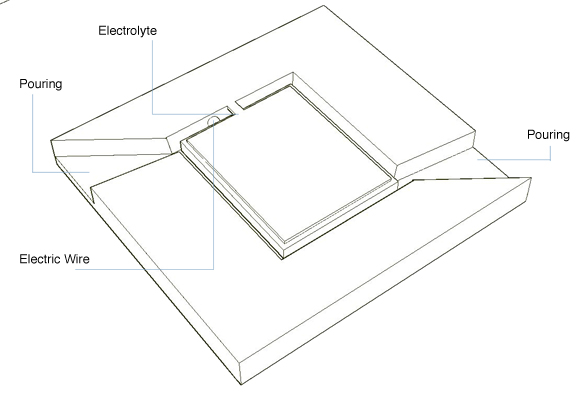

Molding/Casting a rubber seal

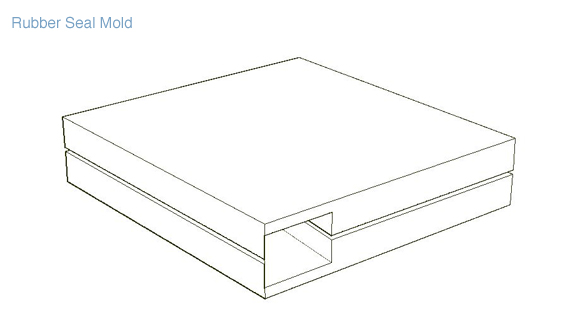

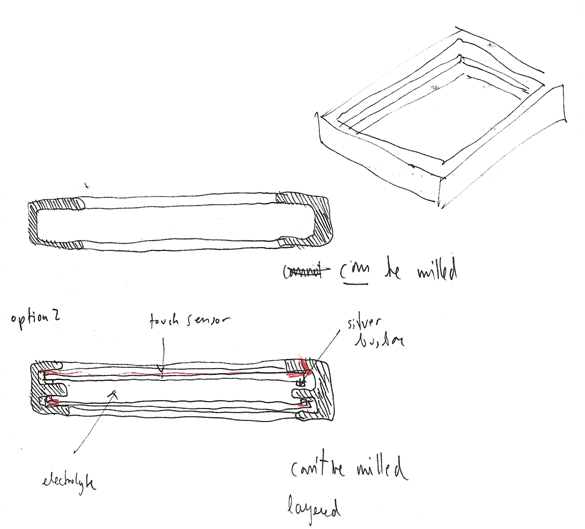

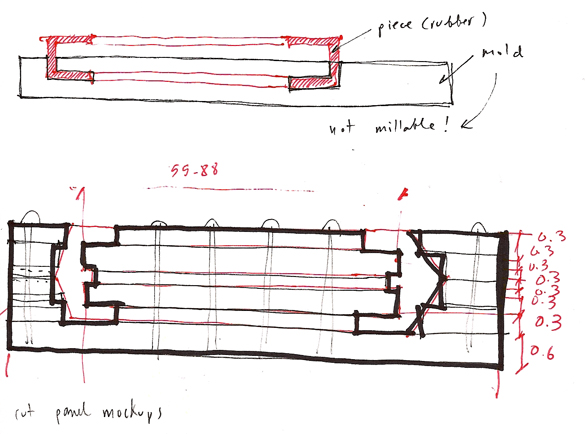

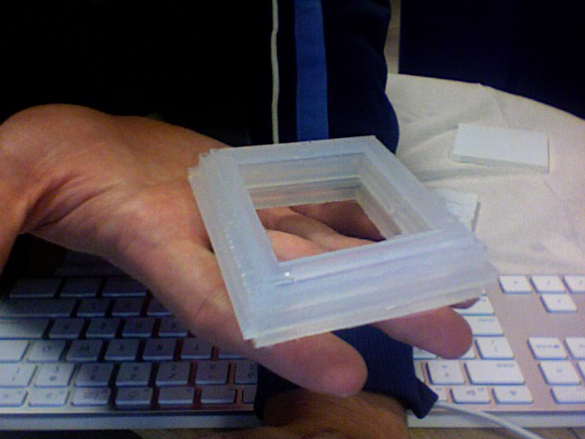

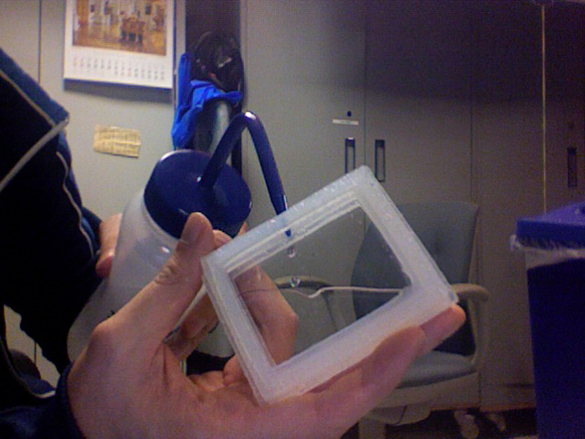

A 3D seal that not only prevents the electrolyte from scaping each electrochromic tile, but also acts as a spacer between the glass panels. I tried two strategies: a laminated mold