- final project

- ∨

grow a tetrahedron - ∨ move a human the sick stick

- ∨ thursday

- ∨ friday

- ∨ saturday

- ∨ sunday

- ∨ monday

- ∨ tuesday

- ∨ bom

i was going to make a tetrahedral sculpture, something recursive and self-similar, that can can unfold into a tree.

but i didn't find a satisfying mechanism to both unfurl and refurl

source: wikimedia - ruggiero

playing with mechanisms

now i got one week to make a final project

( see parkinson's law )

so let's move

move a human

always wanted to make a kickstick

( gondolier style / punting on a skateboard )

some cool people from rise robotics made the first kickstick

they're folks from mit (aaron and some other rise co-founders)

and kyle, parker and jeff from risd

i want to dumb it down a bit and

make a wizard skate stick for myself

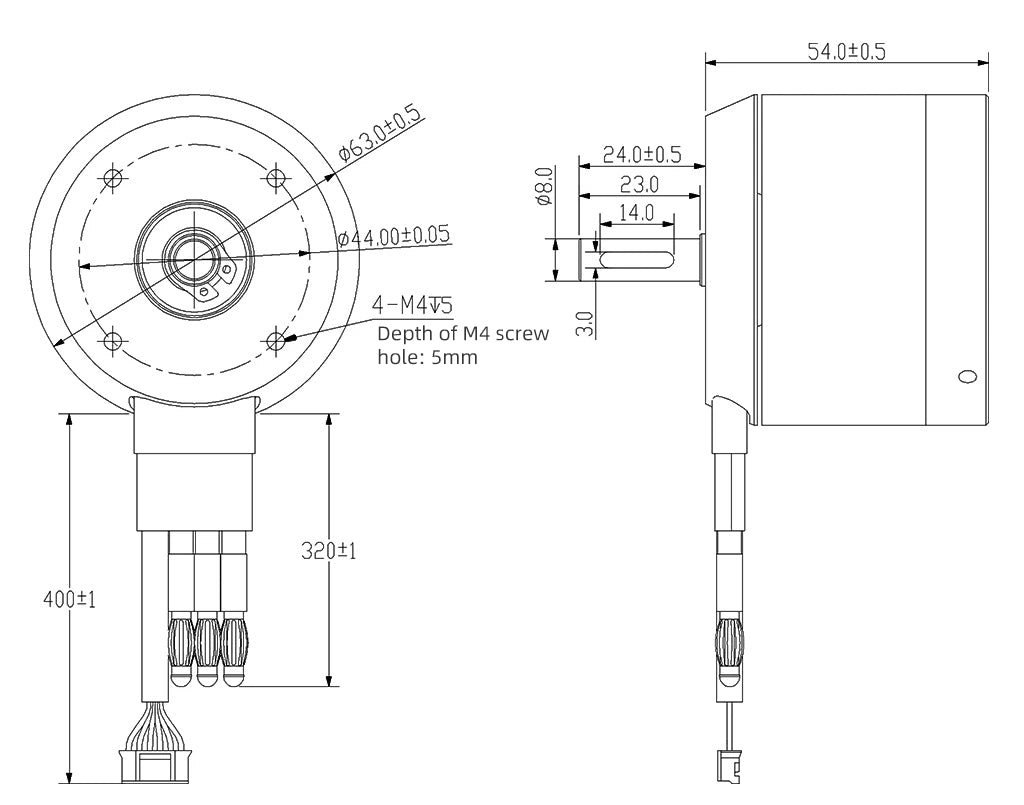

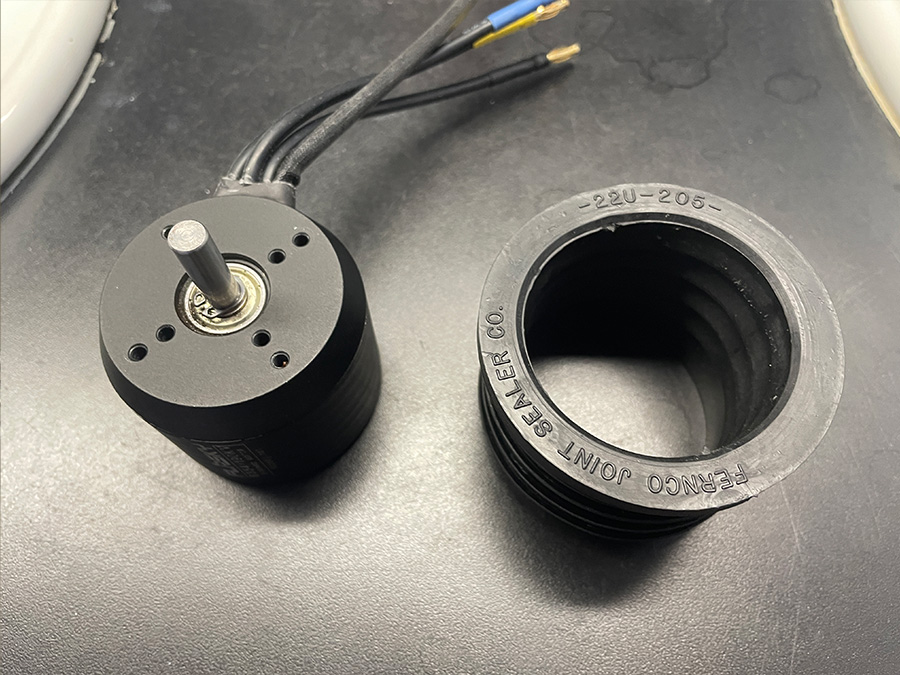

jen ordered me a BLDC

10s of dollars > about $90

got here thursday

50A flipsky 6354 190KV BLDC

• Max Power: 2450 Watts

• Max Current: 65 Amps

• Max Volts: 12S

• Max Torque: 7Nm

• M4 screws

Hole depth = 5mm

1/4in plate = 6.35mm

need M4 at 10-12mm length

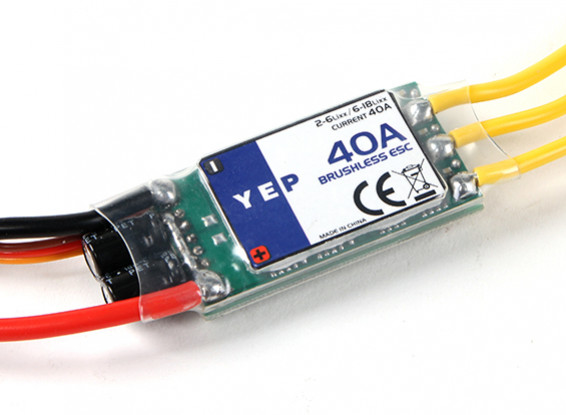

