Grinding/Abrasive Cutting

Grinding

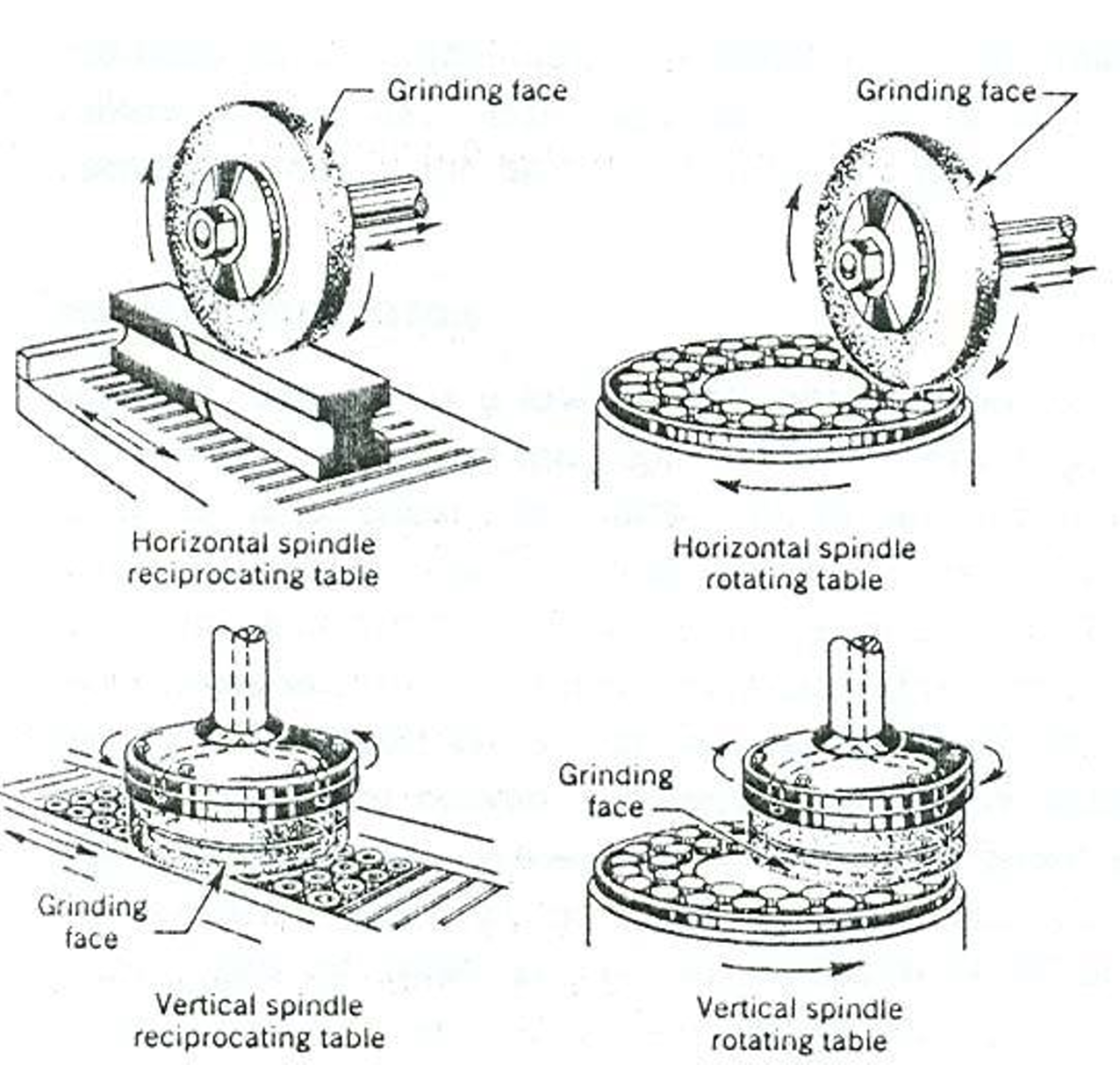

Surface Grinding

- Horizontal-spindle Grinder

- Vertical-spindle Grinder

1. Grinders with a horizontal spindle, often referred to as peripheral grinders, are ideal for tasks requiring high precision, such as machining angled or tapered features, as well as slotting or creating recessed areas. The wheel's flat edge, the periphery, comes into contact with the material being worked on. This grinder type is commonly used for shaping components like pins, pistons, connecting rods, and the races of bearings.

