Jellyfish Protein

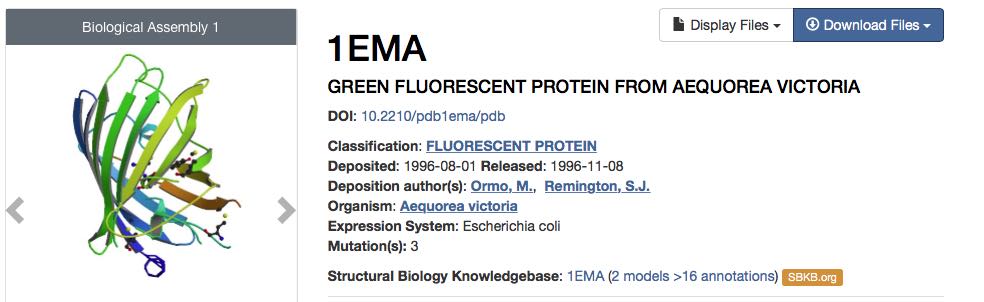

JELLYFISH, threatened by human activity, offer beautiful (and useful, in this case!) secrets... Introducing green fluorescent protein. This magical molecule literally glows green! The ability to stand out against a non-glowing background makes this useful for labeling and marking things. It's become a workhorse for molecular biology studies. The structure of this protein, as for many others, has been determined by a clever technique called x-ray crystallography. We can make a realistic 3D model from the atomic coordinates available for download at the Protein Data Bank (where you can learn lots more about this molecule along with other amazing proteins found in nature).

Every protein in the database contains its structure (or arrangement of atoms) as on the left.

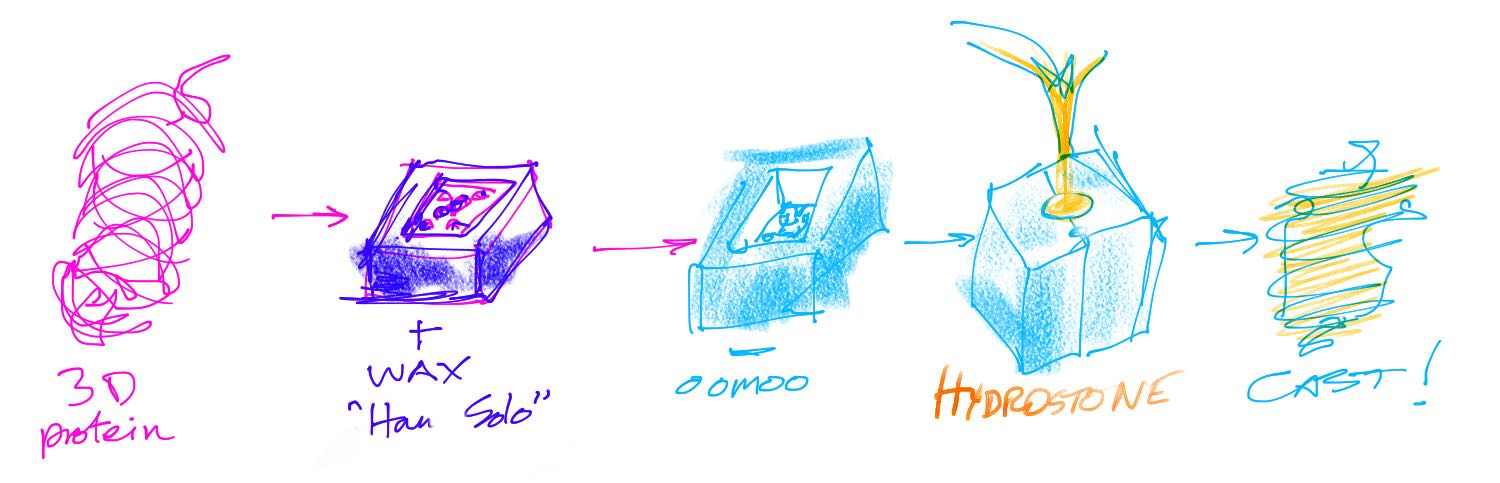

Our goal here is to use data to recreate this protein, learning a little about biology, design, and fabrication along the way. We're going to create a realistic, data-derived mold and cast. Here's a sketch of the process. We make a positive in wax, then a negative in silicone 'oomoo', then back to a positive in a medium called Hydrostone.

