Week 2: Electronics Production

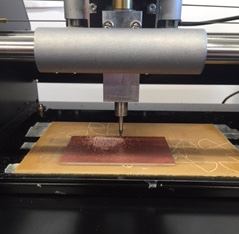

The first problem I encountered making my FabISP programmer occurred while using the Modela Mill. Even with the correct depth (.1mm) and an attempted deeper mill (.2mm), the machine was not cutting sufficiently into the board.

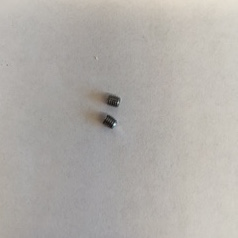

The tool seemed to be fine so I guessed that the set screws were not closing tight enough on the tool for some reason. After replacing the screws and setting the mill to cut deeper (.2mm) just to be sure, the mill was able to properly carve out the board.

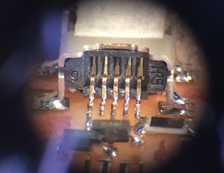

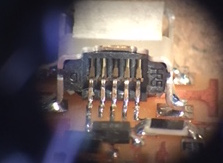

The only other major snafu occurred after soldering. It seemed, after inspection with a microscope, that I hadn't fully connected the leads from the usb component to the board. A quick flood of solder followed by a good ol' slurping up with the copper braid and wham! bam!: connected circuit.

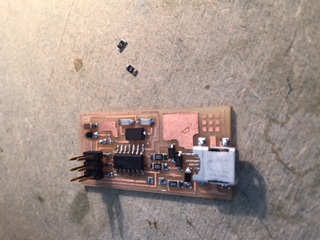

Finished product: