| How to make something that makes almost anything - 2012 Yoav sterman |

|

| The Multi Processes Lathe - 3D copy machine |

| Snap-fits |

|

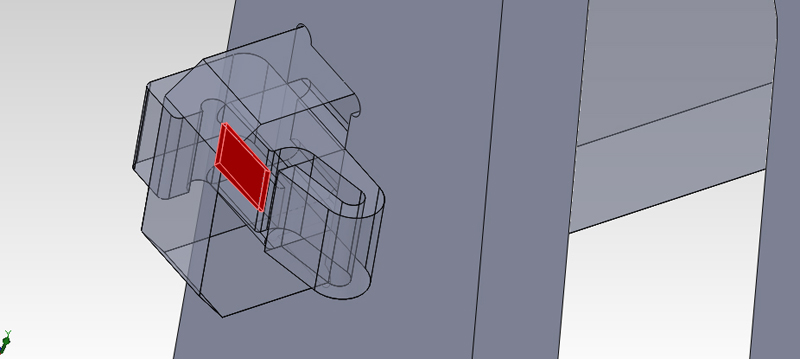

As part of designing the lathe I developed 3 types of snap-fits. Each have a different purpose and advantages. Clip snap-fit.  Collision areas

Collision areas

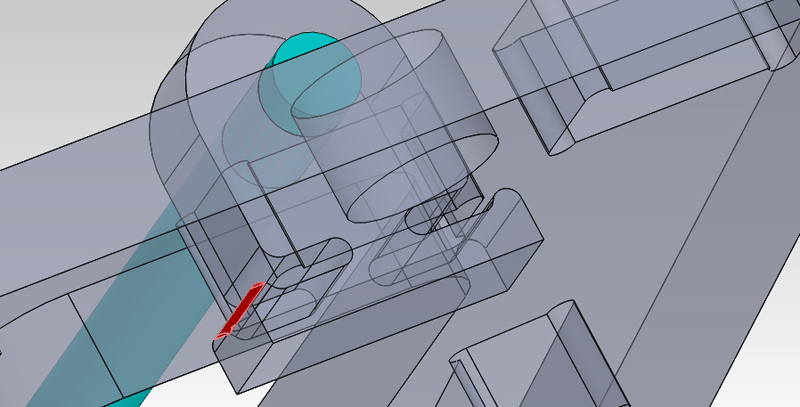

Shaft snap-fit This snap fit is used to assemble the shafts and the shaft bearings without using screws, taking advantage of the accuracy and the strength of the shaft itself. The snap-fit part attaches the shaft to the perpendicular HDPE piece and shaft itself attaches the snap-fit part to the same HDPE piece. The only way of un-assemble this structure is by pulling out the shaft, something that can’t happen by itself because of the high friction and the force of the snap.  Collision areas

Collision areas

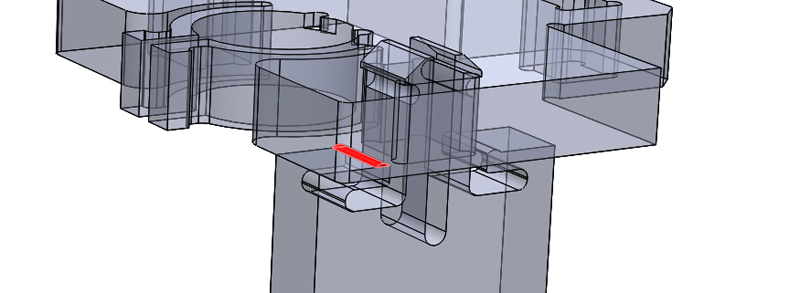

“standard” snap-fit with improvements This snap fit approach is similar to the MTM snap-fits, however it is easier to do and undo. The idea is to have a straight surface on the “one”s shapes that form the snap and a tension element underneath it . This snap-fit is less accurate and strong compared to the clip snap-fit however, it takes less space and it is not using an extra piece.  Collision areas

Collision areas

|

|

Introduction Concept Project goals The evolution of the machine design Ouija board Contact |