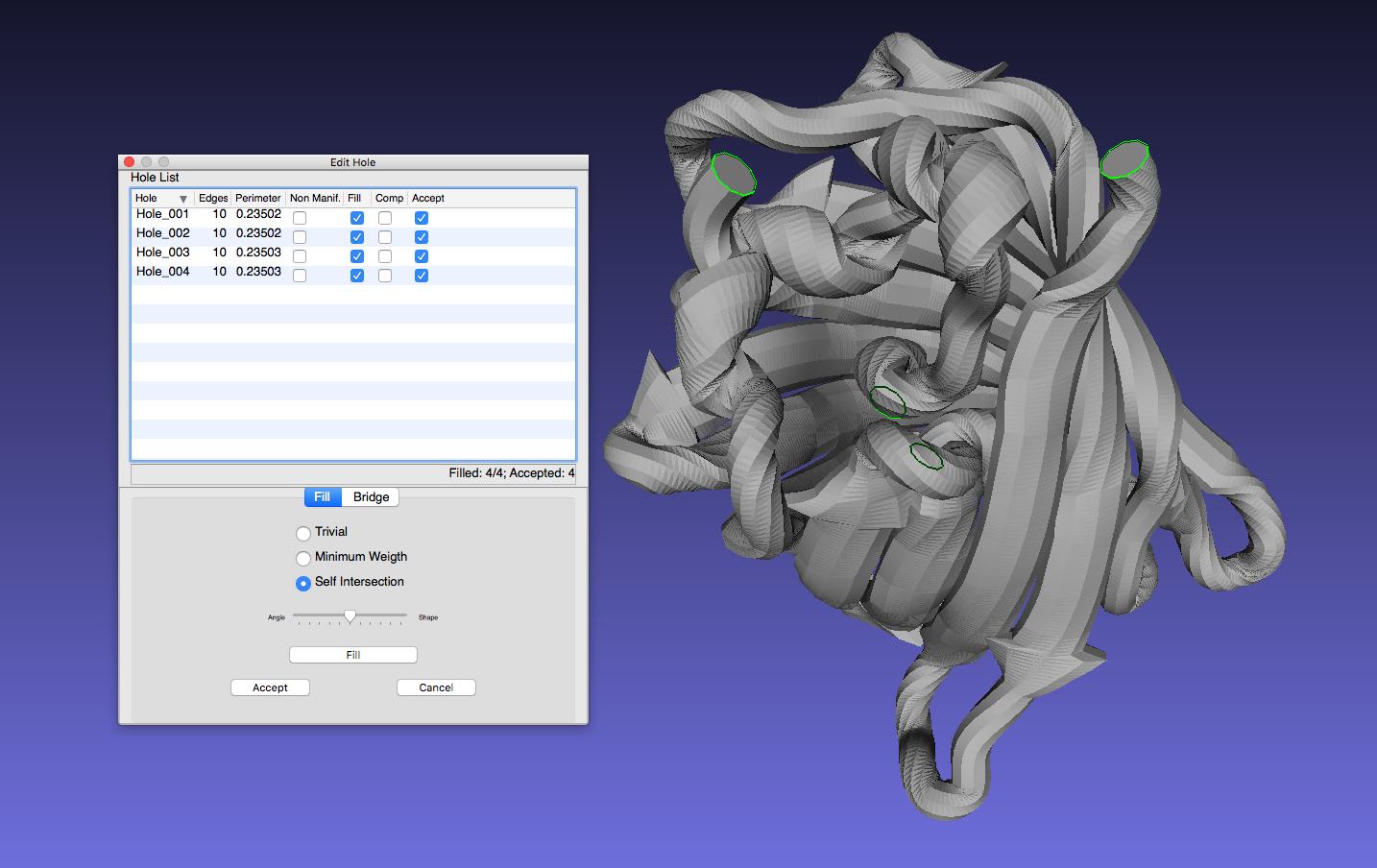

I exported meshes from a free PDB file viewer and imported these into useful software from Italy called MeshLab to repair 'holes' (incomplete shapes) in the edges of the protein.

