Design

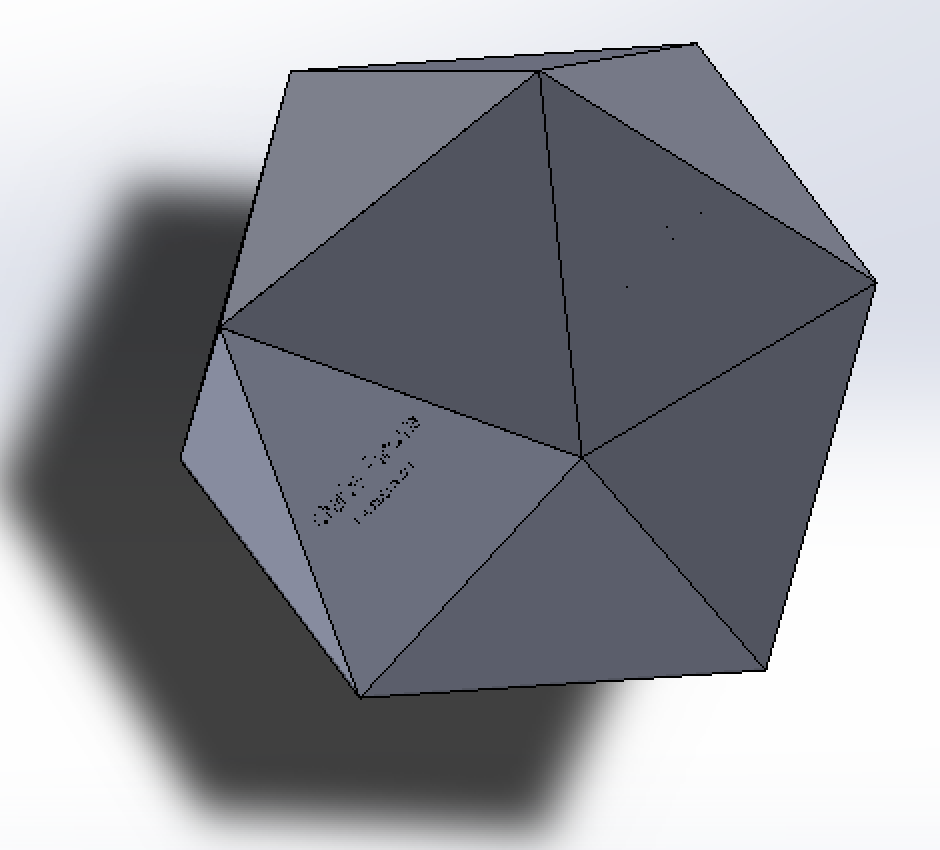

The goal is to make a large (1m end-to-end) icosahedron with embedded LEDs along its edges.

