Week 1

Principles & Cutting · HTMAA 2025

Week Highlights

Laser Cutter Characterization Results

Project Deliverables

Successfully fabricated and assembled parametric design modular construction kit based on laser cutting origami crease patterns on cardboard.

Applied vinyl stickers and completed takehome assignment

📁 Design Files Available

Download CAD files, view SVG patterns, and access all design assets from this week's assignments

📄 View Design FilesTable of Contents

Course Content

Training & Documentation

CAD/CAM, Laser, Vinyl

This week focuses on the fundamentals of digital fabrication: computer-aided design (CAD), computer-aided manufacturing (CAM), laser cutting, and vinyl cutting. We'll learn the complete workflow from design to finished parts.

This Week's Goals

- Master CAD fundamentals

Parametric design, constraints, and best practices - Laser cutting workflow

Design → CAM → cut → test → iterate - Vinyl cutting techniques

Vector graphics, weeding, application

Assignments

- Parametric construction kit

Design and fabricate a modular construction kit - Vinyl cutting project

Create a vinyl sticker or decal - Documentation

Document the complete design and fabrication process - Safety training

Complete laser cutter and vinyl cutter training

Tools & Materials

- CAD software — Fusion 360, Onshape, or similar

- Laser cutter — Epilog or similar CO2 laser

- Vinyl cutter — Roland or similar plotter

- Materials — Cardboard, acrylic, vinyl sheets

Training Documentation

Comprehensive training notes and media from laser cutter and vinyl cutter sessions.

Laser Cutter Training

Focusing Process

- Focus view follows the laser beam

- Use zoom in/zoom out to get better view

- Press Z, the number with checkmark shows how much to move

- Use focusing stick until it just hits the edge of the material

- Bed moves during focusing process

Cutting Process

- Control P to print, use max power with fast speed

- Go to universal program for cutting

- Turn on power for air compressor

- Press green button to start cutting

Vinyl Cutter Training

Software Setup

- Use Chrome browser

- Go to modsproject.org

- Select Program → Open Program

- Choose Roland vinyl cutter: cut program

- Load image (SVG or PNG format)

- Change dimensions with DPI settings

- For PNG: be careful with curves as it changes pixels

- Can invert to change where black areas are cut

- Set origin (defaults are usually fine)

- Blue lines = cut, red lines = rapids (knife lifts up)

Machine Setup

- Lever sets tension on drive wheels

- Clamp down at the end

- Wheel needs to be in white sections

- Press power (if just turned on)

- Select sheet and press enter

- Use arrow keys to move around

- Hold origin for new origin point

Connection & Starting

- Get device and connect properly

- Can change cut force but probably not necessary

- Send file to cutter

Weeding Process

- Weed early - pick out pieces you don't want

- Fold vinyl over itself, don't go straight up

- Use tweezers for precision

- Use transfer paper to lay front of vinyl on transfer paper

- Peel backing of vinyl off carefully

- Don't just plop things down to avoid air bubbles

- Use squeegee as you lay down to prevent air bubbles

- Consider sticker vs stencil applications

Useful Documentation

Additional resources and guides from Anthony Pennes for laser cutting, vinyl cutting, and image compression workflows.

Anthony's HTMA Guides

Comprehensive guides covering essential digital fabrication techniques, parameter optimization, and workflow best practices.

Image Compression Guide

Essential techniques for optimizing image file sizes, setting up batch processing tools, and maintaining repository efficiency.

📖 View GuideLaser Cutting Guide

Complete laser cutting workflow including safety, parameter optimization, joint design, and troubleshooting techniques.

📖 View GuideVinyl Cutting Guide

Detailed vinyl cutting techniques, software setup, machine operation, and weeding processes for professional results.

📖 View GuideNote: These guides were created by Anthony Pennes and are maintained as supplementary resources for the HTMAA course. View original Slack message for context.

Class Week Resources

Official course resources for project management, computer cutting, and Git recitation materials.

Lecture Information

-

Project Management - MIT Academy

Comprehensive guide to project management including file synchronization, version control (Git, GitHub, GitLab), web development, and documentation workflows. Covers essential tools for managing digital fabrication projects.

-

Computer Cutting - MIT Academy

Complete resource for computer-controlled cutting including laser cutting, vinyl cutting, and other cutting technologies. Covers safety, machine operation, material selection, and design considerations.

Recitation Information

-

Hands-on Git tutorial covering version control fundamentals, repository management, collaboration workflows, and best practices for digital fabrication projects.

Laser Cutter Characterization Group Assignment

Systematic testing and documentation of laser cutter parameters for optimal cutting performance. Assignment started: September 11, 2025 Assignment completed: September 16, 2025

Machine Specifications

Available Lasers

- CO₂ Laser: 75W (large machine)

- CO₂ Laser: 60W (small machine)

- Fiber Laser: Back of lab

Test Parameters

- Rate: 500 pulses per inch (PPI)

- Power: 100%

- Speed: 30% (increased by 2.5% each test)

Laser Cutter System Details

Universal Laser Systems CO2 Laser Specifications

Hardware & Software

- Laser System: Universal Laser Systems CO2 Laser

- Control Software: Universal Control Software

- Design Software: Inkscape for vector design and cutting

- File Transfer: Inkscape used to send cuts directly to laser

Print Settings & Color Coding

- Red Line (0.001"): Vector cut - full power cutting

- Blue Line (0.001"): Engraving - raster engraving

- Optimization: Used weak vector cut for engraving to save time

- Line Weight: 0.001" for both cutting and engraving operations

Workflow Note: The Universal Control Software provides precise control over laser parameters, while Inkscape serves as the design interface for creating and sending cutting jobs. The color-coded line system allows for efficient batch processing of both cutting and engraving operations in a single job.

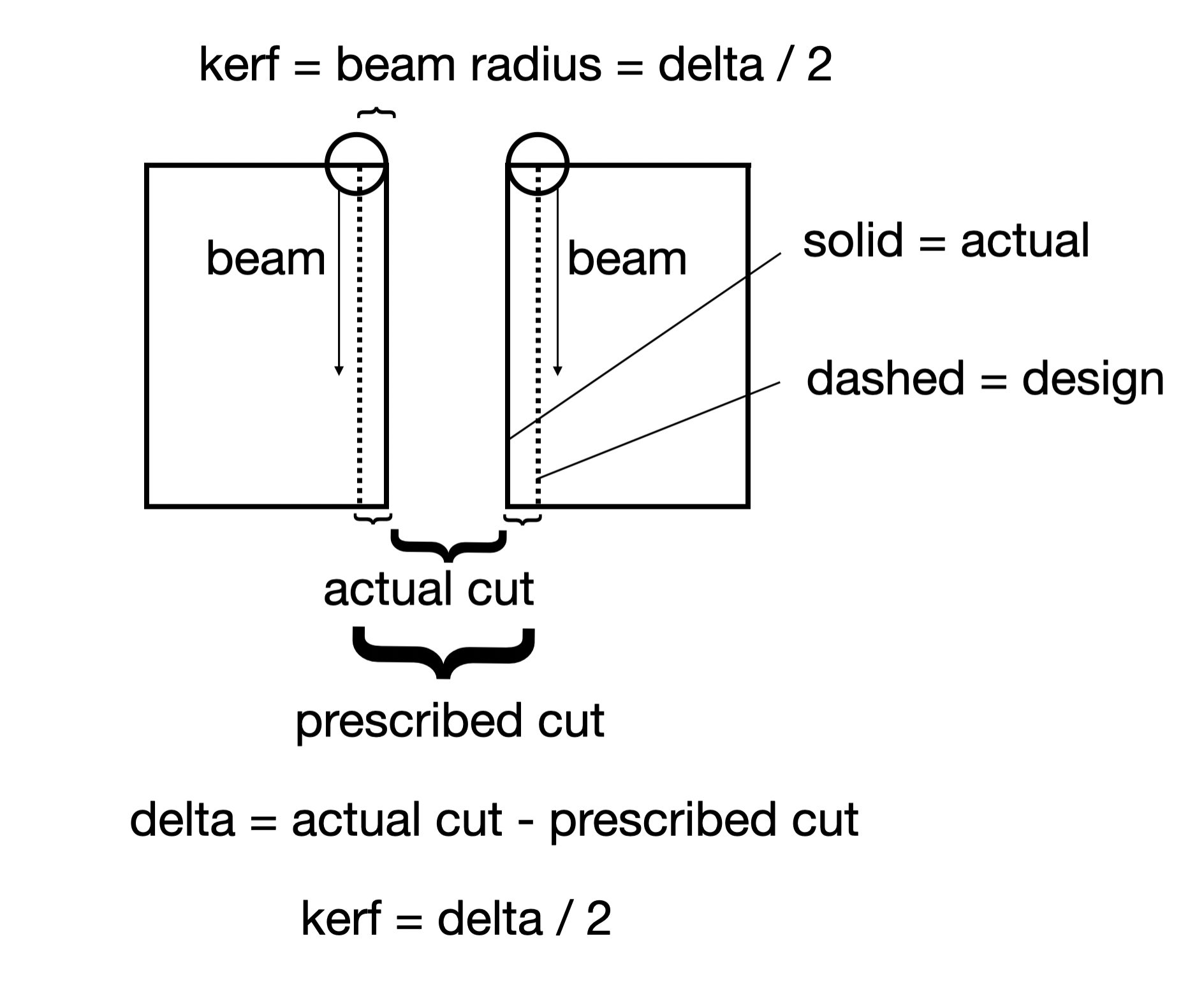

Focus & Positioning

- Focus Point: Cut at the focal length (white part of the focusing stick)

- Kerf Measurement: Measure deltas between intended and actual cut dimensions

- Focus Accuracy: Critical for achieving clean, precise cuts

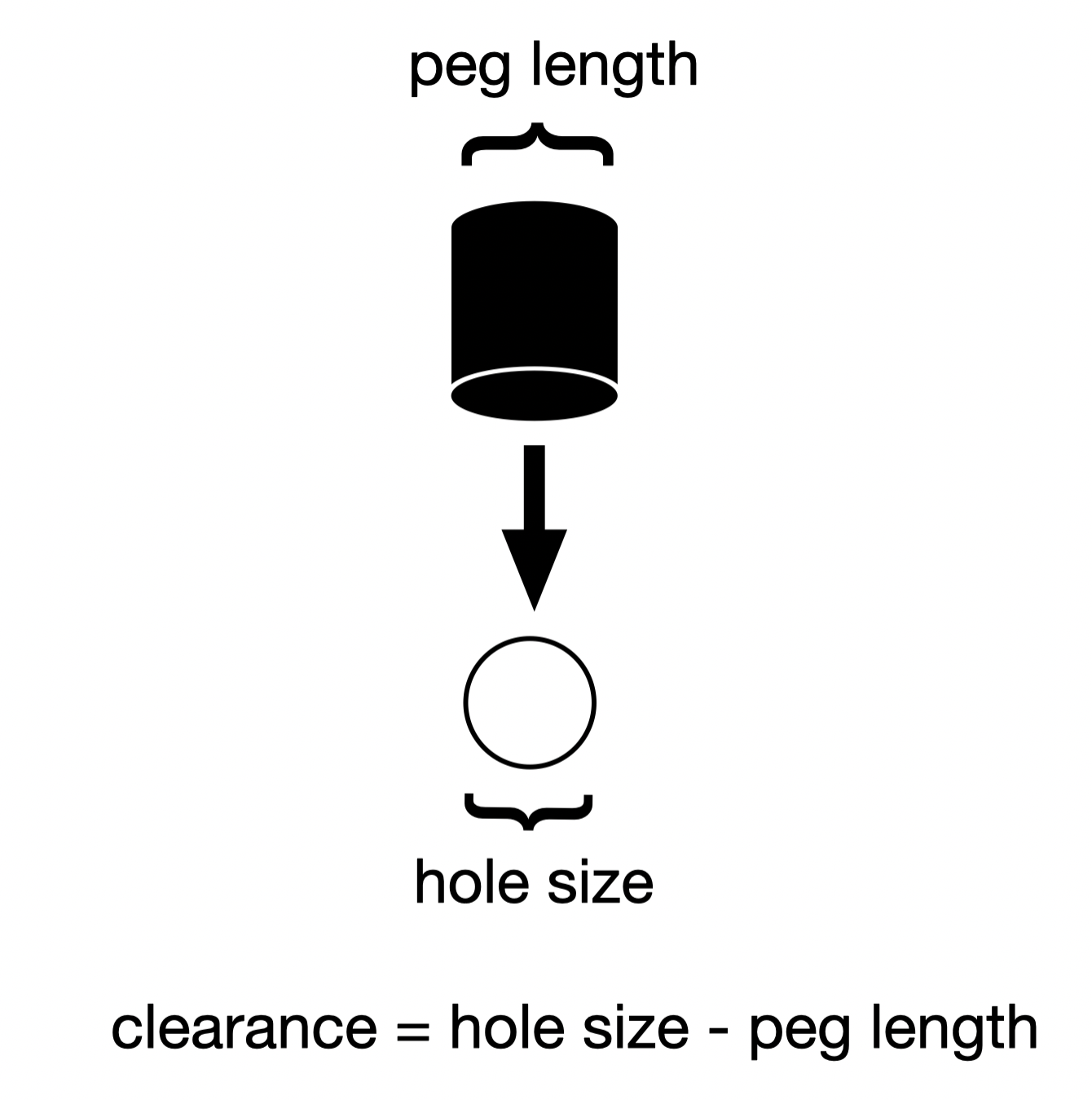

Joint Design & Clearance

Joint Type

Finger joint - interlocking design for structural connections

Clearance Definition

Size of the slot that provides tight enough fit for assembly

Material Considerations

Material choice significantly impacts joint quality and assembly precision

Key Learnings

- Speed increment of 2.5% provides systematic testing progression

- Focus accuracy is critical for dimensional precision

- Kerf measurement essential for compensating cut width in designs

- Material selection directly impacts joint quality and assembly success

- Systematic parameter testing reveals optimal settings for different materials

Results

Comprehensive analysis of kerf and clearance measurements from systematic laser cutter testing.