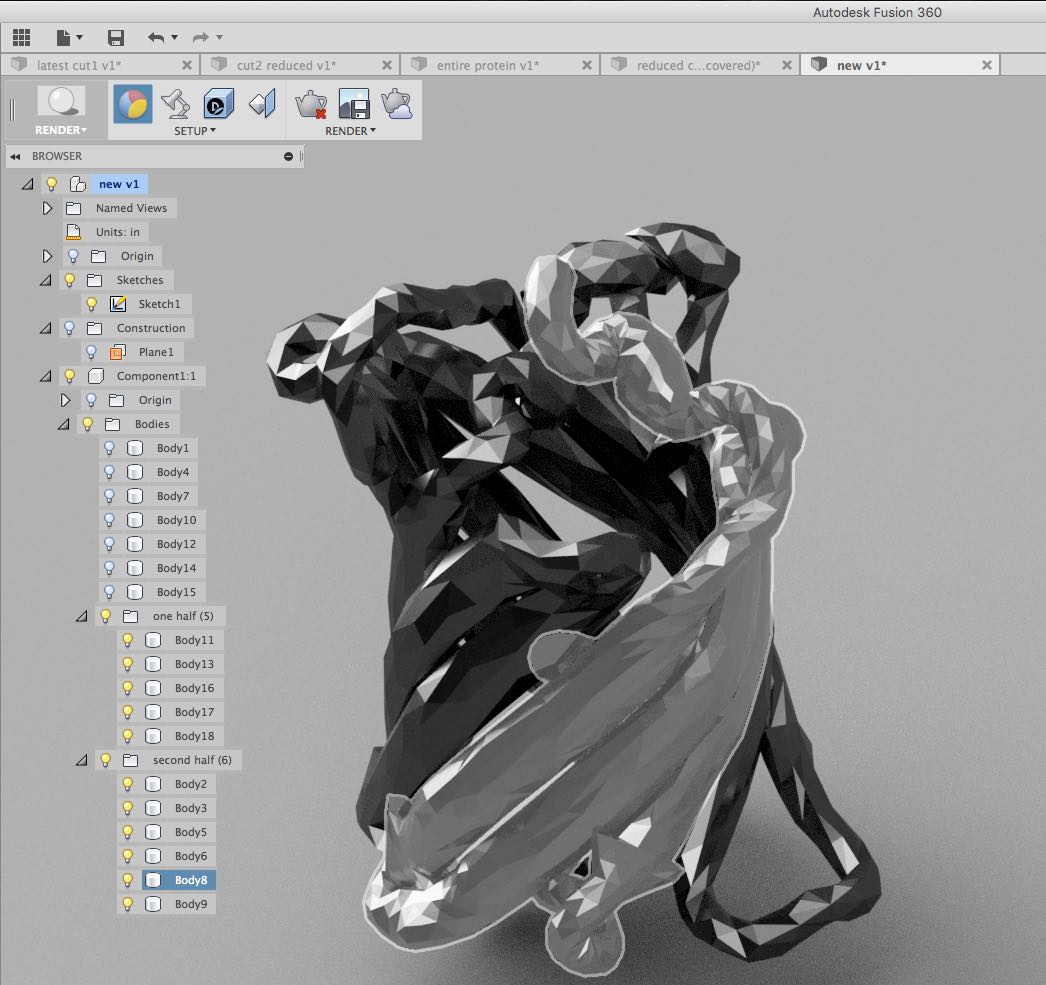

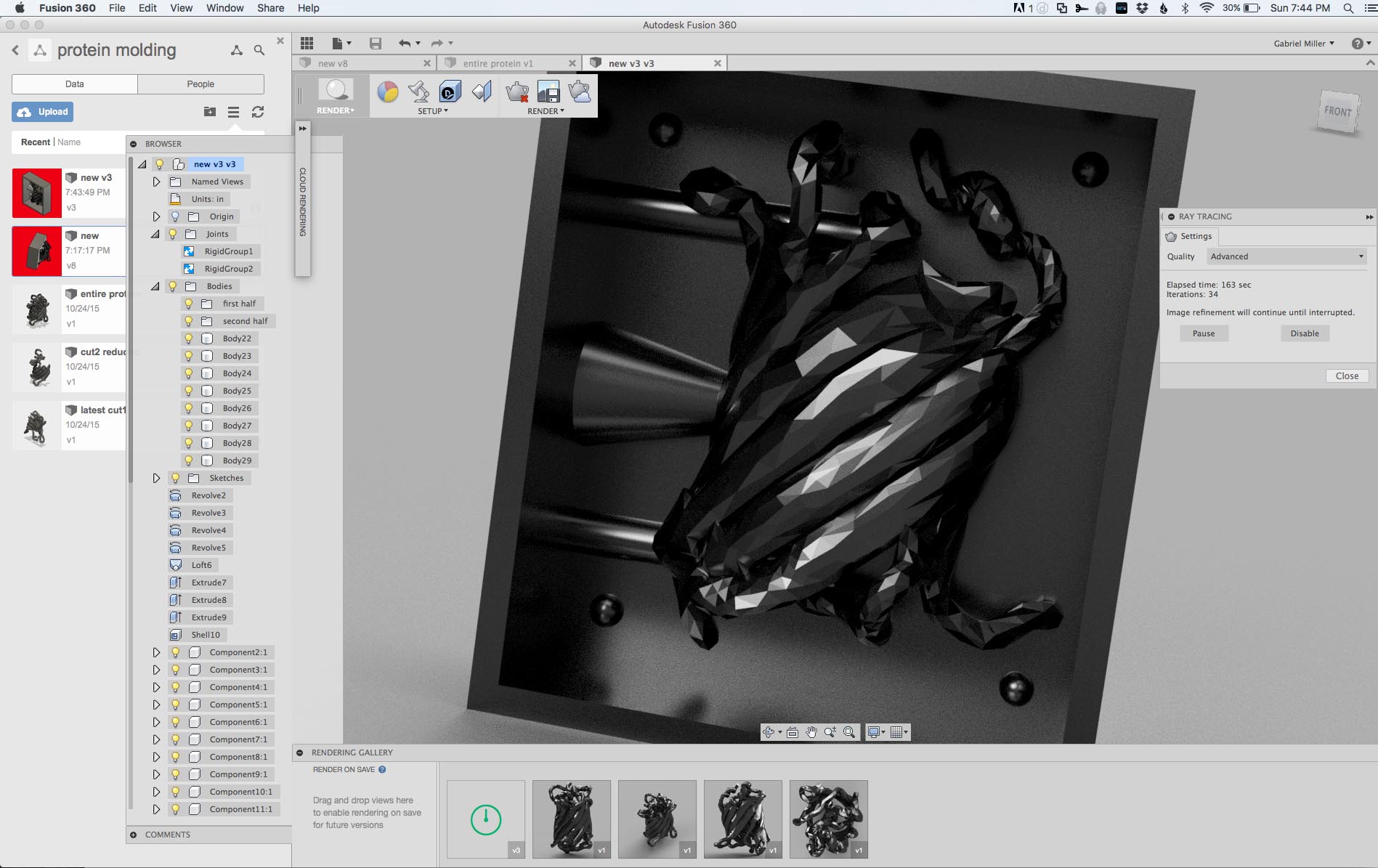

I then opened the file in Fusion360. The overall shape of the protein is called a beta-barrel.

