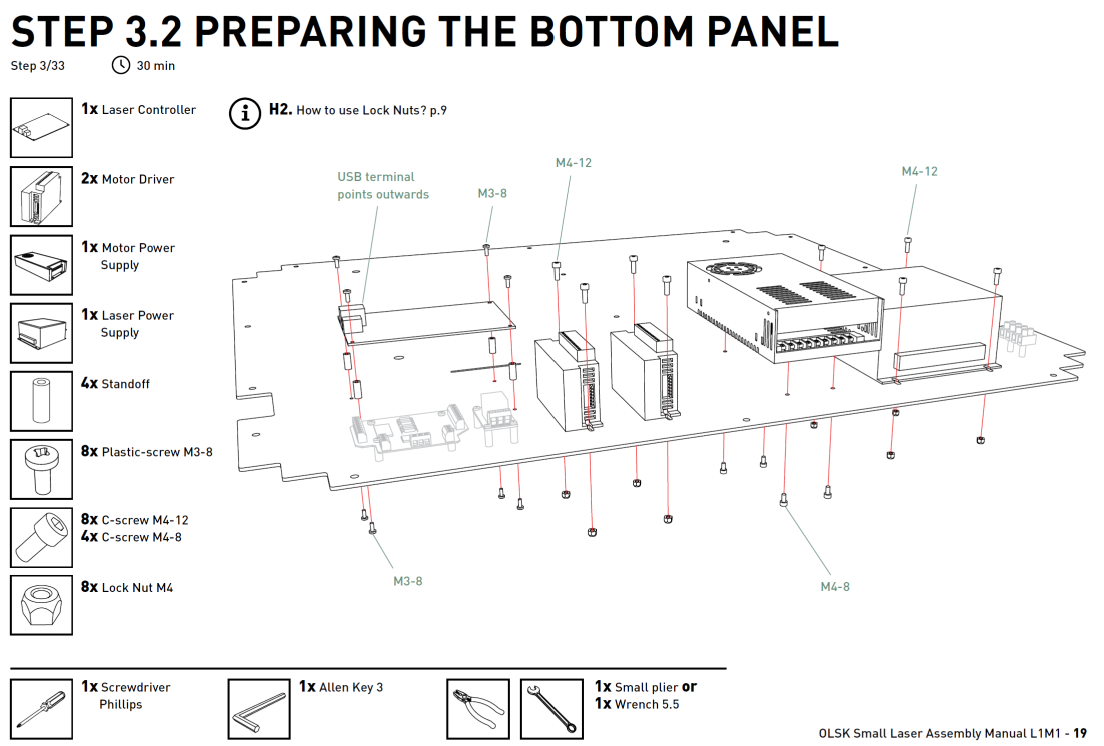

- Focus on replicability by enabling the fabrication of the machines by conventional fab lab machinery

- Focus on Documentation to resemble pictorial documentation guides like LEGO and IKEA.

Snapshot of build manual for the OLSK laser cutter design

- Iterative design with each machine undergoing 3 major design iterations supported by user feedback from build workshops and continued usage

- Focus on several aspects such as design for manufacturing, design for assembly, design for usability, design for affordability etc.

- Project completion Q4 2024

Challenges to design for Low Resource Contexts

Migrant-run Steel fabrication workshops in Oman

- Constrained resources

- Limited access to financing

- Limited access to advanced manufacturing capabilities

- Lack of infrastructure

- Machines when present, often analog and substandard in quality/ worn out > difficult to fabricate to tight tolerances

- Deficient access to international markets

- Low digital, technological and general literacy levels - A key barrier

- Source: Exploring the Potential of Open Source Machine Tools for Sustainable Industrial Development in Low Resource Contexts - A Case Study of Migrant-Run Microenterprises in Oman

Design principles for low resource contexts

- Appropriate design - Designed to be contextually appropriate, that takes local resources, needs, preferences and capabilities into account.

- Frugal Design > Focus on key components

- User centered design or Co-design

- Example of frugal automation of an oxyfuel cutter

An handheld oxyfuel cutter was automated with a user centered design using local materials and basic 3d printer parts like nema17 motors and an arduino ramps board.