Interactive Data Analysis

View and interact with the complete dataset in Google Sheets:

Measurement Methods

Systematic measurement approach for characterizing laser cutter kerf and joint clearance using precision calipers.

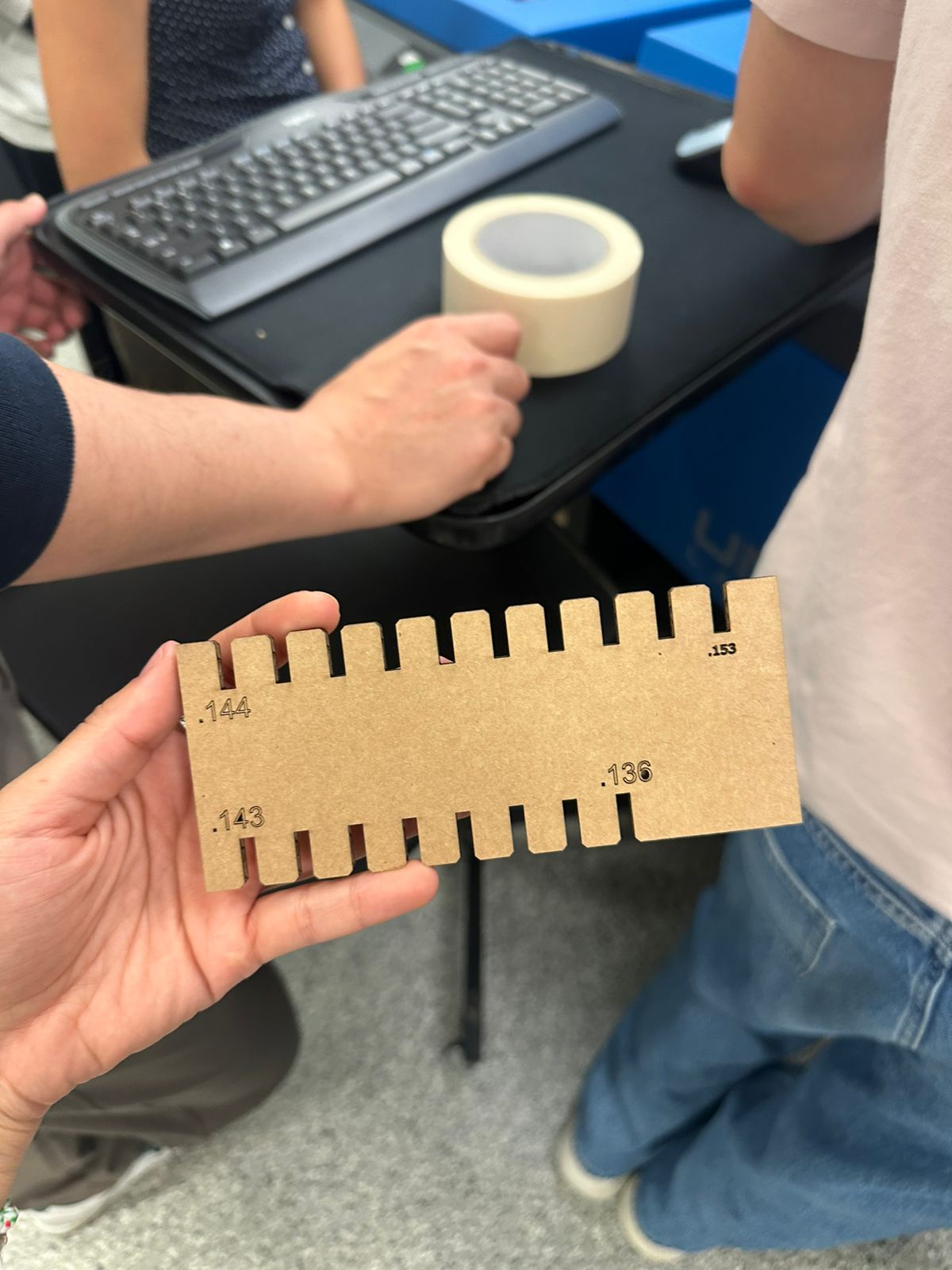

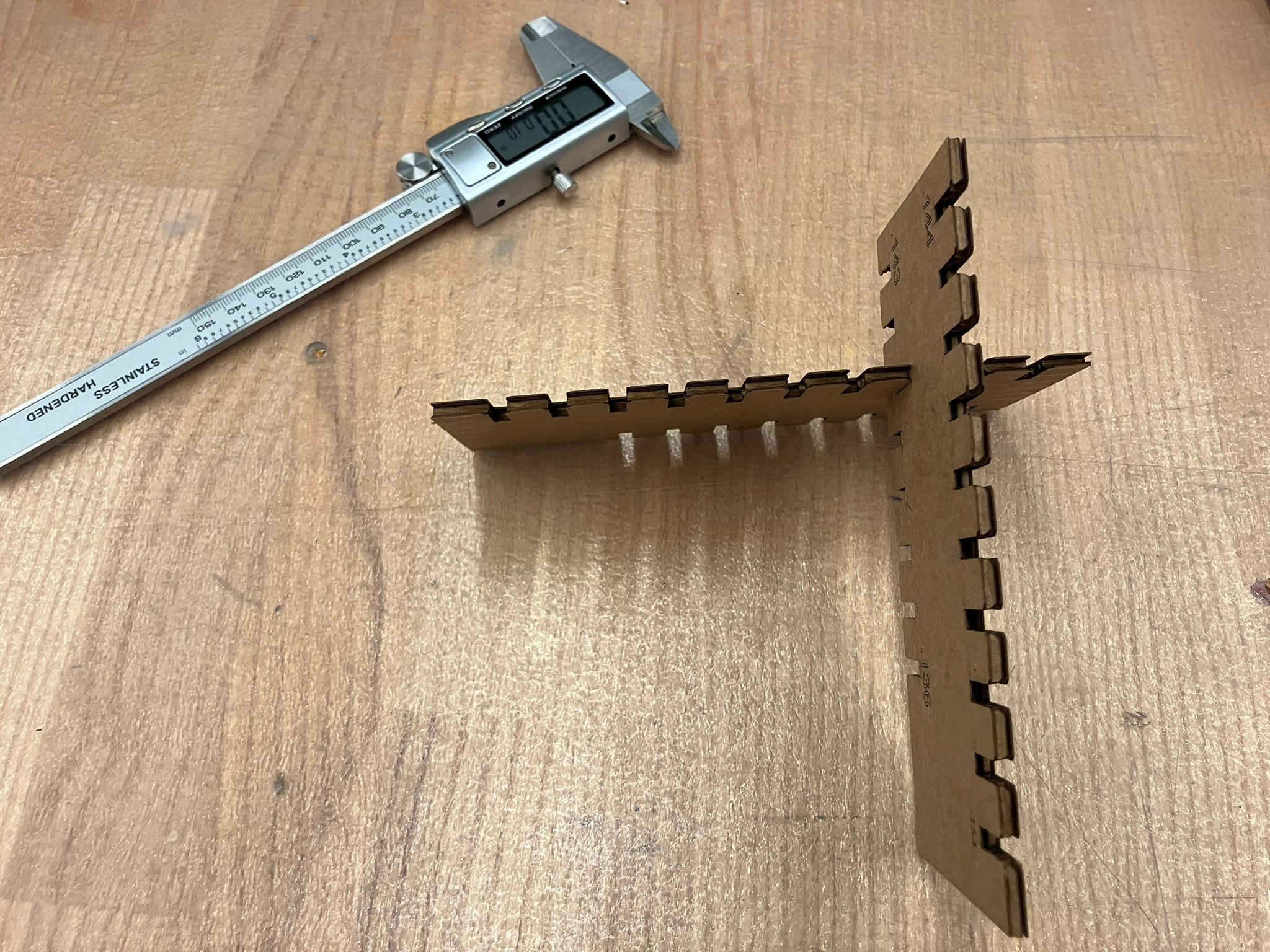

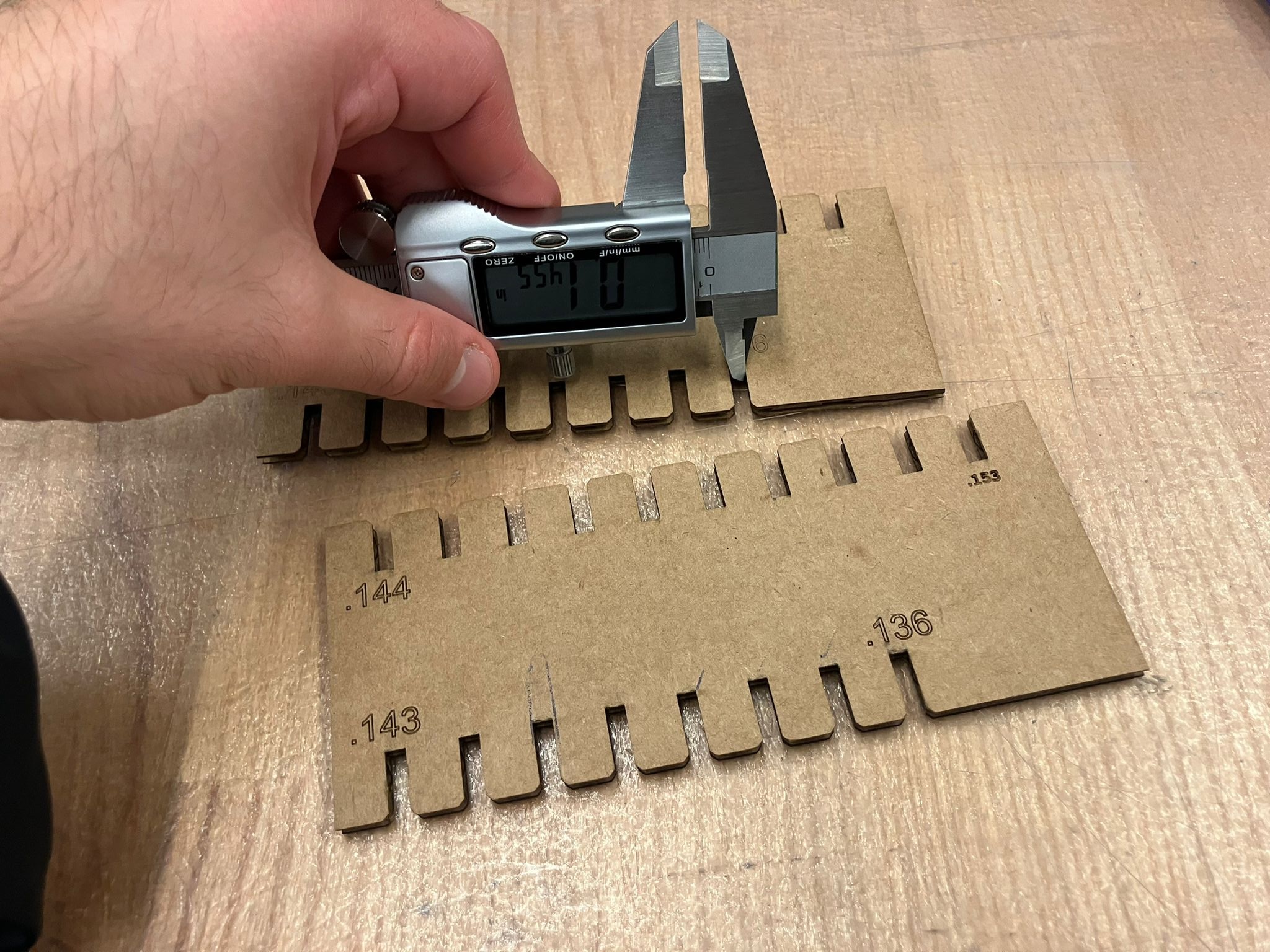

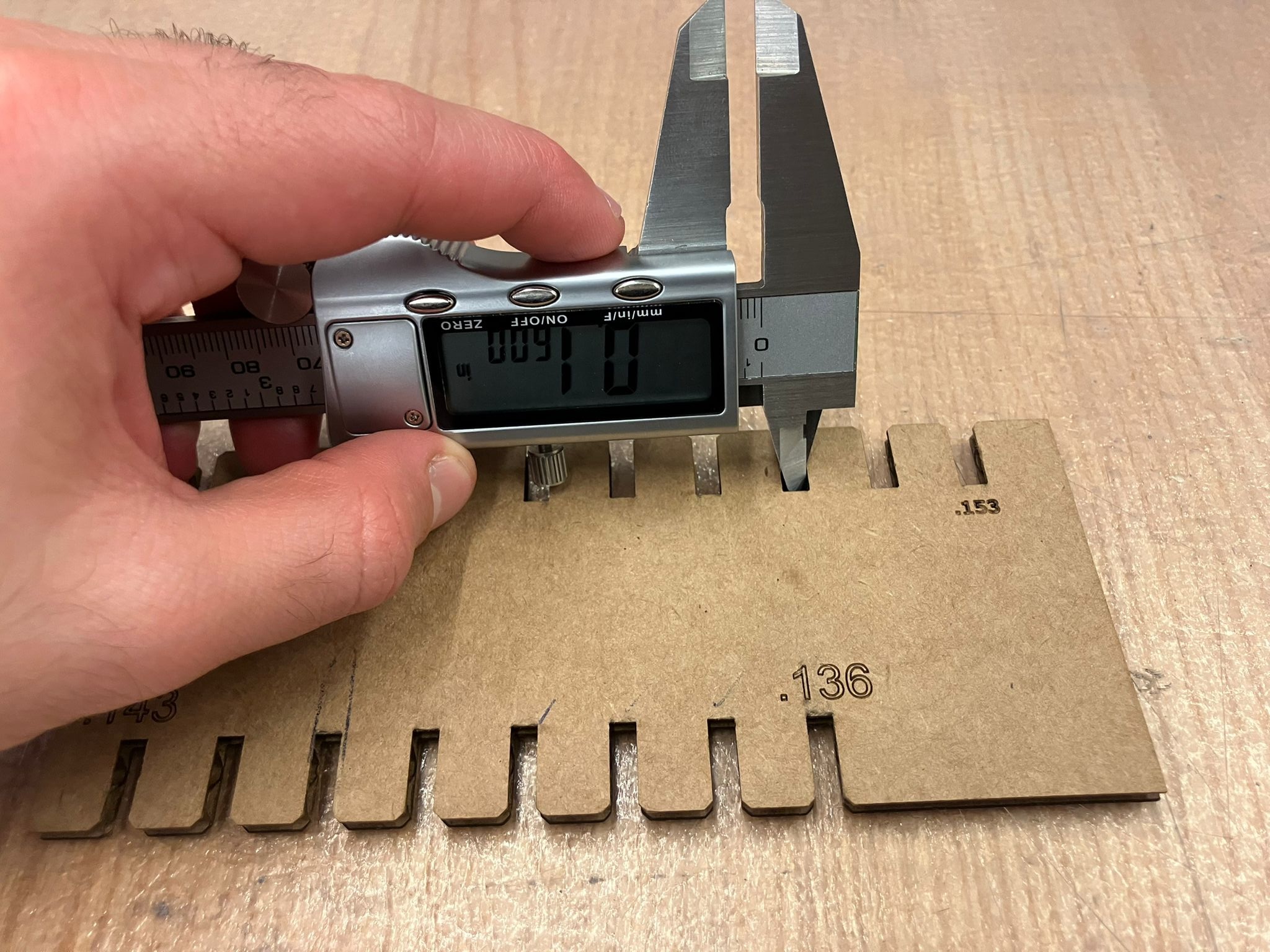

Peg and hole measurement setup

Top measurement view

Bottom measurement view

Measurement Protocol

- Kerf Analysis: Three measurements were taken for each prescribed cut dimension on the joint gadget during laser cutter training

- Clearance Analysis: Three measurements were taken for both hole and peg dimensions

- Clearance Calculation: Clearance = Hole Size - Peg Size (negative values indicate interference fit)

- Statistical Analysis: Averages and standard deviations calculated for precision assessment

Kerf Concept Diagram

Kerf Definition: The width of material removed by the laser beam during cutting. Measured as the difference between prescribed cut dimensions and actual cut dimensions.

Kerf Analysis Results

| Prescribed Cut (in) | Actual Cut #1 (in) | Actual Cut #2 (in) | Actual Cut #3 (in) | Average (in) | Std Dev (in) | Avg Kerf (in) |

|---|---|---|---|---|---|---|

| 0.136 | 0.142 | 0.1405 | 0.1445 | 0.1423 | 0.0020 | 0.0032 |

| 0.137 | 0.142 | 0.1475 | 0.149 | 0.1462 | 0.0037 | 0.0046 |

| 0.138 | 0.148 | 0.1495 | 0.147 | 0.1482 | 0.0013 | 0.0051 |

| 0.139 | 0.146 | 0.146 | 0.1475 | 0.1465 | 0.0009 | 0.0038 |

| 0.143 | 0.155 | 0.1555 | 0.1545 | 0.1550 | 0.0005 | 0.0060 |

| 0.144 | 0.1535 | 0.153 | 0.15 | 0.1522 | 0.0019 | 0.0041 |

| 0.152 | 0.163 | 0.1655 | 0.165 | 0.1645 | 0.0013 | 0.0063 |

| 0.153 | 0.166 | 0.169 | 0.168 | 0.1677 | 0.0015 | 0.0073 |

Clearance Concept Diagram

Clearance Definition: The dimensional difference between hole and peg sizes. Negative values indicate interference fit (hole smaller than peg), while positive values indicate clearance fit.

Clearance Analysis Results

| Measurement | Sample #1 (in) | Sample #2 (in) | Sample #3 (in) | Average (in) | Std Dev (in) |

|---|---|---|---|---|---|

| Peg Size | 0.1505 | 0.1535 | 0.1505 | 0.1515 | 0.0017 |

| Hole Size | 0.156 | 0.1575 | 0.1545 | 0.1560 | 0.0015 |

| Clearance | -0.0055 | -0.004 | -0.004 | -0.0045 | 0.0009 |

Key Findings

0.0049 inches (4.9 thousandths)

-0.0045 inches (interference fit)

±0.0017 inches (high precision)

±0.0009 inches (very consistent)

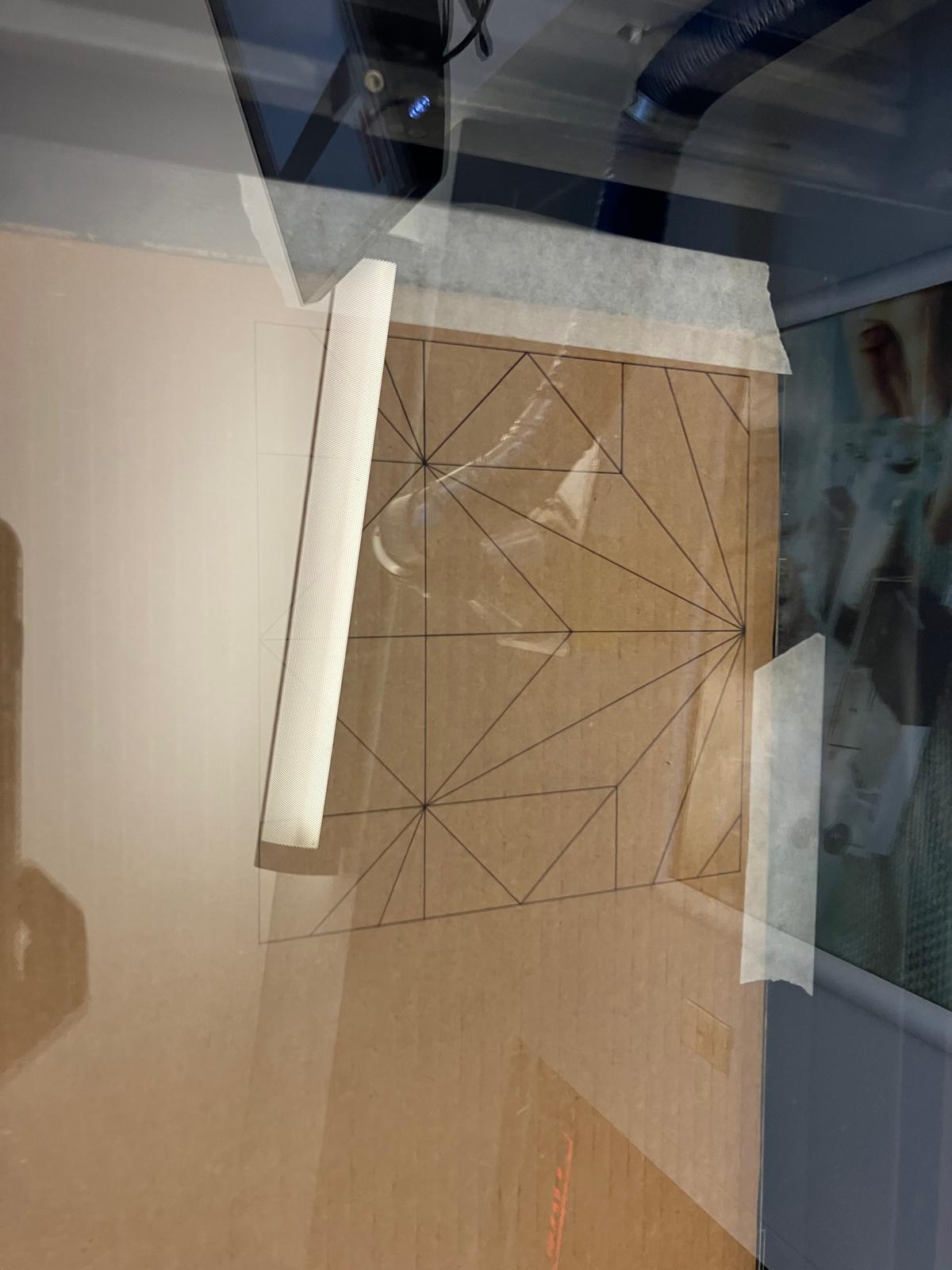

Parametric Construction Kit Individual Assignment: 3D Parametric Design

Design and fabricate a modular construction kit using laser cutting and vinyl cutting techniques. Assignment started: September 10, 2025. Assignment completed: September 15, 2025

Preparation & Planning

Initial research and clarification discussions with instructors and classmates to understand assignment requirements and technical constraints.

Key Clarifications

Technical Insights

Acknowledgments

Special thanks to Erik Demaine for guidance on vinyl cutting crease patterns and fold differentiation techniques, and Anthony Pennes for clarifying assignment requirements, file formats, and material options. Their expertise was invaluable in understanding the technical constraints and design possibilities for this project.

Design Process

- Research and ideation for construction kit design

- Create parametric CAD model with adjustable parameters in Fusion 360

- Generate CAM toolpaths for laser cutting

- Test cut on cardboard to verify fit and function

- Iterate design based on test results

- Final cut on appropriate material

- Design and cut vinyl project (separate from construction kit)