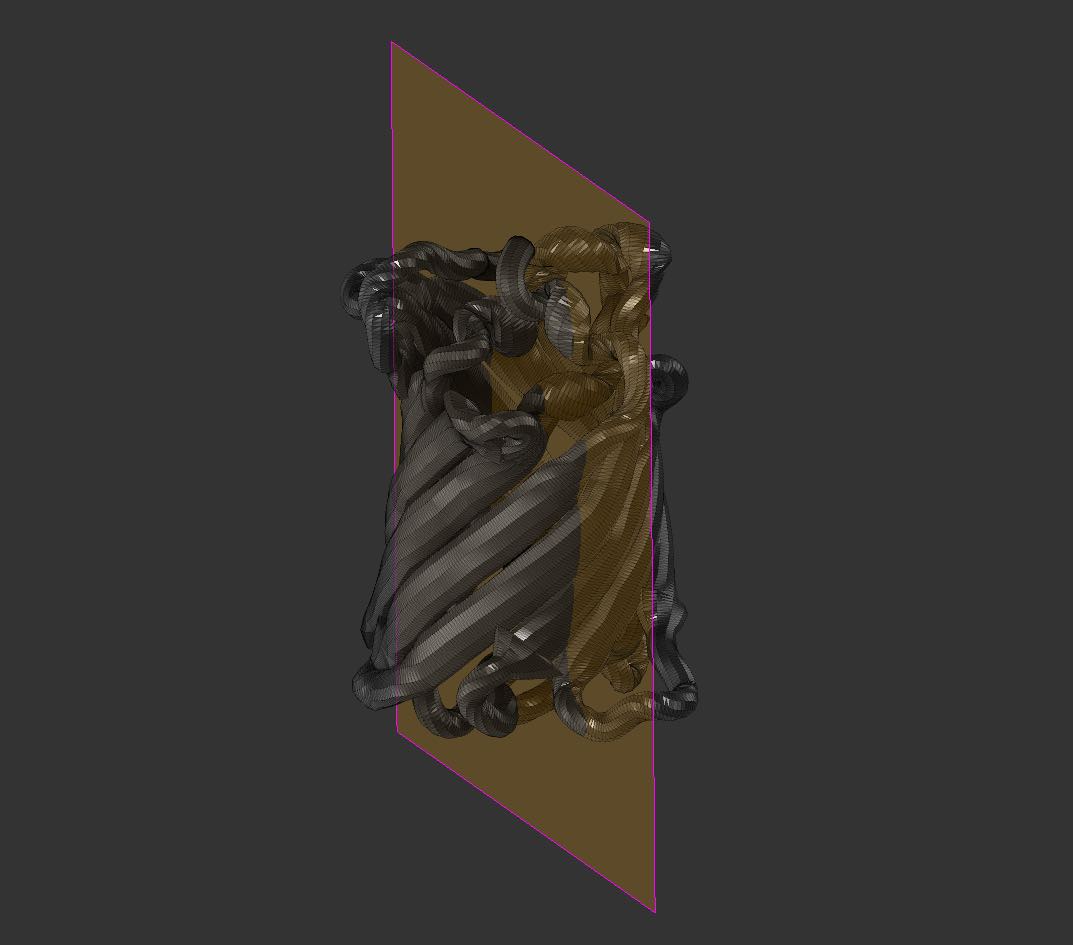

Using a construction plane, I sectioned the protein in half, preparing to make a two-part mold.

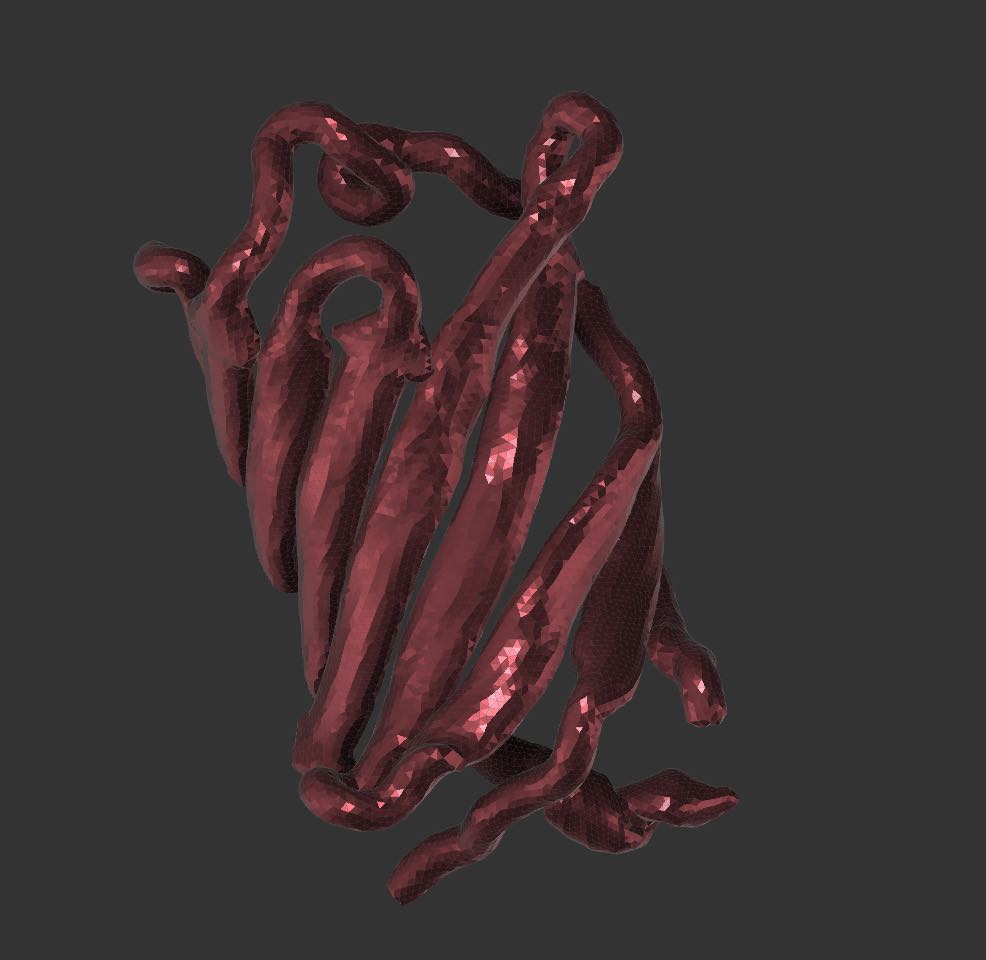

Here's one half of the protein looking like a ruby slipper.

