Introduction

Sustainability

Can the development, deployment and use of tools or machines be conducted in a way that is responsible to the environment, economically viable, socially equitable and technologically adaptable?

Usability

How can we design and develop tools or machines so that they are easy to use?

Accessibility

How accessible?

- Financial affordability

- Physical access

- Educational

- Inclusivity

Presenters

(no particular order)

J.C. Mariscal-Melgar, Alexander Kyaw, Luisa Lange, Michel Langhammer, Mohammed Omer

Sustainability

- Four pillars: Human, Social, Economic, Environmental

- Sustainability and Sustainable development

Circular Economy

A model of resource production and consumption to go from linear wasteful economies to restorative and regenerative economies.

- Core principles: Reduce, reuse, recycle, recover

- Aims: sustainable development, economic prosperity, environmental quality and social equity

- Enablers: business models, consumer involvement, government, institutions

Can we cycle valuable metals, polymers, alloys, etc. so that they maintain their quality and continue to be useful beyond the shelf life of individual products?

Can goods of today become the resources of tomorrow?

- butterfly diagram

- Technical cycle

- Reuse (e.g. disassembly and reuse of parts)

- Physical transformation (e.g., reshaping plastics)

- Chemical transformation (e.g., depolymerization of plastics, pyrolysis, gasification)

- Biological cycle

- extraction

- decomposition

- regeneration

- Technical cycle

Circular Design methods

Circular design explanation (Video)

Circular design refers to a strategic approach aimed at developing products and services for the circular economy.

- Circular design methods (Ellen Macarthur Foundation)

- understand -> define -> make -> release

- Understand how to design for circular flows

- Define clearly the challenge or problem to solve

- Create or implement a working concept or prototype

- Release the project and ensure it is useful as long as possible

- understand -> define -> make -> release

| Understand | Define | Make | Release |

|---|---|---|---|

| circular flows: restorative and regenerative design | Identify circular opportunities | user-focused research research | product journey mapping with longevity in mind |

| regenerative thinking: local production networks | start small and then scale | circular brainstorming | create an aligned narrative with stakeholders |

| learning digital systems and processes | build collaborative teams | measure impact within the system | iterate design |

| inside-out (understand materials that go into products) | develop strategies to engage with stakeholders | Continuous learning: Embed feedback | |

| get inspired from nature | consider business models | understand and breakdown material choices | |

| create a brand promise | test concepts with rapid prototyping concept | ||

- Resource pressure Method: Uses six design parameters to design circular projects. Material required, product lifetime (frequency of replacement), material loss (in manufacturing), primary material content (demand for extracted resources), recyclability/reuse, cascadability (extending material utility)

- Circular design frameworks : 5 strategies - (1) circular supplies focused (prioritises biological cycles), (2) resource conservation focused (preventative, minimal resources), (3) cycle focused (design aimed at circulation of materials), (4) long life use focused (design aimed for reuse, repair) and (5) whole systems designs for value creation (innovative solutions combining all other strategies)

FabCity

The Fab City movement has set itself the goal of producing almost everything that is consumed in the city by 2054.

-

- The Fab City Full Stack. Credit: Tomas Diez and Zoe Tzika, Fab City Foundation

- Layer 1 - Developing infrastructure and technologies for local production

- Layer 2 - Enabling new forms of learning

- Layer 3 - Incubating value-generating projects

- Layer 4 - Orchestrating efforts between local communities and initiatives

- Layer 5 - Prototyping place-based interventions

- Layer 6 - Applying bioregional strategies

- Layer 7 - Sharing knowledge with global networks

-

- Interfacer Platform (Video)

- digital product passports

- EU DPP commission initative

- Track and tracing

- Supply chain visibility

- Full lifecycle monitoring

- Better compliance

-

Challenges

- Supply chains

- Indicators

- Measuring flows

- Material flow analysis

Open Source Hardware

Documentation

-

Design for repair and replicability

-

Documenting

-

Assembly manuals

-

Gitbuilding (Open Flexure Microscope)

-

OSH-autodoc (inspired by Daniele Ingrassia's Fabulaser Mini Manual by Marc Kohlen and Liane Honda)

