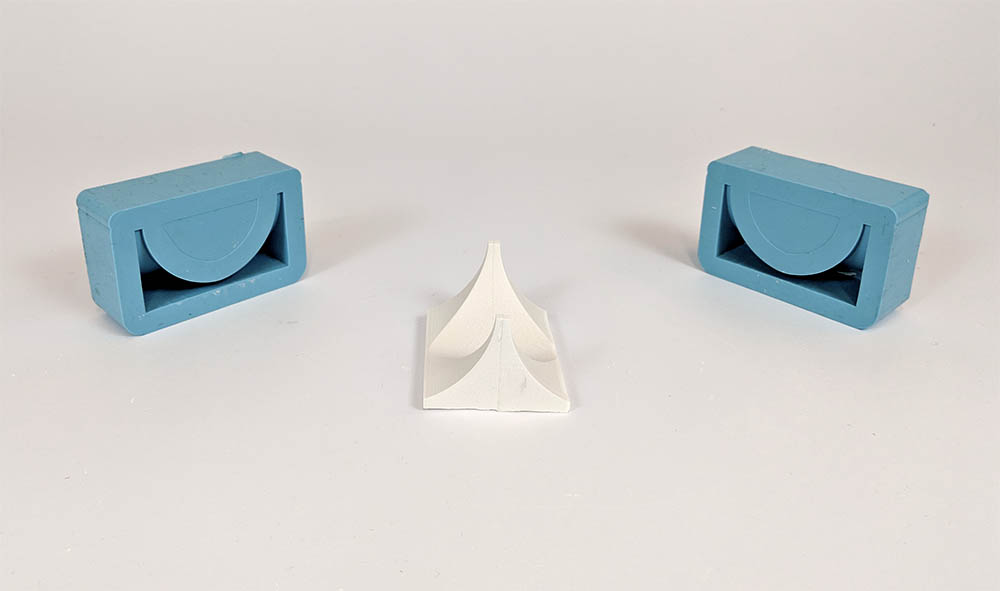

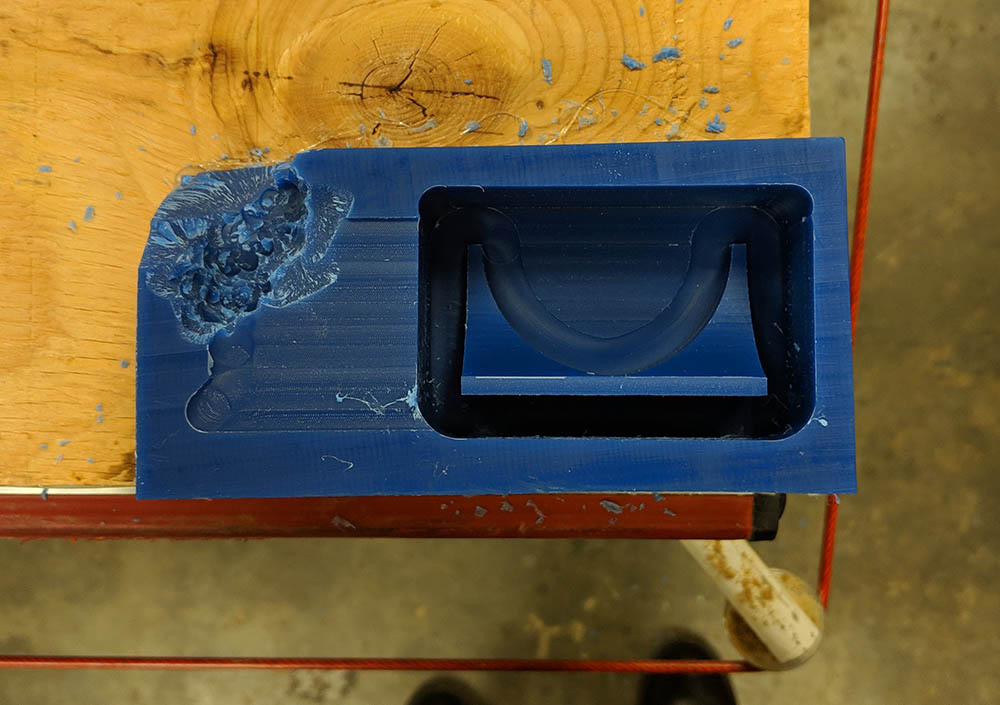

Molding (milling)