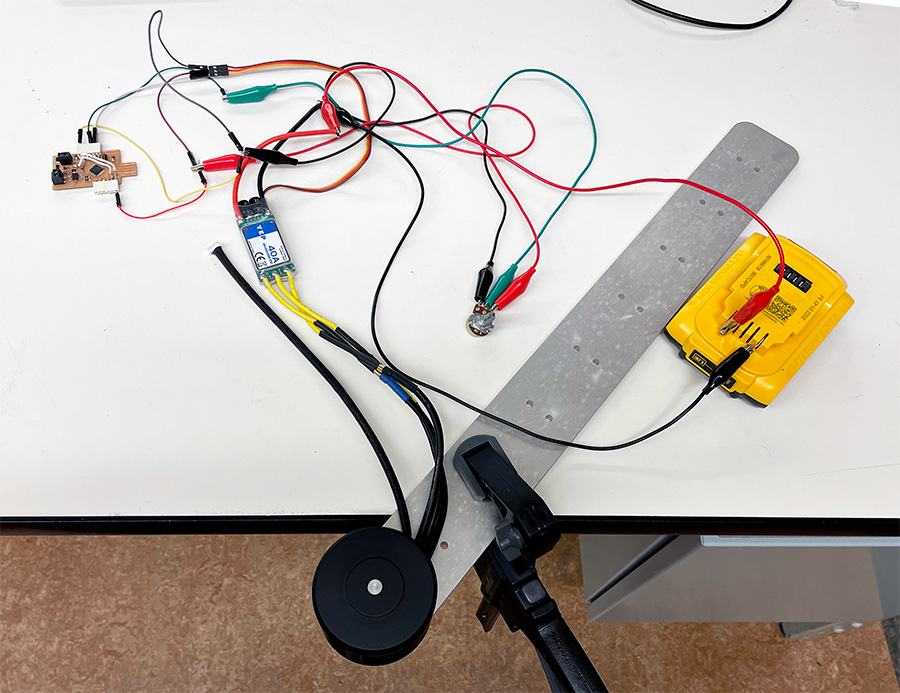

40A ESC

these were stocked at archshops

• Max Cont Current: 40A

• Max Burst Current: 50A for 10 seconds

• Input Voltage: 2-6 cells li-XX or 6-16 Ni-MH/Ni-Cd battery

• BEC: 5.5V/5A Switching BEC

• PWM: 8~16 KHz

$26.95

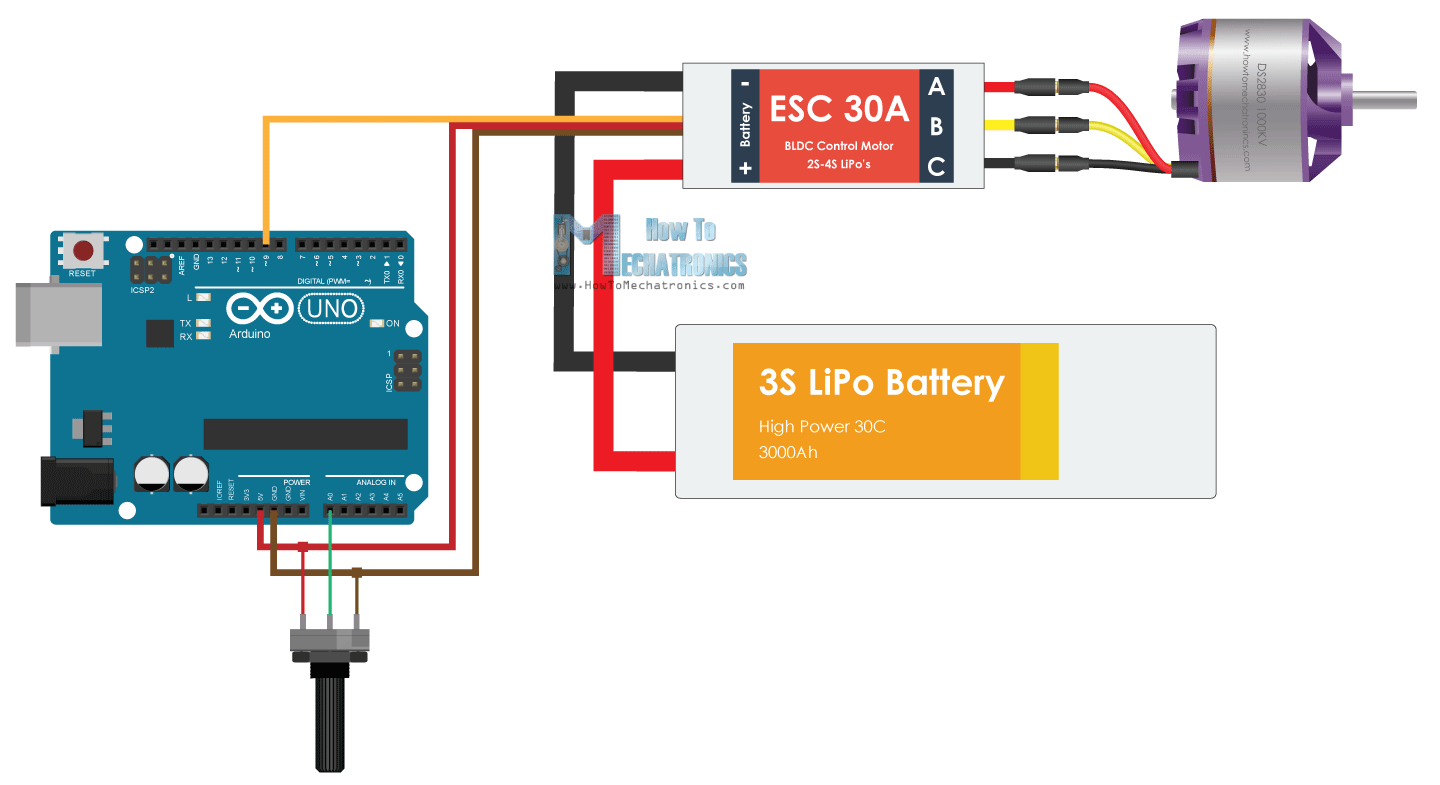

wiring diagram

source

got some motor dimensions

dxf file

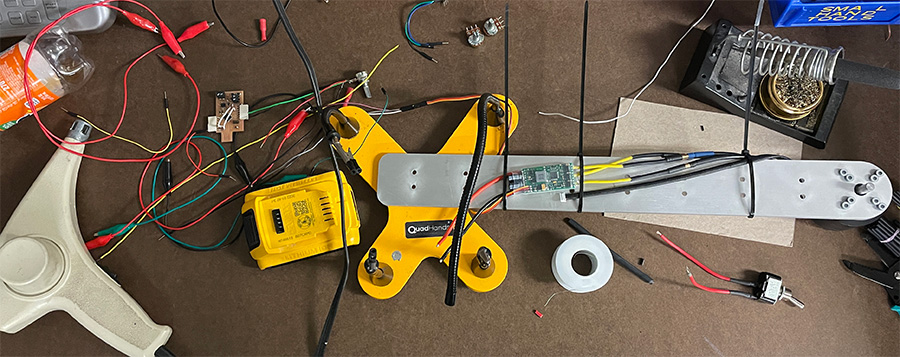

picked up some 1/4" aluminum plate offcuts

thanks will

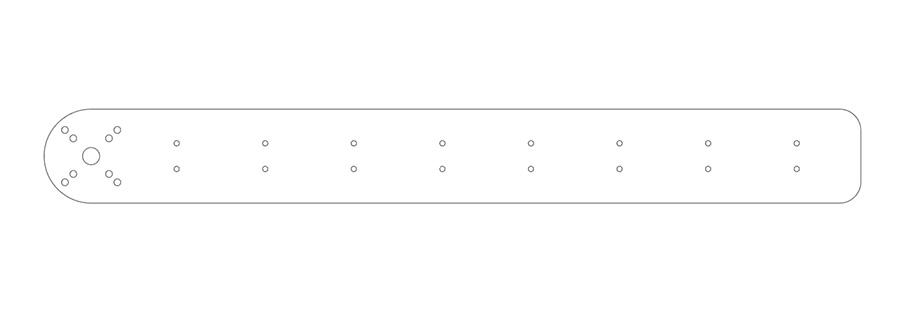

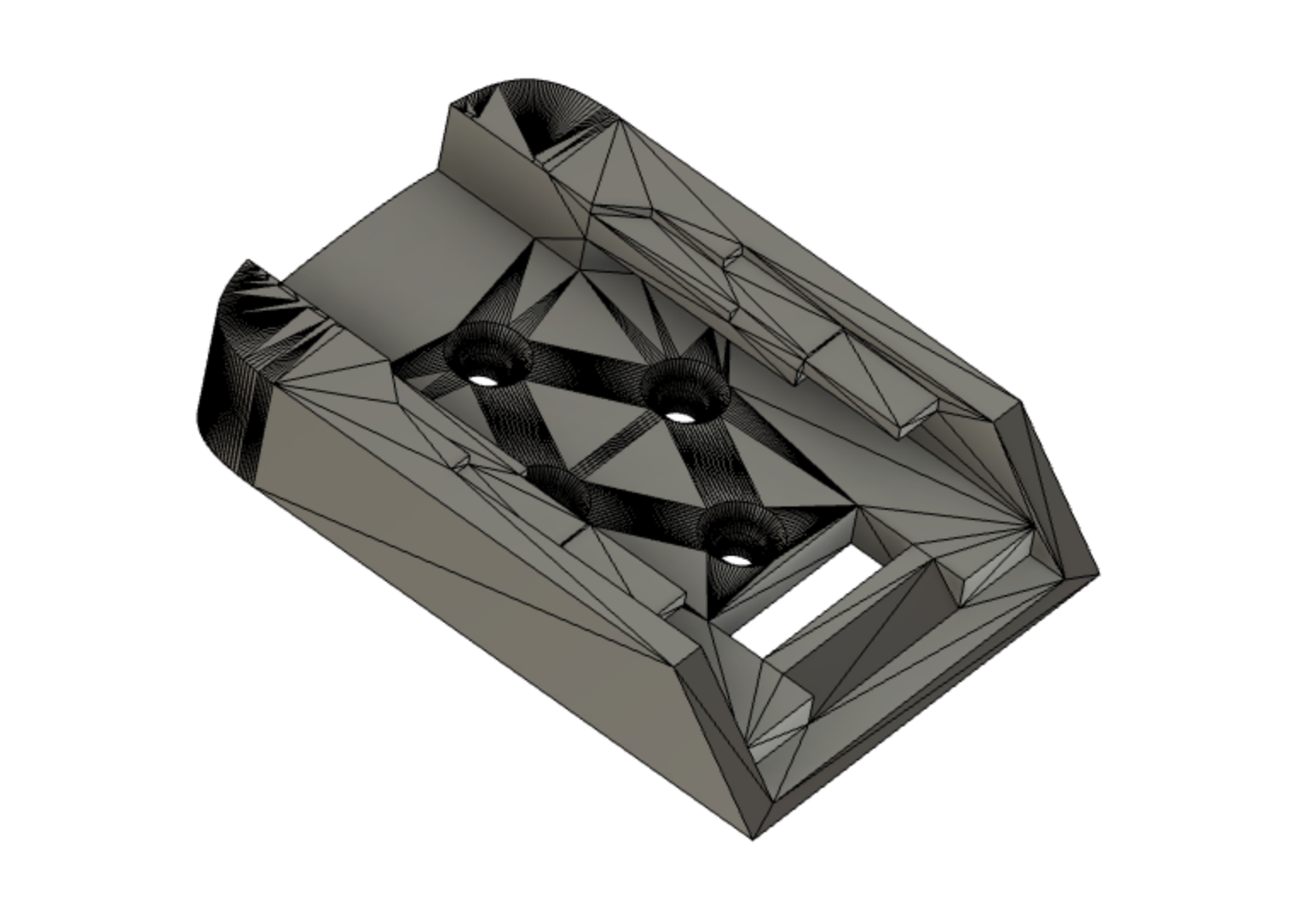

designed a motor mount