Use of digital fabrication technologies

- Focuses on CNC 2d fabrication methods for the fabrication and manufacturing of machine parts

- Avoids the need for user to be highly dextrous or experienced with mechanical precision builds, preventing assembly and fabrication errors

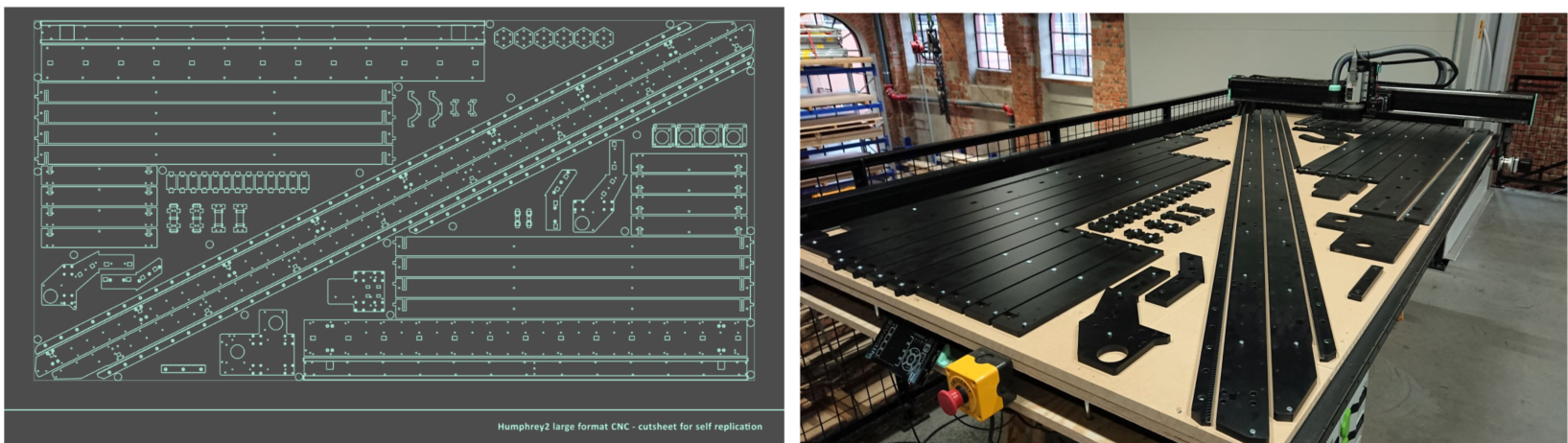

- Example: Humprey 2 from Jens Dyvik's fabricatable machines, where almost the entire machine structure can be machined from a single sheet of POM