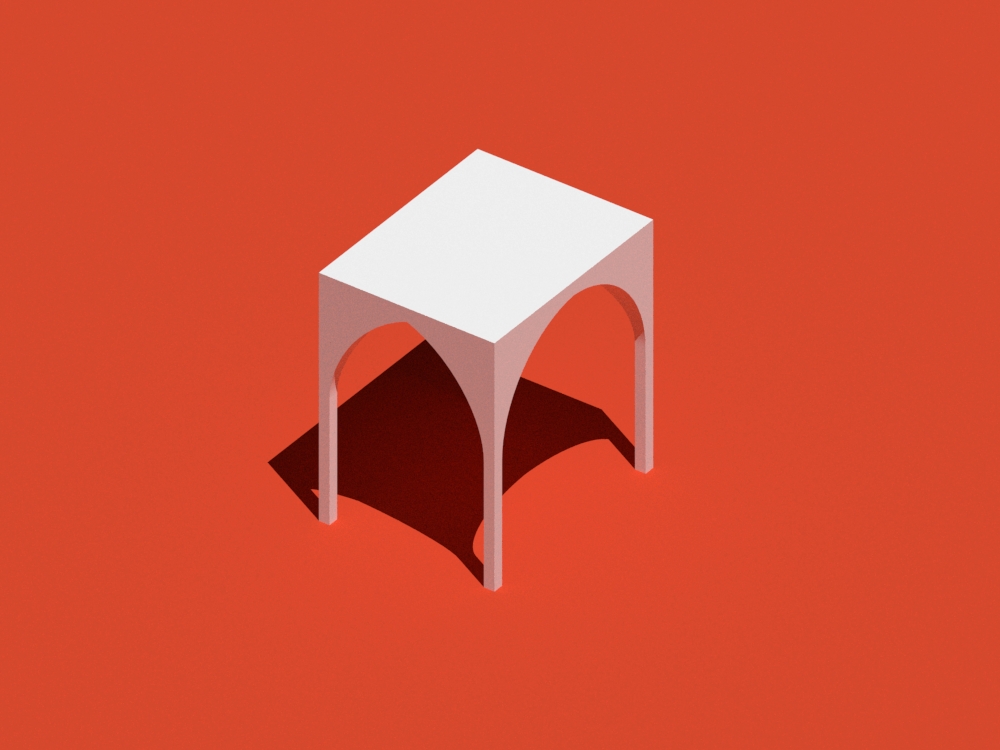

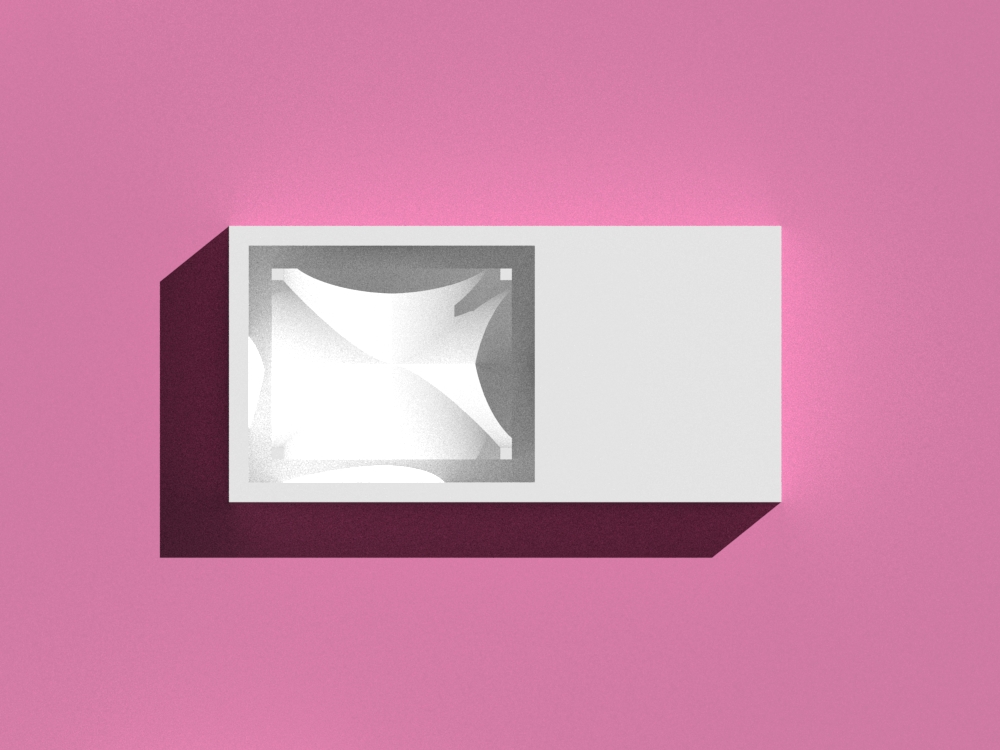

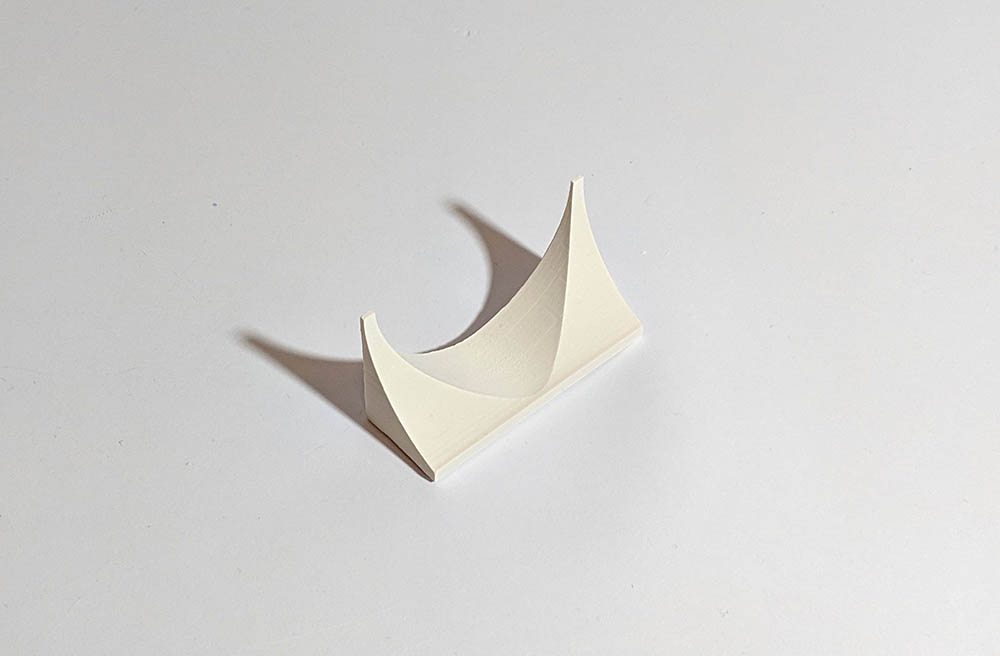

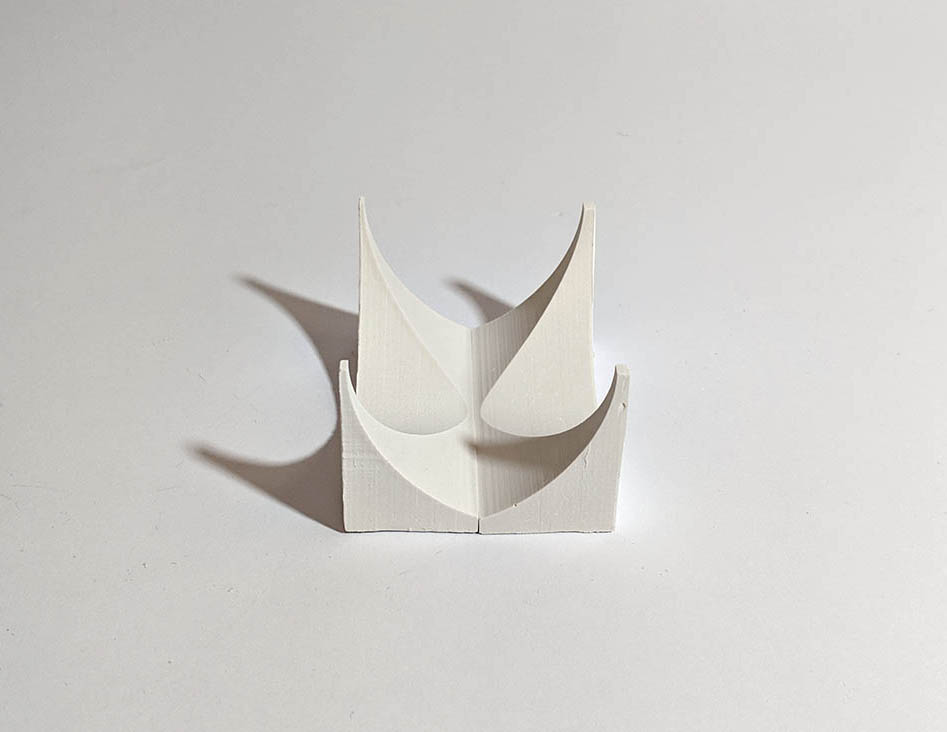