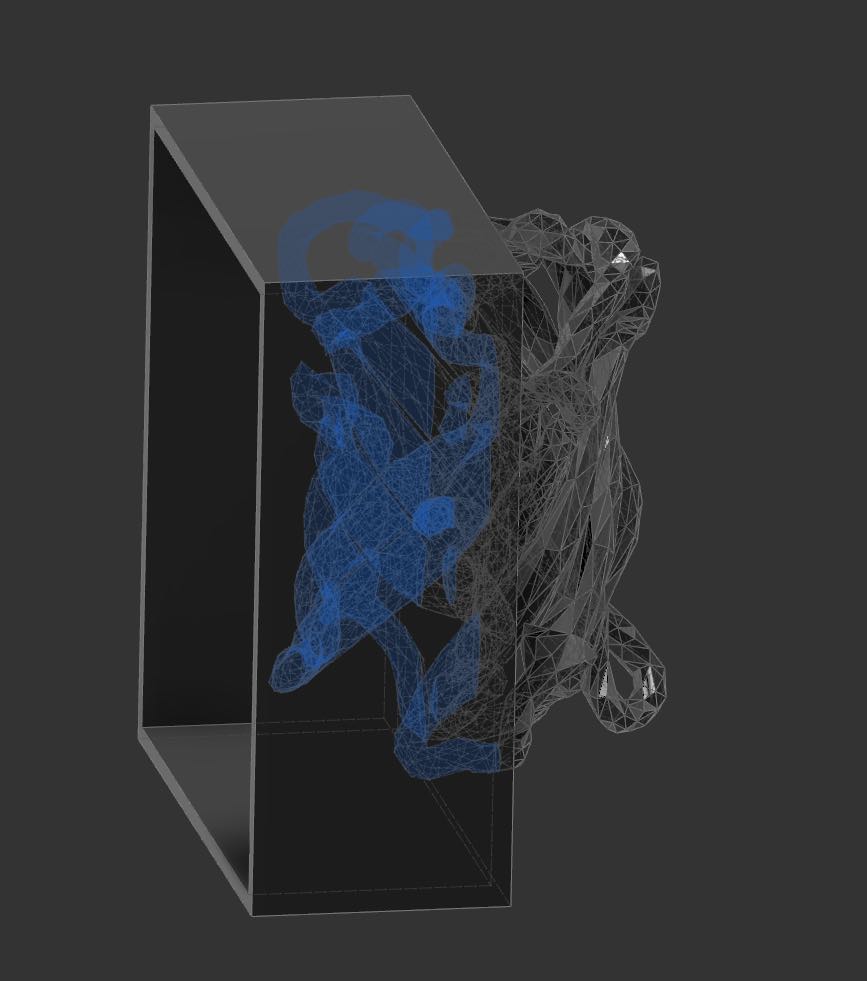

Then I modeled a box around one half to create the wax mold to contain the Oomoo (silicone casting medium).

Here is the model complete with three extra elements added to aid in pouring: the 'sprue' (where you pour in) and two risers to allow excess material and venting.