-

lego

-

-

Reusing parts

-

Read the docs

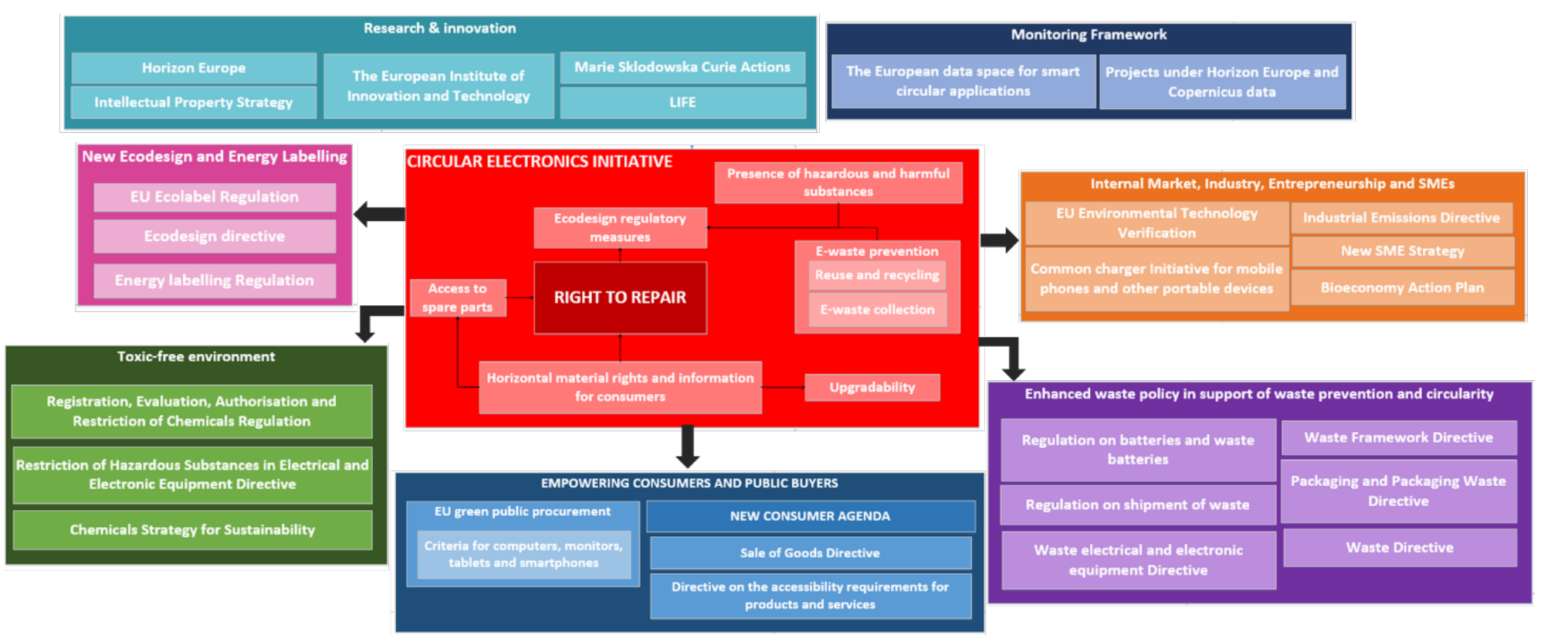

Repairability

- Right to repair movement

Right to repair landscape in the EU (source: Towards an effective right to repair)

-

Environmental impact of electronic products (at diffent life cycle stages)

- mining and production of raw materials

- processing, assembly and transport

- use (e.g. lifespan, energy efficiency)

- end-of-life (collection, disposal, recycling)

-

Active Disassembly: disassembling products into their separate components

- Active disassembly using smart materials (ADSM)

- Use of smart materials in order to change shape or size and facilitate the release of parts.

- Shape memory alloys

- Shape memory polymers

- Active disassembly based on the shape memory effect of polymeric materials (video)

-

Design for disassembly DFDS (video)

- Fewer parts

- Pure material parts

- Removable batteries and circuits

- Modular design

- Joining methods:

- Standardised fasteners

- snap-click

- press-fit

Disposal methods

- Direct reuse (material reuse in existing form)

- Recovery (material purified to its original form for reuse)

- Recycle (material transformed into another substance)

- Fuel Blending (material substituted in place of virgin fuels)

- Treatment (Material is neutralised to allow for disposal)

- Incineration (Material is safely burned without energy recovery)

- Landfill (material is sent to an approved landfill)