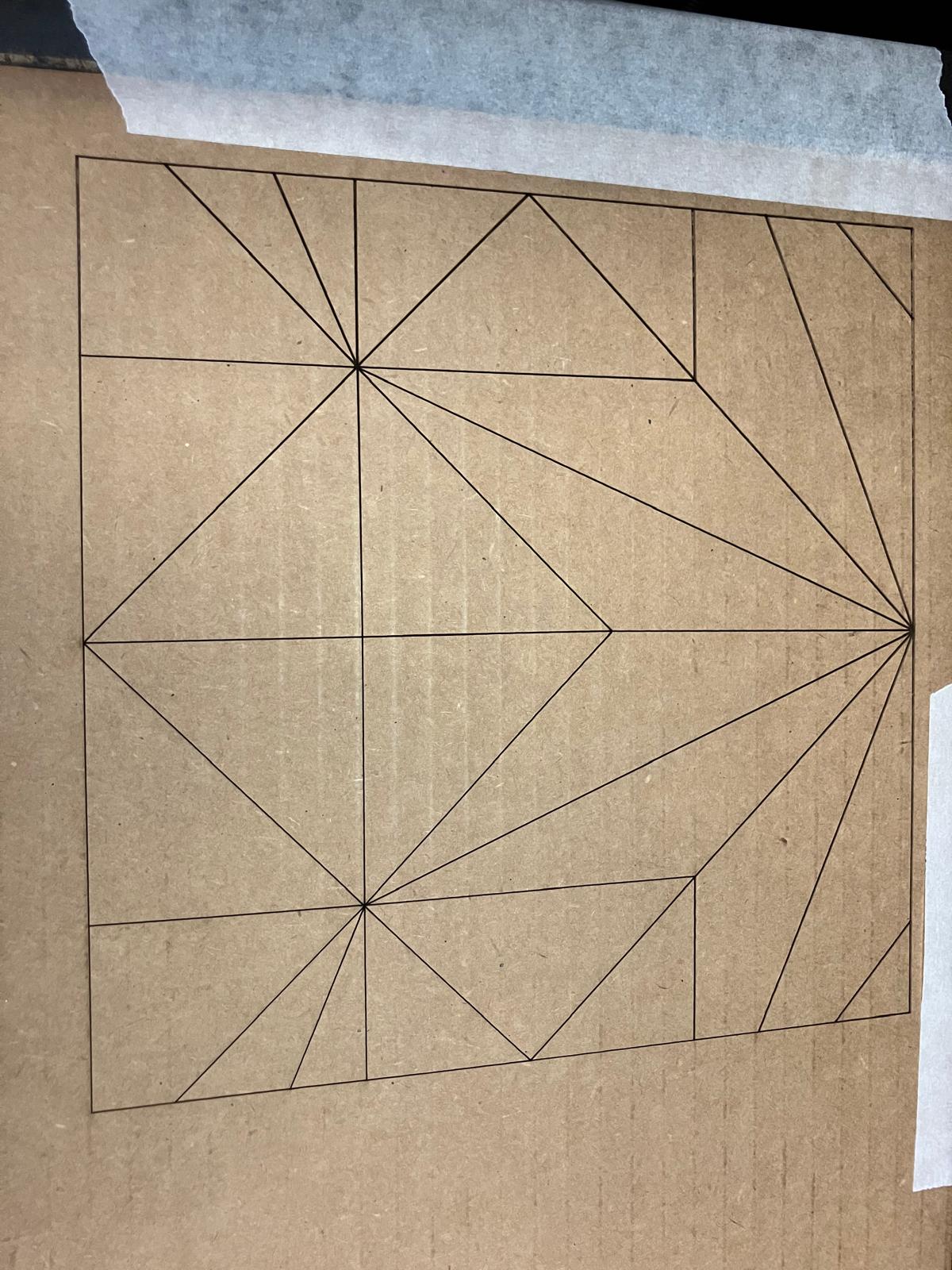

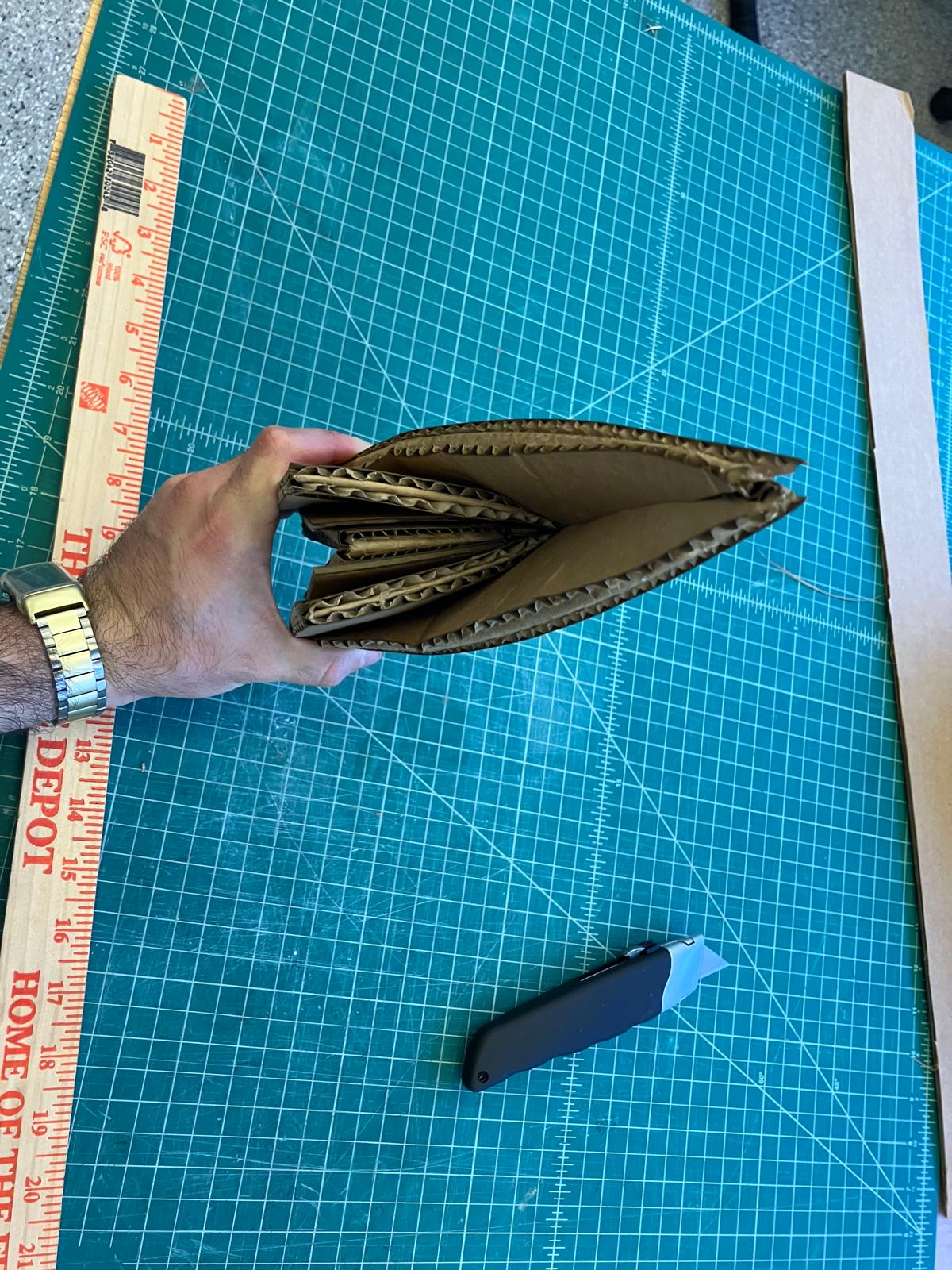

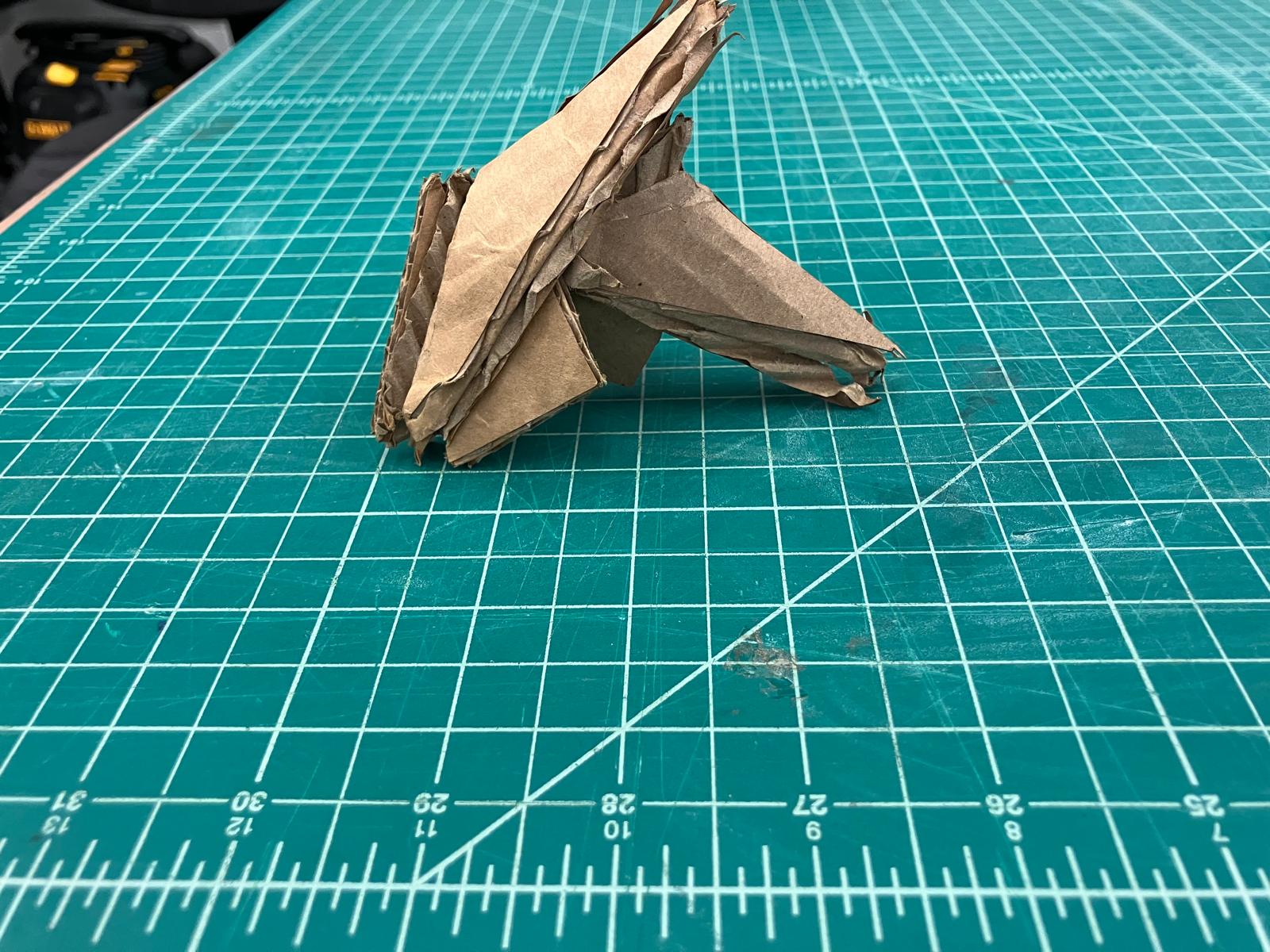

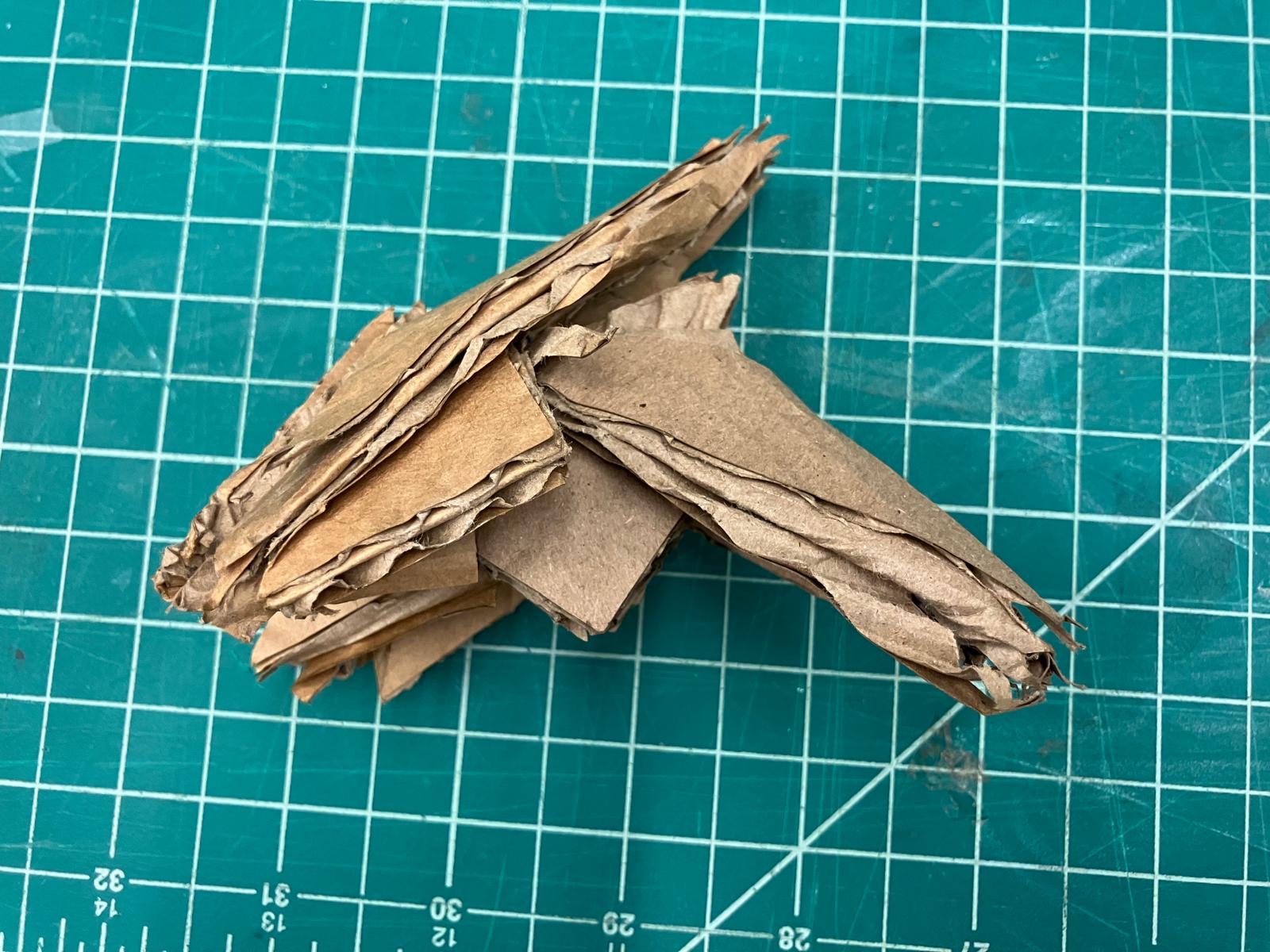

Hand‑folded Prototype Assembly

I hand‑folded the crease pattern to validate the assembly. The parts do come together when the folds are reasonably close to the intended lines. A second, refolded gadget produced a noticeably cleaner assembly.

Single Gadget

Double Gadget

Assembly Detail

Full Pattern Failure

We tried cutting the full crease pattern on one side. It failed when layers with opposite cuts overlapped and had to be push‑folded through during the final folding step — the piece broke.

First Success Folded Single Gadget

First assembly of two gadgets. Folds were smooth after separating mountain and valley cuts onto opposite sides to avoid breaking during push‑folds over multiple layers. The shop cardboard was tight in the assembly pocket; thinner Amazon box cardboard folded by hand fit better. Next step: make the laser‑cut pattern more exact.

Cut Strategy Videos

Left to right: clear mountain cut, flip and cut the opposite side, clear valley cut.

Mountain vs Valley Sides

Measurements confirming mountain vs valley sides.

First Gadget Assembly

Side profile and insertion step demonstrating clean folds without tearing.

Double Gadget Cut Variations

Exploring double‑part strategies: sequential cuts, flips between sides, and opposite‑side cuts.

