How to Make [Almost] Anything | Life + Times Of v.2019

Maharshi Bhattacharya | Masters in Design Studies

Harvard University | Graduate School of Design

Maharshi Bhattacharya | Masters in Design Studies

Harvard University | Graduate School of Design

In week 6 we explored design, milling and assembly to make something big. I decided I wanted to learn MasterCAM and carry out my first ever milling using Foam.

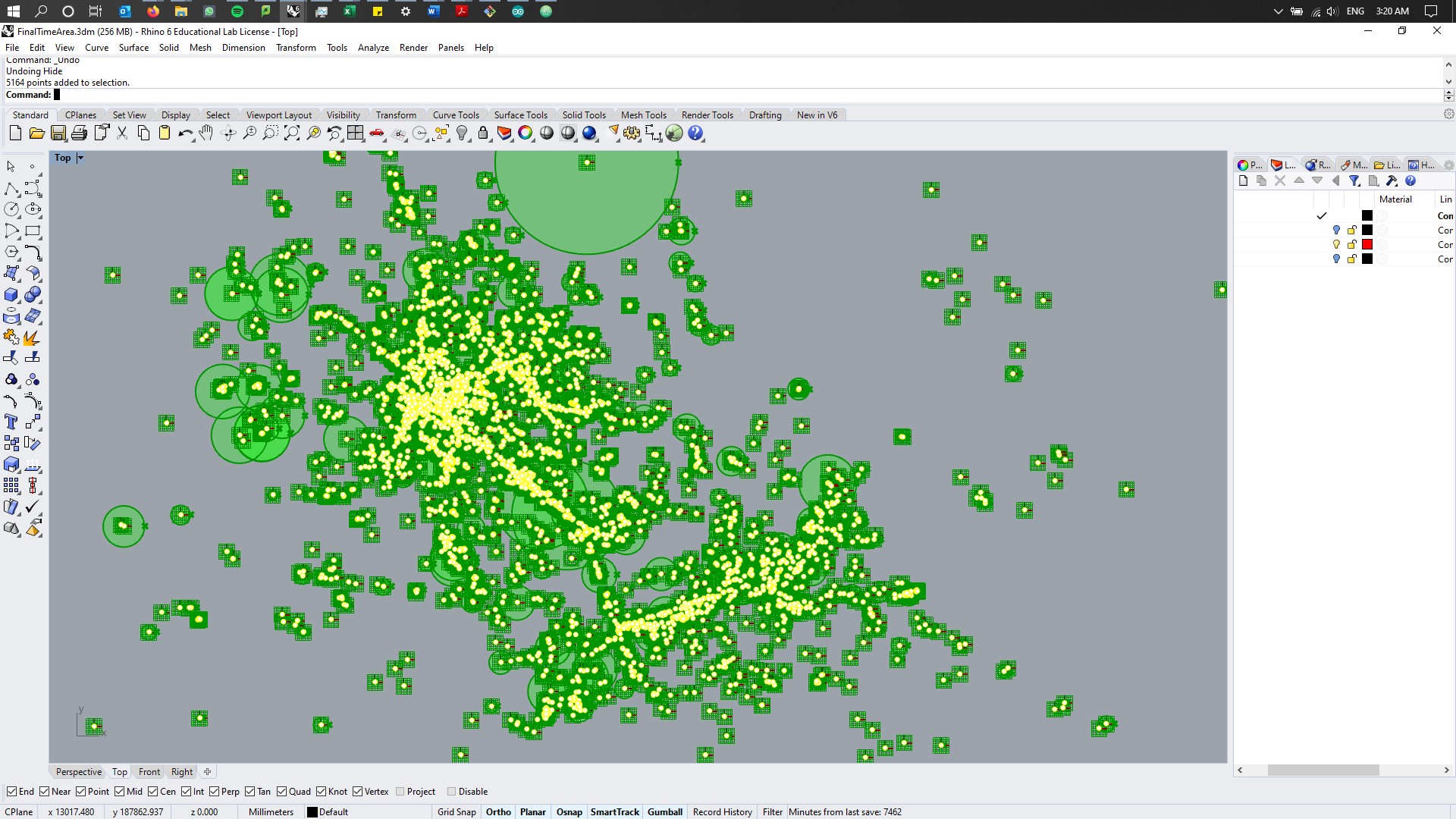

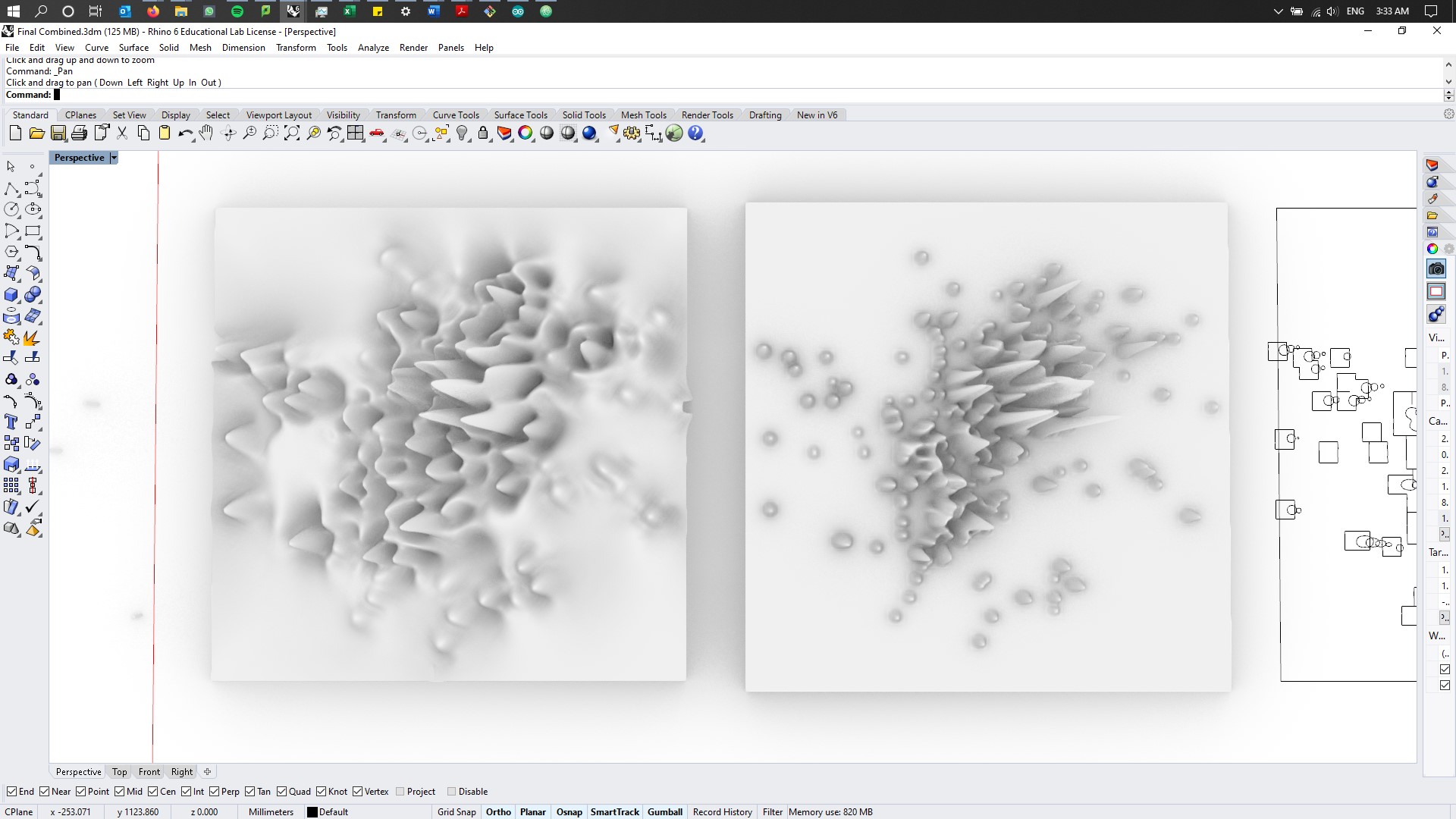

In Rhino, and using Grasshopper, I worked on previously collected student population data across Cambridge wherein each point is the location at which most time is spent.