M4 bolt holes, holes for drywall screws

made a quick file to waterjet

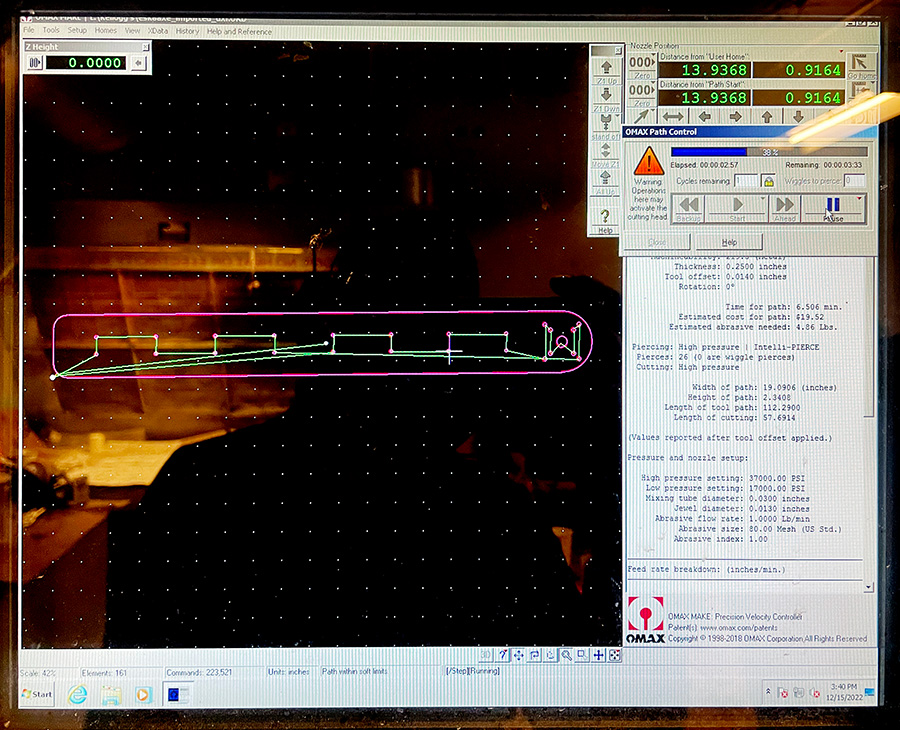

file on the OMAX

thnks shah

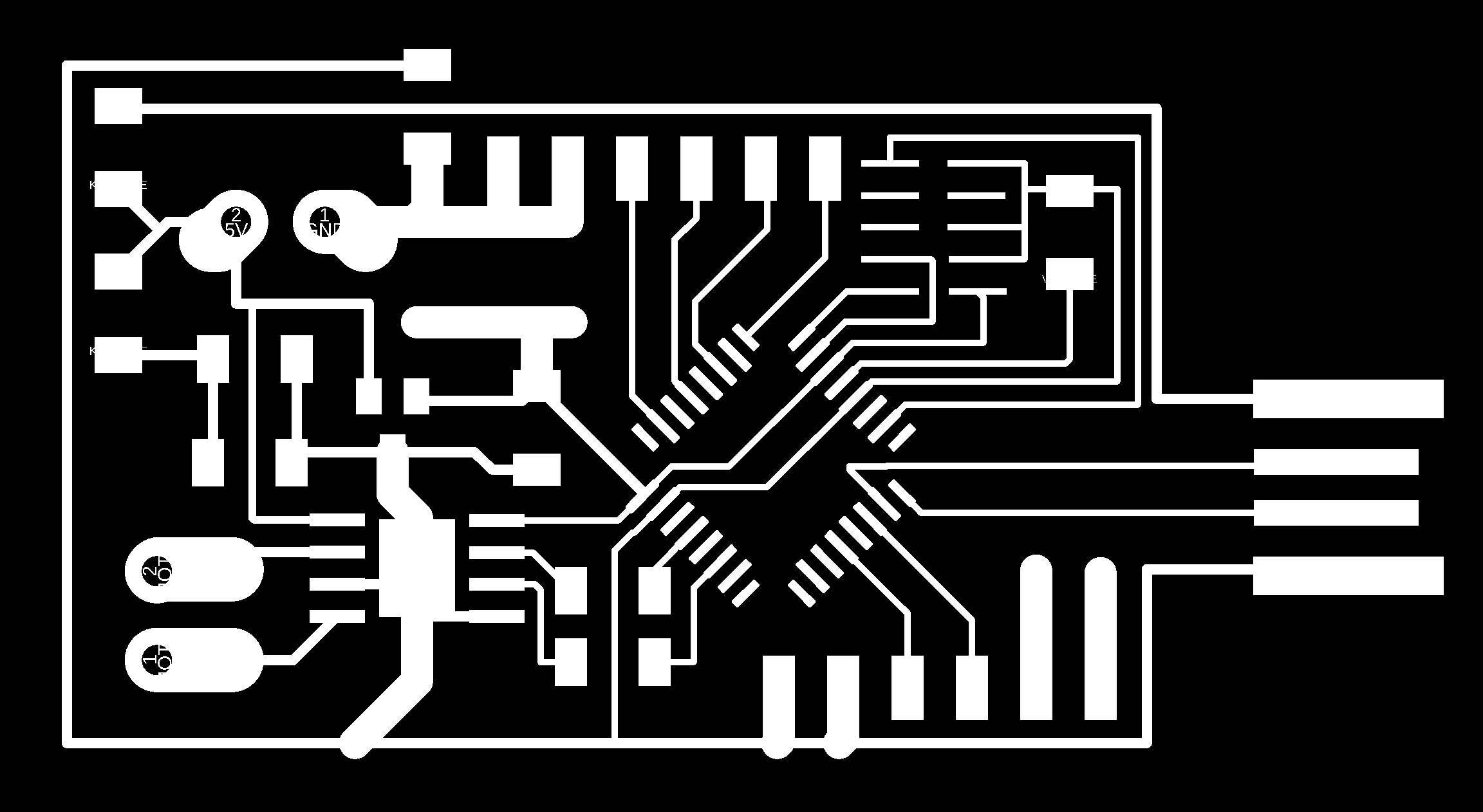

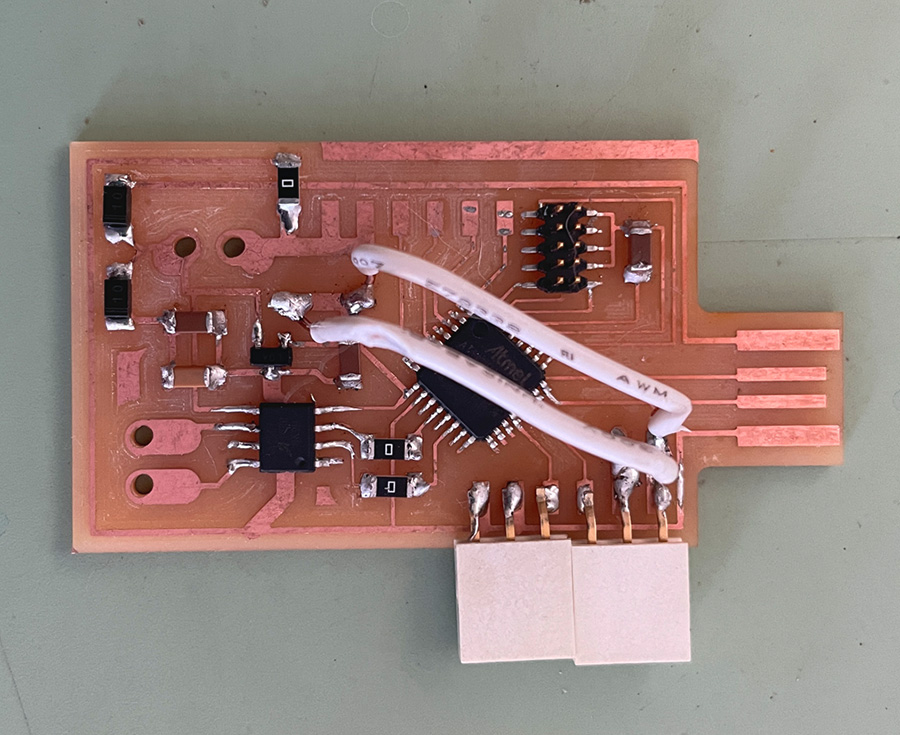

triage: don't have time to design a new board

so gonna use the motor driver board from wk 10

only need VCC, GND

one pin for pot, one pin for pwm to ESC

pin 3 > PA02 - ANALOG

pin 5 > PA04 - ANALOG

motor driver traces png

that'll do

note to future jerome: just get a $3 servo tester, it'll do the trick

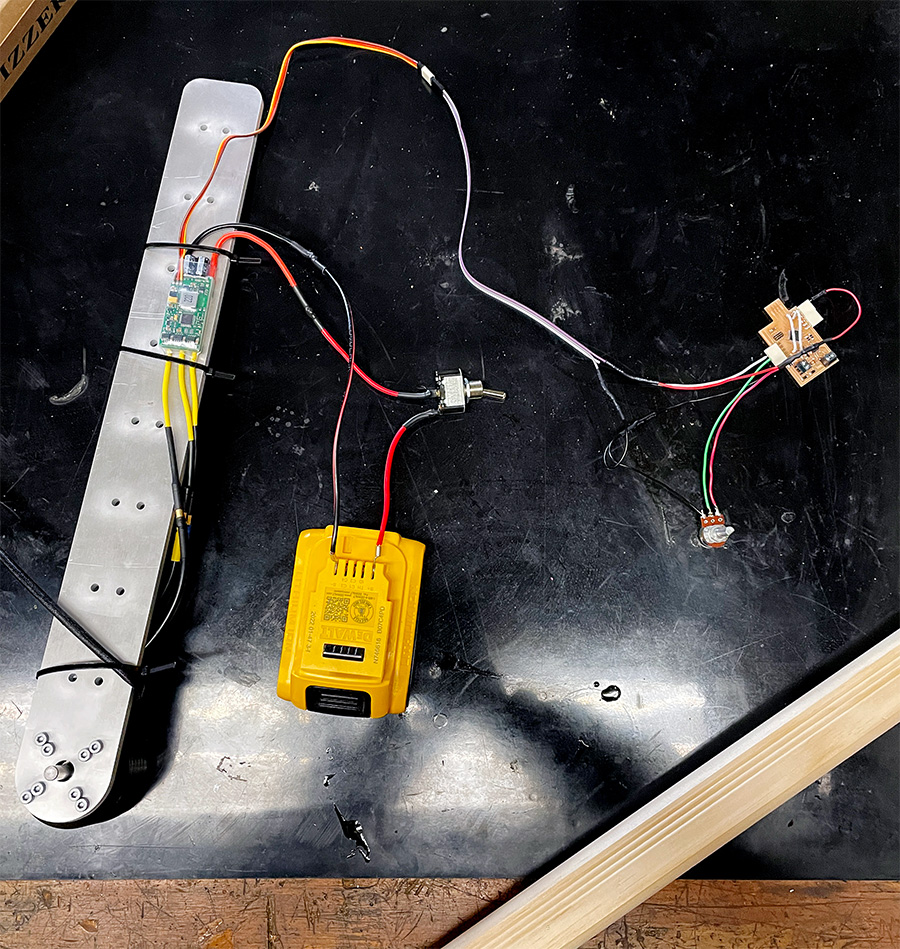

POWER

i wanted to use a lawn mower battery - 60V 5Ah

