Waterjet Cutter & NC Mills

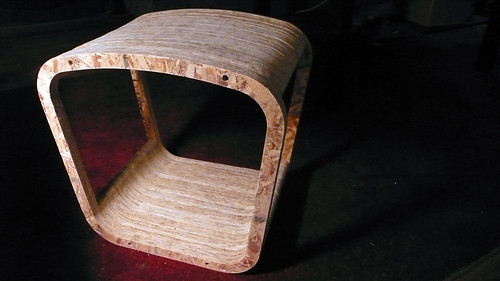

The goal of this week was to "make something big". I chose to use the CNC router since I've waterjet cut a good deal at the GSD and OSB was available for us to route. I wanted to make a stool because we need more seating in our apartment.

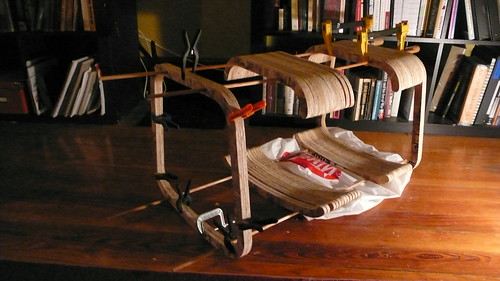

If I were to do it again I'd make the stool 1 1/2" taller than I did. Also, laminating the pieces together with wood glue was tedious and messy - especially without proper clamps and in my living room rather than a shop. I wanted to run 3/8" threaded rods through the holes and keep the stool together without glue - however I couldn't find anything in Cambridge.

A limiting factor for the project was getting it home on the MBTA bus after I cut the pieces. Therefore a stool may qualify as "making something medium" rather than "big". My goal was to cut the entire project out of single 4' x 8' sheet of OSB. However, Tom Lutz and I decided to split the pieces onto 1 1/2 sheets to prevent splitting and movement while cutting. Here is the original Rhino file. And more photos are here on Flickr.

| |

|

|

| Final + Assembly | |

|

|

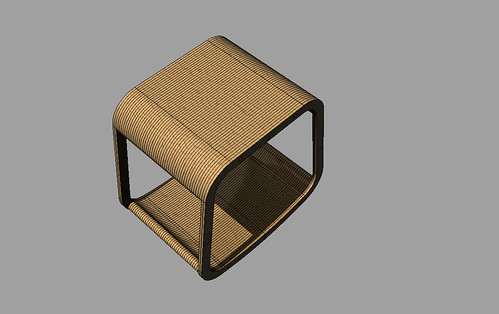

| Original Design Render 1 | Original Design Render 2 |

|

|

| Routing | Sanding |  |

|

| Travel Home via 85 Bus | Assembly |