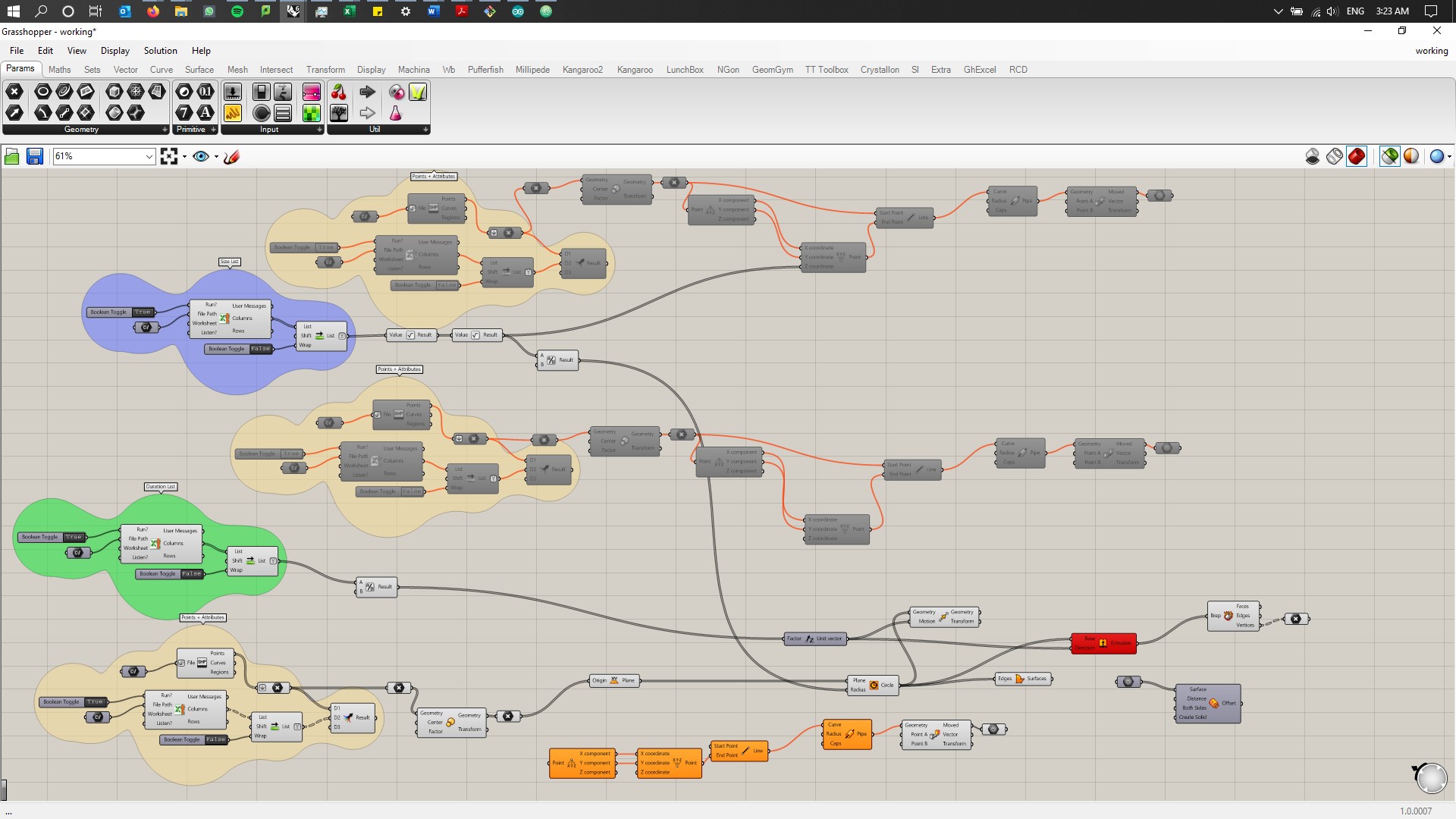

I made a script on Grasshopper to abstract the data, for example, mapping the time spent to a certain height range.

