How to Make [Almost] Anything | Life + Times Of v.2019

Maharshi Bhattacharya | Masters in Design Studies

Harvard University | Graduate School of Design

Maharshi Bhattacharya | Masters in Design Studies

Harvard University | Graduate School of Design

This week’s order of business: 3D scan an object and print it and design and 3D print a small object, few cm3, limited by printer time that could not be made subtractively.

For scanning a 3D object, I used a disassembled violin. (I love the instrument: shape and sound). Cleaning it was quite an effort, but the outcome was worth the toil (exercise in patience).

Scanning a destringed violin with an Artec Eva Lite 3D scanner.

Cleaning up the scanned model to remove parts of the scanned environment.

Scanned model after refinement (idealized, remeshed and textured).

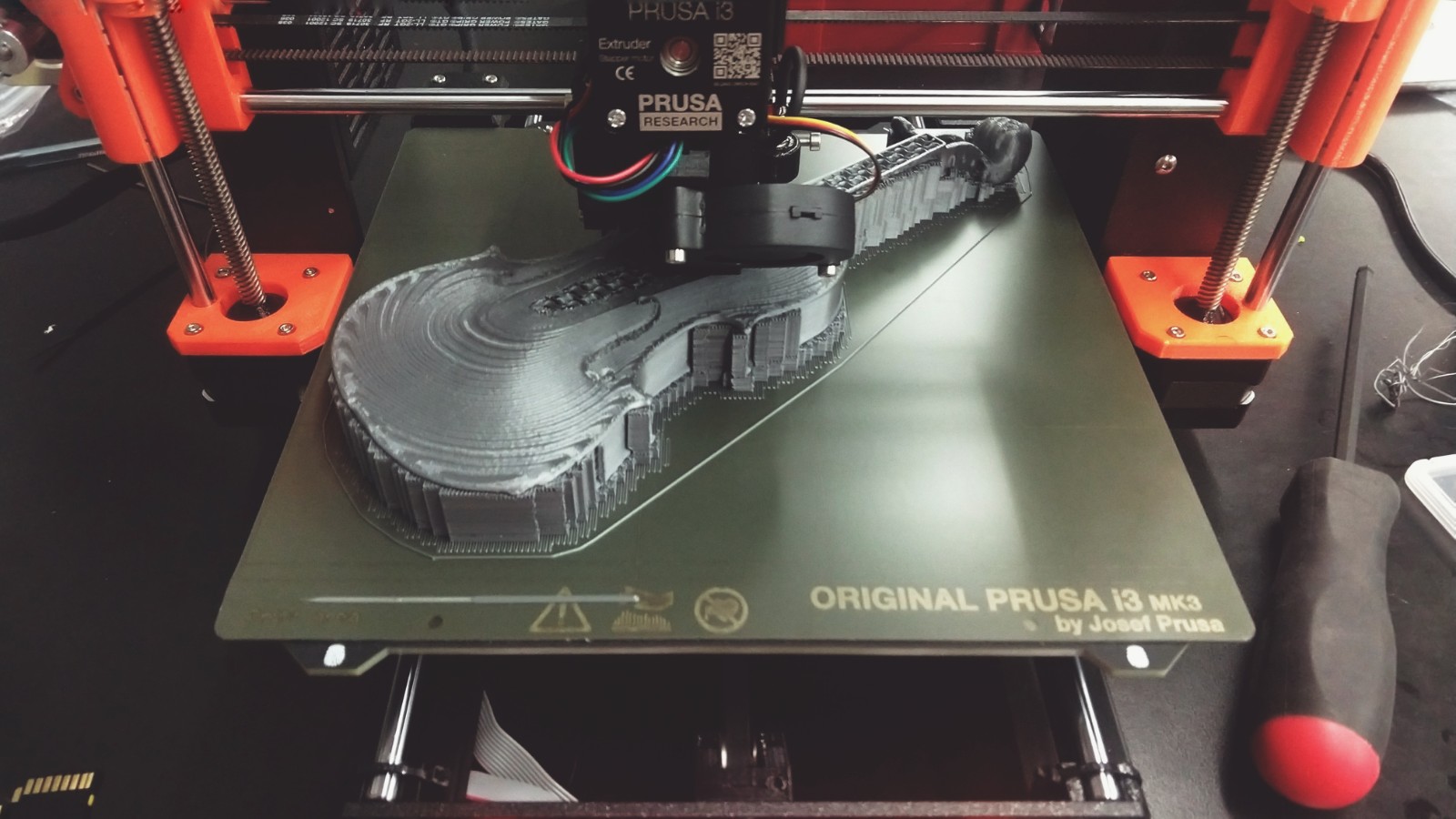

Printing scanned model with supports added in the GCode file.