but it was too big

ESC voltage of "2-6S" means two to six 3.6V cells in Series

so that's 24V max

a dewalt 20V powertool battery is perfect!

B+ pin is hot, B- pin is GND

anthony is the saviour who bestowed his wisdom and patience upon me

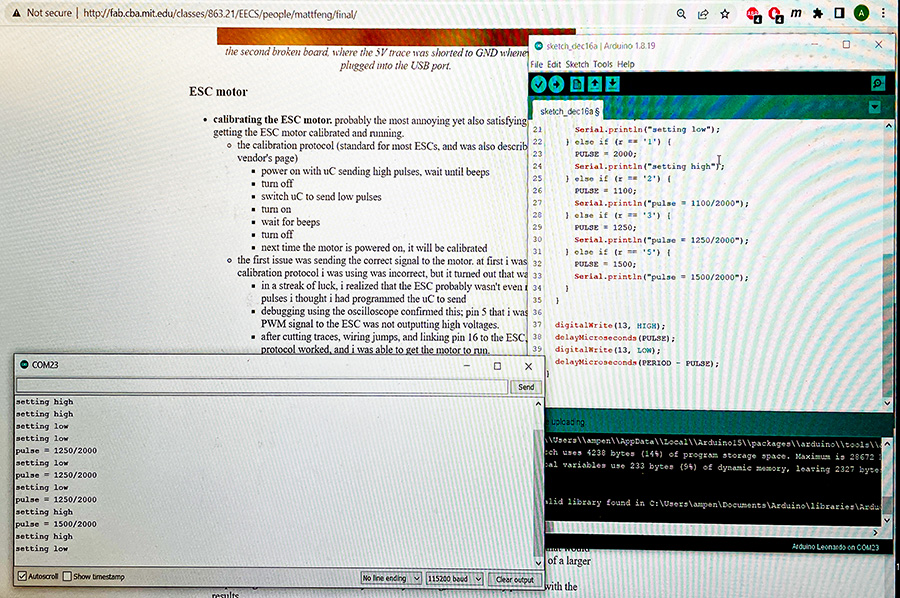

first tested with a Leonardo > basic pot to servo sketch

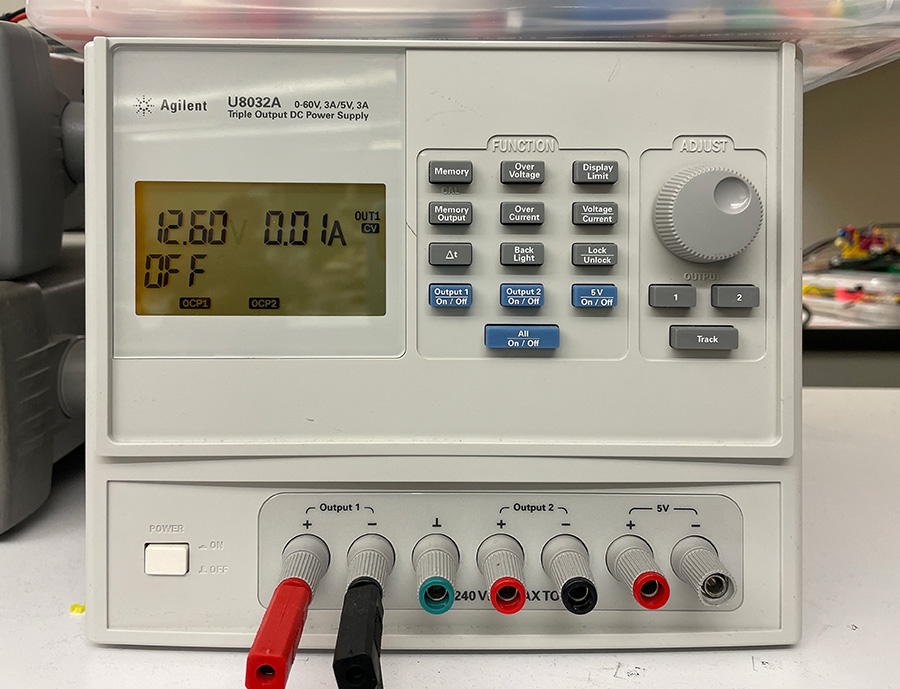

then powered by dc power supply before trying battery

EECS has great drawers of lugs, terminals and junk

then tried a sketch from former fablabber who made a centrifuge

servo ESC sketch

the ESC has a start-up sequence to map the potentiometer values

ESC start-up

DC power supply (not cranked yet)

And Anthony thus wroteth:

"Driving servos with SAMD chips. The typical arduino servo library doesn't (unless updated in the last year) work on SAMD devices. That being said creating your own PWM to set servo position is straightforward in software. It's perhaps a little clunkier in hardware though Neil has done most of that for you here and there is a nice library for the SAMD21 that uses hardware interrupts. Also a number of other choices that you can find on the good ol' google."