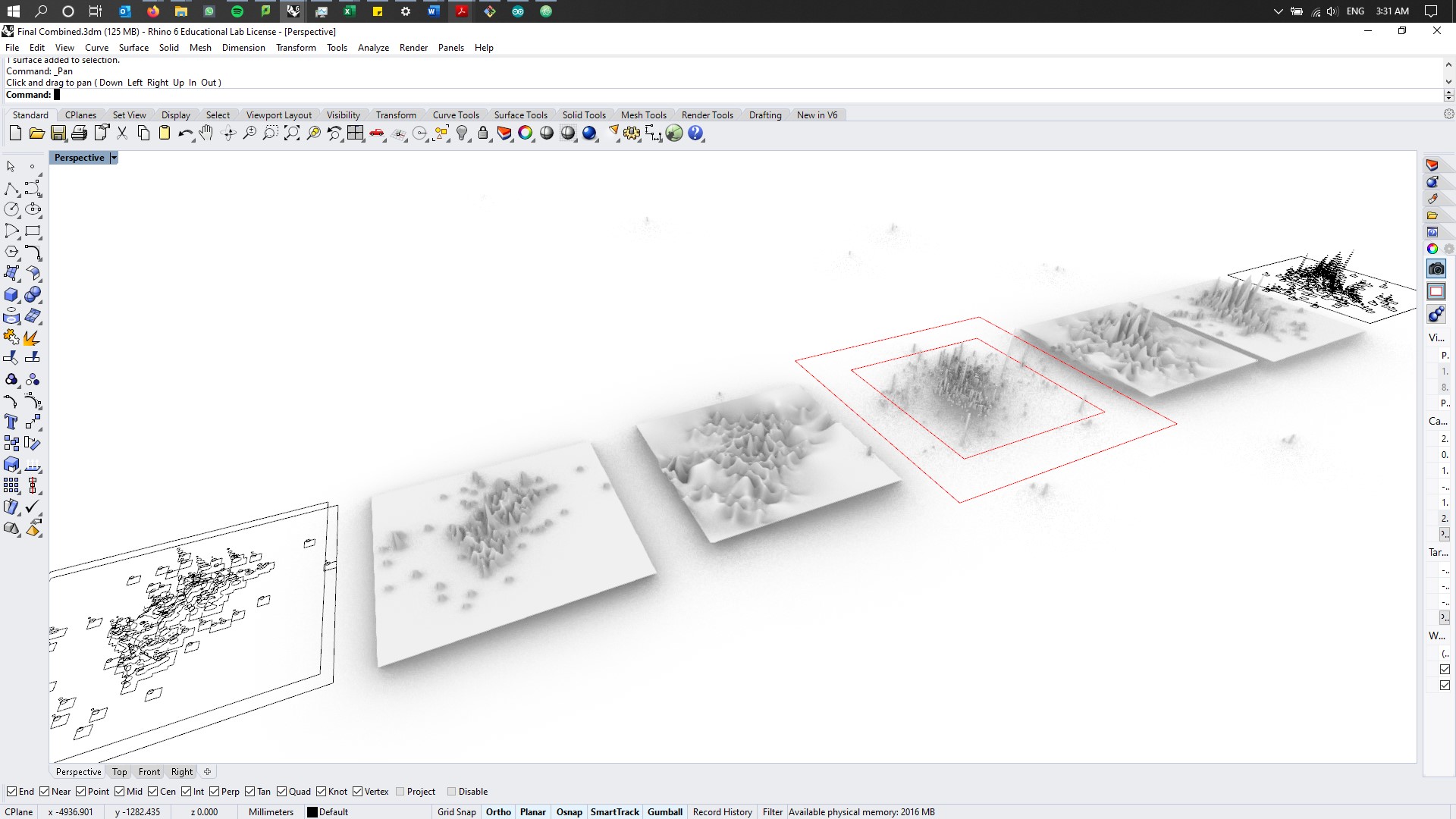

I further abstracted what came out of grasshopper - draped, contoured and remeshed to refine the model...

