The Melnikov Press-Fit Kit

Figure 1. The cutsheet for the Lasecutter looks like this.

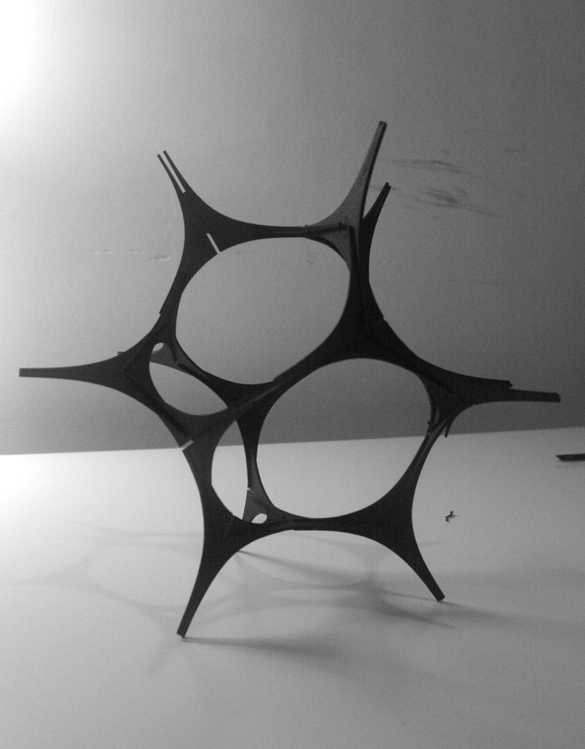

This project is an exploration in 3-D of some simple geometric principles I am interested in since I started styudying Konstantin Melnikov's work (check some references to my previous work on Melnikov Grammar here). Melnikov's geometric principles work on the plane. Can they be translated to space?