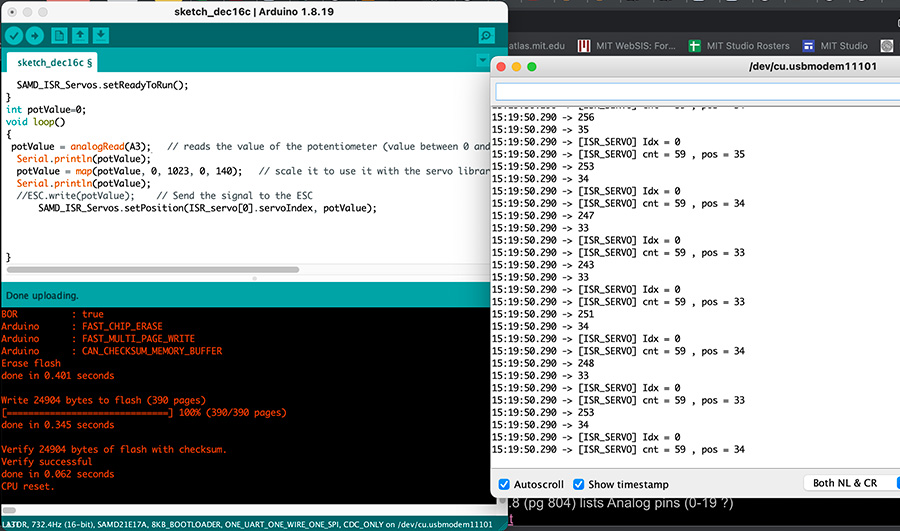

Library for my SAMD21

servo sketch (new library)