Initial vault unit

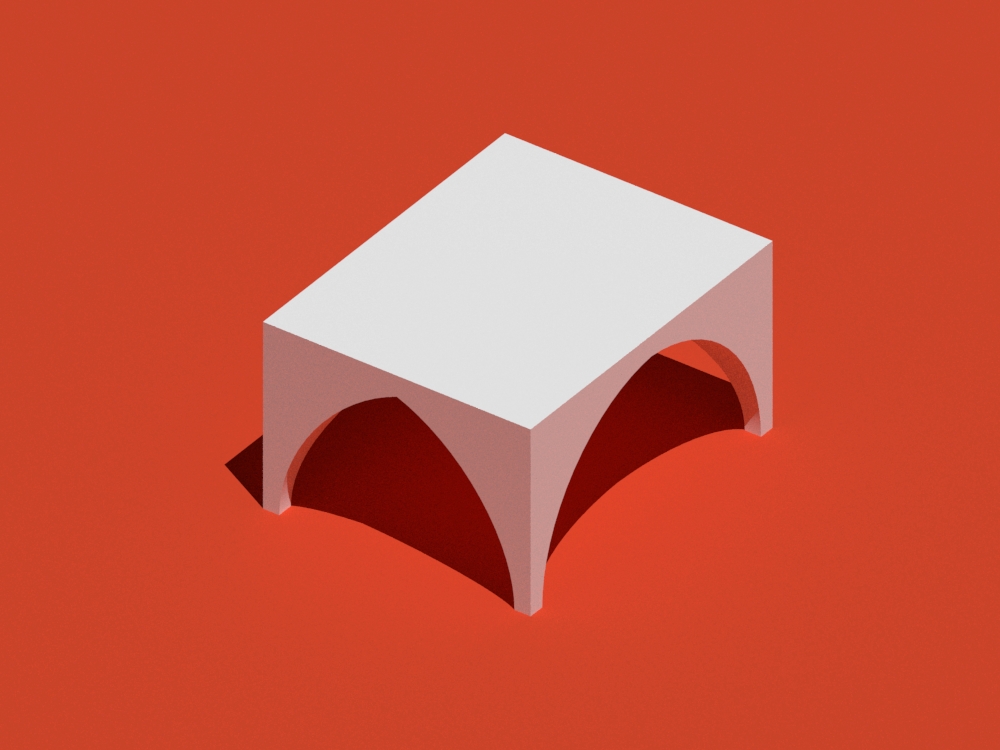

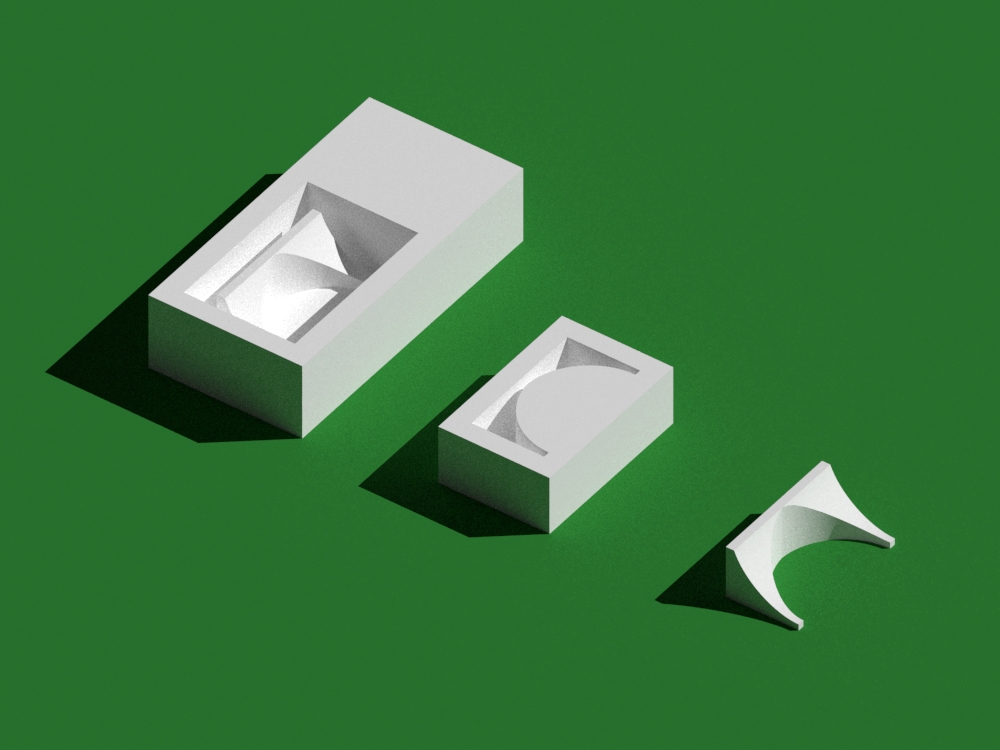

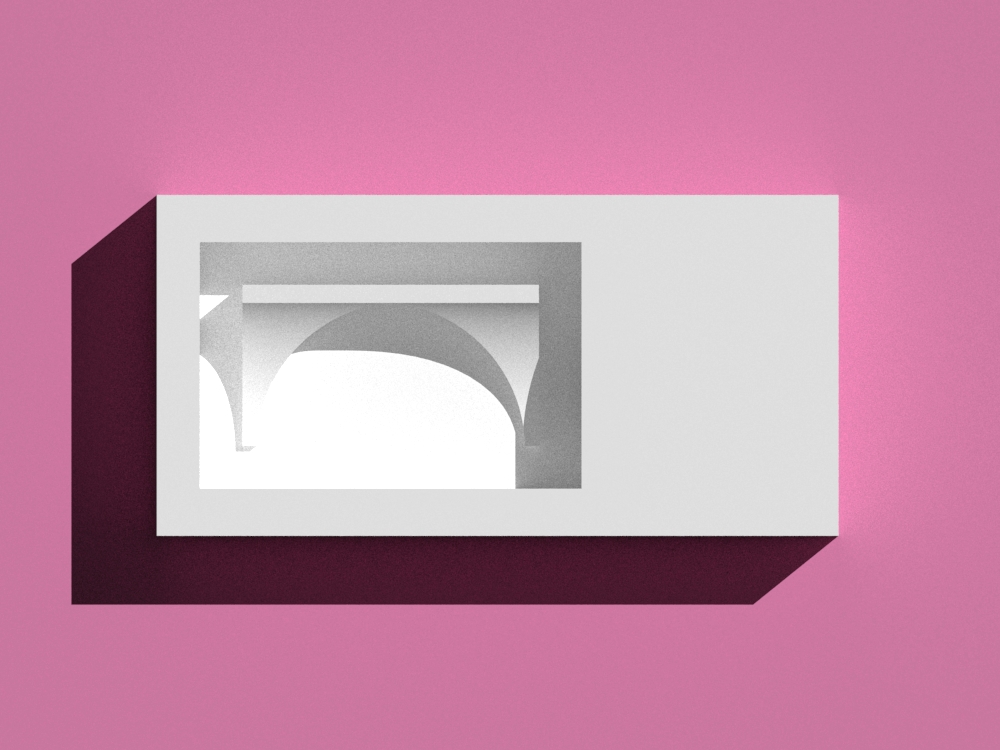

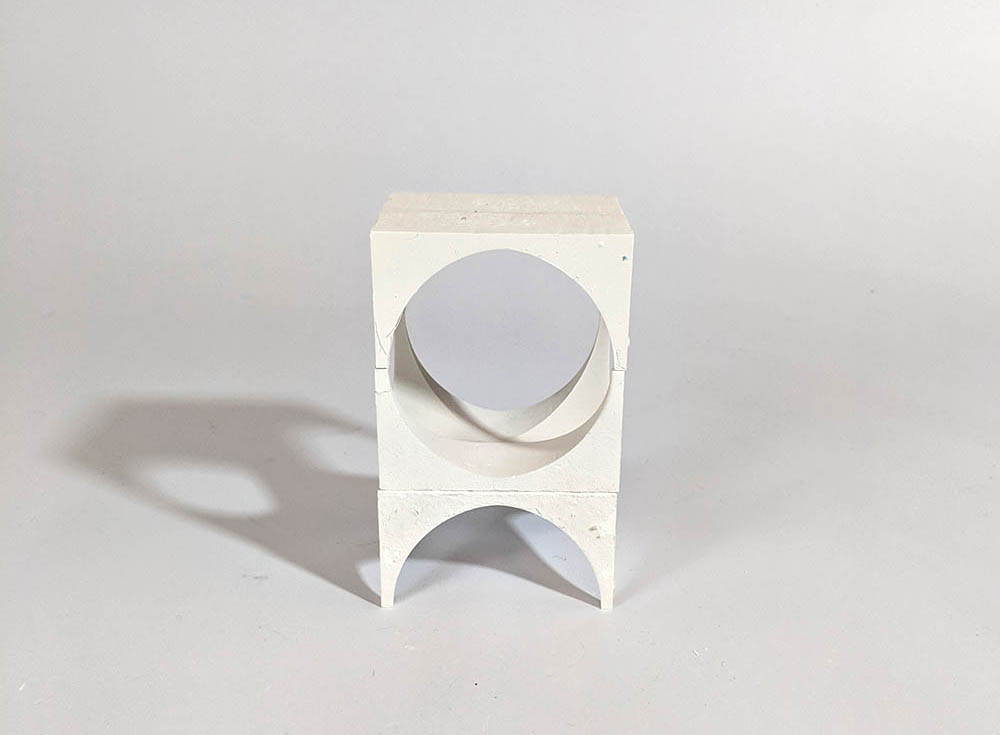

