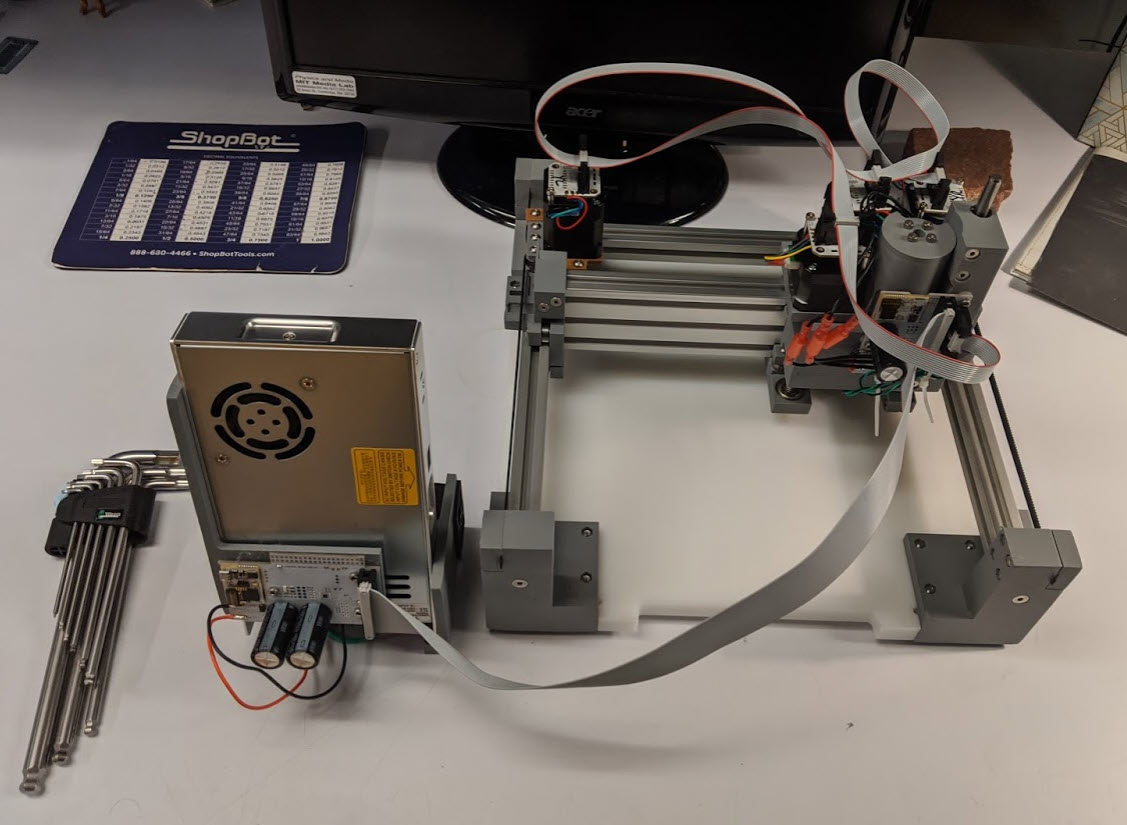

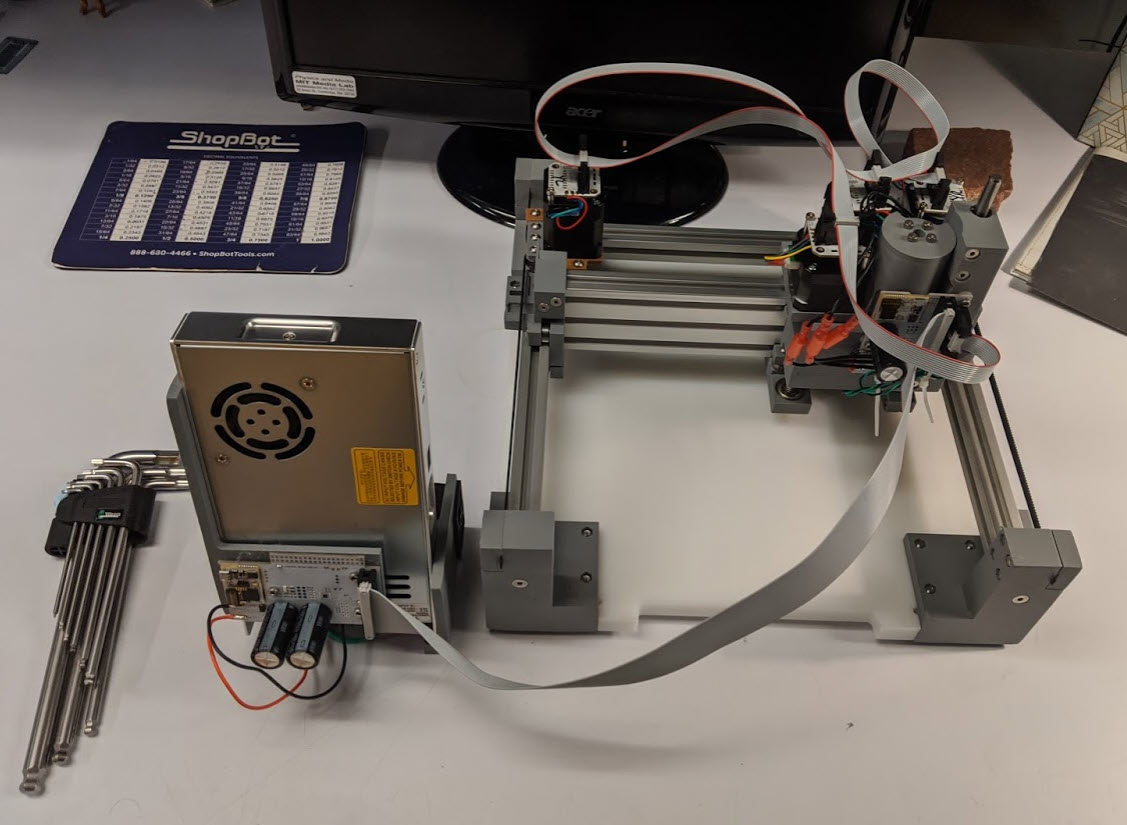

For week 6 our task was to set up our new CNC circuit mills, and then cut and stuff a microcontroller programmer.

Everything went together smoothly except for a missing bag of hardware which I was able to pilfer from 023. Jake did a really good job filming instructional videos (honestly much better than the assembly guides for some commercial machines I have had to assemble). Clank assembly took ~4 hours. In addition to designing the mechanical hardware + stepper drivers, Jake designed a single-cable bus architecture that makes waking him up super simple - all you do is plug a single ribbon cable into 4 steppers and everything is talking to each other. Very neat!