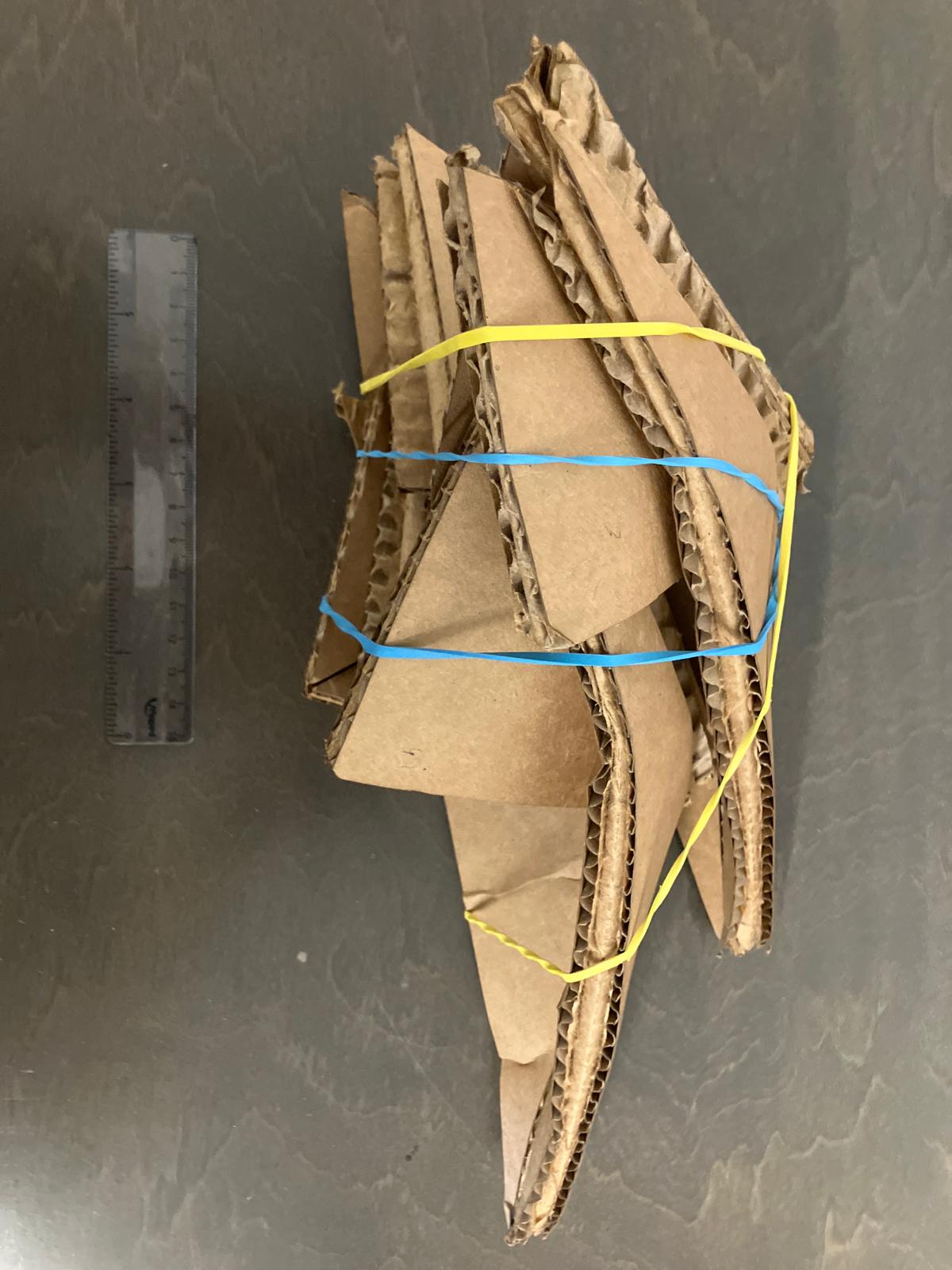

Double Gadget — Rubber Band Assist

Temporary rubber band used to hold alignment while completing final folds.

First Success Assembly

Switched to thinner Amazon cardboard because the shop cardboard was too thick for the assembly pocket. The Amazon box folded by hand fit perfectly and assembled smoothly. Three gadgets worked with the thinner material. Rubber bands are just for compression — they assemble without them, though the bands make it easier to keep them as one unit during insertion into the next gadget.

Quadruple Cut Strategy

Scaling up to quadruple cuts: sequential cuts, flips between sides, and opposite-side cutting strategies.

Double Gadget — Amazon Cardboard (No Support)

Three views of the double gadget assembled with Amazon cardboard, showing clean folds and proper fit.

Assembly Process with Support

Assembly sequence showing compression, support positioning, and insertion process for stable construction.

Triple Gadget — Final Assembly

The culmination: triple gadget assembly demonstrating successful scaling with Amazon cardboard and support techniques.

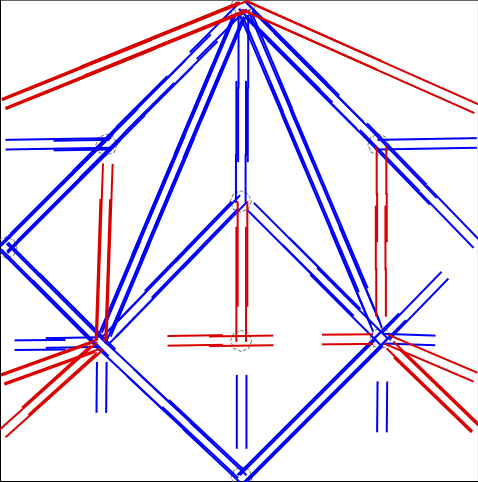

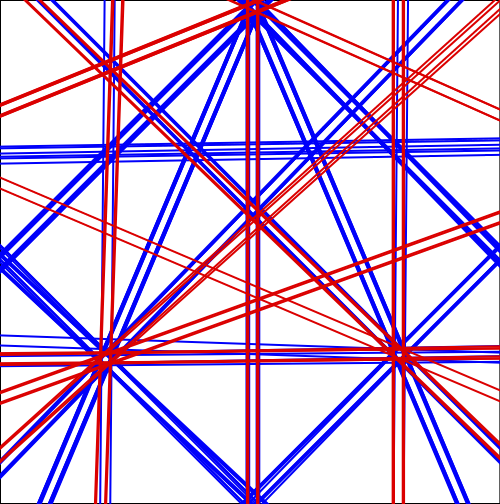

Further Refinements: Thick Origami

Applying thick‑origami concepts to avoid layer collisions and enable folding with real material thickness.

Guidance from Erik Demaine

From a discussion with Erik Demaine: double each crease into parallel offsets and open vertex regions as polygons to prevent collisions. A uniform spacing works for a first pass, but for correctness the spacing between the doubled creases should depend on how many layers lie between faces in the final folded state. I plan to estimate per‑crease layer counts from an unfolded model and adjust offsets accordingly.

Citation: Jason S. Ku and Erik D. Demaine, “Folding Flat Crease Patterns With Thick Materials”, Journal of Mechanisms and Robotics, 8(3), June 2016, pp. 031003‑1–6. View paper

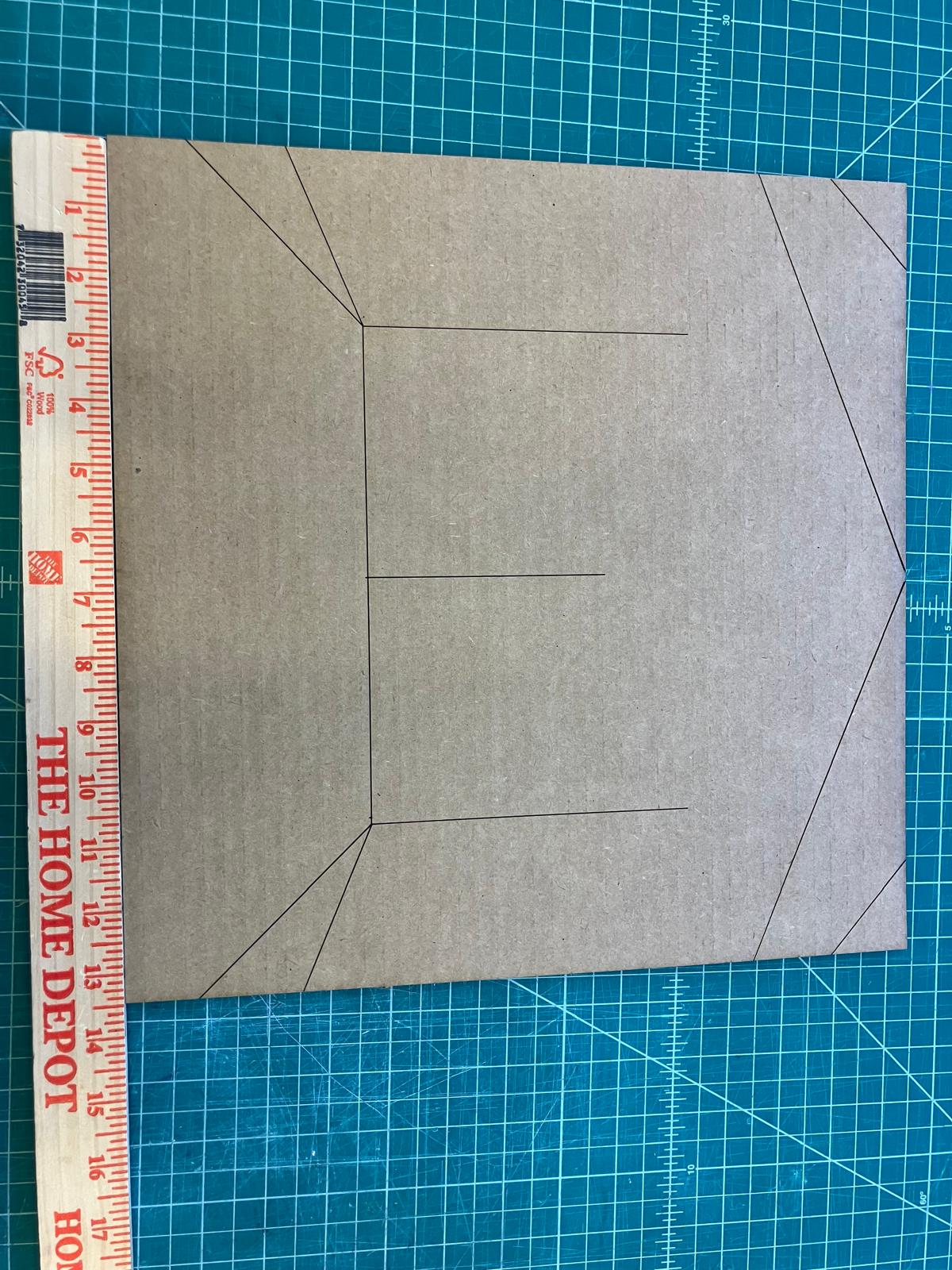

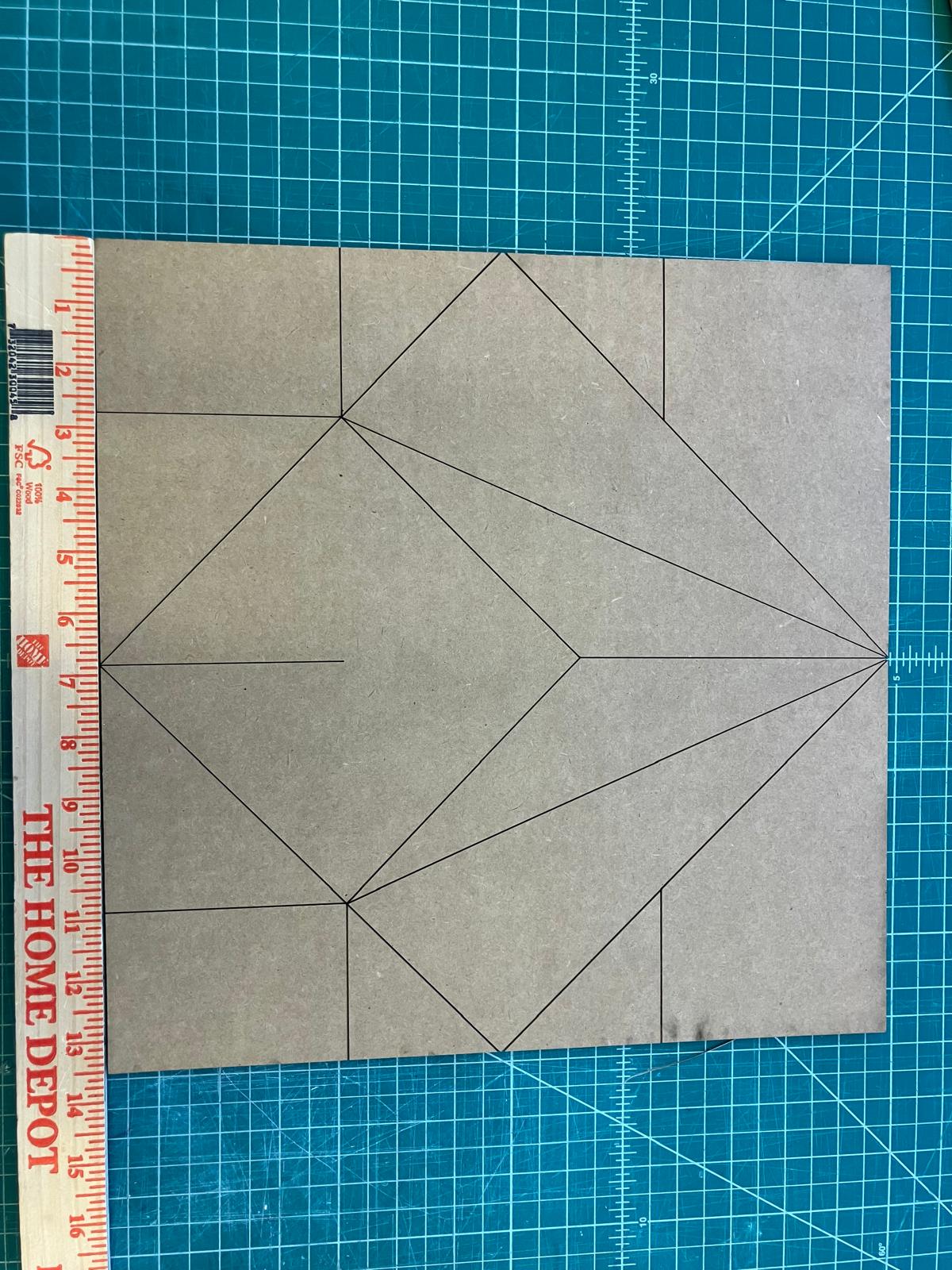

Thickened Crease Patterns

- Estimate: double each crease with a uniform offset and add regular polygons at intersections.