Trimmed vault

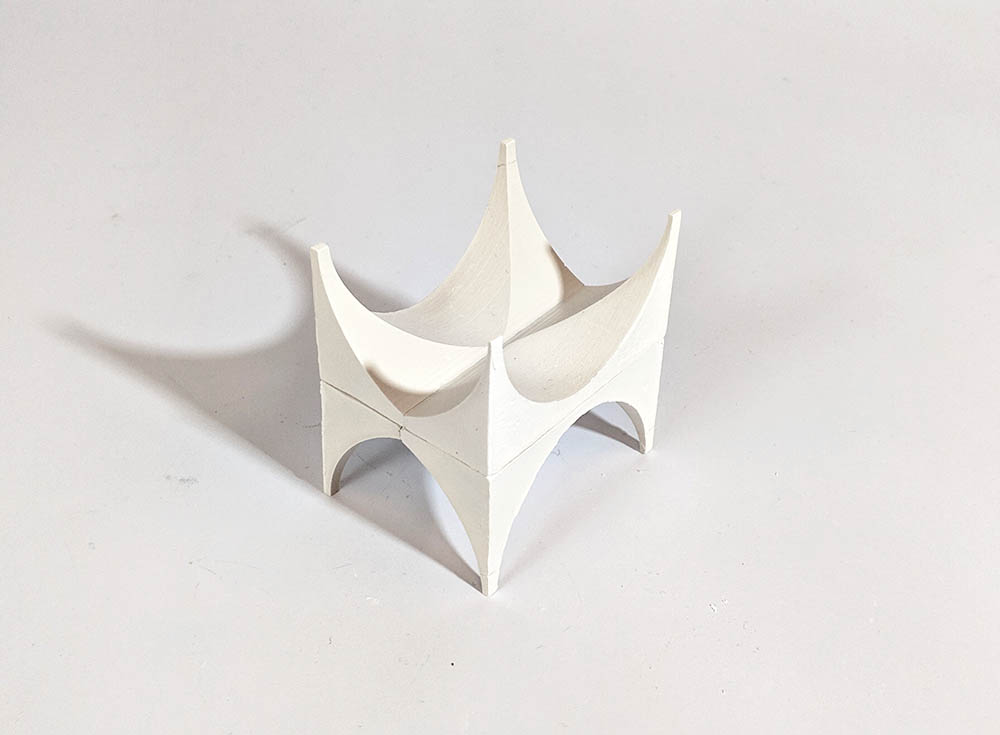

I'm still working on a study for a Chicago building, and I wanted to see if I could create a series of stacking vaults that would stand without gluing. The test vault I modeled had trimmed legs, and I initially thought I could possibly fit the entire unit in one cast.

