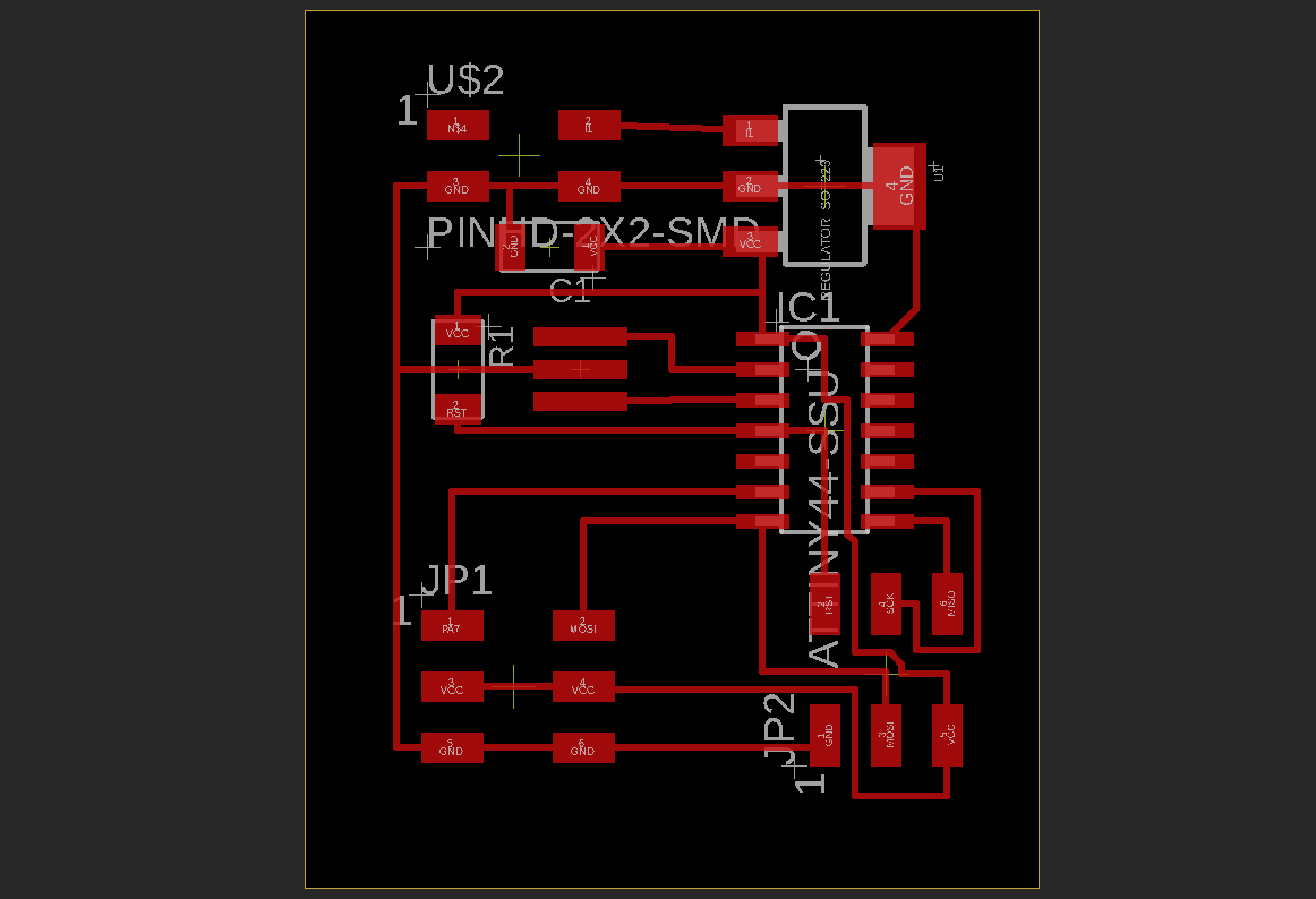

Eagle / PCB design

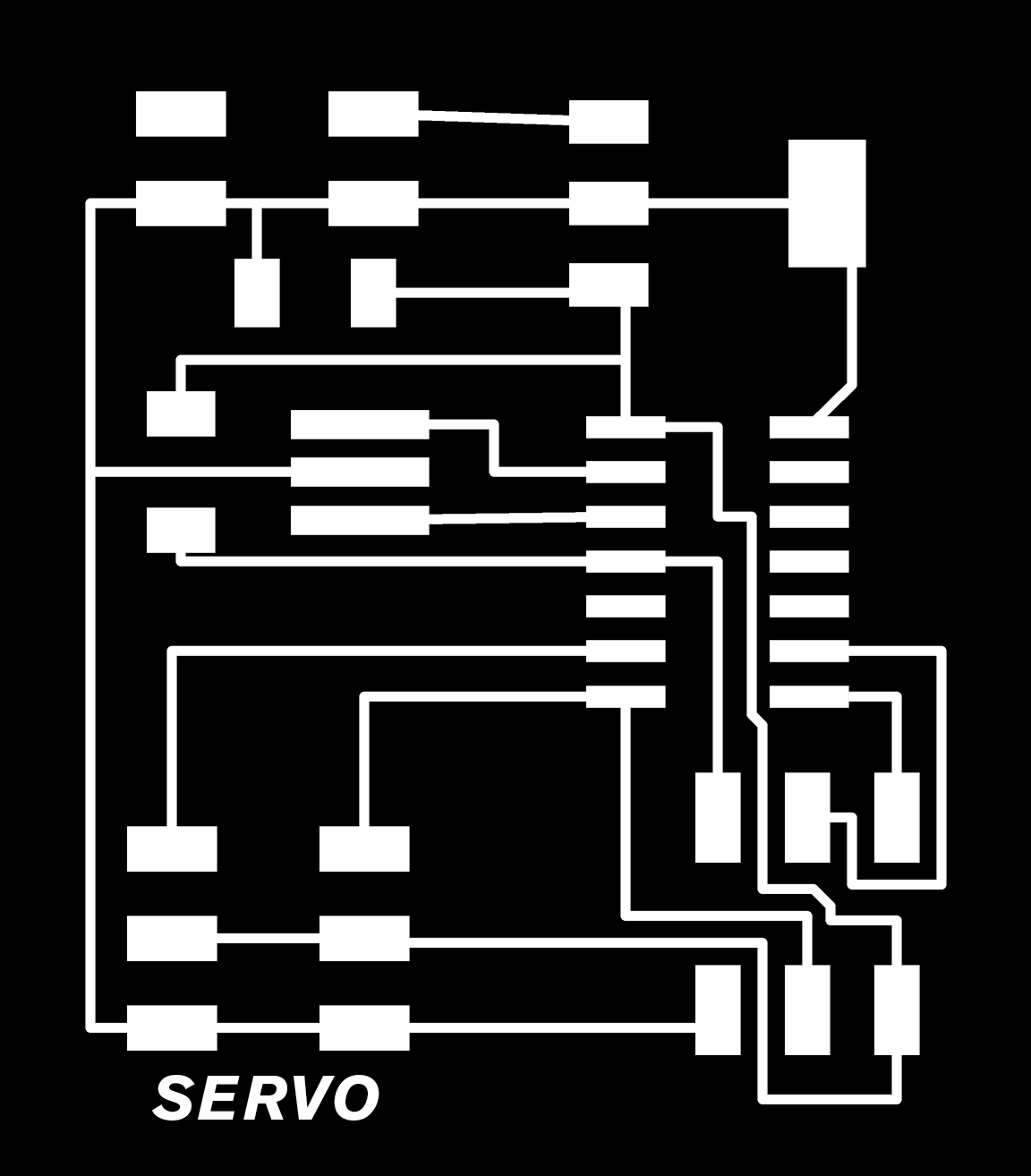

Redrawn schematic of the servo controller

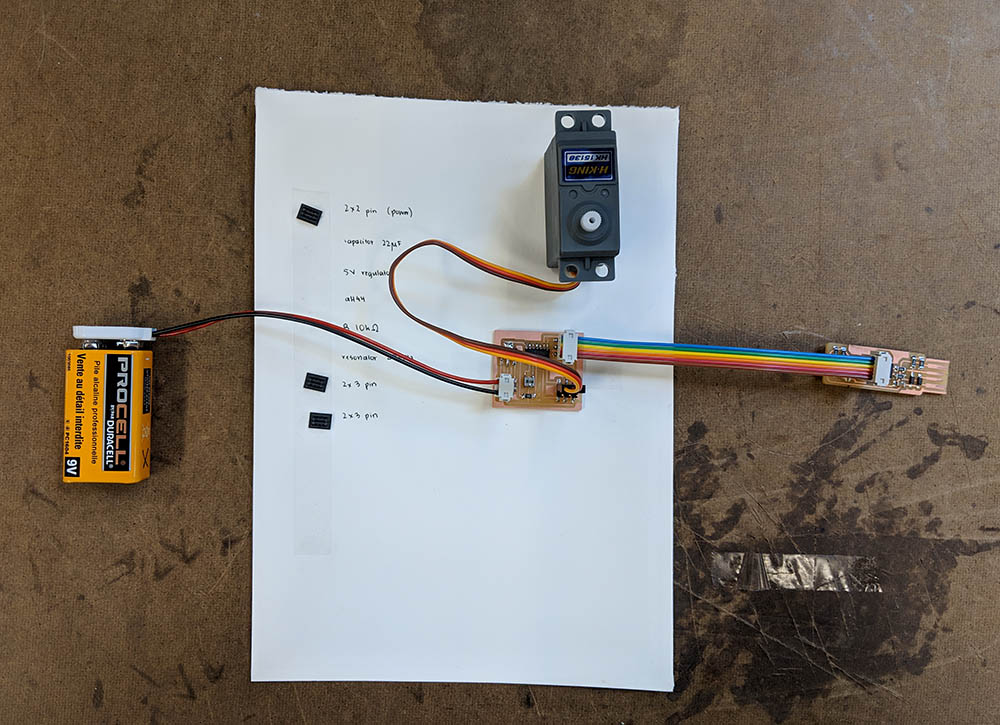

As Jung and I finally started to concretize our final project idea, we delved into testing output devices that could help the ceramic dripper. I focused on getting servo motors to work, while Jung tested DC motors. I followed Neil's schematic to see if I can reproduce it & test the behavior /control of the servo.