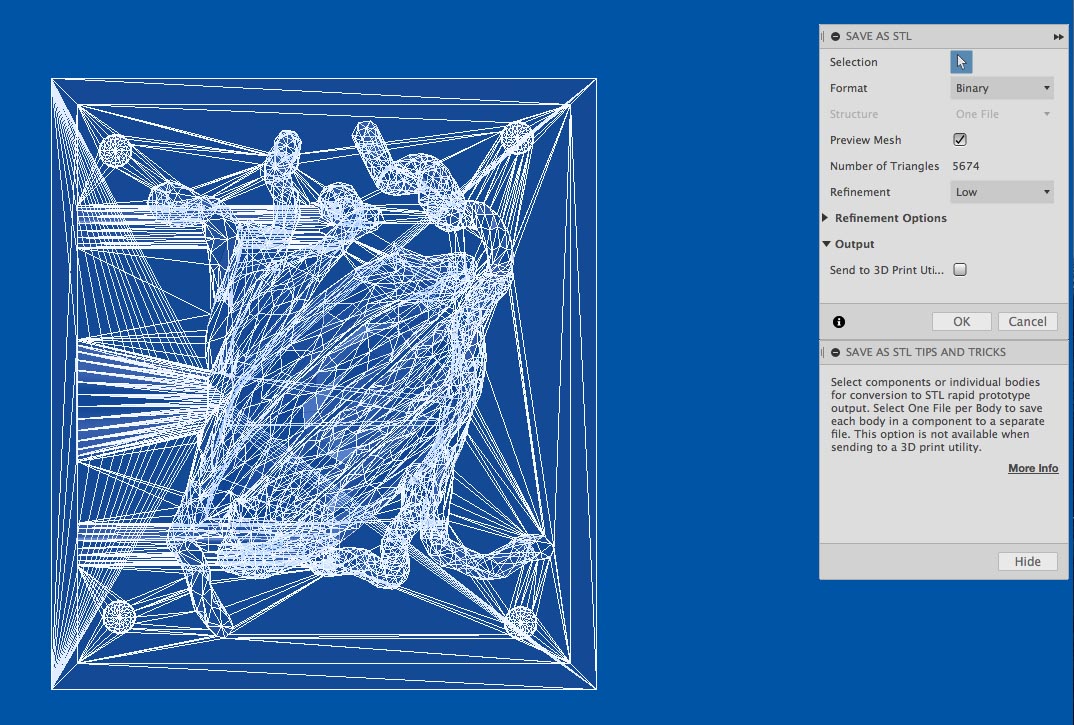

Here is the a '.stl' filetype generated by Fusion360 for the wax cutting step.

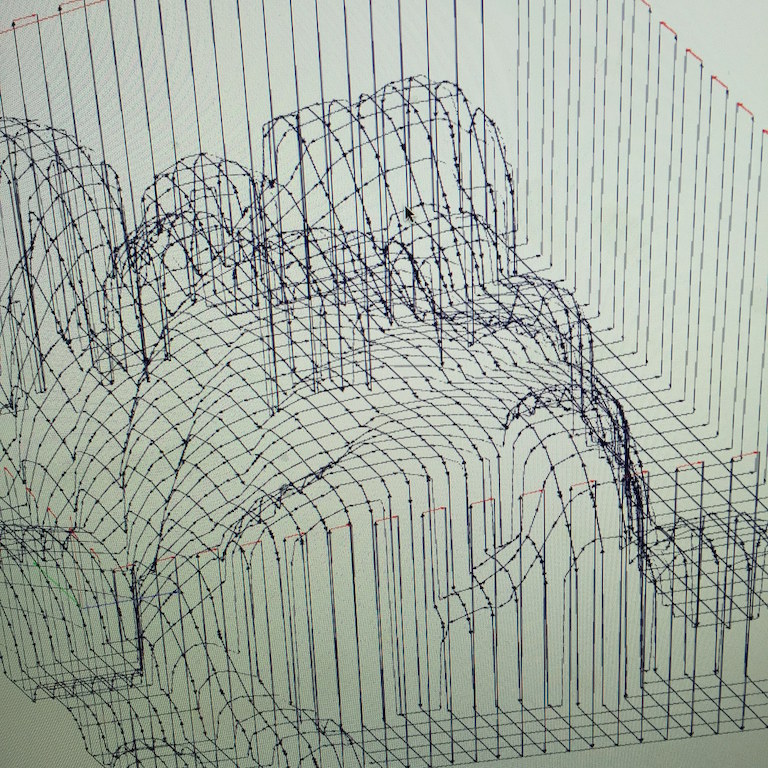

The fabmodules environment then read in the .stl file to produce a toolpath for the wax-cutting end mill.

Your browser does not support the video tag.

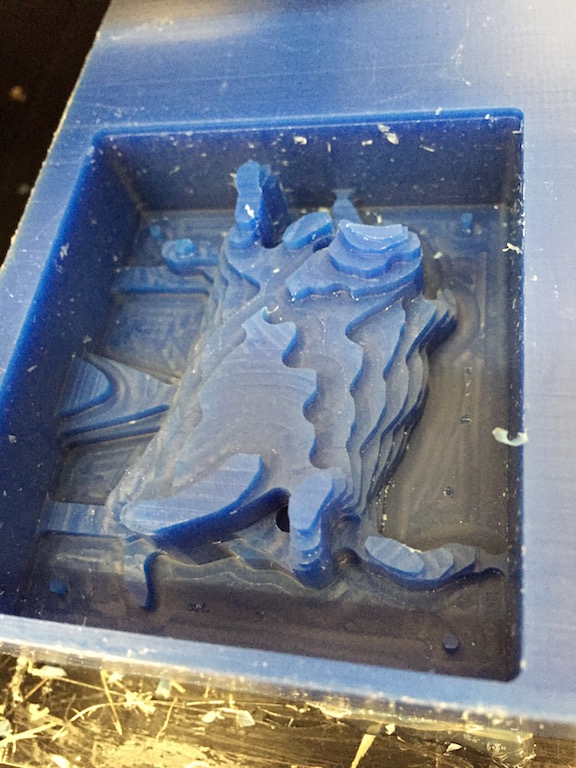

Here is the Modela desktop mill cutting away wax.

