3D Scanning and Printing

For ths assigment I was interested in the irregular surfaces of plants. To what extent can these textures be captured and reproduced?

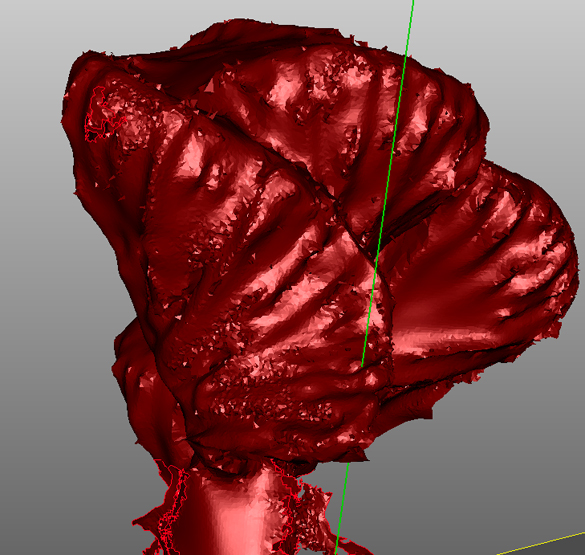

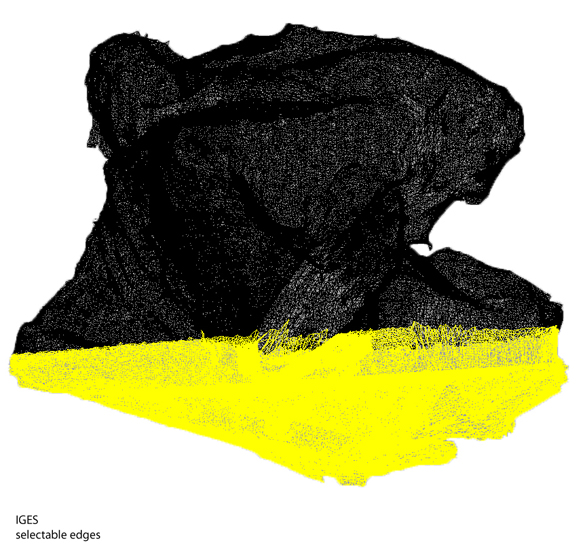

Figure. The cactus' flower, scanned using the Minolta Vivid 910 at the MediaLab. A non-contact 3D digitizer. Ths image shows the model imported into Rhino.

A photo of the cactus' flower

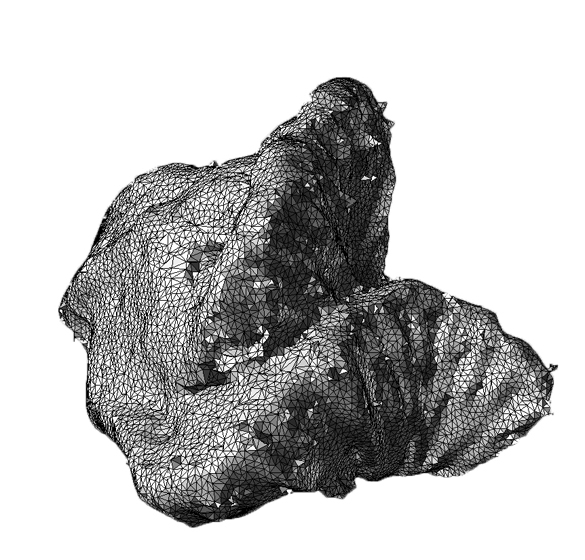

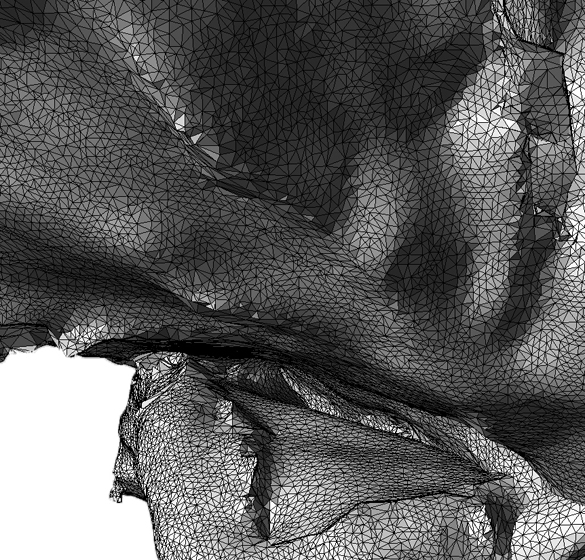

The geometry resulting from the scan and the processing is a mixture of the data read by the Minolta scanner and the patching algorithms used for filling holes. This figure shows a simplified mesh in Rhino. A fascinating change of scale.