- Exact: compute sector‑aware offset polygons at vertices using incident crease angles.

How the Estimate Works

Input: crease segments with mountain/valley labels; sheet size S; target thickness t

offset = t / S (or a chosen fraction)

for each crease c:

draw two lines parallel to c at ±offset

for each vertex (intersection of original creases):

place a small regular polygon (e.g., octagon) centered at the vertex

Output: doubled creases + vertex holes

How the Exact Method Works

Input: crease lines; sheet size S; target thickness t

offset = t / S

for each crease c:

compute unit direction v and normals n1,n2

define two infinite offset lines at ±offset along n1/n2

for each vertex:

collect incident creases; sort by angle into cyclic order

for each adjacent pair (i, j):

pick the offset side that lies inside the angular sector

intersect those two offset lines → one polygon vertex

connect all vertices in order → convex vertex polygon

trim faces/creases by polygons as needed

Output: doubled creases + exact vertex polygons

Next Step — Layer‑Aware Offsets

Following Erik's advice, offsets should scale with the number of layers between faces in the folded state. Plan: estimate per‑crease layer counts and set per‑crease offset = k × thickness × layers(c), while keeping vertex polygons valid to avoid collisions.

Vinyl Cutter Individual Assignment: 2D Parametric Design

Design and cut vinyl stickers and stencils using the vinyl cutter. Assignment started: September 15, 2025 Assignment completed: September 15, 2025

Project Overview

Planned to vinyl cut lab logo stickers at first. Collected .png or .svg for each logo for the vinyl cutter software, and executing the complete workflow from cutting to final application. I hope to come back to the lab logos when there is less traffic on the vinyl cutter, I was more excited to see the fine detail of the vinyl cutter with the 2D parametric design at first!

Lab Logo Designs

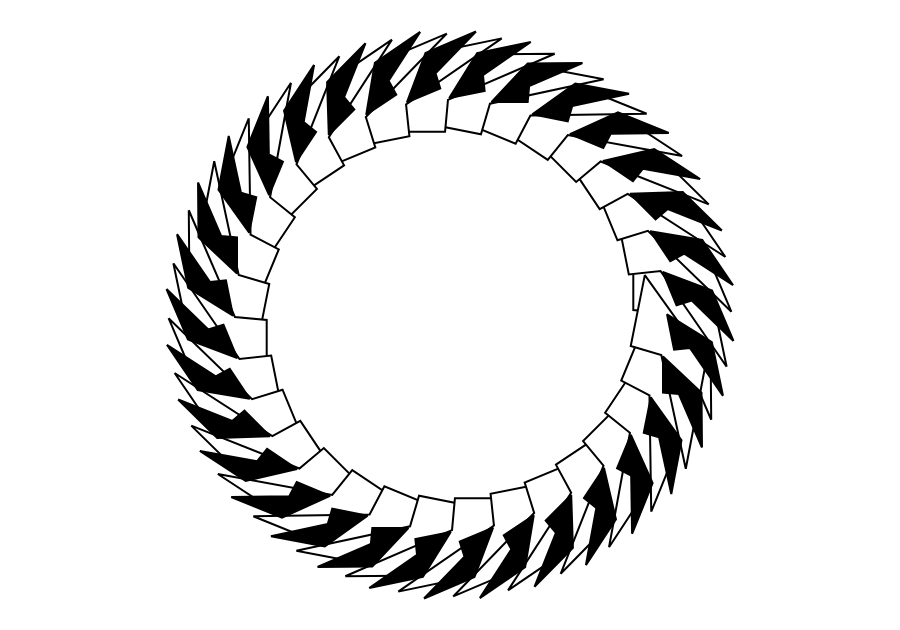

2D Parametric Sticker Design

Used a parametric sticker design that can be infinitely customized through an interactive web application. The design demonstrates the power of parametric modeling in creating personalized vinyl stickers with adjustable parameters for size, complexity, and visual elements. The assignment demonstrated both successful execution and troubleshooting when equipment issues arose.

Interactive Design Generator

This web-based generator was created as a final project in 6.5310 last semester and was used to download a PNG of the default design shown above. Generate unlimited variations of this parametric design by adjusting parameters in real-time to create custom stickers for any application.