then tried my SAMD21 board

needed that new library

but the sample sketch was a bit hairy,

so anthony helped me with that too

combo'ed with the Loop from the first basic sketch

here's the sketch

and we're mobile

solder and heatshrink connections

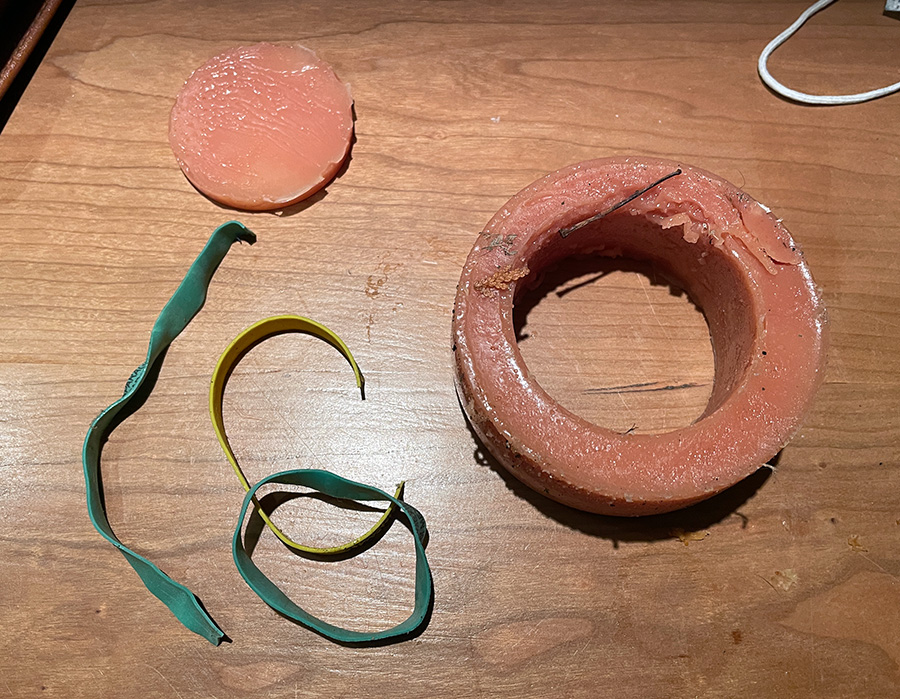

gotta cast a tire

i found a vaccuum hose adapter thats the same size as the motor

and hot glued it onto a mug

i had some leftover urethane from molding/casting week

16 hrs later: goop

one edge didn't seem to set well

it was too soft / wrong durometer

makeshift mold with leftover reoflex

gunk

time to put it together

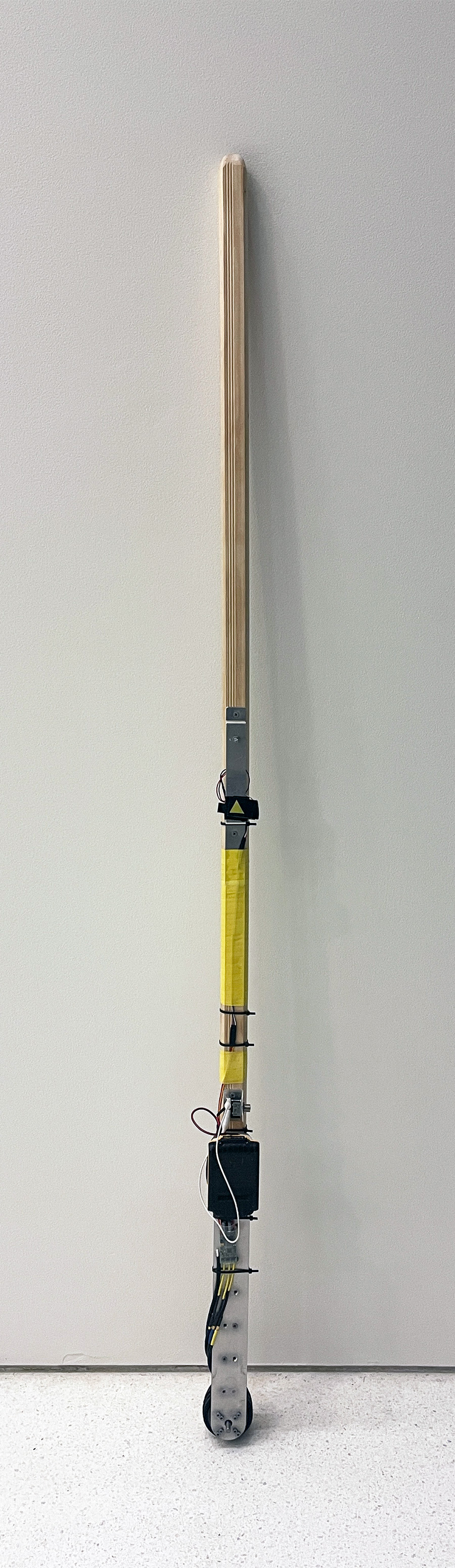

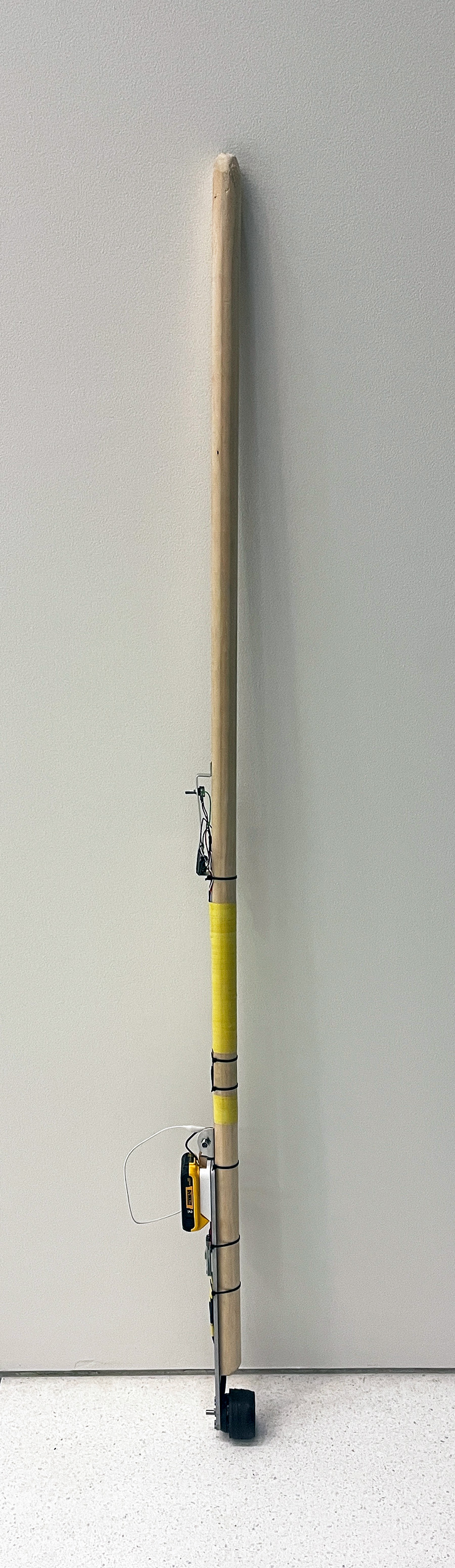

gonna use a wooden hand rail,

leftover from a home renovation

it has a nice flat face

1 1/4" exterior screws

zipties

yellow tape

sick stick... assemble!

countersink some holes

triage: gotta find a tire

kyle suggested 1/4in square o-ring's

i went to home depot to see if they had any o-rings

but instead found some rubber flex plumbing

this flex joint was nominal 2x2in

and fits so snug!

it cuts really easily with an olfa knife

flex joint for the wheel

cuts easily with a knife

kyle on video

kyle helped me 3D print a file

found this dewalt battery holder STL online

edited it in Fusion: removed the rear for the power pins

• Import Mesh >

• Generate Face groups >

• Convert Mesh (parametric)/

• Now its editable as a Solid object. Export STL.

edited stl

tuesday

i couldn't help but go skating this morning

and i took a tumble right before the final review

• busted the power switch

• 3D printed battery holder split

• the ESC seems to have error codes

was able to bypass the switch with alligator clips

it was rideable again

but then the tire started slipping off

twas a fun night! woohoo htmaa!

front

side

• bldc motor (50A) ~ $90

• ESC (40A) ~ $27

• SAMD21 mcu (VCC,GND, 2 pins w/ PWM)

• Dewalt battery 20V ~

• tire: 2" rubber flex joint (plumbing)

• 10K potentiometer ~

• rocker switch for power ~

• M4 x 12mm bolts for motor mount ~

• drywall screws to attach plate to stick ~

• 1/4" aluminum plate to mount motor ~

• tape, zipties

• stick ~

• check out VESC (avoid RC startup sequences)

• use a $3 servo tester to avoid milling a board

• try a finger throttle or slide potentiometer

• recess switches to survive impact

• some donut-like thing to protect hardware from falls

• glue tire to motor

• learn how to program "braking"