in lasercut acrylic, and a 3D printed mold, made in the invision machine.

A 3D printed mold

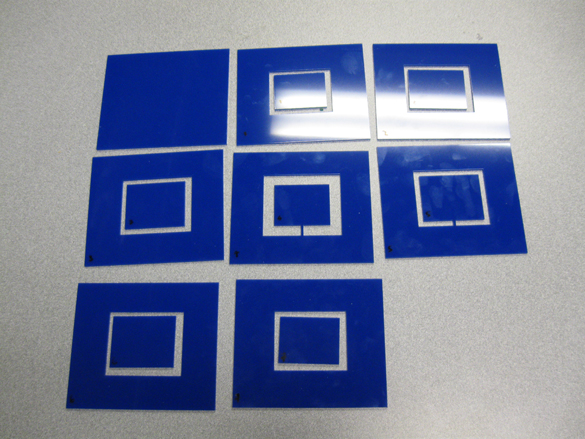

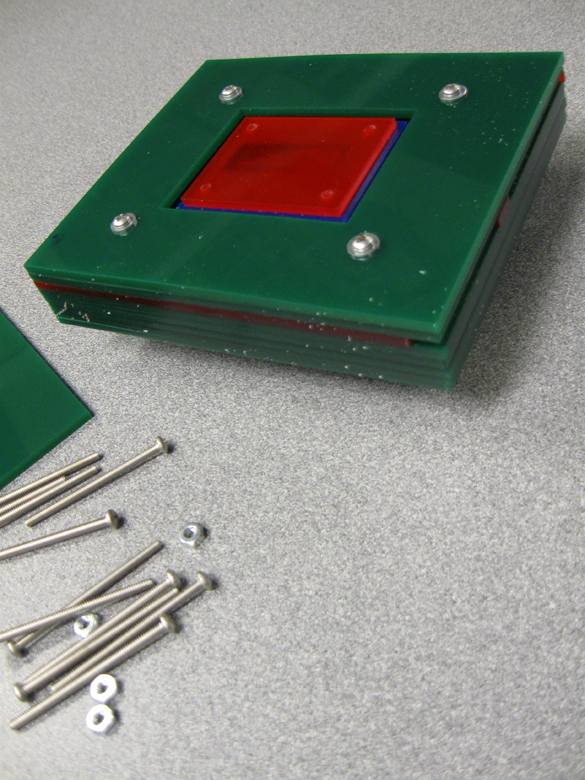

Laminated Mold (Lasercut)

I tried molds of varying sizes, as it is the elasticity of the rubber is key for keeping each electrochromic tile sealed. I tried at 90% and 80% of the full size. I tried with the clear rubber solution (dragon skin) and the amber to test different results.

|