2. Conversely, grinders that feature a vertical spindle, known as wheel-face grinders, are favored for rapid material removal. The grinding wheel's face descends onto the piece positioned beneath it. These machines are particularly effective for processing items like stators, wafers, rotors, gears, and the inner components of rings and plates, in addition to stops and spacers.

Tool Grinding

Cuttermaster CM-01P

Mini Bonelle II

Cuttermaster CM-01P

Mini Bonelle II

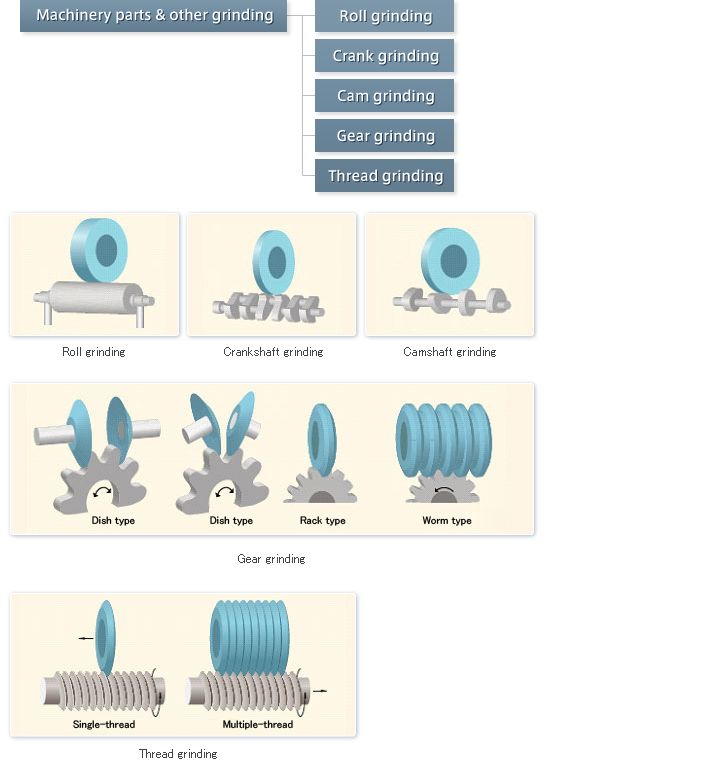

Machinery Parts Grinding

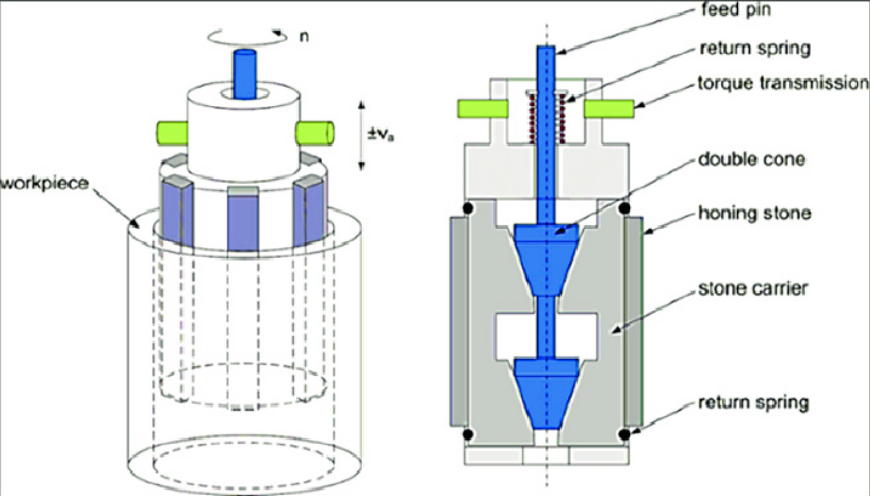

Honing

Honing is a precision finishing process in machining that enhances the geometry and surface texture of a workpiece. Using an abrasive hone or honing stone, which rotates and reciprocates against the workpiece, honing gently removes material to achieve tight dimensional tolerances and specific surface finishes. This method is crucial for correcting roundness and alignment in cylindrical bores, making it essential for manufacturing components like engine cylinders and hydraulic systems where precision fit and surface lubrication are vital for optimal performance and durability.