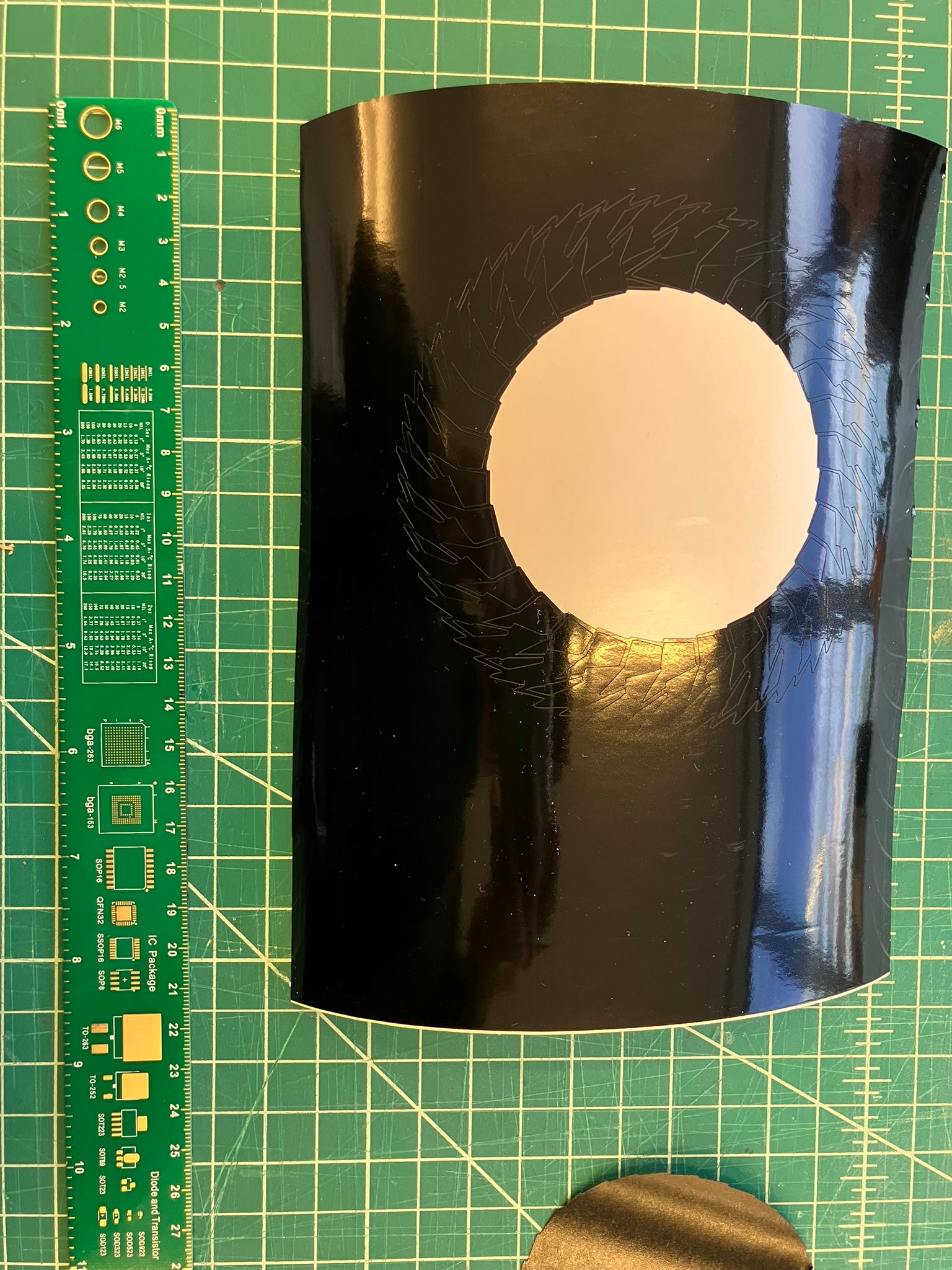

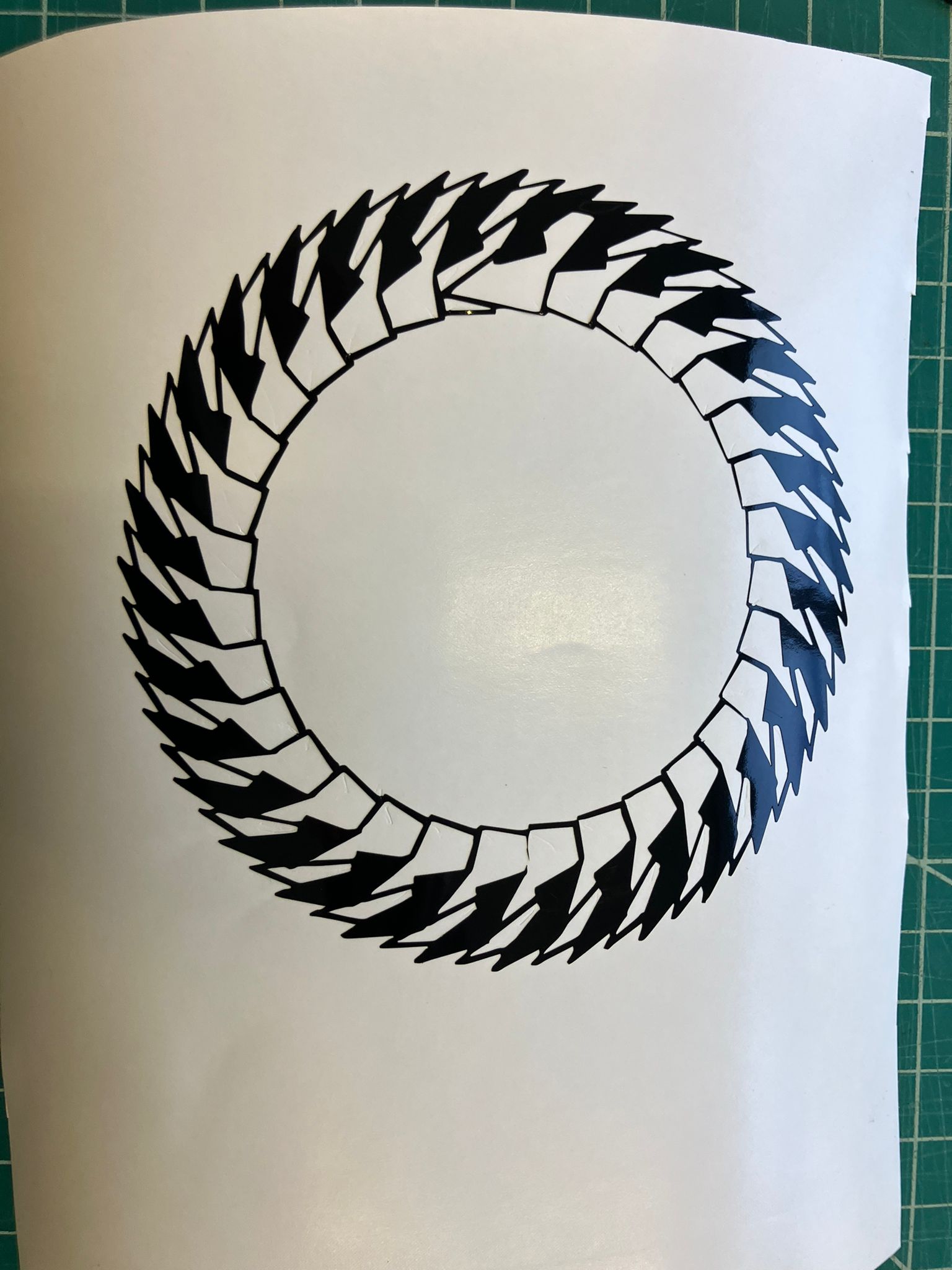

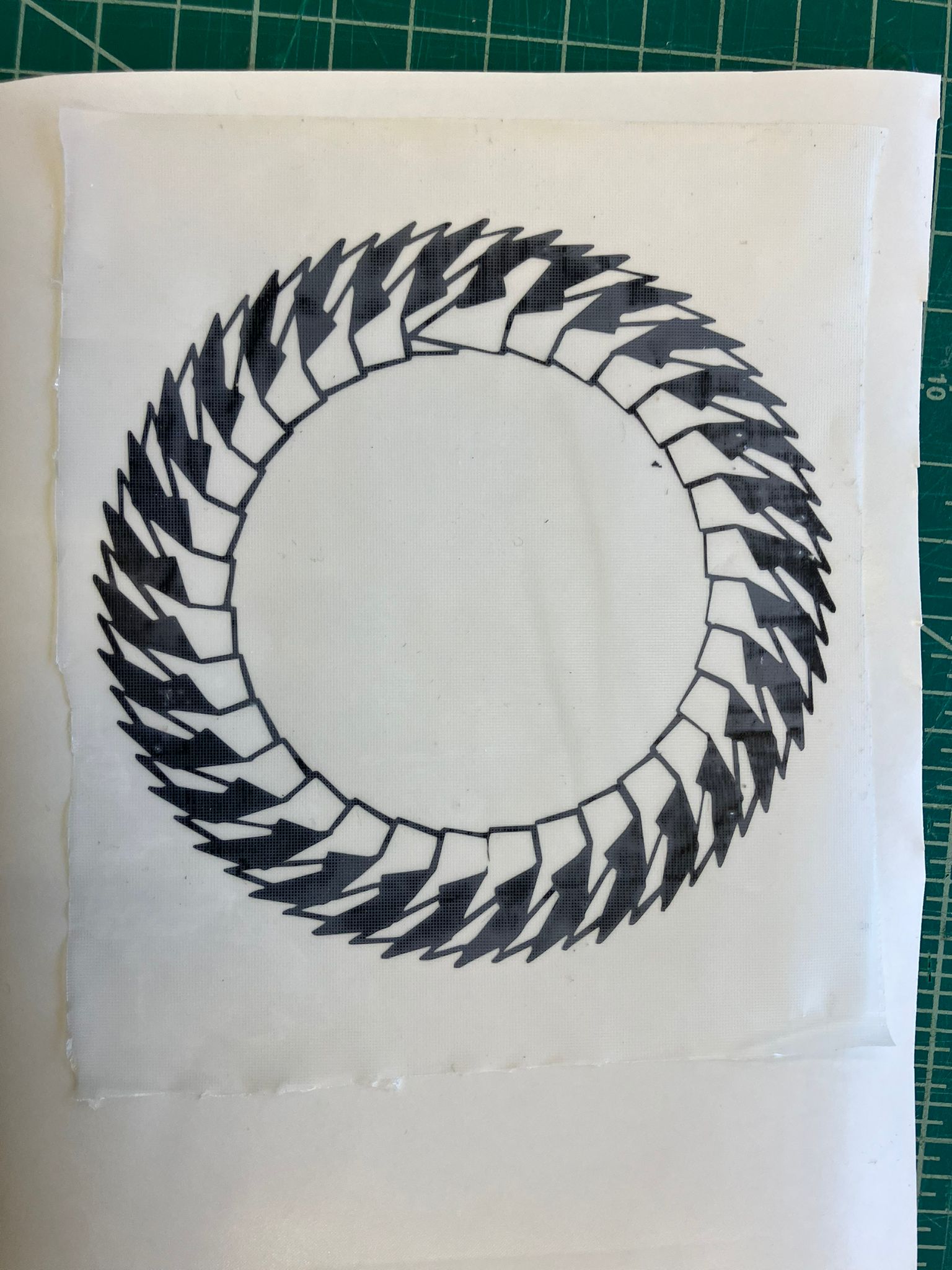

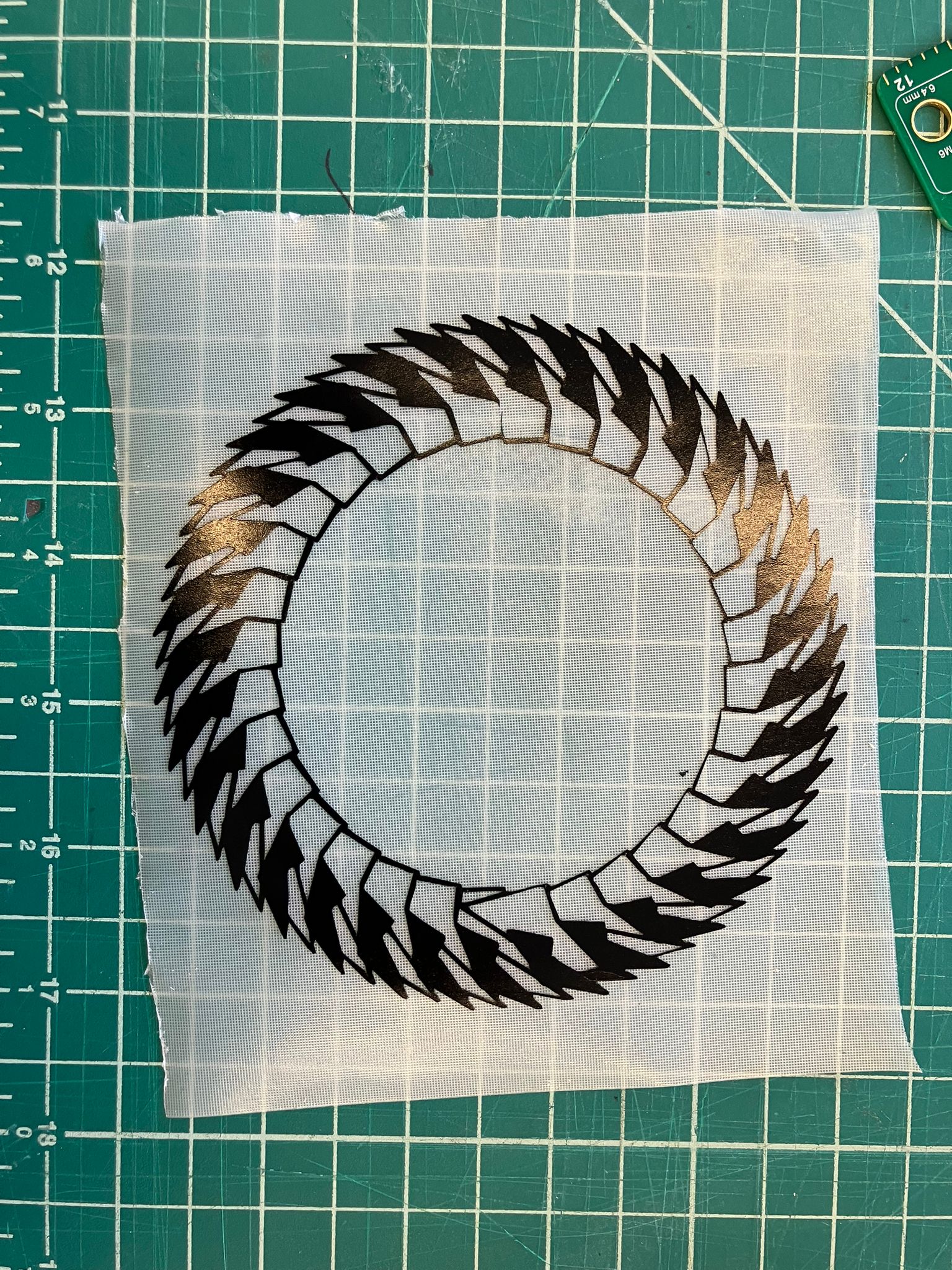

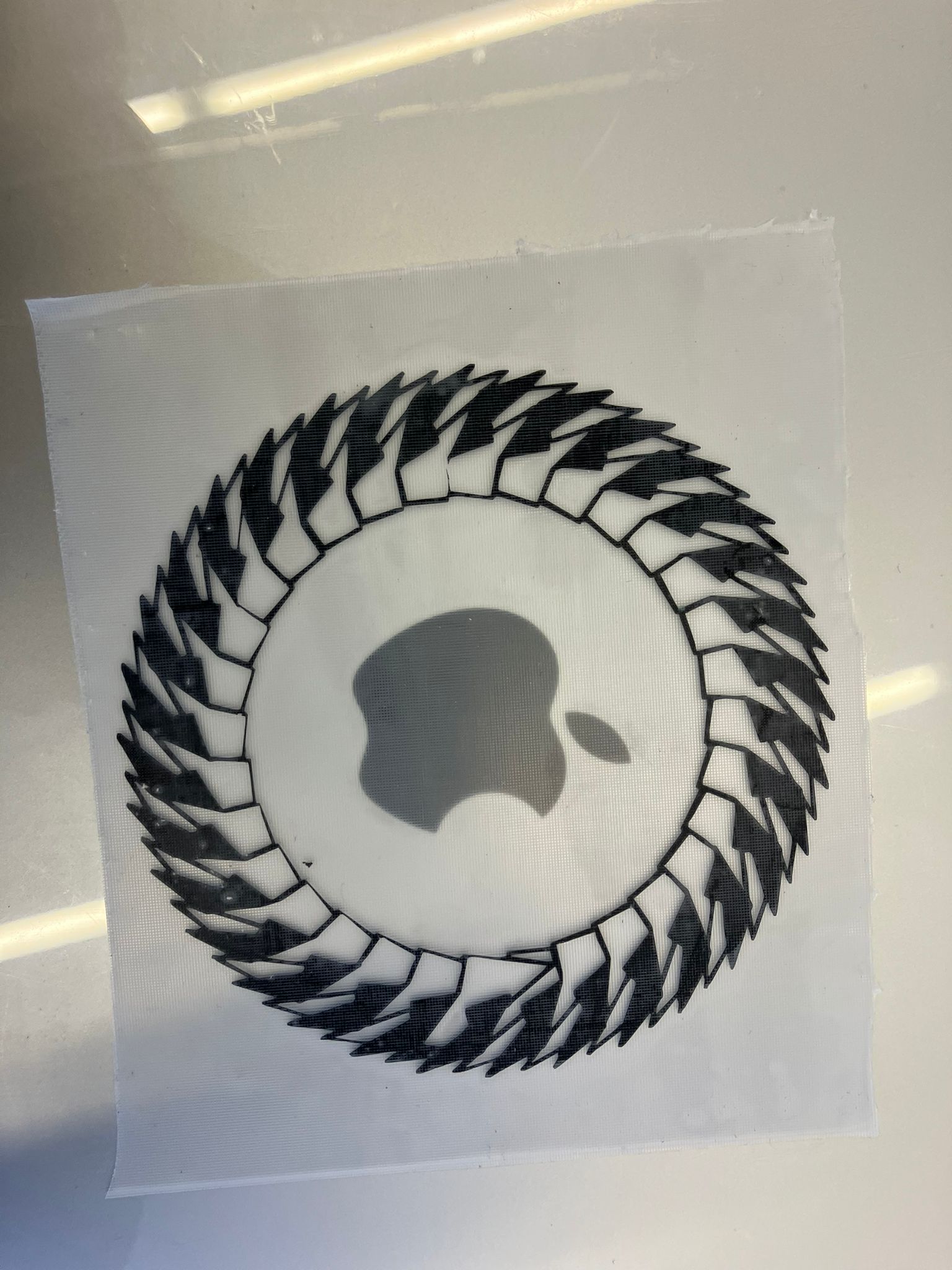