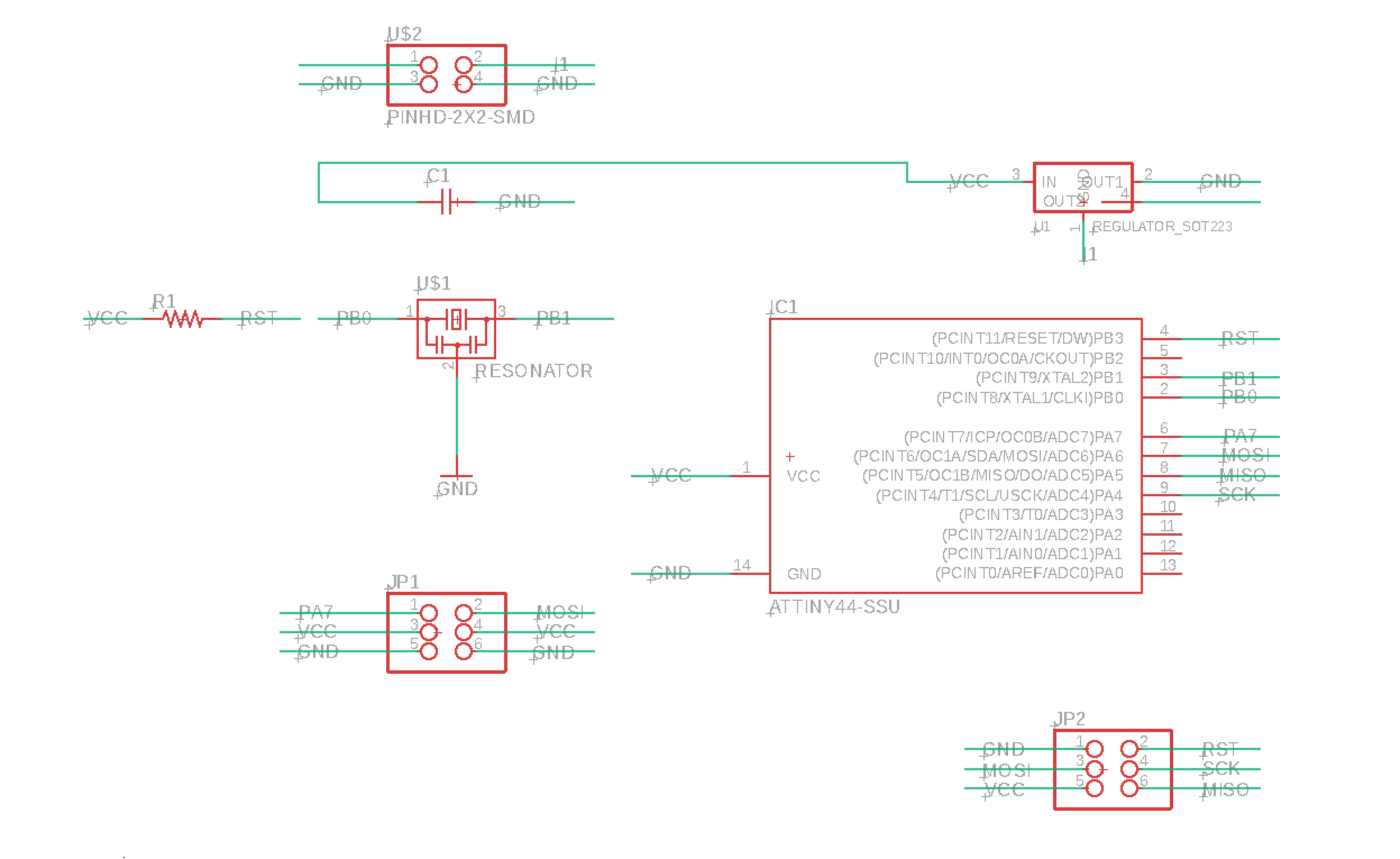

Eagle schematic

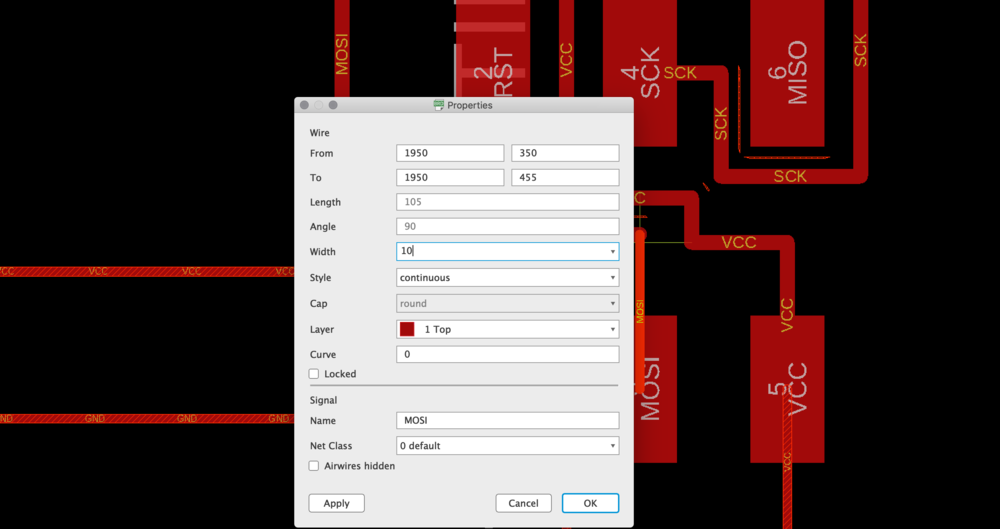

After finishing the routing and checking the design rules, I suddenly had over 52 issues with the trace width--which I had to go and fix individually. Somehow, and