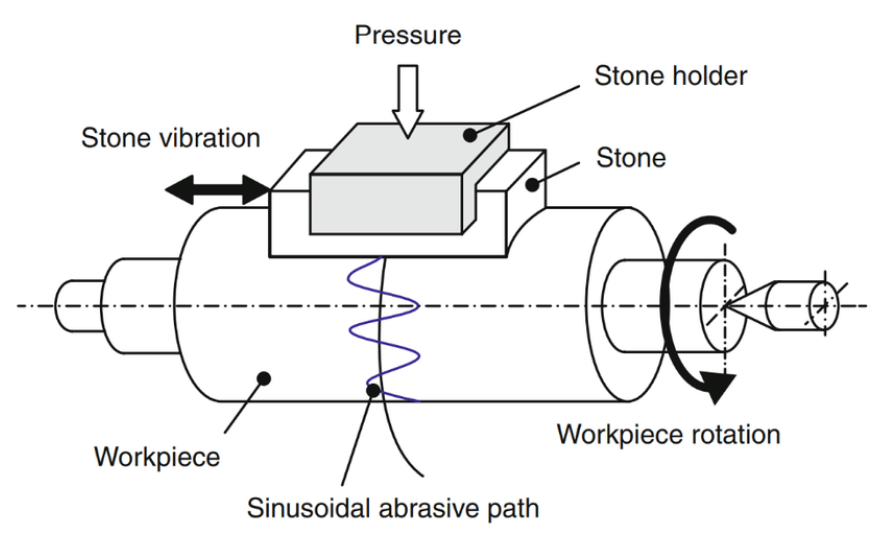

Superfinishing/Short-stroke honing

Super finishing, also known as short-stroke honing and microfinishing, is a precision machining process that improves the surface finish of a workpiece beyond what is achievable with conventional machining methods. It removes very small amounts of material to produce extremely smooth and precise surfaces, often achieving surface roughness values below 1 microinch (0.025 micrometer). This process is typically used on components that require minimal friction and wear, such as engine parts, bearings, and shafts, enhancing their performance and longevity.

Lapping

Lapping is a precision finishing process used to achieve ultra-smooth surfaces and high accuracy in flatness by sliding two surfaces against each other with an abrasive material in between. Unlike honing, which uses a tool to remove material, lapping relies on a loose abrasive applied to a lapping plate or surface. This method employs a rotating lapping plate and an abrasive slurry to microscopically remove material from the workpiece, allowing for the finishing of metals, ceramics, and glass. Commonly used to produce mirror-like finishes and precise thickness control, lapping is essential in manufacturing components where surface quality and geometric accuracy are critical, such as in optical lenses, semiconductor wafers, and sealing surfaces of mechanical parts.

Buffing & Polishing

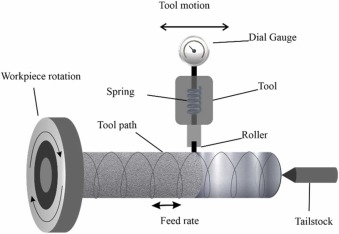

Burnishing

Burnishing is a finishing process that smoothens and hardens the surface of a workpiece by rolling or rubbing a hard ball or roller against it under pressure. This method improves surface finish, reduces friction, and increases wear resistance without removing material, making it ideal for enhancing the performance and durability of metal parts.

Abrasion Techniques

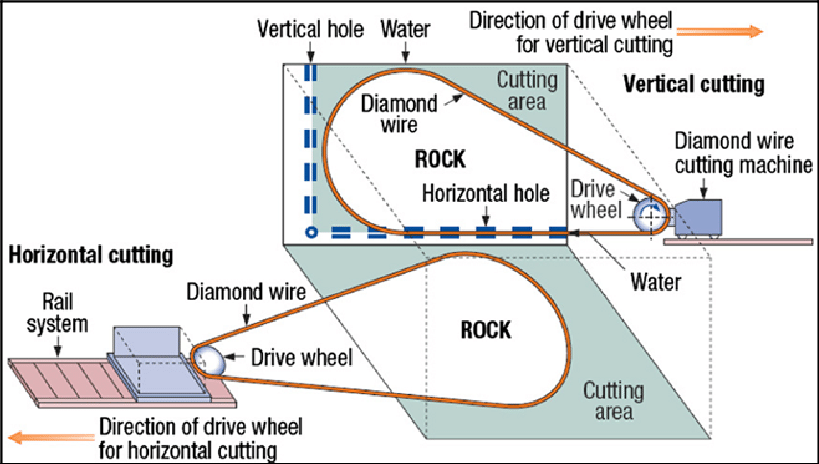

Diamond Wire Saw

TBD

The diamond wire saw is a cutting instrument that embeds diamonds onto the wire's surface. Through continuous mechanical motion and applying pressure to the wire, it leverages the extreme hardness of diamonds to cut through materials. This process is enhanced by the cooling and lubricating effects of oil or water, facilitating the efficient slicing of various substances.