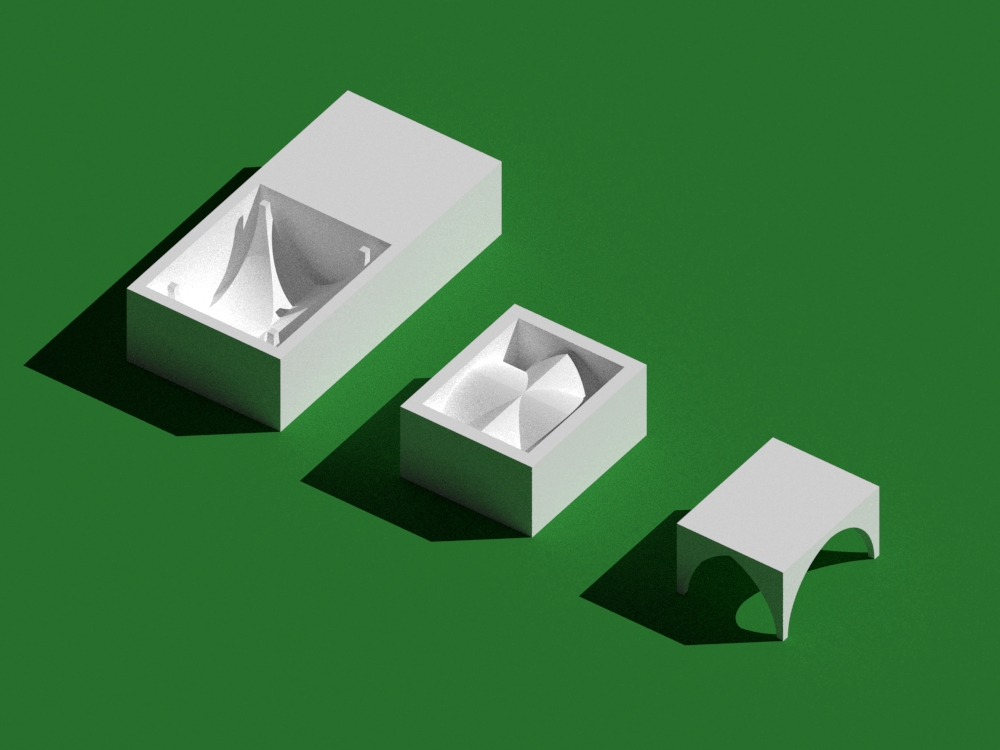

Initial plan

Initial plan

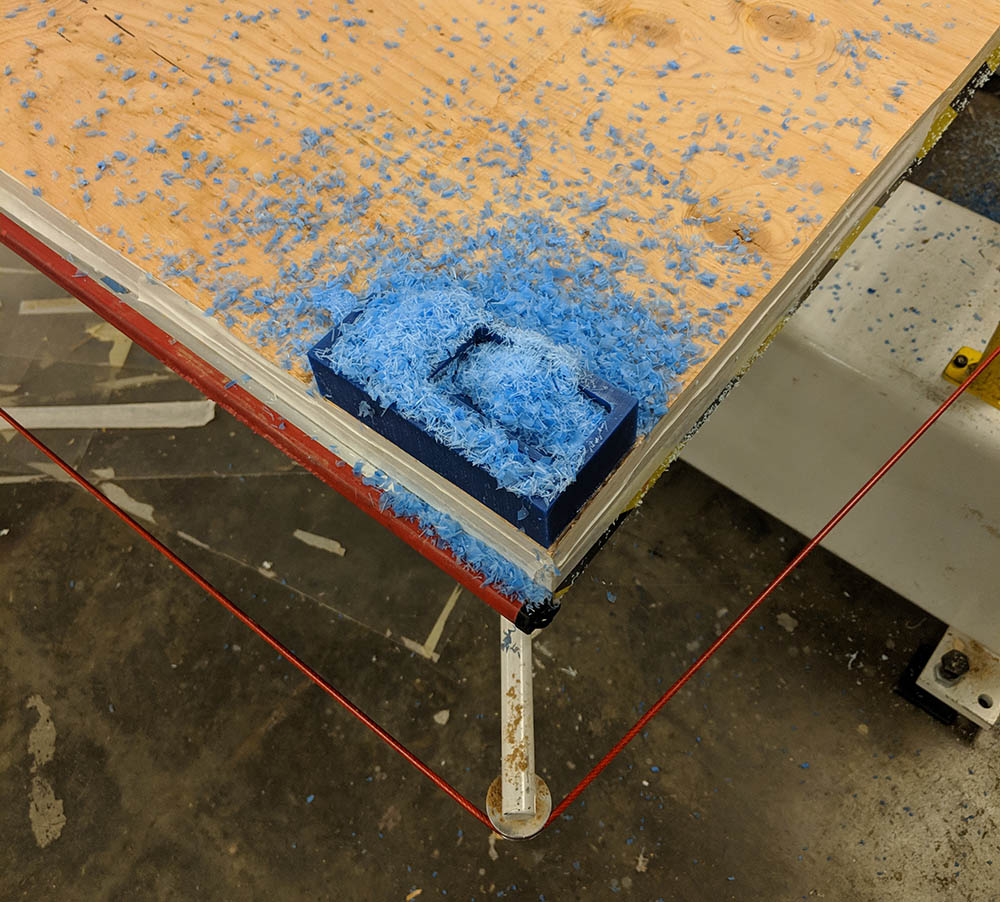

Milling

I have my architecture studio midterm this week, so I wanted to get started with this assignment early and used Jung's precious shop-monitor time to set up my Mastercam file at N51 using the Onsrud. This was definitely an unwise and rushed choice on my part, since as Chris warned, the Onsrud runs much faster (even with the lowest feed rate) than the ShopBot or the other options in RPL or at N51. But since I was pressed on time, I went ahead--and the path worked out well, except that I glued the piece insufficiently at first and it let go midway through the roughing pass. (I used the 3/8" endmill for roughing & contour, and the 3/8" ball end for the surface finish with a really small stepover after testing the flat and ball ends.) The path was also quite fast since the finish was limited to a small area (the curvature of the vault)

Collisions everywhere!