-

Assembly from triangles

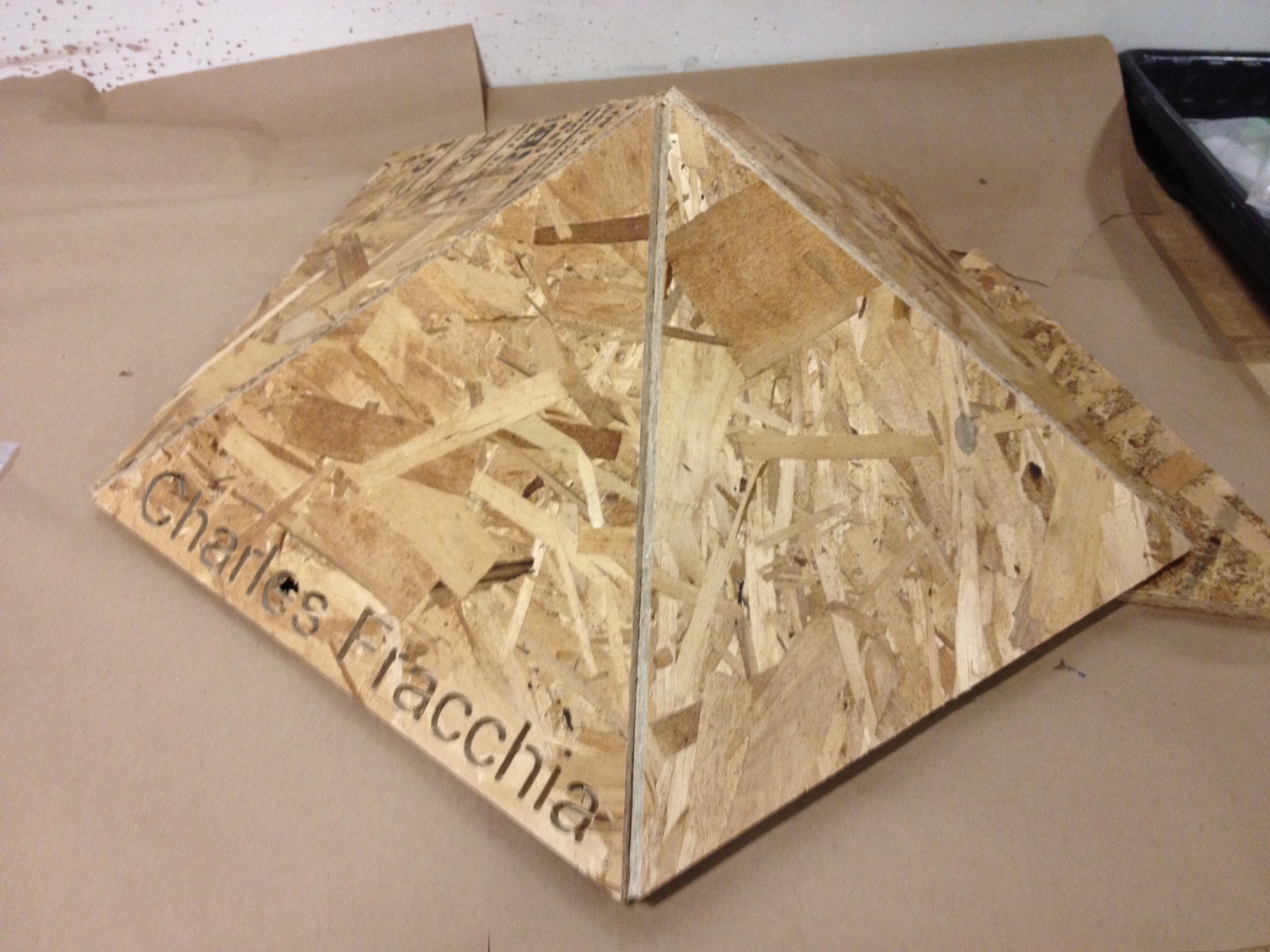

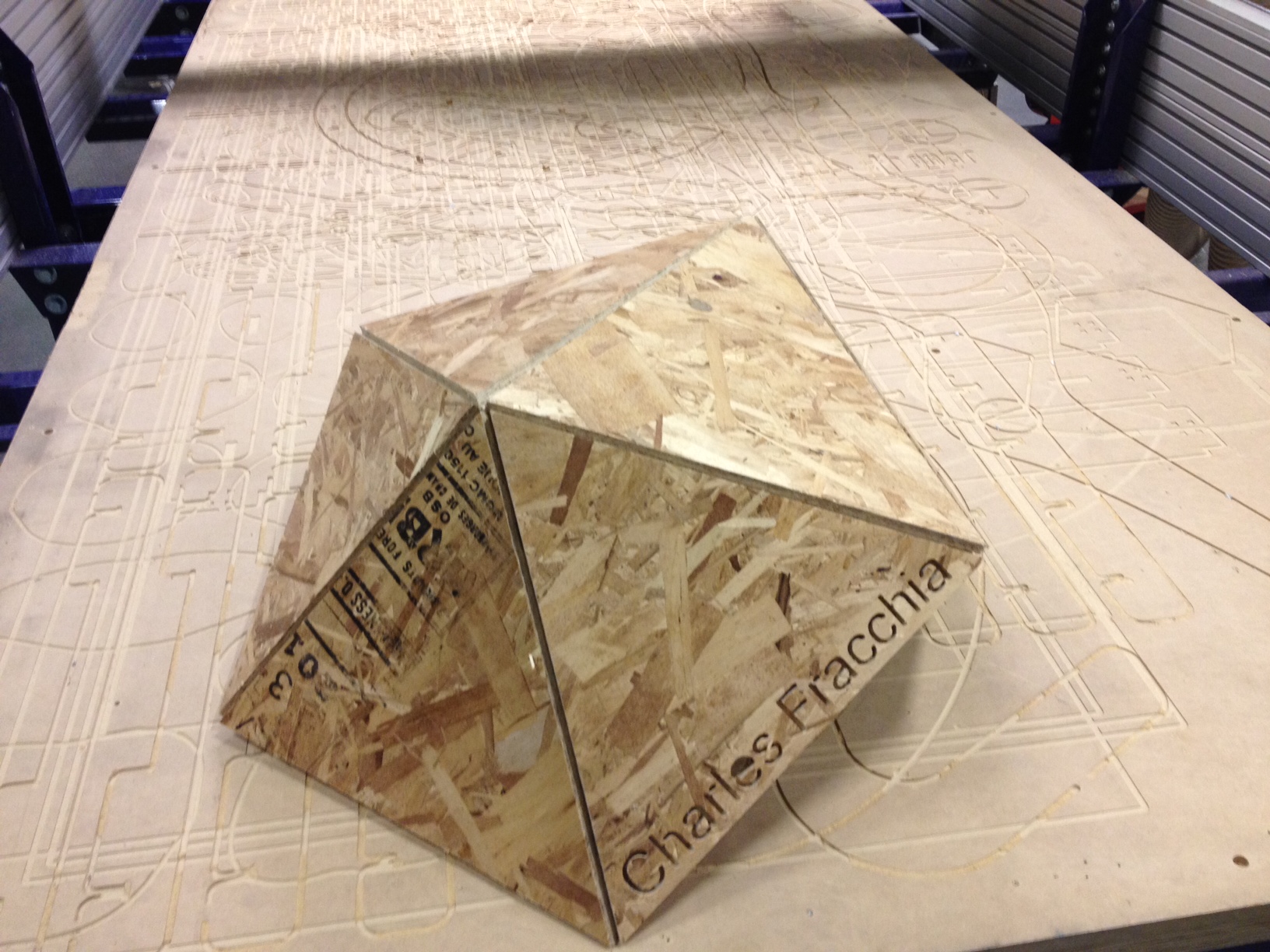

Unlike my previous model of the icosahedron, this one is assembled from 20 equilateral tapered triangles. I inscribed my name on one side by cutting out the letters yet not the whole way through. I am planning to work out the appropriate thickness to leave for LEDs to shine through.