Examples of sustainability of waste streams

| Waste | Disposal | Opportunity |

|---|---|---|

| Ammonium sulfate | Wastewater treatment (*) | fertilizer manufacturing |

| Metal plating waste | Landfill | Metal recovery |

| Calcium fluoride | Landfill (*) | Cement |

| Lithography solvents | Fuel blend (*) | Cyclohexanone recovery |

| Food Waste | Landfill | Soil conditioner |

Some Examples

SDG 6 Open call for water action

MNT reform: Modularity by design

Material sourcing

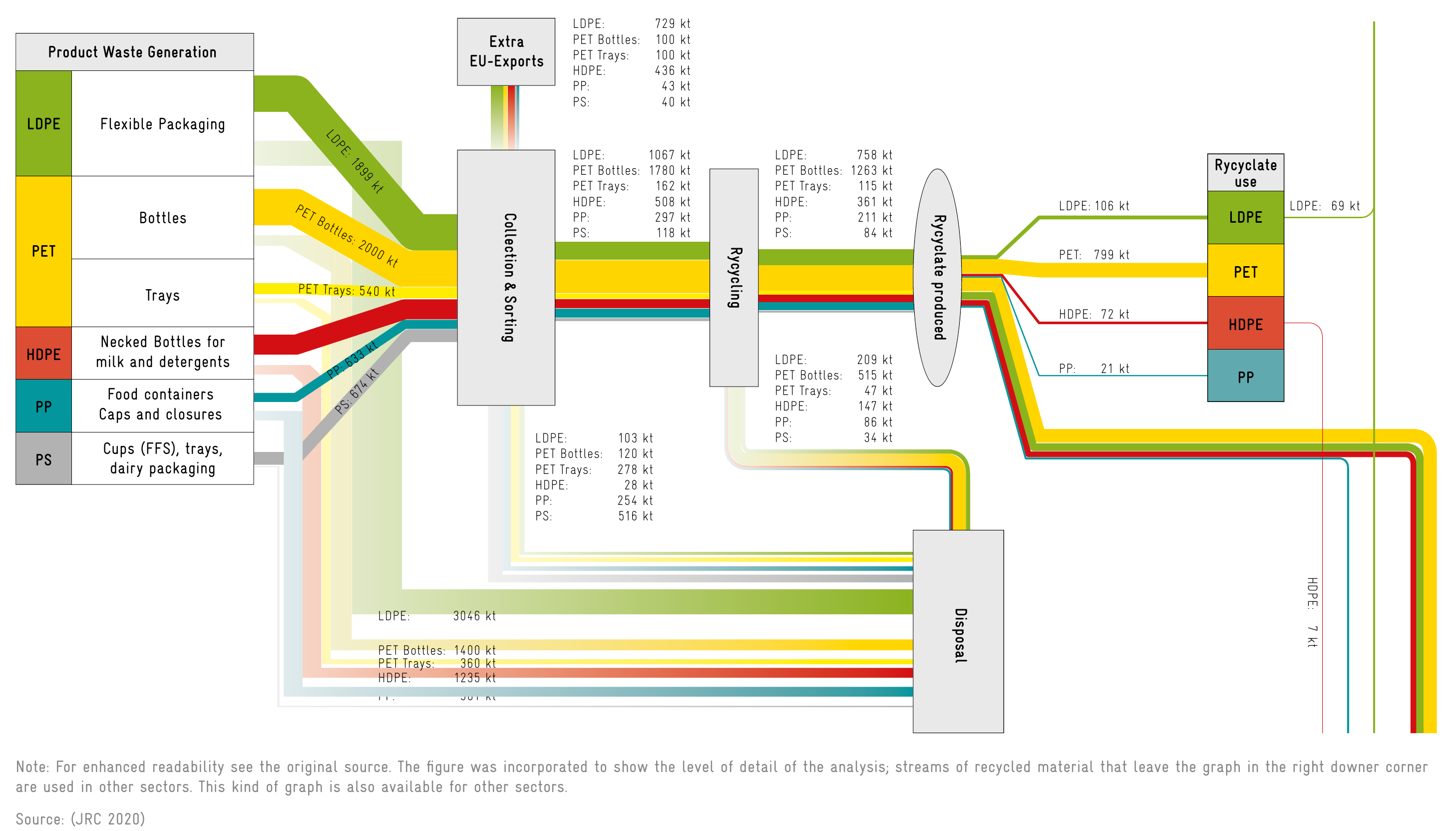

Plastic

Examples

- Material Database as open access

- machines, designs and marketplace for distributed plastic recycling and manufacturing