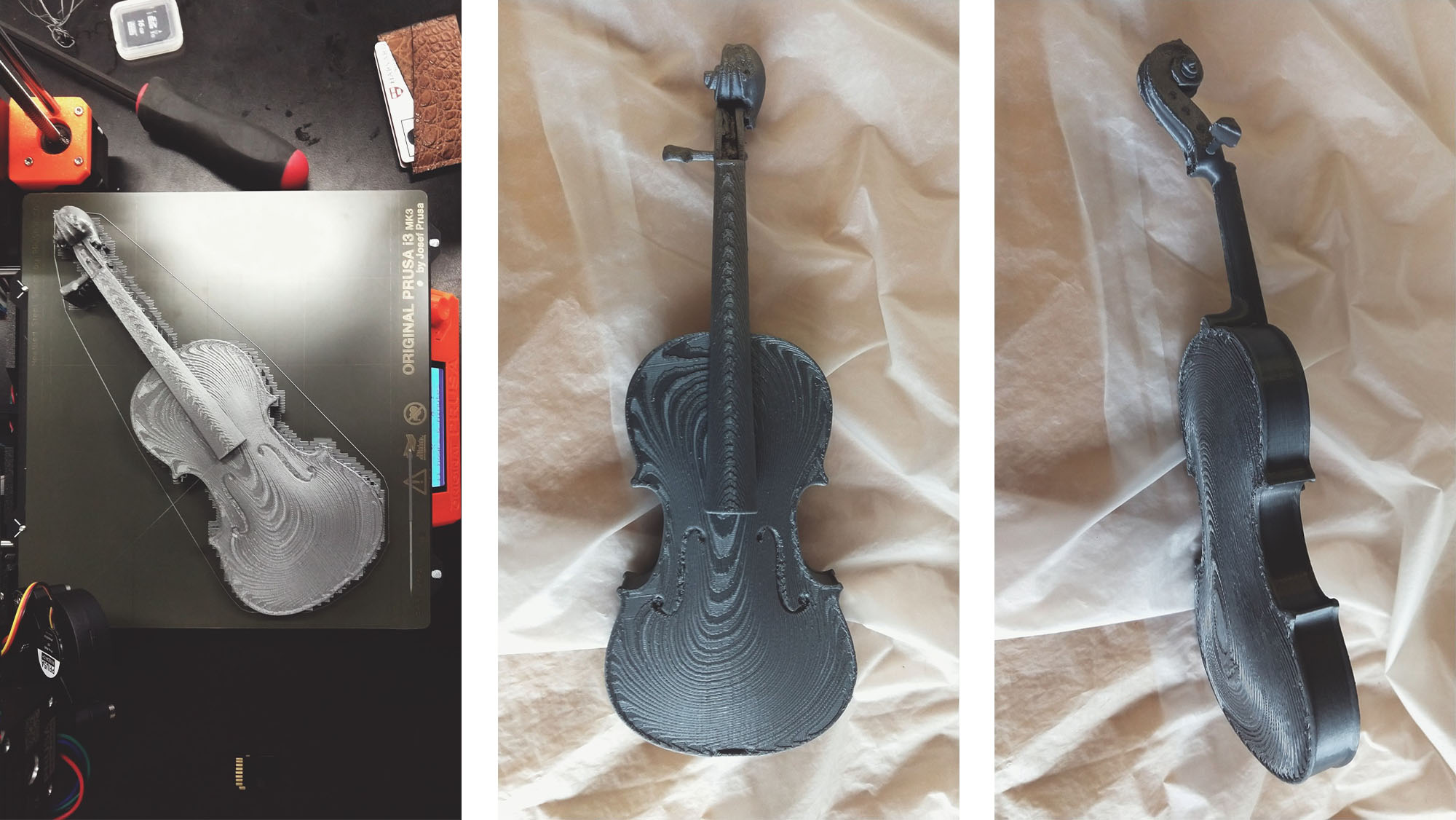

Final printed model.