-

Assembly from triangles

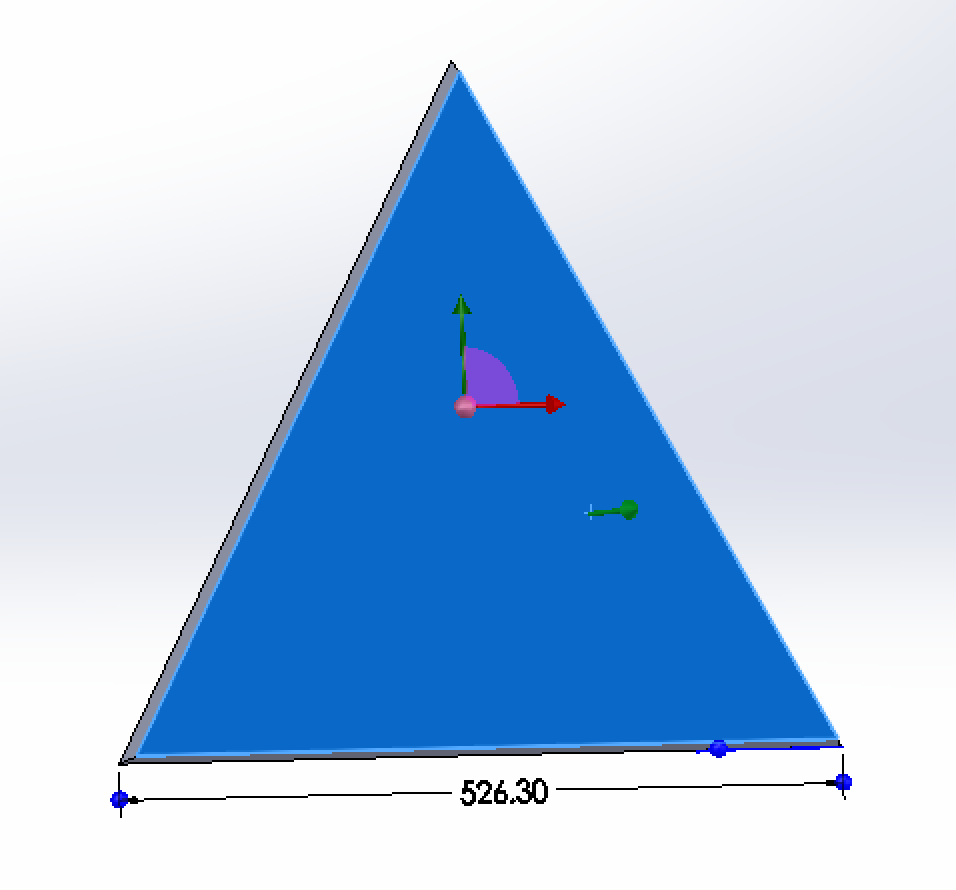

Unlike my previous model of the icosahedron, this one is assembled from 20 equilateral tapered triangles. The side length is 526mm in order to achieve a 1000mm, end-to-end icosahedron.

-

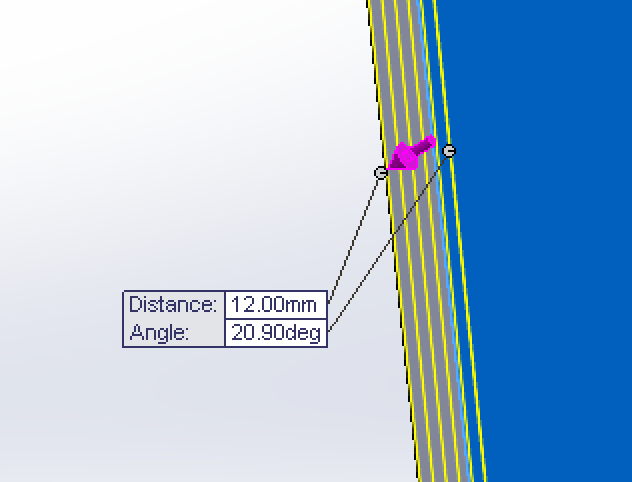

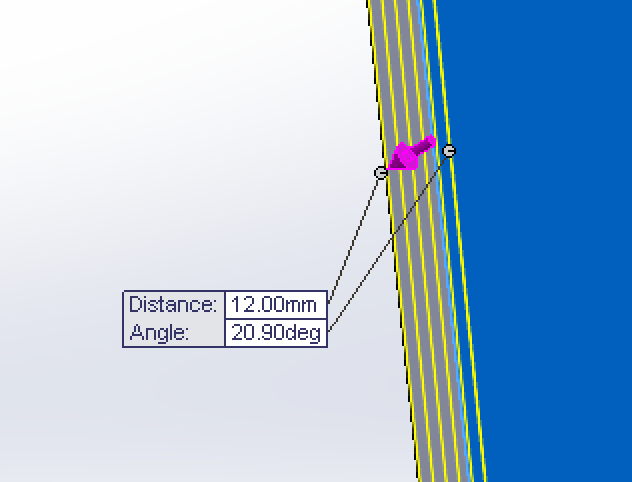

Chamfer detail

The chamfer angle was calculated using the following formula: x= ((360-138.2)/2)-90= 20.9°. The -90 is necessary because SolidWorks calculates the chamfer from based on the right angle.

Construction

-

Head of the Icosahedron

The best method to assemble the panels seems to be to use generic brackets, bend them to the correct angle (180° - Dihedral angle = 42°) using the metal bender in the CBA shop, and screw them in to the panels but leave some slack to allow assembly of the whole sttructure. This is quite forgiving on the angle of the bent brackets, which is hard to get very precise given the number of parameters to control on the bender.

-

Add one panel at a time.

-

Completed Icosahedron

I stopped at 15 faces assembled, to get the "sprouting out of the ground" feel to the icosahedron. Given that I want to put that at the front of my house in between the fall leaves, and that I have a specific orientation for the text to be legible, I opted to not put the bottom cap.