Despite the limitations of the scanner (it can only capture the parts of the object that are in the laser's path), some of the object's features are digitized. The ability to explore the details of this plant's accidents is full of possibilities for formal exploration.

Rhino Reference

http://en.wiki.mcneel.com/default.aspx/McNeel/CommandList.html

Some things to do with a mesh (from an email sent to the class by Jonathan Ward):

you can covert mesh to nurbs with the command

meshtonurb

(this allows you to use more transforming operations on your model that will not work with a mesh)

you can then convert a nurb back to a mesh with

mesh

this one allows you to trim or split your mesh with intersecting objects:

meshsplit

smooth

and for 3d printing:

checkmesh

weld

Also, when exporting a mesh as an STL, Rhino may tell you that your model will not work for rapid prototyping, but this is not always the case.

This is something I found wirking with the mesh in Rhino:

Most times when Rhino says that the object is not valid for rapid prototyping is because the object is not a solid. You can make sure that the object is a solid in Rhino 4 by checking that it has no naked edges (you can do this by analyze

-> edge tools -> show edges : show naked edges

This will show you the edges and you can then edit them manually/delete them.

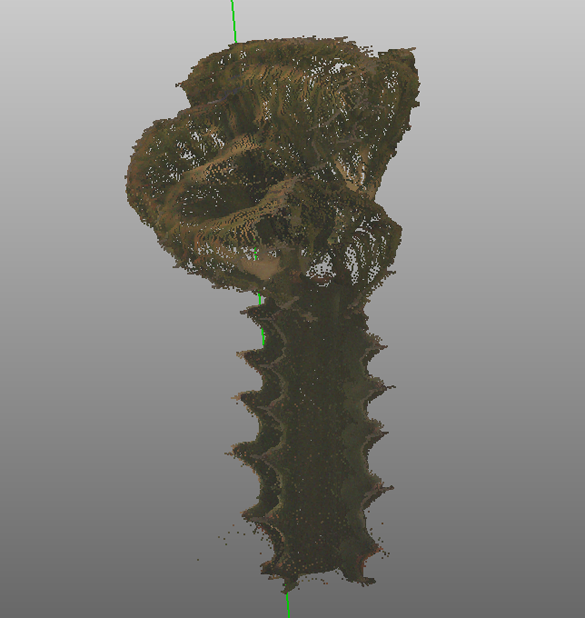

The point cloud that results from the scan

A closer look to the point cloud. The scan returns around 300 000 3D points.

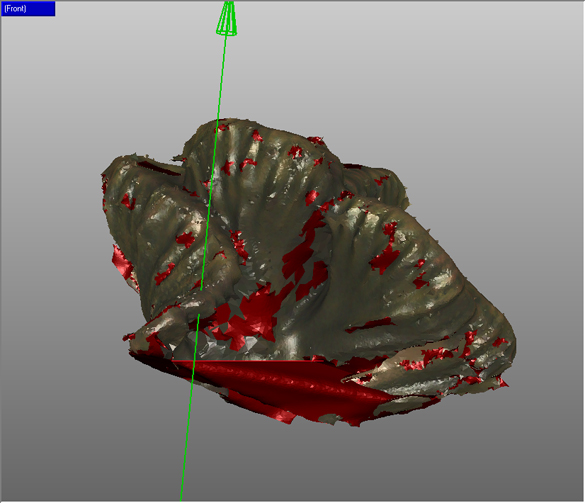

The red surfaces are the areas that are closed by the 'fill holes' option of the scanner's software. Patching the holes took the software around 10 minutes of processing time.

Exporting the geometry as IGES and importing it into Rhino permits individual selection of edges, this doesnt happen if the geometry is exported as STL.

Most times when Rhino says that the object is not valid for rapid prototyping is because the object is not a solid. You can make sure that the object is a solid in Rhino 4 by checking that it has no naked edges (you can do this by

analyze -> edge tools -> show edges : show naked edges

This will show you the edges and you can then edit them manually/delete them.

Devoid nature

A wise man

p.s.

Computation is a Generative Craft

|