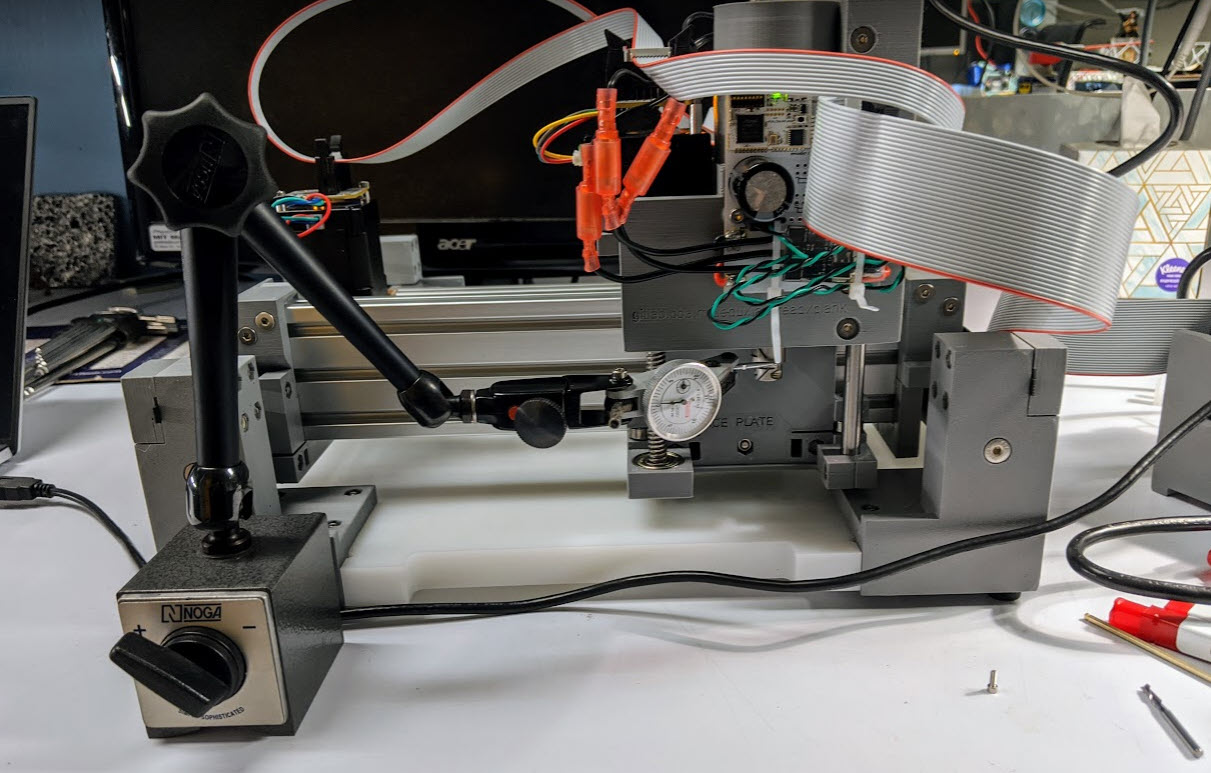

I did some quick runout measurements on the collar of the sketchy shaft adapter we are using as a collet. It actually wasn’t too bad (although I didn’t get an 1/8” shaft and measure at tip which I should have done).

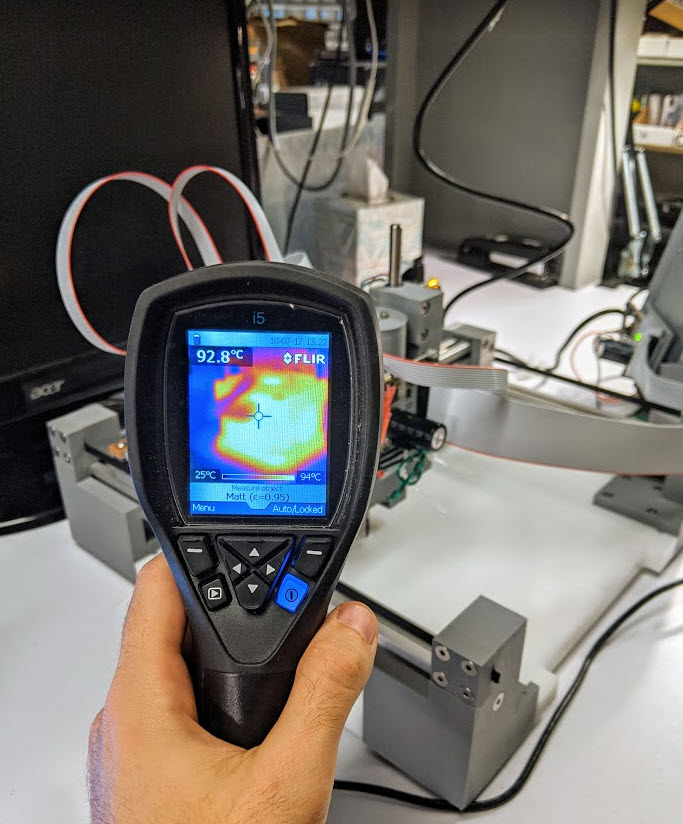

My Z-motor was running super hot which turned out to be a firmware bug (also a firmware bug preventing us from adjusting it lol). Despite being disturbingly close to the melting point of PLA, it smells fine and hasn’t caused any problems from what I can tell.