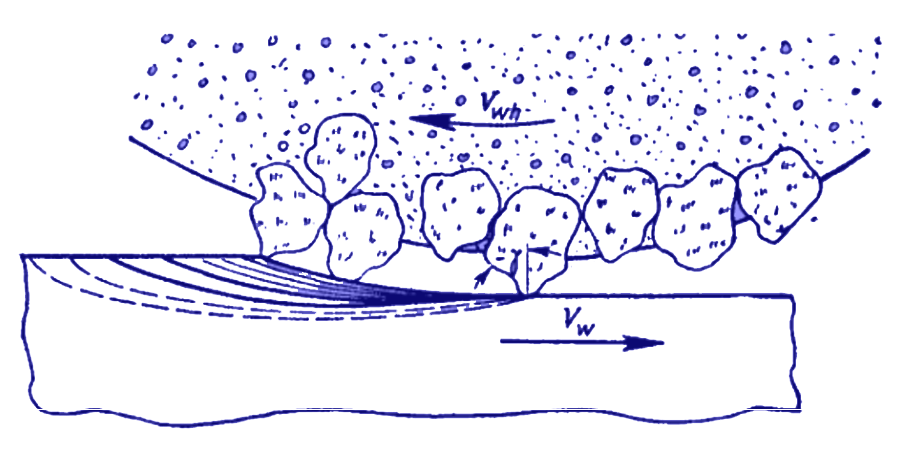

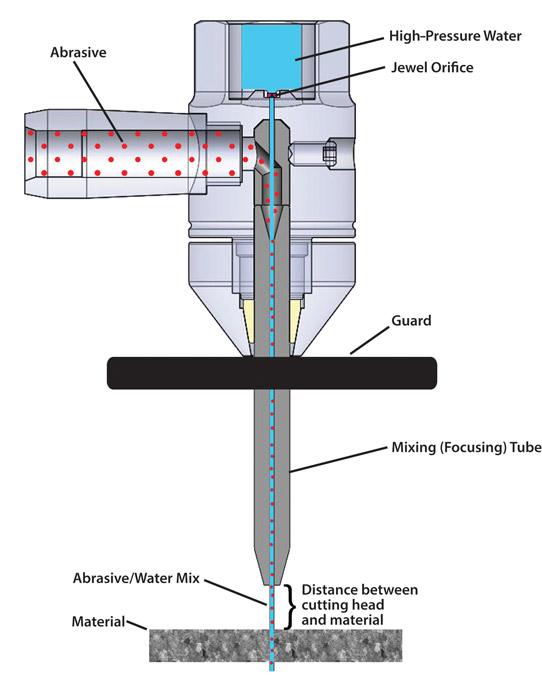

Abrasive Waterjet

Abrasive waterjet cutting is a process that uses a high-pressure stream of water mixed with abrasive particles to cut through various materials. The abrasive particles, typically made of garnet, erode the material upon impact, allowing for precise and clean cuts without heat-affected zones. This method is versatile, capable of cutting through metals, ceramics, stone, and composites, making it suitable for a wide range of applications in manufacturing and fabrication.