Cleaned and ready!

I decided to have a bit of fun with printing weird geometries. I started with an Oloid and abstracted the conventional shape of the volume to my liking. I finally printed two iterations of the shape. Next, I did some work on assembled geometries in order to make a fidget gear cube for myself. The geometries should be able to move around a fixed axis.

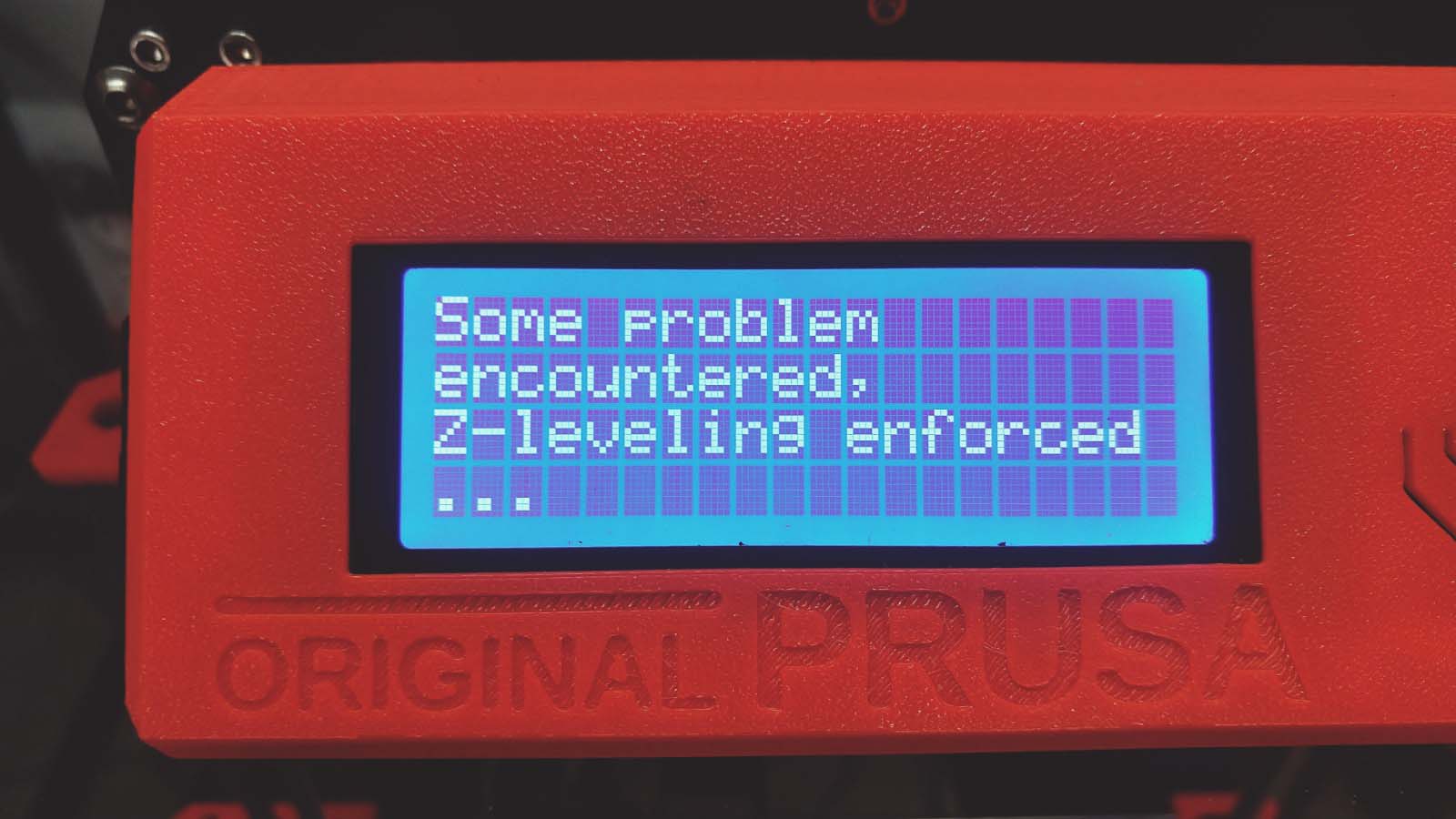

Ran into a bit of problem with the first oloid iteration.

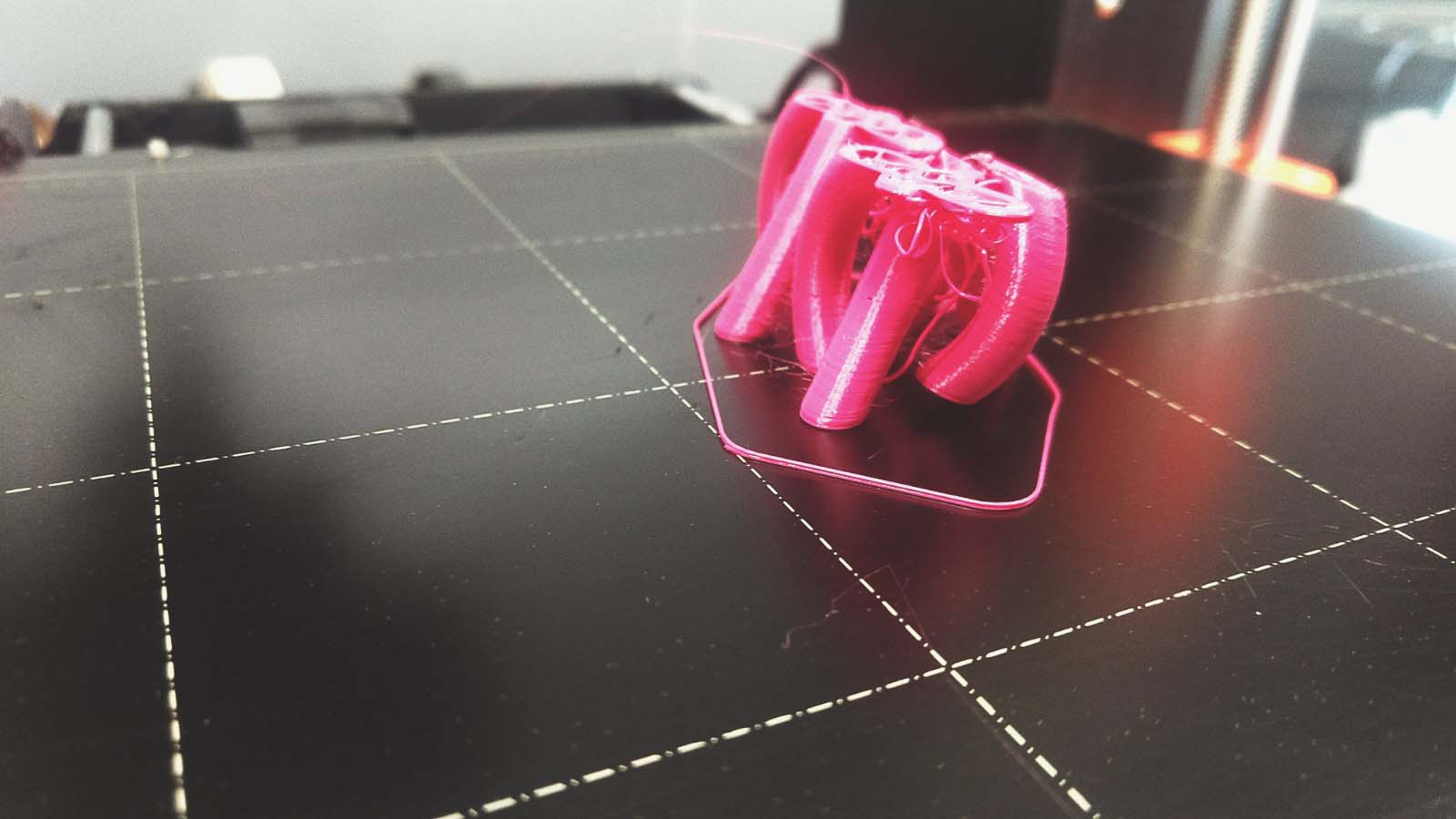

Looked nice, but more problems would follow.