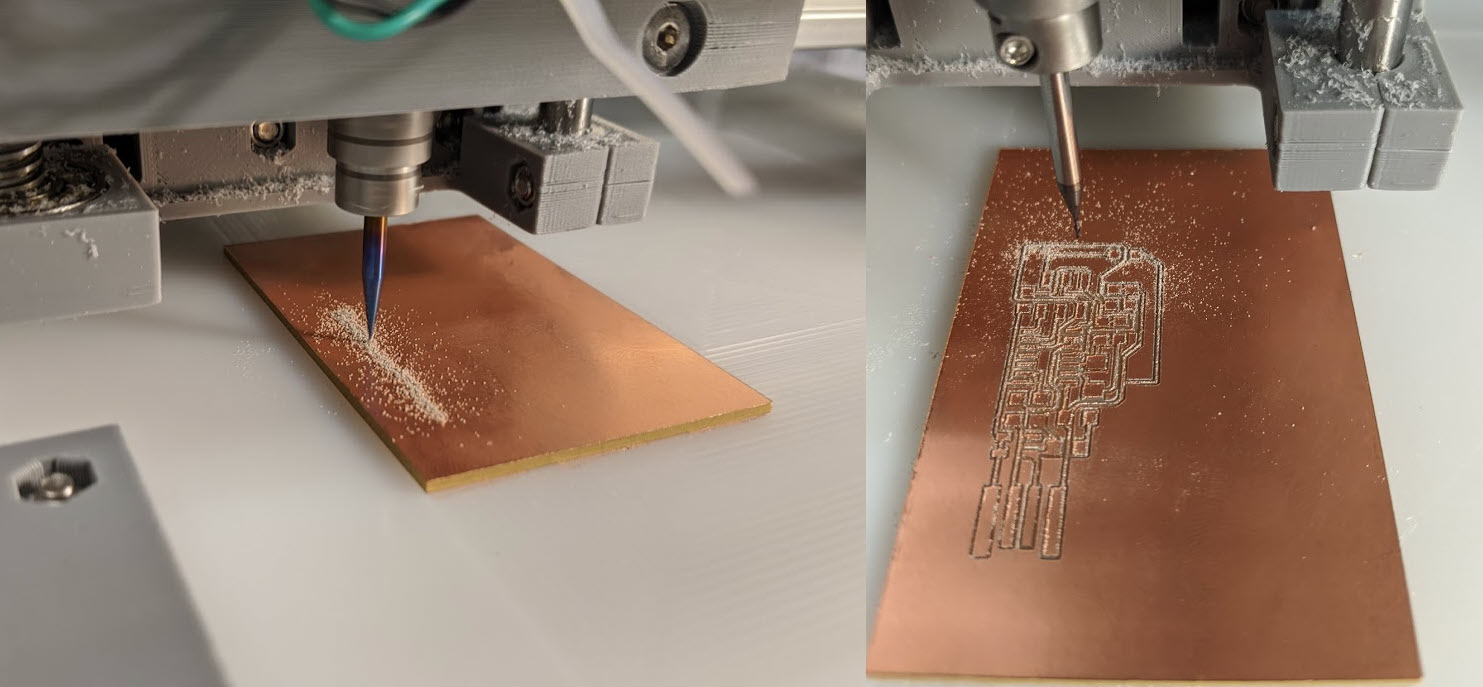

After the lil guy was built I surfaced my bed with an 1/8” end mill as shown below. For long jobs if your computer falls asleep it will interrupt streaming moves to the bus! So make sure you keep your computer awake. Other than that I had some weird resonance at 10k rpm which is the default surfacing spindle rpm, which I resolved by just editing the g-code and bumping up to 11k where it went away. See Alfonso and I “making it rain snow” below.

I gave Jake a hard time for not designing a coreXY machine, which would probably have been perfect for this application. Even cooler, they were popularized by Ilan Moyer while he was at the CBA in 2012!. Oh well, maybe next year :)

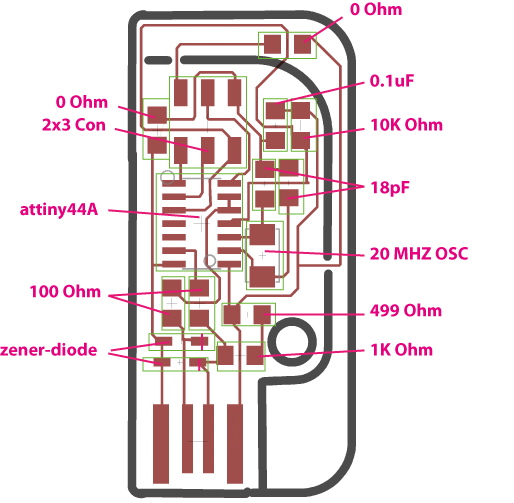

I went with Valentin’s neat programmer design that allows you to break away all of the components needed for programming like one of those Nucleo development boards.

This page was also super helpful for actually understanding what was going on.