First a rought cut...

Then heating to create smoother contours. (This step can be avoided with proper settings in fabmodules.)

Oomoo ready for pouring...

Curing time- few hours.

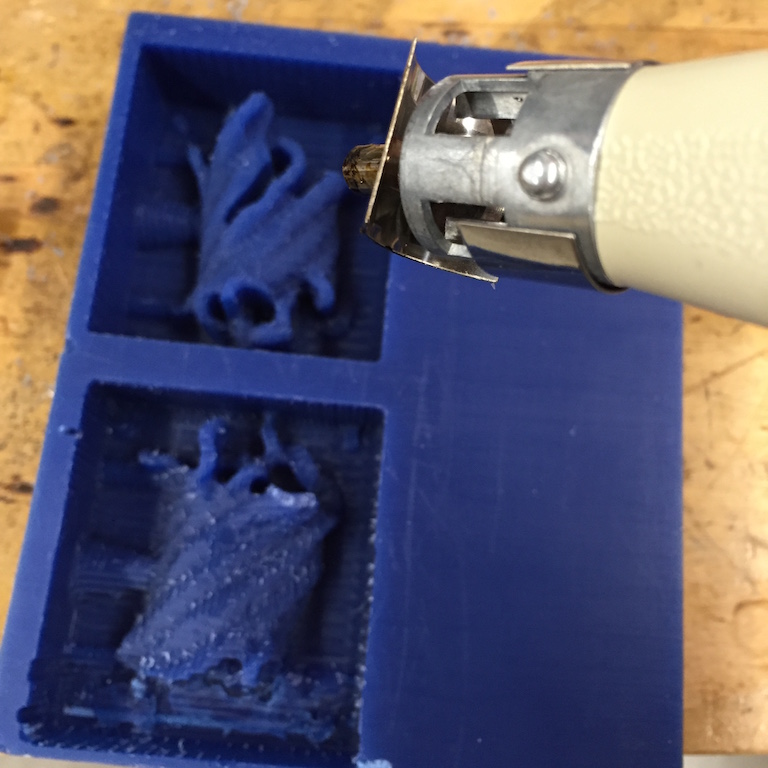

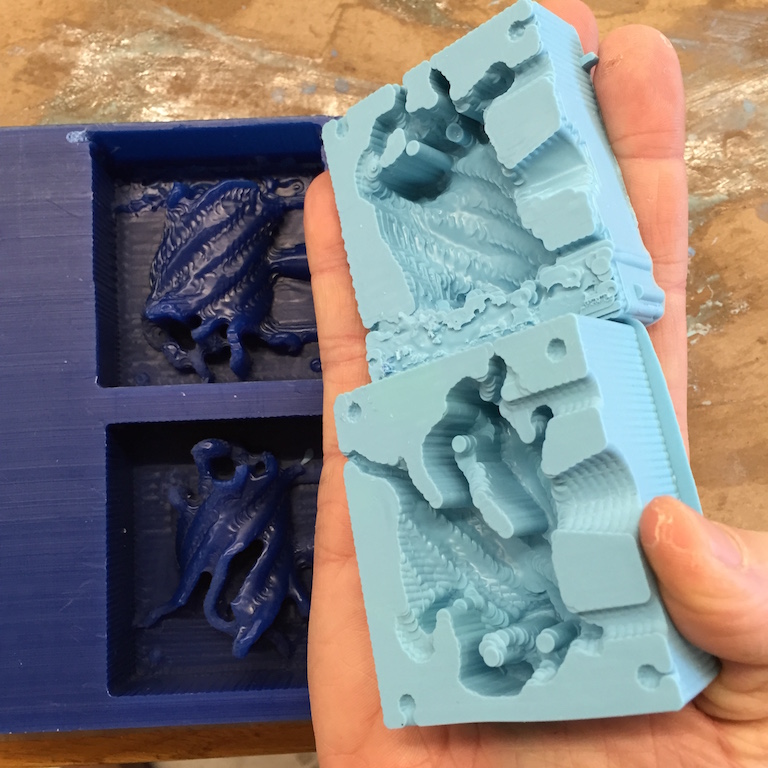

The molds came out nicely, and reproduced lots of detail.

The result before filing away excess from the risers and sprue.

Your browser does not support the video tag.

Here's the final result: a handcrafted version of the iconic glow-in-the-dark protein!