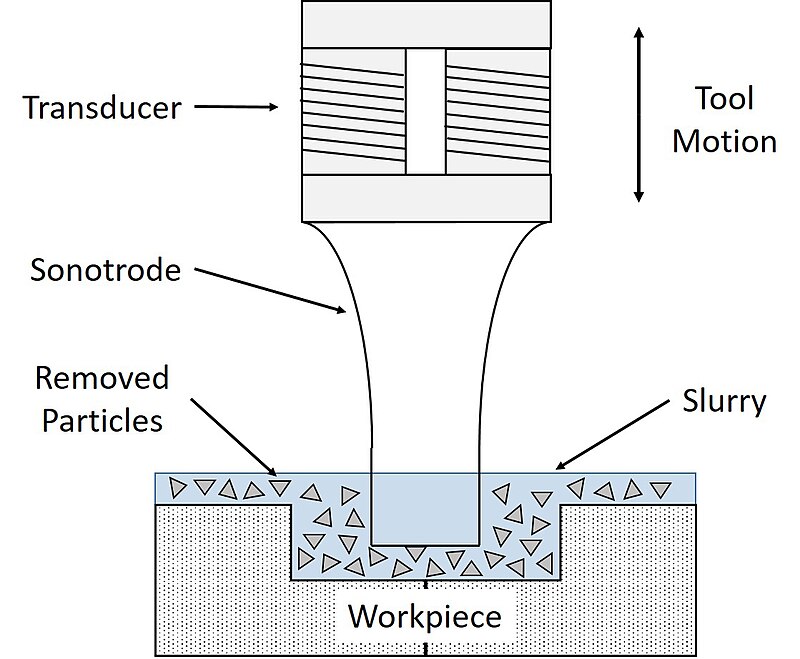

Ultrasonic machining & Abrasive Slurry

Ultrasonic machining uses ultrasonic vibrations to remove material from a workpiece. It involves a tool vibrating at high frequencies in the presence of an abrasive slurry, which consists of fine abrasive particles suspended in a liquid medium. The tool does not directly contact the workpiece; instead, it presses the abrasive particles against the surface, gradually eroding it with the help of ultrasonic motion. This method is especially useful for machining hard, brittle materials like ceramics and glass without generating excessive heat or causing significant surface damage.

Other

Adaptive Robotic Carving from Giulio Brugnaro on Vimeo.

Sources

Koyo Machinery. "How Does a Surface Grinder Work?" Koyo Machinery Blog, URL: www.koyomachinery.com/blog/how-does-a-surface-grinder-work_ae8.html#:~:text=There%20are%20three%20basic%20types,grinders%20and%20double%2Ddisc%20grinders.

Perform Advanced Grinding Operations, URL: http://ndl.ethernet.edu.et/bitstream/123456789/90464/1/Perform%20Advanced%20Grinding%20Operations.pdf

Diamond Wire Saw: The Definitive Guide, URL: https://www.dymend.com/diamond-wire-saw-the-definitive-guide/

Abrasive Slurry, Advanced Gear Manufacturing and Finishing, 2017, URL: https://www.sciencedirect.com/topics/engineering/abrasive-slurry#:~:text=The%20abrasive%20slurry%20is%20a,material%20removal%20by%20micro%2Dchipping

H, Santhosh & Kumar, R & S, Deepak & S, Vasu. (2023). Modelling and Analysis of The Effect of Plateau Honing Operation on Cylinder Liners. Journal of Mines, Metals and Fuels. 355-362. 10.18311/jmmf/2022/32932.

N. Sinha, Mechanical Engineering Department, IIT Kanpur, Abrasive Machining Processes.https://home.iitk.ac.in/~nsinha/Abrasive_machining_processes.pdf

Micallef, Christian & Zhuk, Yuri & Aria, Adrianus. (2020). Recent Progress in Precision Machining and Surface Finishing of Tungsten Carbide Hard Composite Coatings. Coatings. 10. 731. 10.3390/coatings10080731.

Ahmed Raza, Sudhanshu Kumar, A critical review of tool design in burnishing process, URL: https://www.sciencedirect.com/science/article/abs/pii/S0301679X22002900

Ultrasonic machining, Wikipedia, https://commons.wikimedia.org/wiki/File:Ultrasonic_Machine_Process.jpg#/media/File:Ultrasonic_Machine_Process.jpg

Pressure Matters in Abrasive Waterjet Cutting, The Fabricator URL: https://www.thefabricator.com/thefabricator/article/waterjetcutting/pressure-matters-in-abrasive-waterjet-cutting

KURE GRINDING WHEEL CO., LTD. Grinding Methods, URL: https://en.kuretoishi.com/support/knowledge/category/

Mini Bonelle II, Metallmodellbau, URL: http://www.metallmodellbau.de/MINI_BONELLE_II.php

DIY Tool and Cutter Grinder - Idea Notebook, Bob Warfield, CNCCookbook, URL: https://www.cnccookbook.com/diy-tool-and-cutter-grinder-idea-notebook/