this never happened before, the traces were now required to be at least 10 wide.

Setting trace width

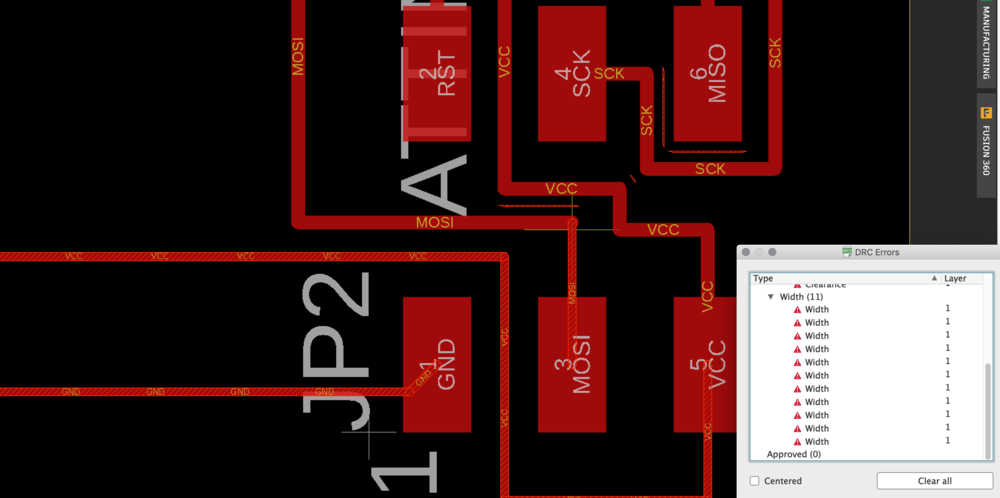

I also had some traces very close to each other, but they passed the rules so I thought they would be fine.... however-->