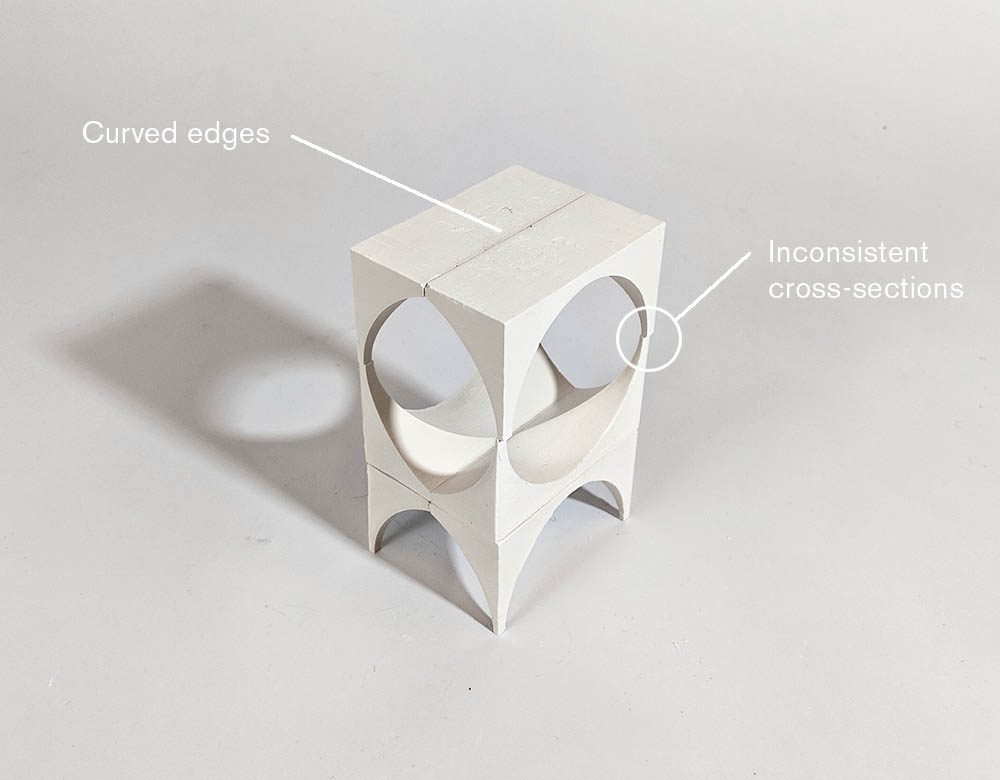

Unfortunately, the first setup did not work with the ends we have at N51 at all... the 1/8" bit kept colliding with the narrow but tall legs sticking up, but I couldn't make them smaller, otherwise I would have lost the curvature continuity at the bottom. Instead, I decided to make a half-module that would aggregate one extra step to compose this initial module.

New plan

New plan

Flat end tool with larger stepover

3/8" spherical tool with 0.1" stepover (still quite fast)

Milling

Clean mill BUT huge chunk missing from the first test, with the hot glue holding down a sheet of scrap plywood that we used to make sure the small piece stays on the vacuum bed.