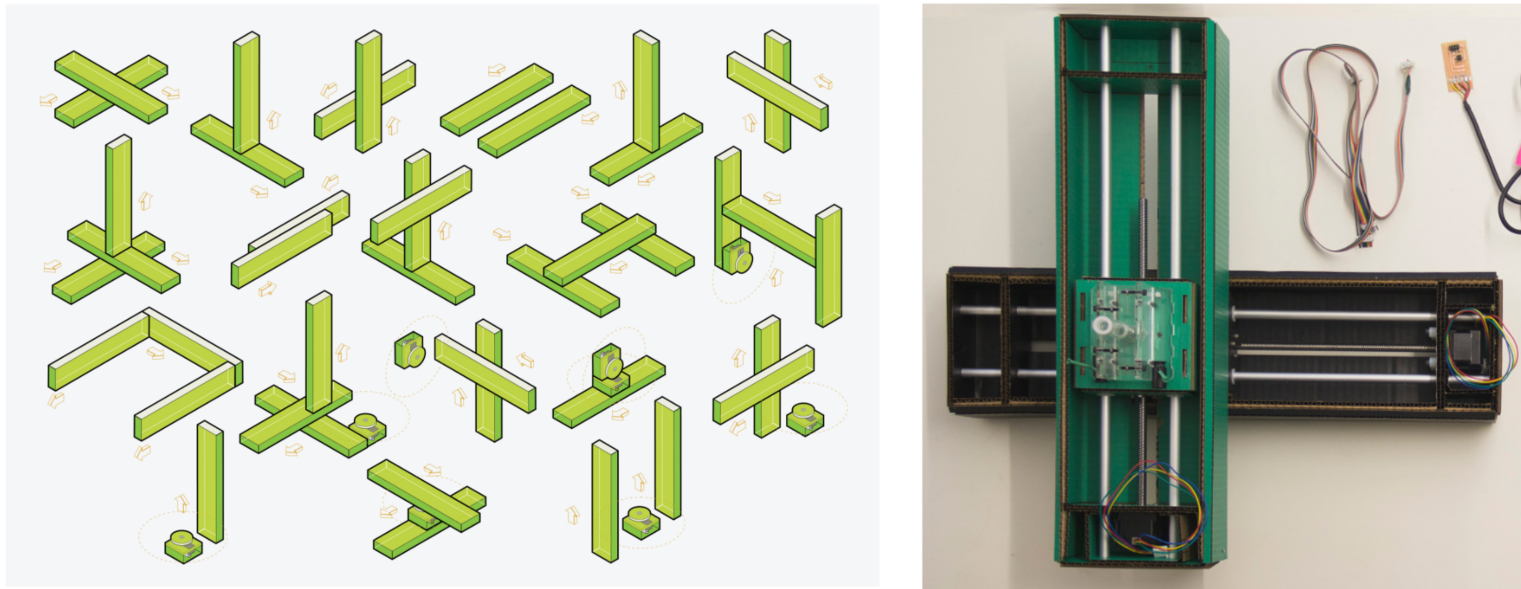

Modularity and parametric design

- Each machine tool subsystem is designed as an individual module that is independent of other modules - eg. linear stages, frame, spindle unit etc.

- Design can be scaled to user spatial requirements, or to save costs

Accessibility (Making machines accessible to everyone)

Accessible platforms/machines

Sharing platforms as a way in which work, ideas, making, becomes more inclusive and accessible.

OpenStructures is an open modular construction project where anyone designs for everyone on the shared basis of a grid. Designs on OpenStructures as well as parts that can be reproduced are shared and evolved through use, redesign, and resharing. These parts are meant to be reproducible in the efforts of personal fabrication/dispersed manufacturing.

They also host workshops and products can be anything from furniture to low tech home appliances, and flexible tools.

Jesse Howard - transparent tools

Similarly are also projects by Jesse Howard, who has a few projects on relatively simple machines/home appliances since they while not complicated, they are often inaccessible to the average user. Furthermore, repair or recycling is essentially impossible with these machines, as when these products cease to function they are essentially disposable.

Appropriate technologies

CACITA - Autonomous Center for Inter-Cultural Creation of Appropriate Technology

Example: Solar Charged Lawnmower

Accessibility (New Modalities, Multimodal approaches and Natural Interactions)

Alternative CAD/CAM Methods for people without technical background

Making Gestures

- The research focuses on a multimodal body-centric approach to interactive fabrication, utilizing a gesture language as the primary mode of communication between the user and the machine.

- The framework aims to democratize robotics among designers by providing tools with a low barrier to entry, making advanced technology more accessible.

- Overcoming operational and representational limitations by facilitating conversation and interaction with machines.

- Start 1:22

Gesture Recognition for Feedback Based Mixed Reality and Robotic Fabrication

- Enables direct manipulation of digital information through natural hand movements, making the interaction with robotic arms more intuitive

- Allows uses to identify nonstandard cut stock in 3D and set robotic toolpaths using gestures .

- Provides immediate visual feedback in the MR interface as users interact with physical objects, allowing for seamless adjustments

- Start 0:17

Computer Aided Design in AR/VR

- The system is designed to be accessible by non-expert users, enabling participation in the design process through an MR user interface that manages module properties and connectivity.

- 3D modeling like move objects, instead of using commands or gumball tool

- The custom MR environment facilitates on-site collaborative design, making the technology more accessible to users in the actual construction setting

- Start 0:7

Speech + Gesture to Reality (Generative AI + Multimodal AI)

Who has access?

3D printed elephant in the room

Digital Fabrication Practices for the Education of Visually Impaired or Blind Youth

Do-It-Yourself Empowerment as Experienced by Novice Makers with Disabilities

Designing makerspaces for accessibility

Inclusion

Shirin Voussoughi

Nation of Makers

Narratives of Being a “Maker”

Dale Dougherty - We Are Makers

The Entrepreneurial Narrative

Debbie Chachra

Visibility/Representation

Megan Smith - Shift 7

Equity in media: images matter

Cracking the code (study with USC)

Leah Buechley