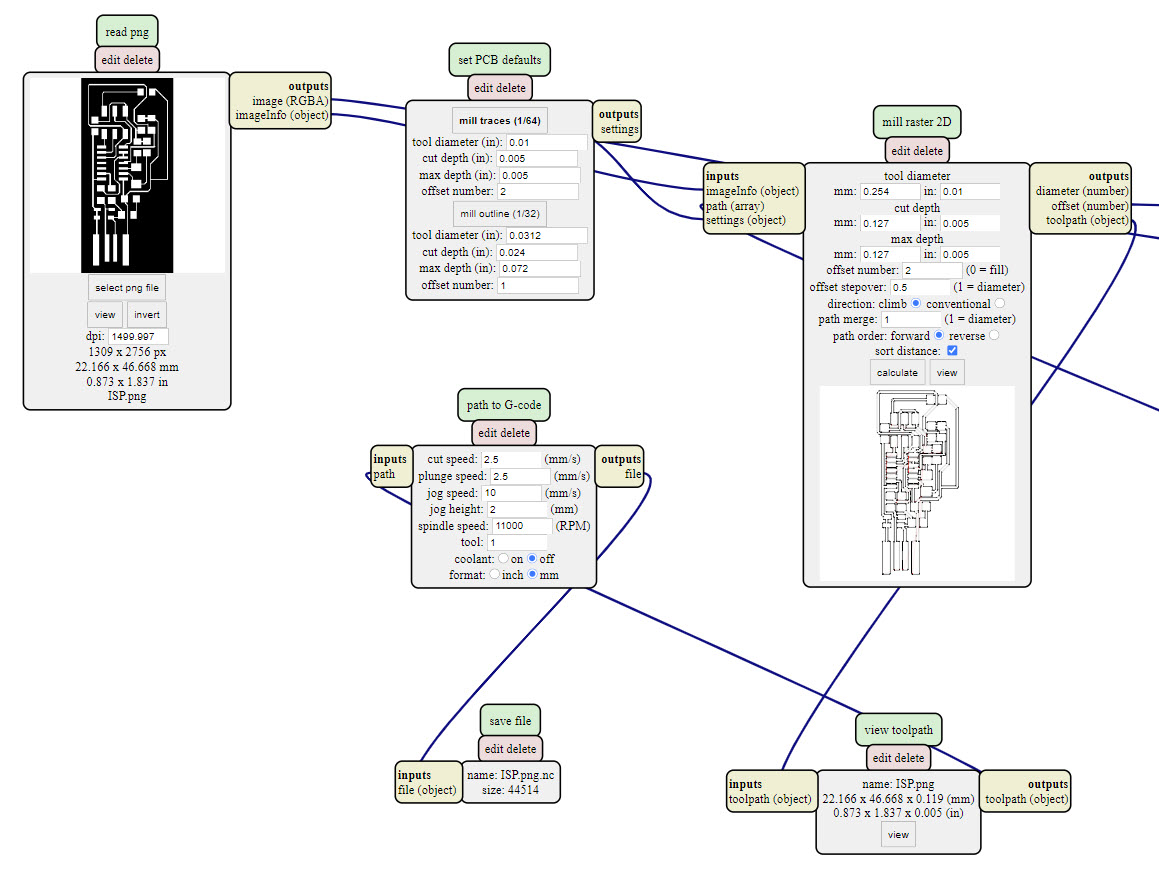

For getting mods working I fortunately had Alfonso’s help. You can see my final settings below. Despite having seen the tool before I had no idea it took .pngs as inputs. Definitely would be neat if programming CNC tools got to this level of automation for more than pocketing and profiling!

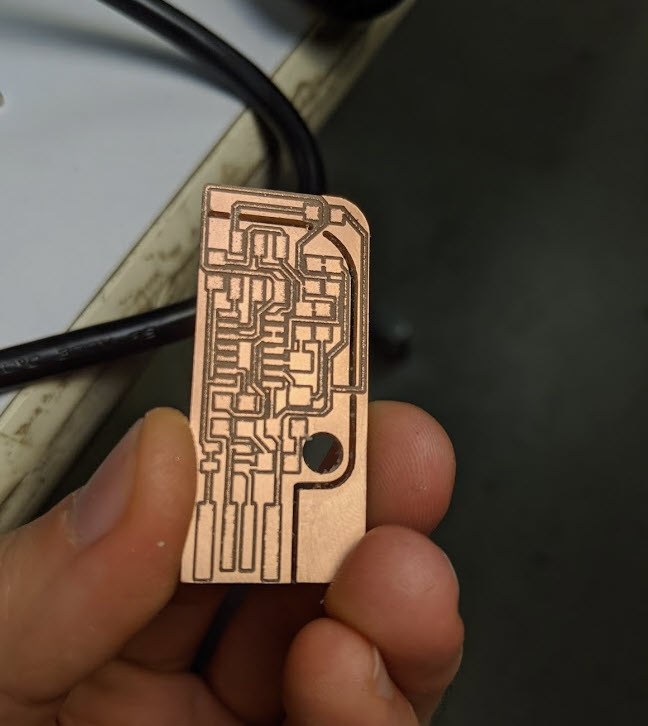

I ran two jobs with one tool change (traces with the cool blue’d PCB engraving bit on the right, and then cut everything out with a 1/32” end mill).

I didn’t get to stuffing this week unfortunately, but you can see my finished circuit below. I got super lucky and there is continuity along those infinitesimally small lines of copper at top right. If work isn’t super crazy I will bop back in here and write an update when I get it stuffed.