Press fit

construction kit:

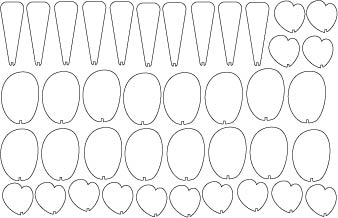

For my press fit constuction kit, I wanted to make something organic. I had used the laser cutter before to make an architecture model, which required each piece to have a specific predefined function. I wanted my construction kit to be more open-ended, like Legos, so that I could make any number of configurations with it. I decided to make a garden for my room. I made grass, stems, petals, pistens, and leaves. Of course, these pieces also have specific funtion, but they don't necessarily assemble into one garden. They can assemble into any garden you want.

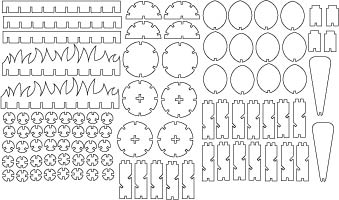

I designed my pieces in Solidworks. I made a separate part file for each different component, and used linear patterns and circulart patterns to propagate my slots though my pieces. For each part, I had one sketch with the shape of the extruded piece, and one sketch that defined the Cut Extrusion, or the slots. This caused a small problem because since there were two separate sketches, I could not use the Chamfer tool to create chamfers, so I made them manually. The corrugated cardboard was 0.165 inches thick, so I made my slots 0.15 inches wide to make sure the pieces fit together tightly. The chamfers really help because even thought the fit it tight, the camfers act both as guides and as compressors. I then made an assembly with all the parts and exported it as a DWG file. I printed from Corel Draw with 75% power, 12% speed, and 300ppi. The cuts were very clean, although I would ocassionally find a small burnt spot.

And Voila. My own beautiful garden that will remain just as beautiful during the winter!

This is what my DWG files looked like. This is what I used to print to the laser cutter.