Concept

Aluminum nodes with motor mounts and magnetic connections, for the programmable surfaces project.

Design & Fabrication

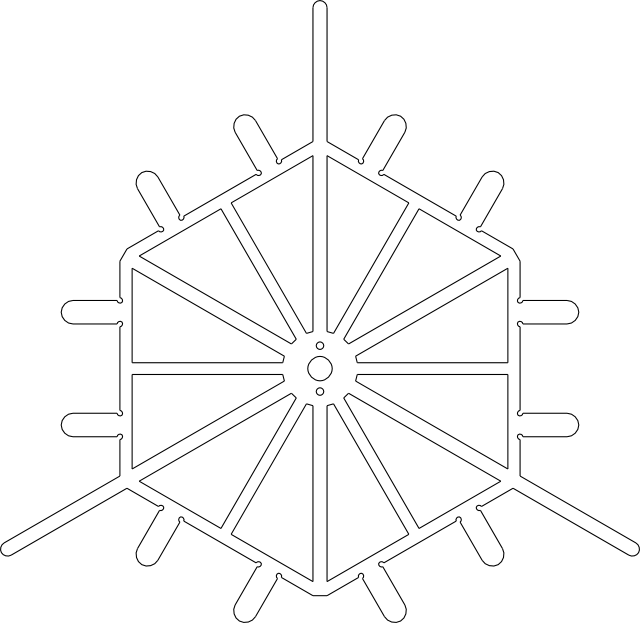

I designed the nodes in SolidWorks, often using rotational patterns to take advantage of the sixfold symmetries. The node was designed as a flat surface (though tools exist for sheet metal design, I didn't take the time to learn them). Note the strain reliefs near the tabs - these improve the bend performance.

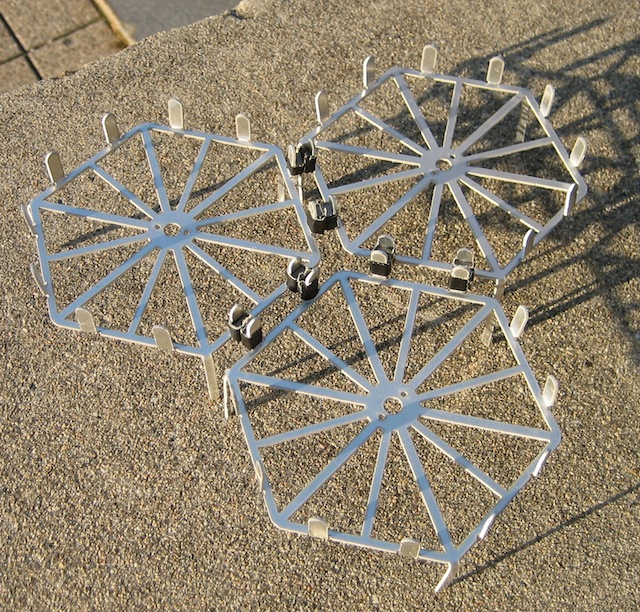

The part was cut on the waterjet. Nothing too interesting to report - everything worked without any major troubles. Initially, I cut a set of three out of 1/4" aluminum, which broke rather than bending at the tabs. Switching to 1/8" aluminum worked much better.

The tabs were bent by hand and magnets were attached using gaffer's tape - this had the unexpected benefit of acting as padding between the nodes.

Pictures

Video