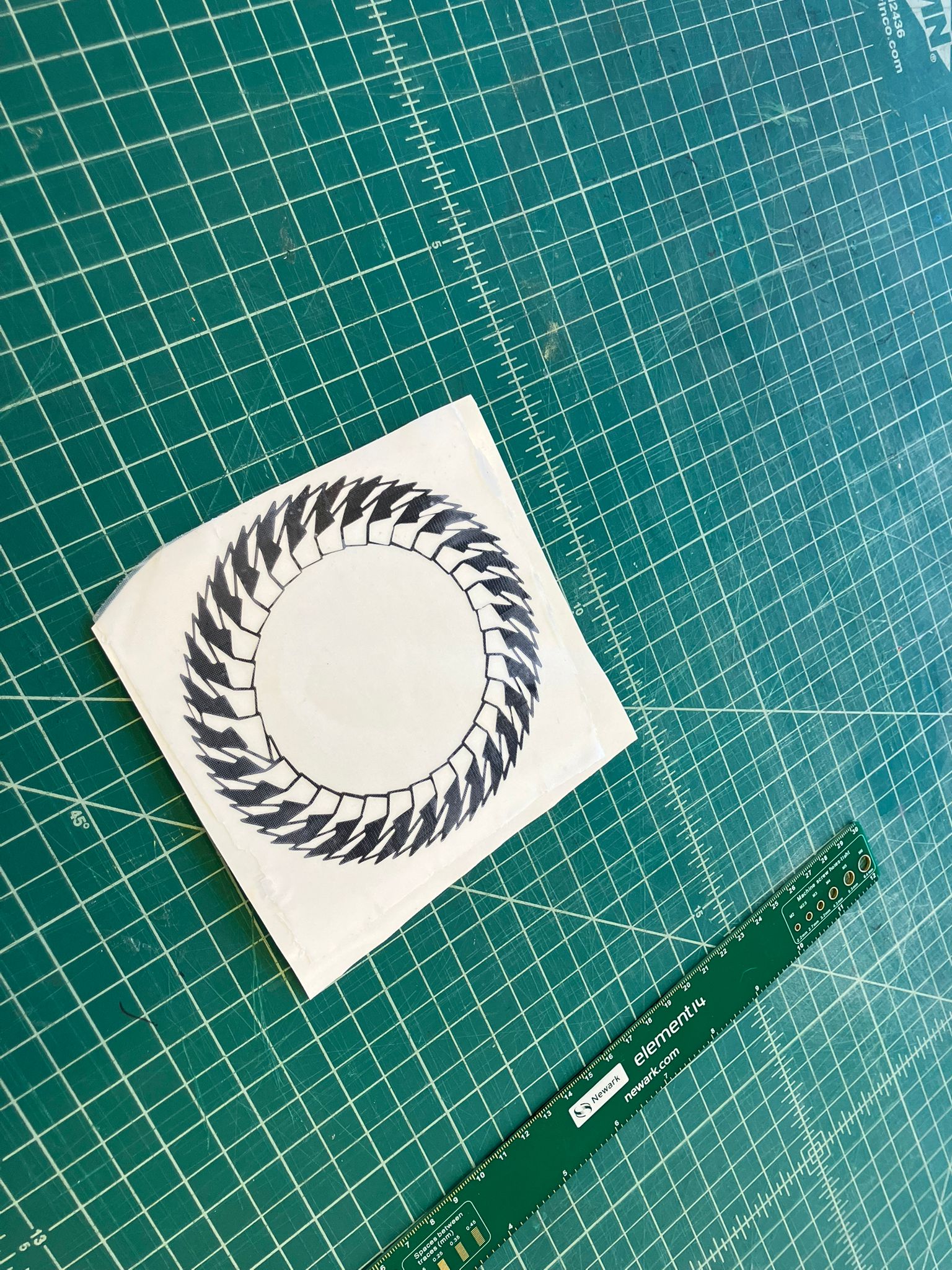

🎨 Generate Custom DesignsSuccessful Cut and Transfer

Complete workflow from vinyl cutting through final sticker application, demonstrating the full process from design to finished product.