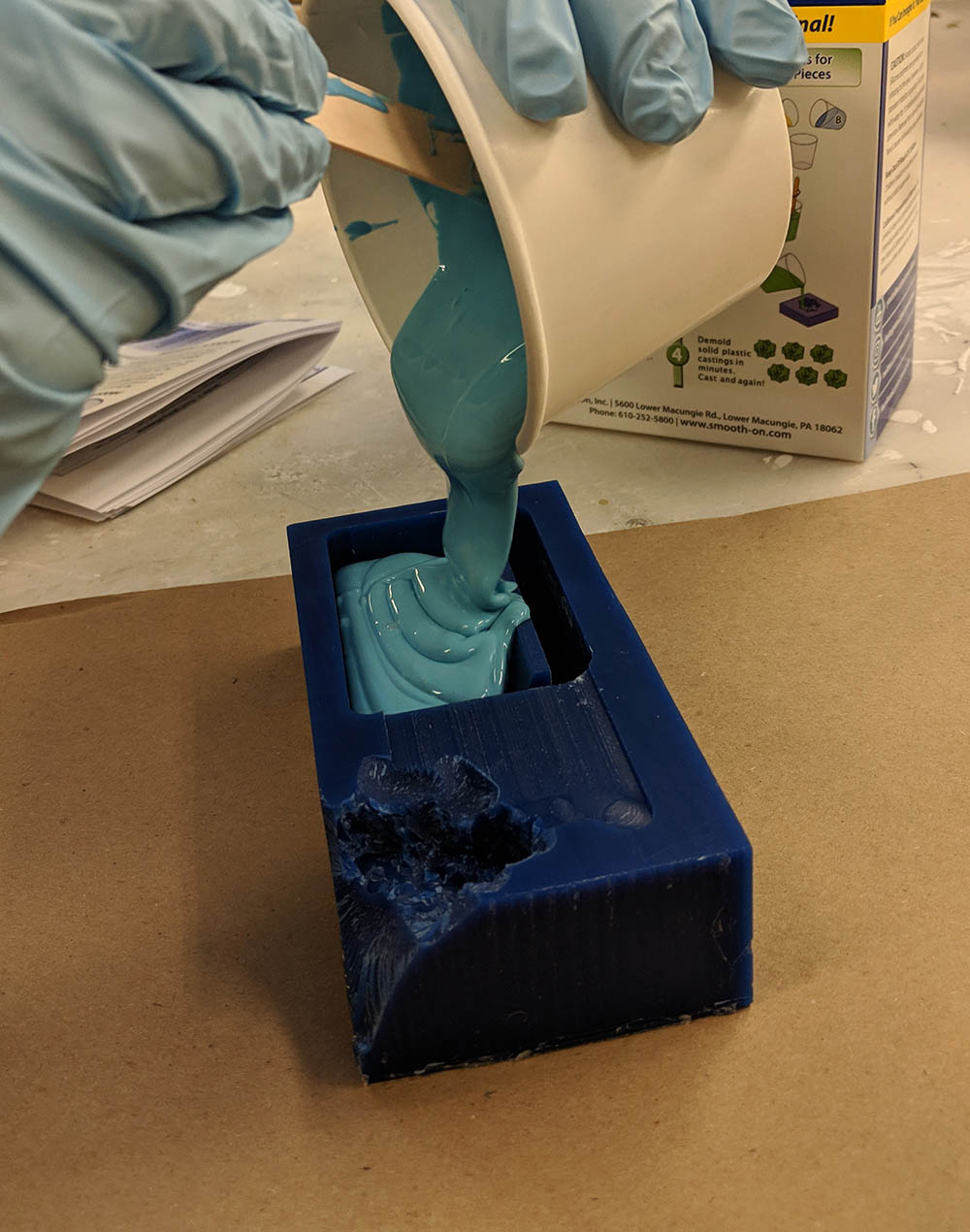

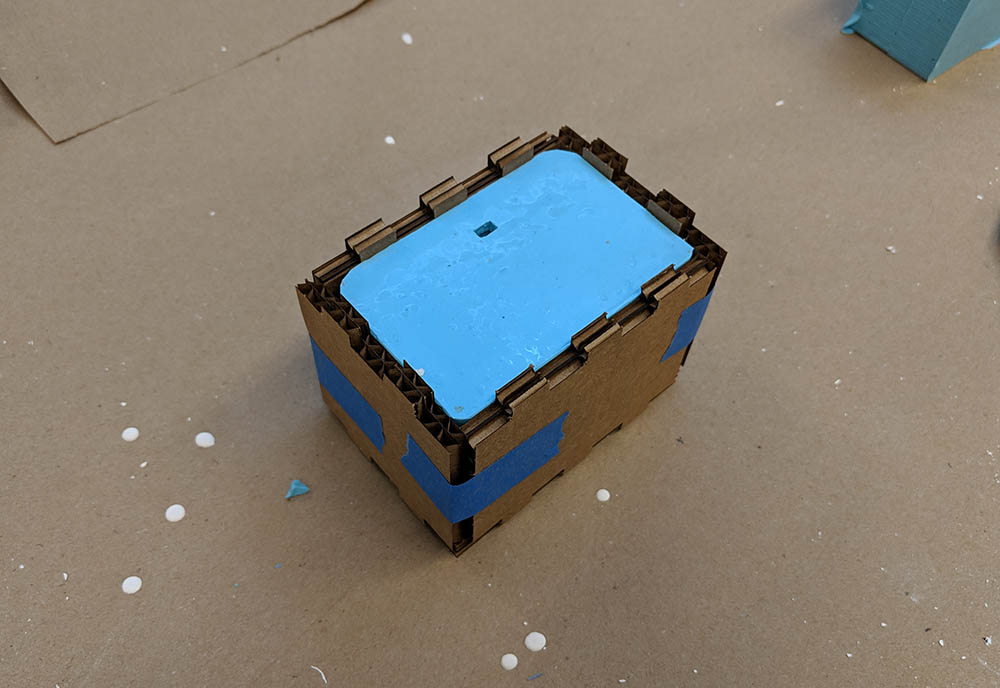

Casting

Casting with Smooth-On was very straightforward and clean compared to other casting I've done with foam or cardboard formwork.

Smooth-On cast

Removing bubbles

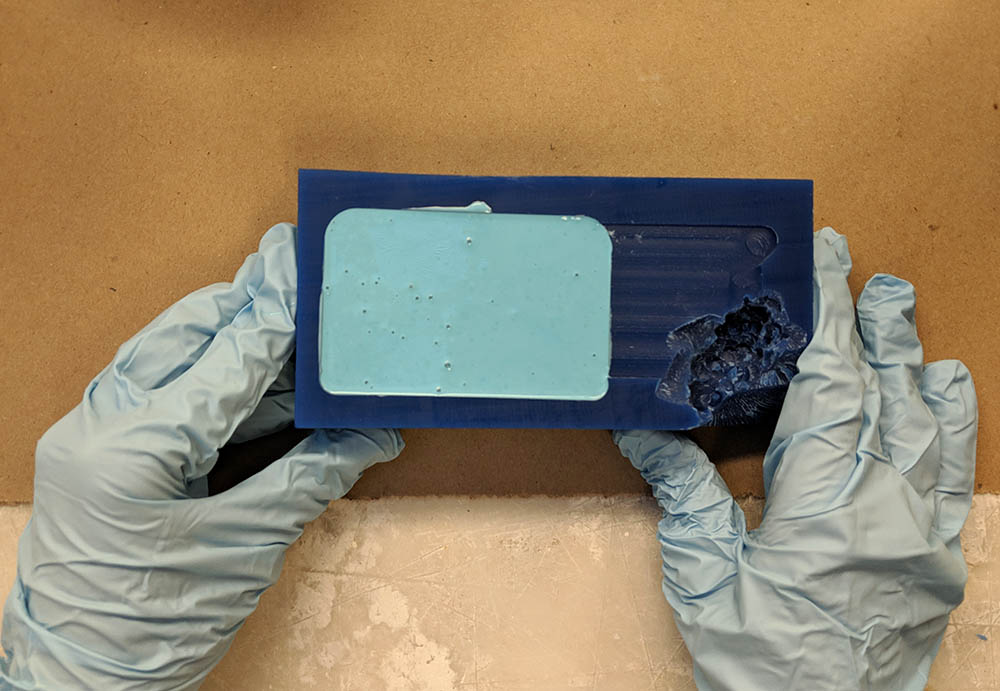

First cast

First cast

First cast

I still wanted to see how to create a larger unit to remove the unever glue lines, and Jung already poured me an extra (!) Smooth-On cast because he had some leftover Smooth-On from his mix (and my cast is tiny). I decided to use this second rubber cast to make one composite two-unit pour.

Second Smooth-On cast

Second Smooth-On cast