PCB Design, Fabrication, & Assembly

The goal of this assignment was to fabricate (mill) and assemble (stuff) a PCB. A PCB or printed circuit board is used to mechanically support and electrically connect electronic components using conductive pathways, tracks or signal traces etched from copper sheets laminated onto a non-conductive substrate. This is something I've never done - thank you to the TAs and classmates for their help. More photos: Flickr Set

I had the good fortune of debugging my board in the High/Low Tech group where I learned about soft circuits and the amazing resource How To Get What You Want. This gives me hope for my final project. Other Final Project related links - Final Project Preparation.

At Long Last

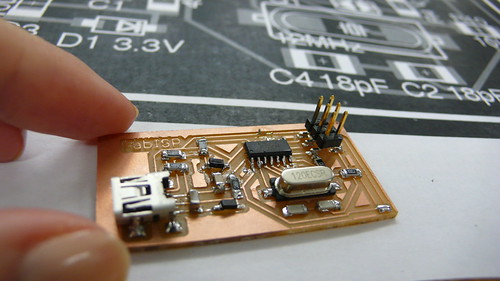

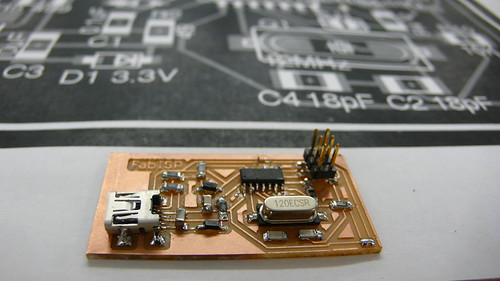

A working FABisp or SEDisp in this case.

|

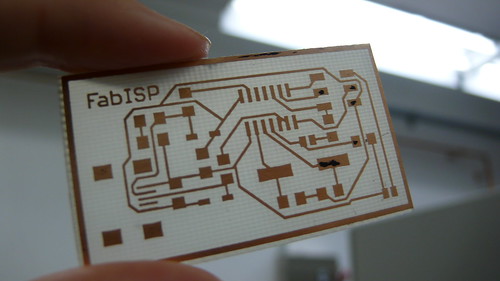

Milling

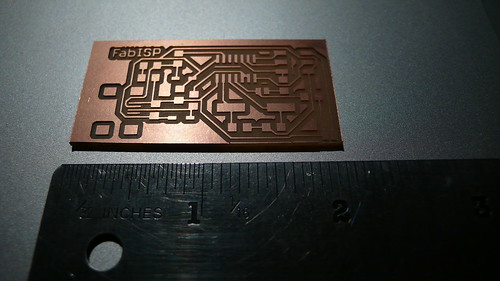

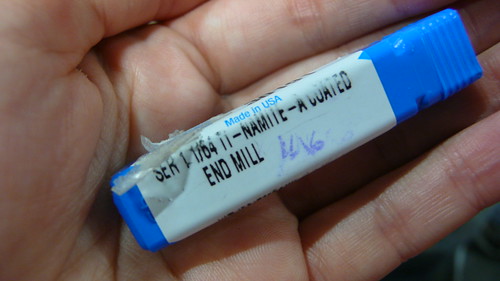

In this case we were given a PCB design and used a Modela or David Carr's Mantis milling machine to trace the design onto a copper sheet. We were helped along by CAMIT.

|  |

| David Carr in action | PCB - 2" x 1" |

|

|

| $100 Mantis Milling Machine | The Modela |  |

| Joint Size Testing | Mantis at work |

|

|

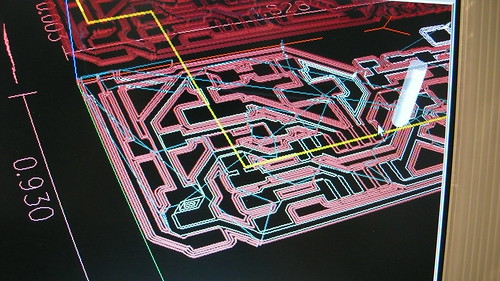

| Mantis Interface | Mantis Interface |

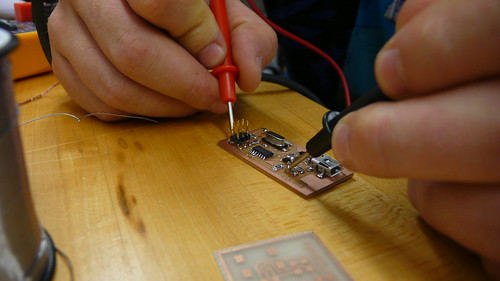

Stuffing

Was more difficult than expected. I'd never soldered anything so tiny.

|  |

| Weller soldering irons | Stuffed |

|

|

| Stuffed | Stuffed |  |

|

| Testing | Etched Board |

|

|

|

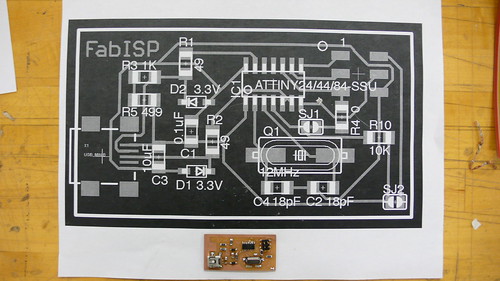

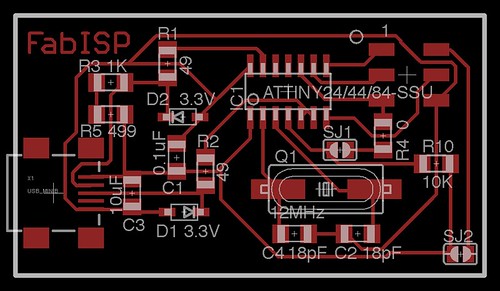

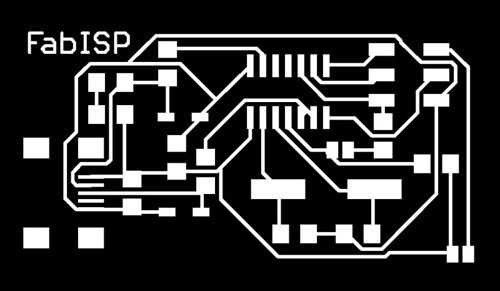

Given PCB Design

|

|

PNG of PCB to Mill |

|