Mission Abort.

Kept at it.

Oloid Iteration 2.

Oloids Complete!.

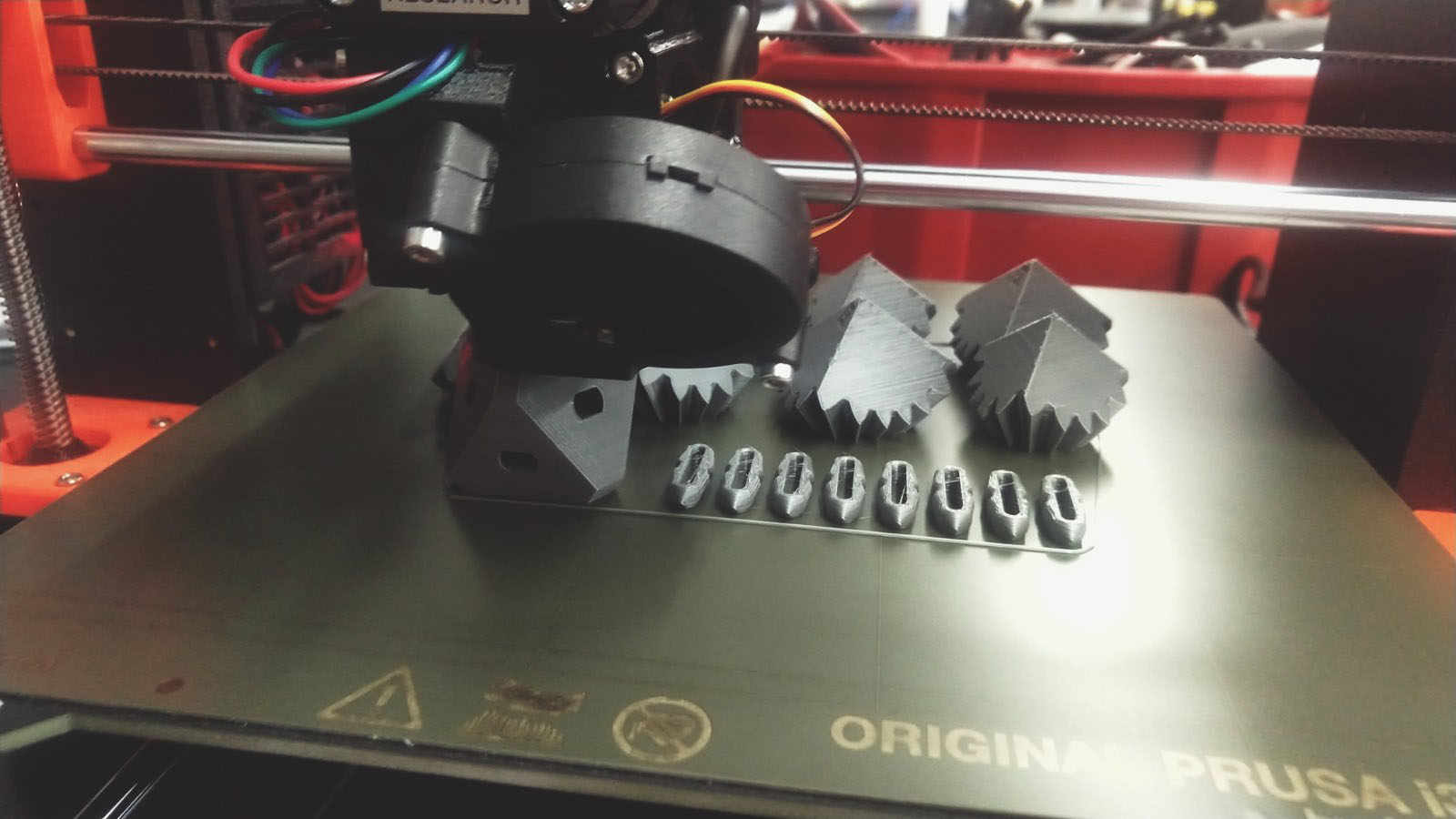

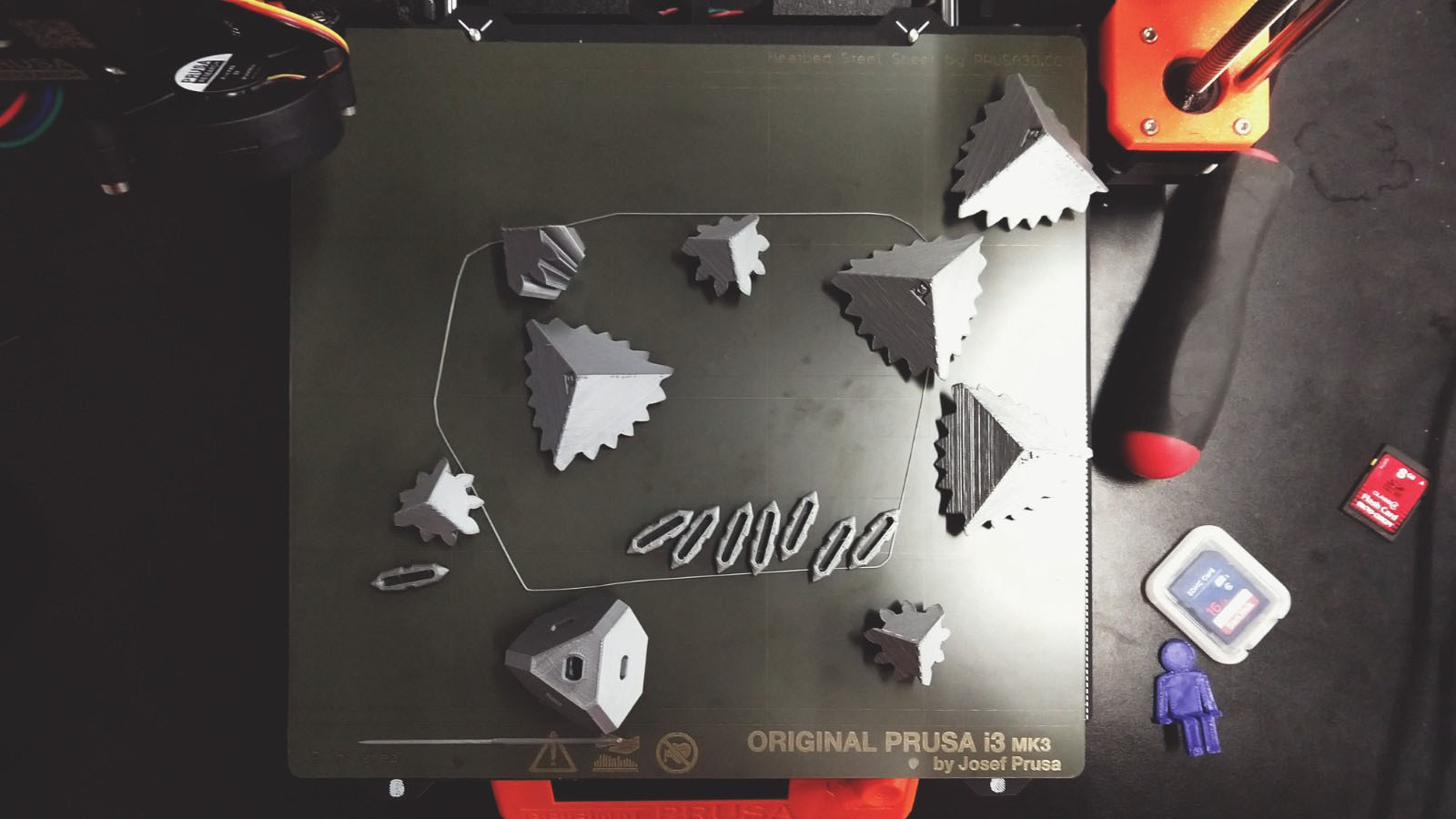