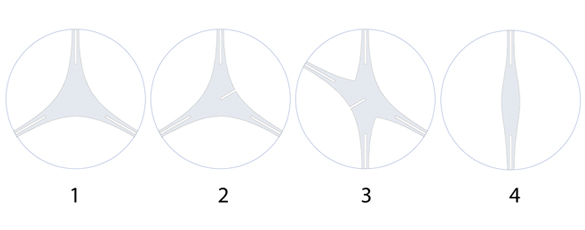

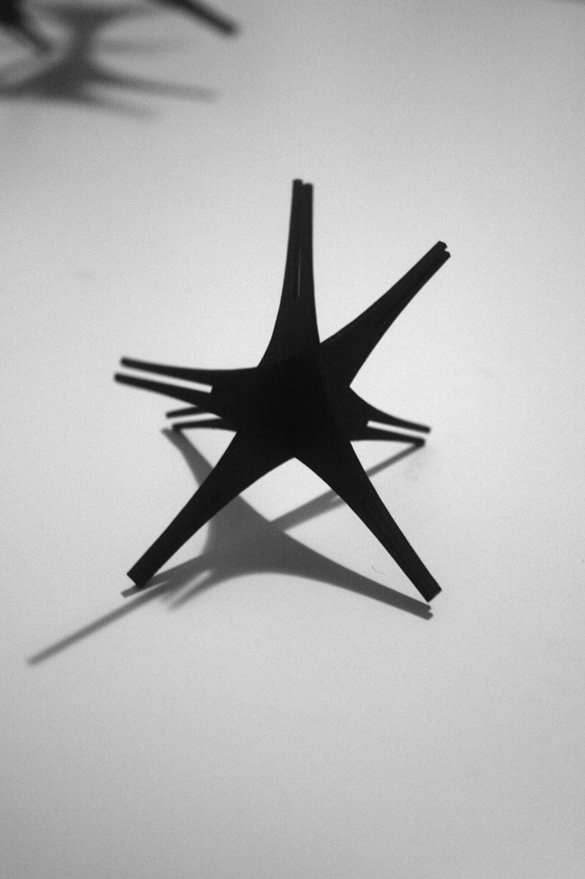

Figure 2. The vocabulary of elements Figure 2. The vocabulary of elements

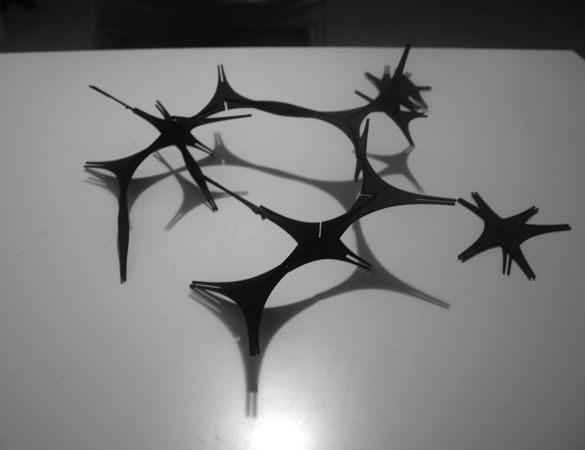

Figure 3. The compound types

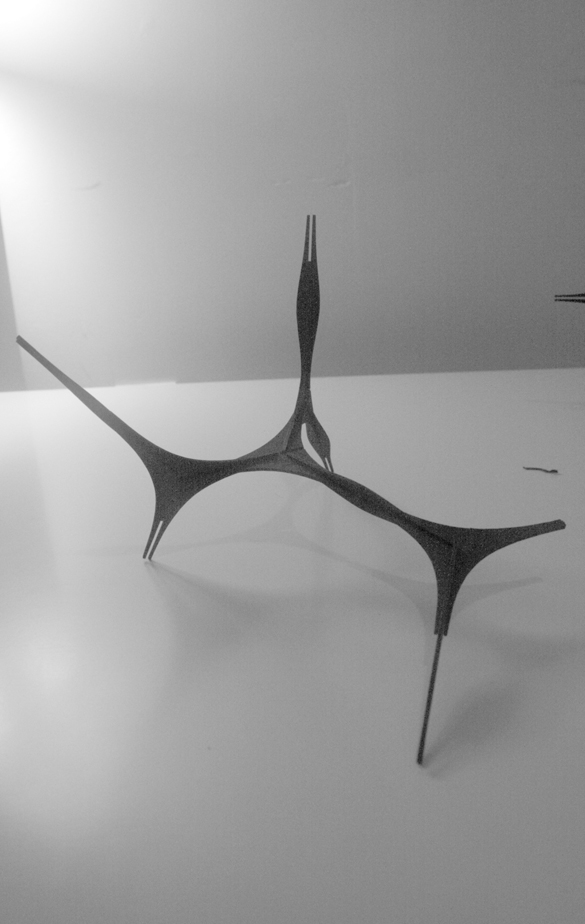

It was very difficult to foresee the kind of artifacts it would generate. I wanted to create an open system.

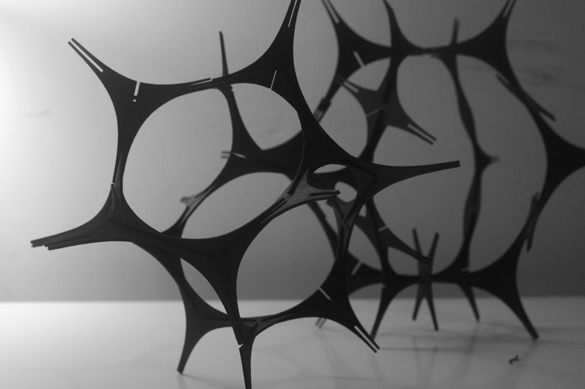

Figure 3 and 4. Some simple derivations of the 3D 'Melnikov Grammar'

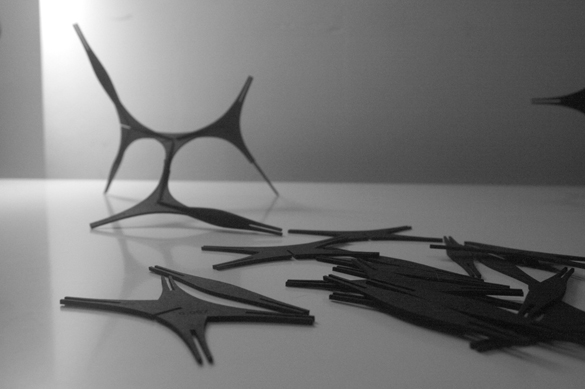

Some photos of the first prototypes: I used 1/16 in chipboard, with a tolerance value of 0.007 in (at each side of the slot).

Figure 5. An idea for the assembly

Figure 6. Some pieces and a structure.

Figure 7. Schematic section of the facade, detail and

front view of a sensor’s node

Figure 8.

Figure 9.

Figure 10.

Figure 11.

Figure.

Figure.

Figure.

Figure.

|