Traces very close & corrected to fit just right

Eagle board passing all the design rules

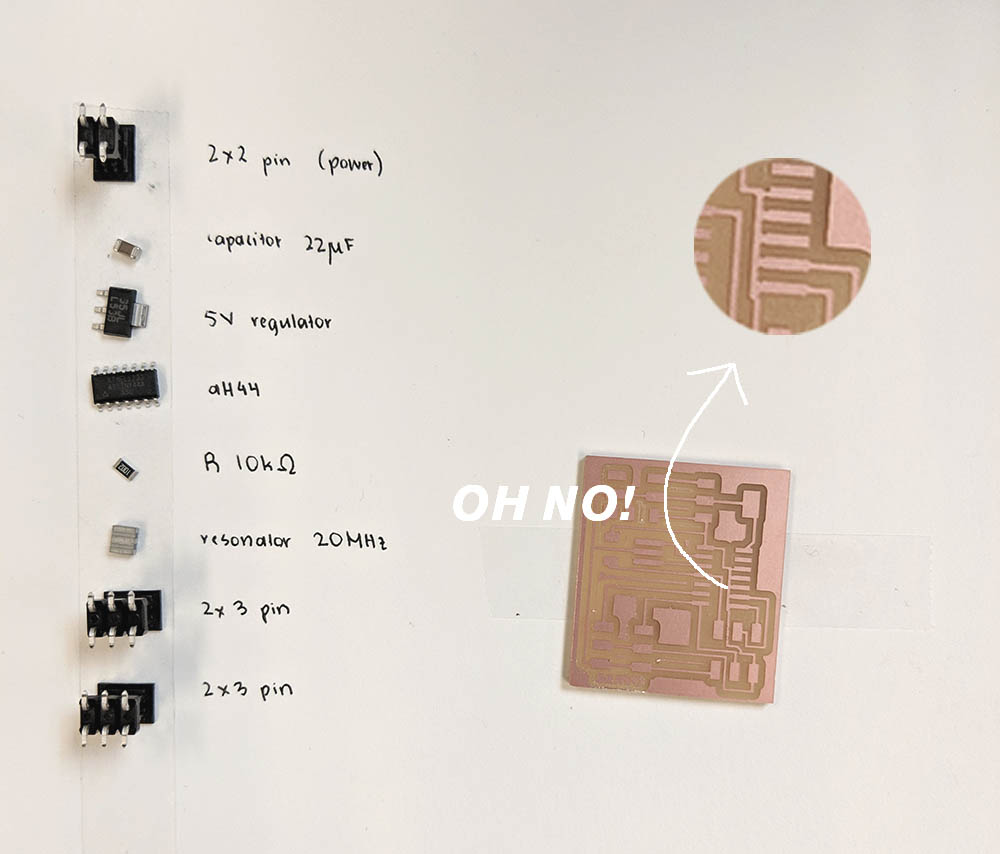

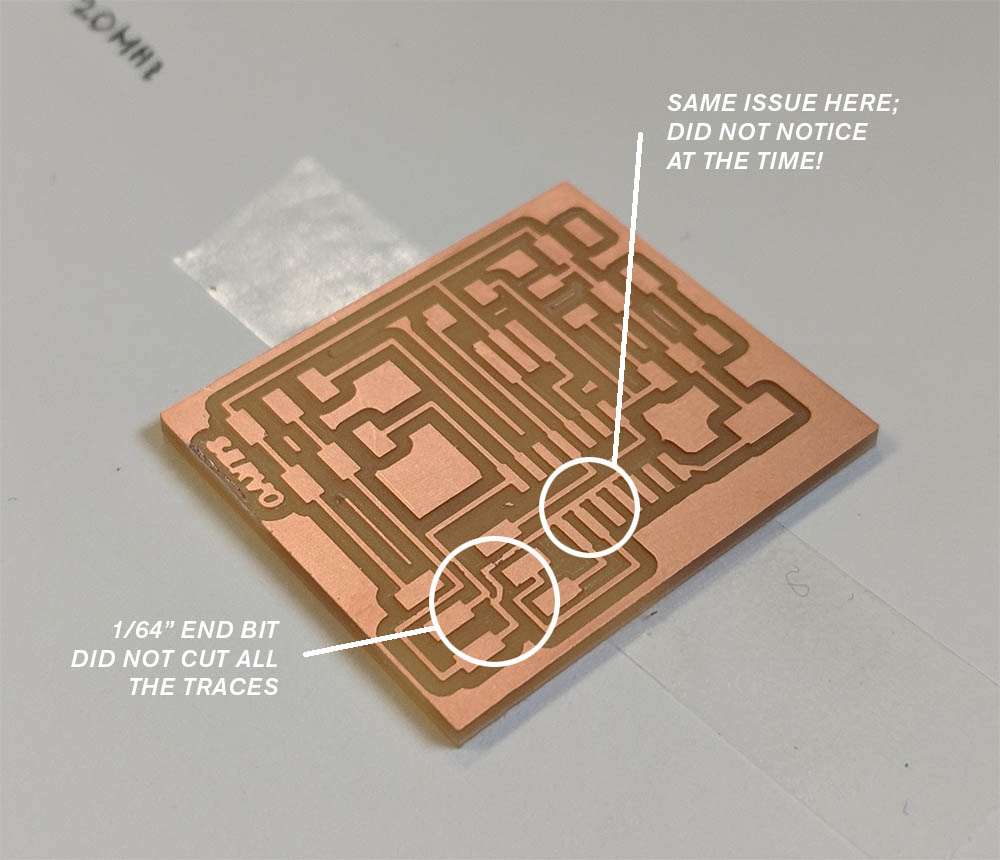

Milled board with a BIG mill mistake unnoticed...

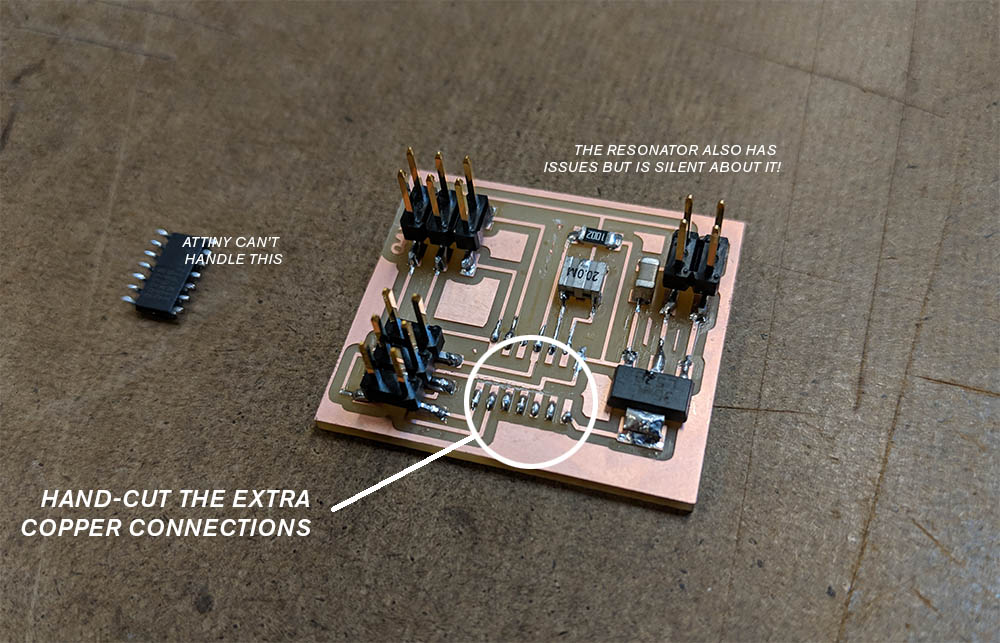

I then milled the board and double-checked the small traces under the 2x3 header to make sure they cut right, and they did seem to touch a little, so I cut that bit by hand. However, what I didn't notice at the time was the fact that the Attiny44's entire right side was not supposed to be connected to the leg traces, but they all were! Big mill tolerance issue went unnoticed.

1/64" mill bit issues

Confident (and quite blissfully ignorant at the time) that I corrected the mill mistakes (which I didn't completely), I soldered the components in a considerably small amount of time.

Testing the board! RC=-1

So, looking back, this obviously didn't work because my board had extra connections to the Attiny... I spent some time debugging the board connections before I realized that that may have been the issue. The multimeter is one's real electronics kin, though! I figured out what went wrong quite quickly.

De-soldering the Attiny44 with the heat gun

After re-soldering the microcontroller, I was hoping the rc=-1 error would finally go away, but it didn't! It persisted. After testing some more connections with the multimeter, I also de-soldered the resonator & re-soldered a new one, plugged the battery back in, programmed the board, and it worked! Happy ending.