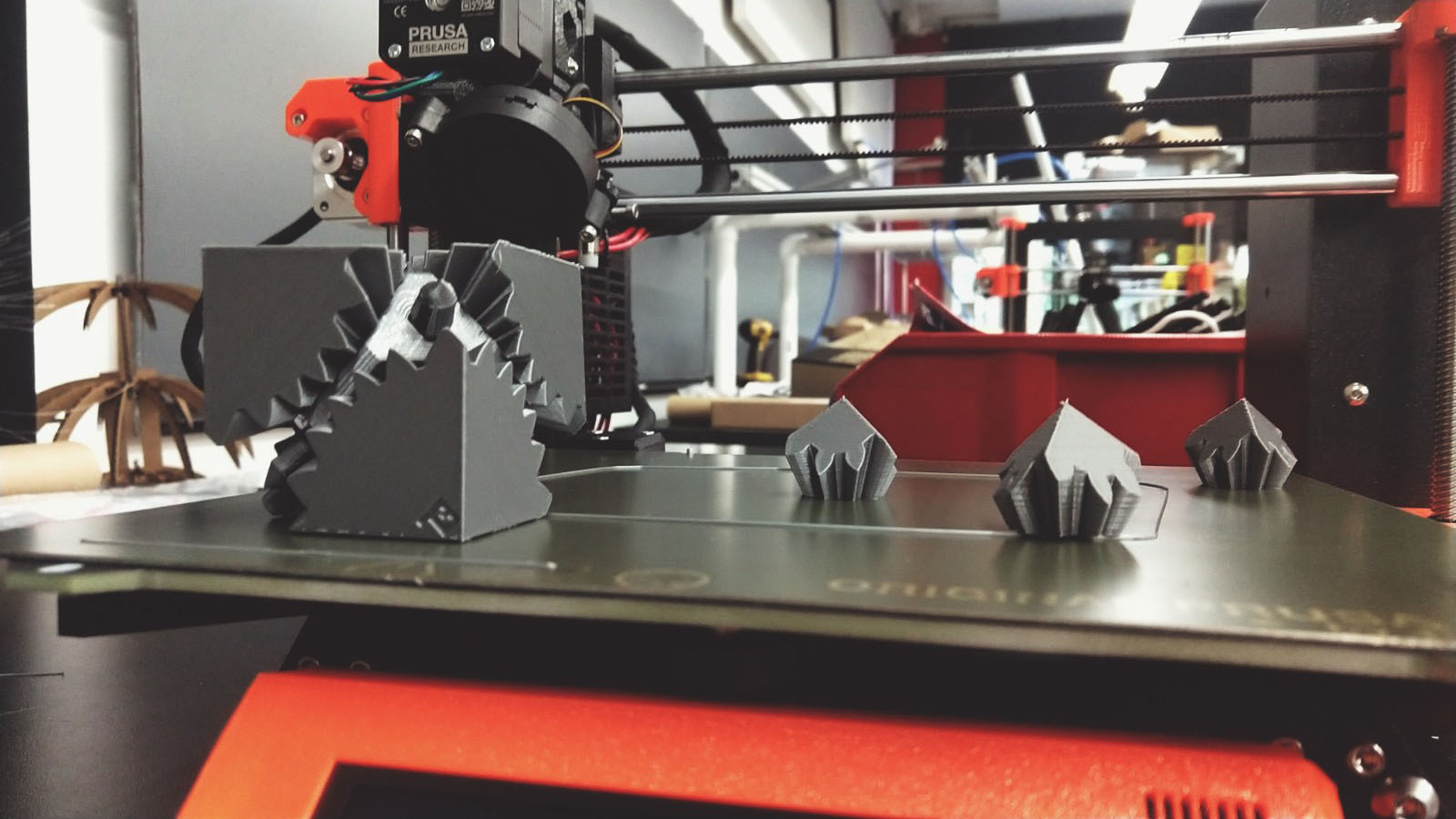

Printing begins on the Gear Cube iteration 1.