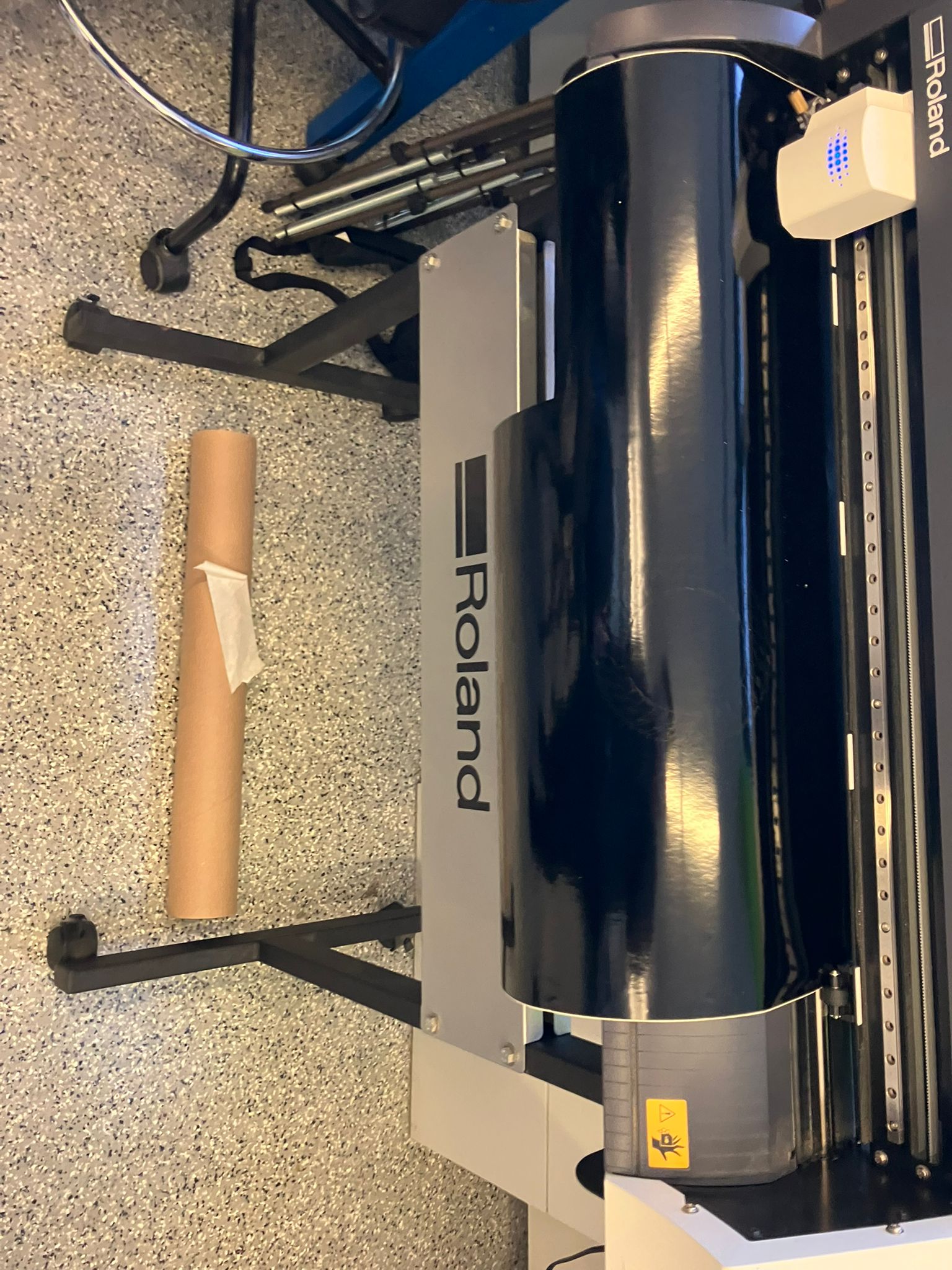

Vinyl Cutting Process

Vinyl cutter in action, cutting the Gladyshev Lab logo design with precise blade control and proper tension settings.

Completed Vinyl Cut

Clean vinyl cut showing precise cuts with proper registration and no tearing or incomplete cuts.

Weeding Process

Systematic weeding process: starting from center, progressing through unwanted sections, and finishing with clean weeded vinyl ready for transfer.

Transfer Paper Application

Transfer paper application process: carefully applying transfer paper to hold vinyl design, then removing it to prepare for final application.

Vinyl Application Process

Final application steps: positioning vinyl on target surface, using tweezers for precise removal of the broken thin vinyl strip, and achieving clean final application.

Completed Takehome Sticker

Final result: applied laptop vinyl sticker and takehome vinyl sticker ready for use, demonstrating successful completion of the vinyl cutting workflow.

Motor Failure

Encountered and resolved a motor failure during the vinyl cutting process, demonstrating troubleshooting skills and equipment maintenance knowledge.

Motor Error Display

Vinyl cutter displaying motor error, indicating a mechanical issue that prevented normal operation.

Roll Failure Analysis

Side-by-side comparison showing the vinyl roll before and after the failure. The roll ran out of material and then fell, causing the vinyl to kink under the cutting wheel.

Troubleshooting Solution

Simple fix process:

- Turn off the vinyl cutter

- Remove tape from the fallen roll to get the weight off

- Readjust vinyl in between the wheels to ensure proper tension

- Start again (or load a new roll if needed)

This common issue occurs when the vinyl roll runs out or becomes misaligned, causing the cutting mechanism to fail. The solution involves proper material handling and machine setup.

Design Files

Download or view design files from this week's assignments.

Laser Cutter Design Files

CAD Files

SVG Files

Cut Files

Kerf and Clearance Design Files

Joint Test Files

Vinyl Cutter Design Files

Reflections & Learnings

Key insights and challenges encountered during this week.

Key Points

- Kerf compensation is critical for precise press-fit assemblies—systematic measurement revealed 0.0049" average with ±0.0017" variation

- Material selection matters: cardboard limitations (warping, structural weakness) require careful design considerations

- Iterative prototyping is essential—initial failures led to successful assembly through design refinement

- Parametric CAD design enables modular, scalable construction kits

- Vinyl cutting workflow requires attention to detail at each step for professional results

Laser Cutting Process Insights

- Understanding kerf and clearance measurements is critical for precise fits—the average kerf of 0.0049 inches with ±0.0017 inches standard deviation demonstrates the importance of systematic characterization.

- Material limitations became clear when working with cardboard: it's not ideal for complex patterns due to warping and structural weakness, requiring careful design considerations.

- The iterative design process from initial failure to successful assembly taught the value of prototyping and testing before committing to final designs.

- Parametric design using Fusion360 proved essential for creating modular construction kits that can be easily scaled and modified.

Vinyl Cutting Learnings

- Weeding techniques require patience and the right tools—proper preparation of the cutting surface and careful material handling significantly improve results.

- Understanding the relationship between cut depth, material thickness, and backing paper is crucial for successful vinyl cutting applications.

- The vinyl cutter workflow from design to application involves multiple steps that each require attention to detail for professional results.

Contributions

Acknowledgements for the help I received this week from my classmates and instructors.

Katrina Li - Training Documentation

This week's training was well-documented by Katrina Li, thank you!

Camron Blackburn - Website Review & Table of Contents Suggestion

Camron reviewed the website and provided valuable feedback on navigation and user experience. She suggested implementing a table of contents to make it easier for visitors to navigate through the different sections of the weekly documentation. This suggestion led to the creation of the sleek, organized table of contents that now appears on both Week 0 and Week 1 pages, significantly improving the overall user experience and accessibility of the documentation.

Mariam Fitaihi - Photos and Videos

Photos and videos of this week's training were taken by Mariam Fitaihi, thank you!

Anthony Pennes - Kerf and Clearance Design Files

Anthony Pennes provided the kerf and clearance design files (HTMAJointTest v0.f3d and HTMAJointTest.dxf) as part of the laser cutter training. These files were essential for understanding joint tolerances and clearance requirements when working with laser-cut materials.

Erik Demaine - Thick Origami Guidance

Erik reviewed my approach to folding thick materials and suggested using the Ku & Demaine thick‑origami method. He pointed me to the paper and emphasized that doubled creases should be spaced according to the number of layers between faces in the final fold. This feedback led me to implement two variants (estimate and exact) of thickened crease patterns and to plan a next step for layer‑aware offsets.

Jesse de Alva - Laser Cutting Assistance

Jesse helped me with laser cutting while figuring out how to do it, providing valuable guidance and support during the learning process. His assistance was crucial for understanding the laser cutting workflow and techniques.

Personal Notes - Laser Cutter Characterization

I took notes on the individual group assignment for characterizaing the laser cutter. :-)

Ethical AI Use

Transparent documentation of AI assistance used in this week's work, following course guidelines for ethical AI usage.

📋 General Guidelines: See General Commands for Cursor on the homepage for standard guidelines and commands used consistently throughout documentation development.

AI-Assisted Web Development in Cursor IDE

This week's webpage development, training documentation, and assignment preparation were assisted by Cursor AI. The AI helped with HTML/CSS implementation, content organization, and structuring technical documentation.

AI-Assisted Section Organization and Content Updates

Cursor AI assisted with organizing webpage sections, cleaning up HTML structure, and updating content for both week 0 and week 1 pages. The AI helped with code refactoring, section reorganization, and maintaining consistent styling across pages.

AI-Assisted Documentation and Link Integration

Cursor AI assisted with adding Anthony's HTMA guides to the Week 1 page, creating a new "Useful Documentation" section, and integrating external resource links with proper styling and organization.

AI-Assisted Week 1 Results Section Development

Cursor AI assisted with creating a comprehensive Results section for the Laser Cutter Characterization Group Assignment, including kerf and clearance analysis tables, measurement methodology documentation, concept diagrams, and downloadable resources. The AI helped integrate Google Sheets data, create professional data tables, and include the complete measurement analysis workflow.

AI-Assisted Week 1 Highlights Section Development

Cursor AI assisted with creating an interactive highlights section for Week 1, including visual improvements to the results display, clickable navigation links to detailed sections, table of contents integration, and enhanced user experience features. The AI helped implement hover effects, proper section linking, and visual hierarchy improvements for better navigation.

AI-Assisted Thick Origami Conversion

A separate chat was used to convert a flat crease pattern into a thick‑origami version following Ku & Demaine.

The AI doubled each crease into parallel offsets and generated vertex polygons (estimate = regular polygons; exact = sector‑aware polygons) and explained how to map desired thickness by setting OFFSET_FRAC = thickness / sheet_size.

AI-Assisted Repository Management and Content Organization

Cursor AI assisted with repository size management by breaking down large commits into smaller, manageable chunks under 10MB each. The AI helped organize media files into logical commits, added the Vinyl Cutter Individual Assignment section with proper styling and image sizing, and provided guidance on git workflow optimization to work within platform size limits.

AI-Assisted Vinyl Cutter Assignment Documentation

Cursor AI assisted with updating the vinyl cutter individual assignment section with comprehensive documentation including successful cut and transfer workflow, motor failure troubleshooting, and 2D parametric design integration. The AI helped structure the content with proper media organization, descriptive captions, and consistent styling throughout the section.

AI-Assisted Design Files Integration

Cursor AI assisted with adding a comprehensive Design Files section to the Week 1 page, including table of contents integration, organized file listings with download and view links, and contextual hyperlinks throughout the page for easy access to design assets. The AI helped structure the files by category (laser cutter CAD files, SVG patterns, vinyl cutter images) with appropriate styling.

AI-Assisted Design Files Integration for Laser Cutter Training

Cursor AI assisted with adding kerf and clearance design files from Anthony Pennes to the Week 1 Design Files section, creating a new subsubsection for joint test files, and properly attributing the contribution in the contributions section with links to both the Slack message and design files section.

AI-Assisted Layout Fixes and Section Structure

Cursor AI assisted with fixing layout and margin issues in week1.html, including resolving width inconsistencies and ensuring proper section structure. The AI helped identify and fix extra closing div tags that were causing content to appear outside their intended sections. The issue was resolved by manually removing the duplicate closing tags.

This work is licensed under a

Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

This work is licensed under a

Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License