..Till I liked the two models I had.

The resulting models were then prepared and sent to MasterCAM, where the toolpath for the Milling Machine bit (C.R. ONSRUD Router) was generated...eventually. The red spots in the second video show areas where the shank or the shoulder of the bit will collide with the foam. Such errors had to be removed by going back to Rhino and tweaking the model or tweaking the toolpath to accommodate the material.

C.R. ONSRUD Router at work.

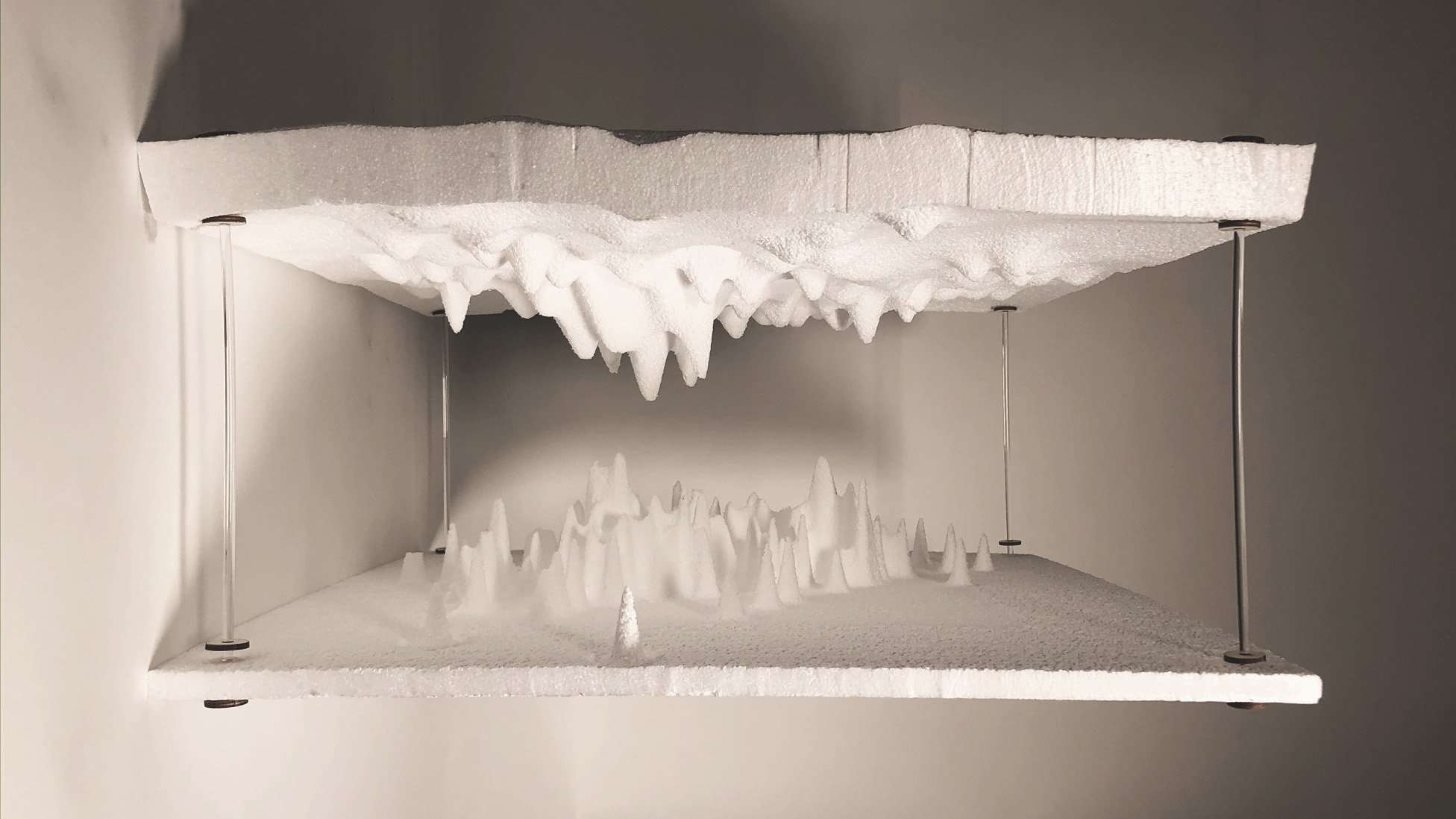

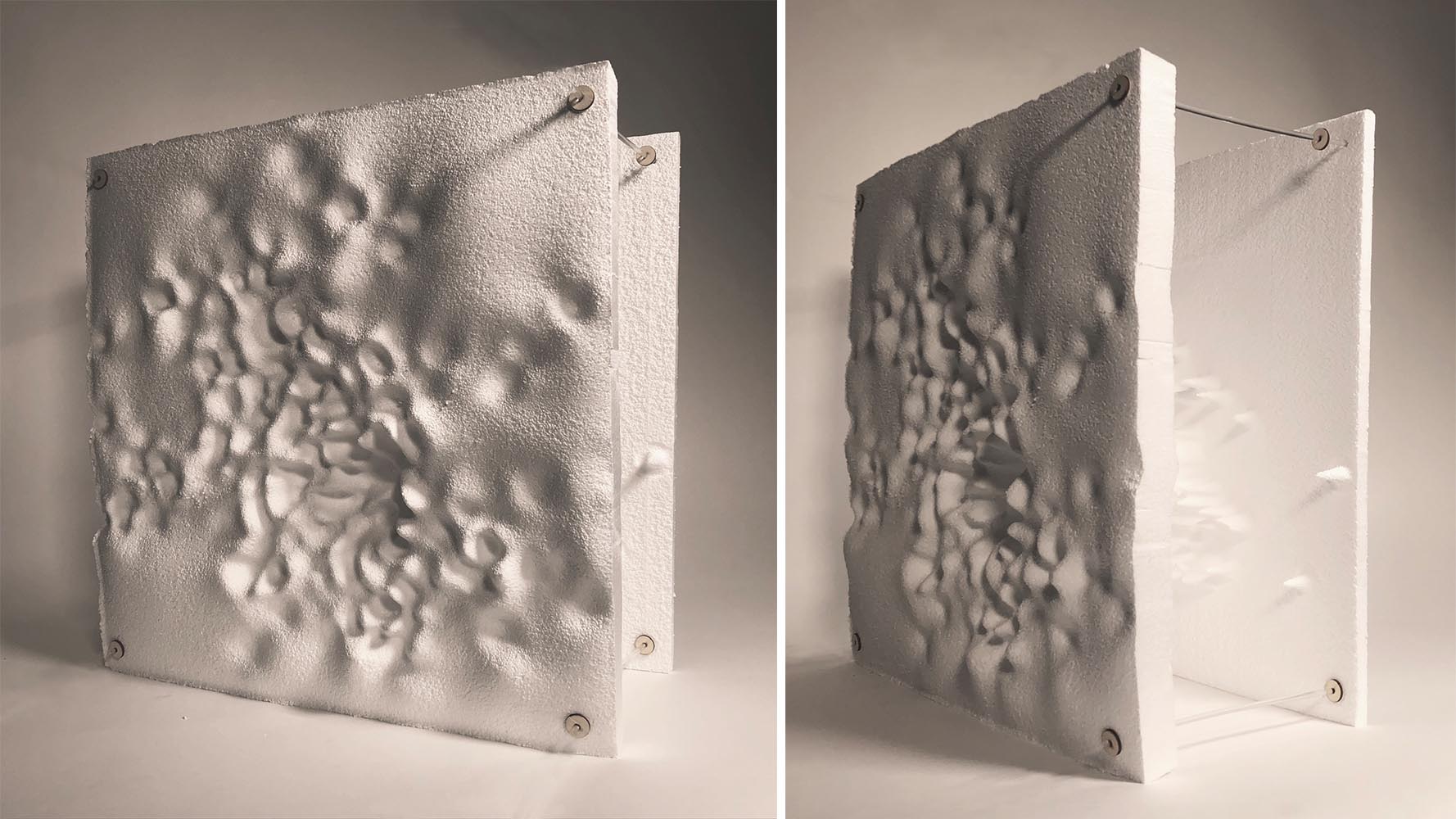

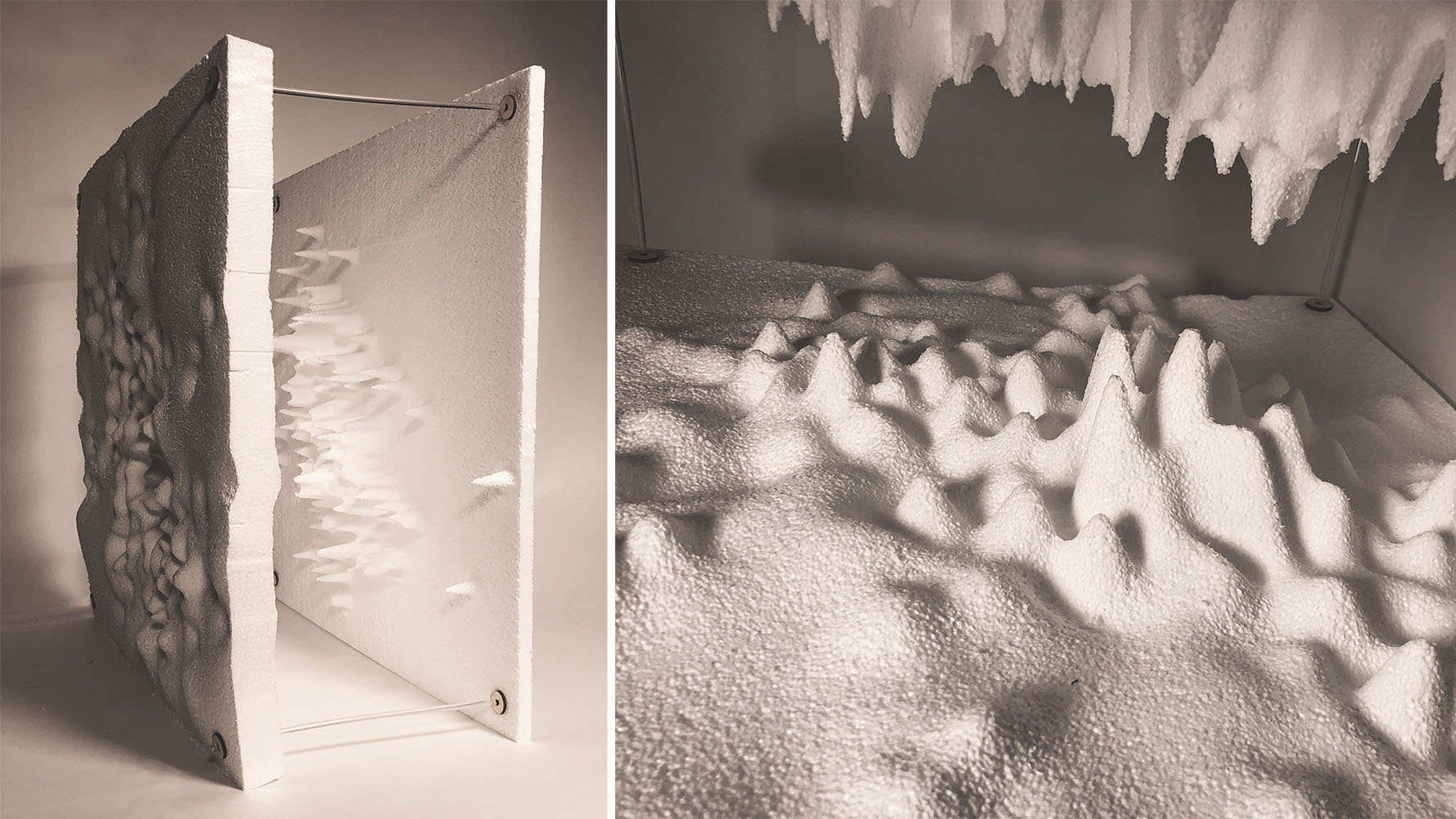

Fresh out of the Milling Machine

Something Big Photoshoot!