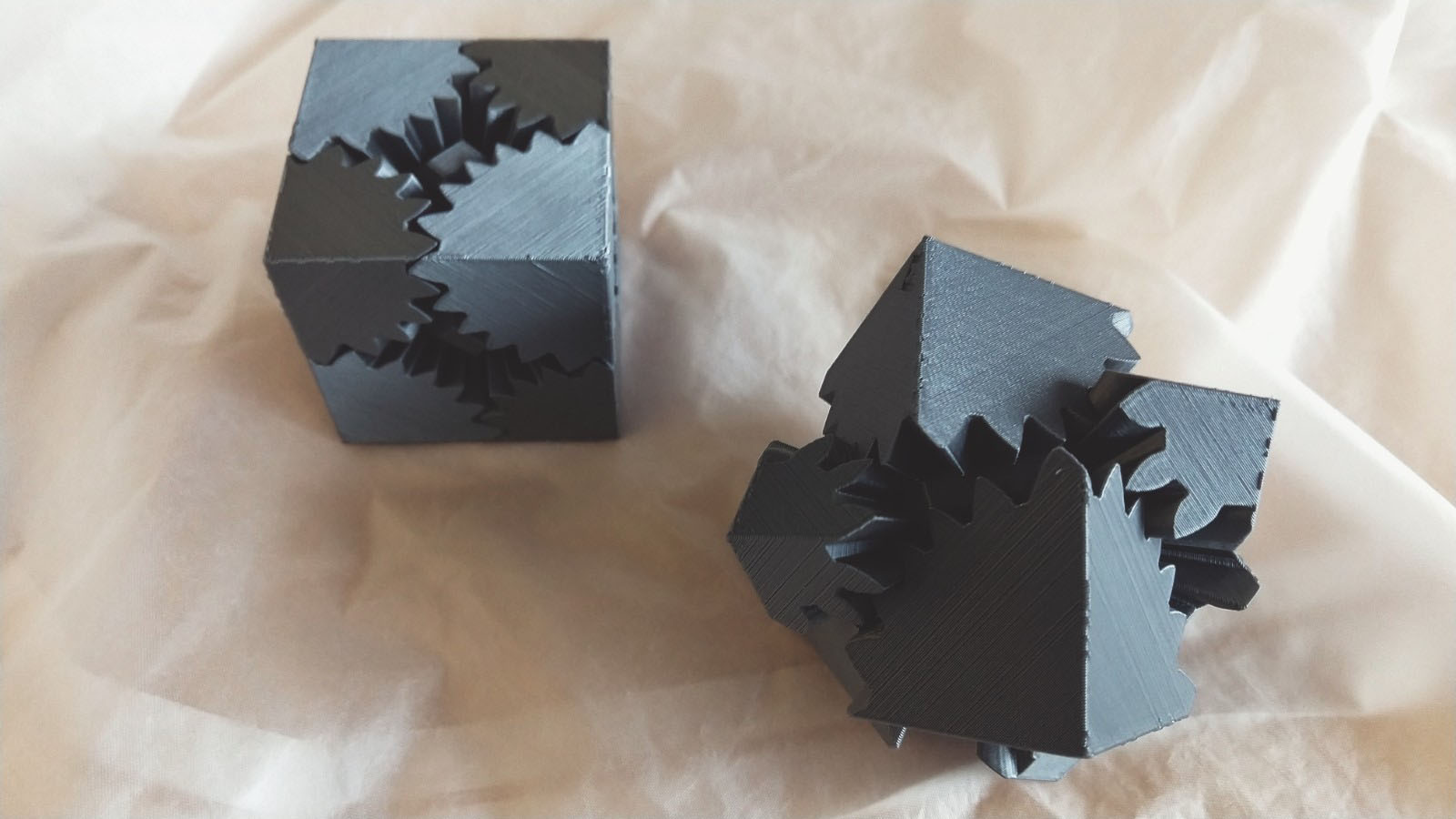

Gear Cube Assembly.

Deconstructed.

Photoshoot!