- modular design of headphones for higher repairability and modification

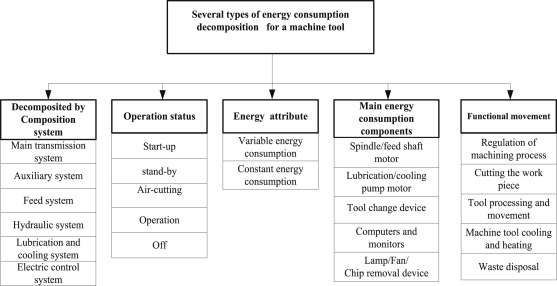

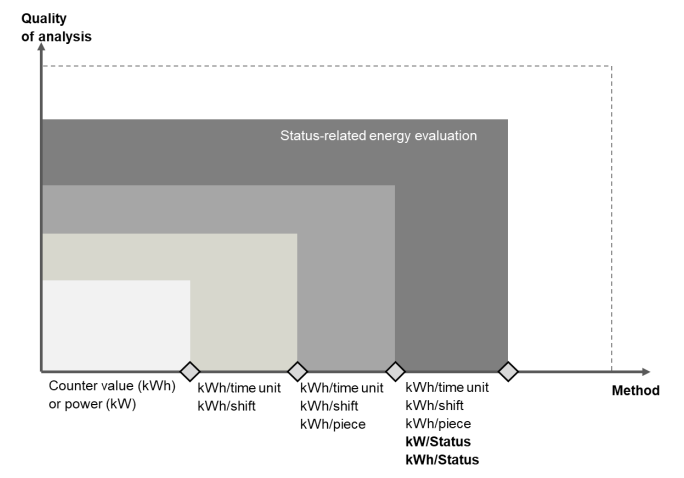

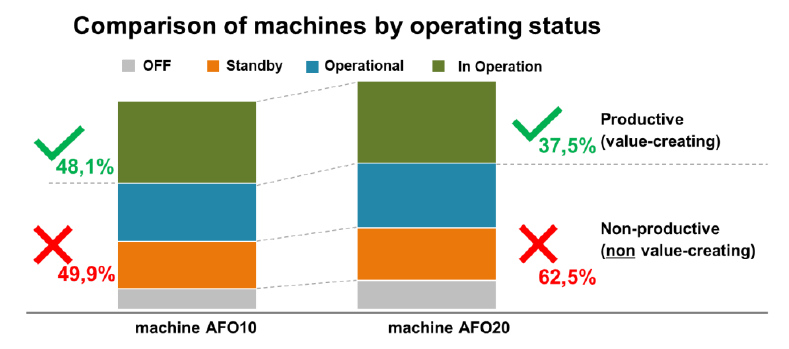

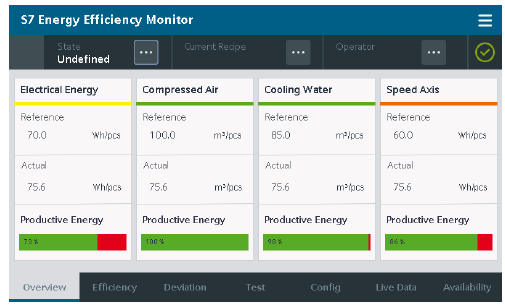

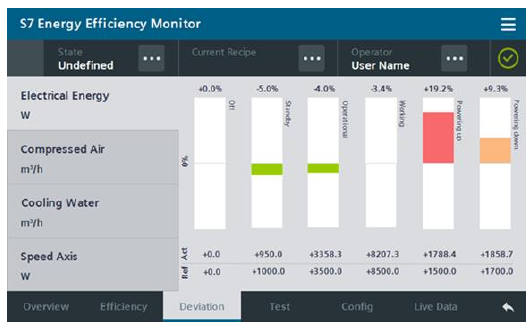

Resource Efficiency in Machine Tools

Modelling of Energy Profiles of Machines Tools

Automation architecture for data analysis of resource parameters from machines

Example from Energy Tracking in Hamburg

![]()

![]()

![]()

Example from Industry

- Energy Monitoring and Energy Management in Industry on Machine Level

- ISO14966 - Environmental evaluation of machine tools

- Media Analysis for Machines, solution from SIEMENS

- Aim: develop machines that are responsible to the environment, economically viable, socially equitable and technologically adaptable

Usability

What is Usability?

usability: extent to which a system, product or service can be used by specified goals with effectiveness, efficiency and satisfaction in a specified context of use. (ISO 9241-11)

- effectiveness: the accuracy and completeness with which specified users can achieve specified goals in particular environments

- efficiency: the resources expended in relation to the accuracy and completeness of goals achieved

- satisfaction: the comfort and acceptability of the work system to its users and other people affected by its use

Usability Standards

Methods to support human-centered design, Martin Maguire

ISO 9241 Ergonomics and Human Computer Interaction

ISO 13407 Human-centred design processes for interactive systems (old)

ISO 9241-210Human-centred design processes for interactive systems (new)

Guiding principles:

- The design is based upon an explicit understanding of users, tasks, and environments.

- Users are involved throughout design and development.

- The design is driven and refined by user-centered evaluation.

- The process is iterative.

- The design addresses the whole user experience.

- The design team includes multidisciplinary skills and perspectives.

HCI

The Eight Golden Rules of Interface Design Ben Shneiderman (1985)

- Strive for consistency.

- Seek universal usability.

- Offer informative feedback.

- Design dialogs to yield closure.

- Prevent errors.

- Permit easy reversal of actions.

- Keep users in control.

- Reduce short-term memory load.

Usability Heuristics - Jacob Nielsen (1994, 2005)

- Visibility of System Status

- Match Between the System and the Real World

- User Control and Freedom

- Consistency and Standards

- Error Prevention

- Recognition Rather than Recall

- Flexibility and Efficiency of Use

- Aesthetic and Minimalist Design

- Help Users Recognize, Diagnose, and Recover from Errors

- Help and Documentation

Usability goals:

- Learnability

- Efficiency

- Memorability

- Errors (as in low error rate)

- Satisfaction

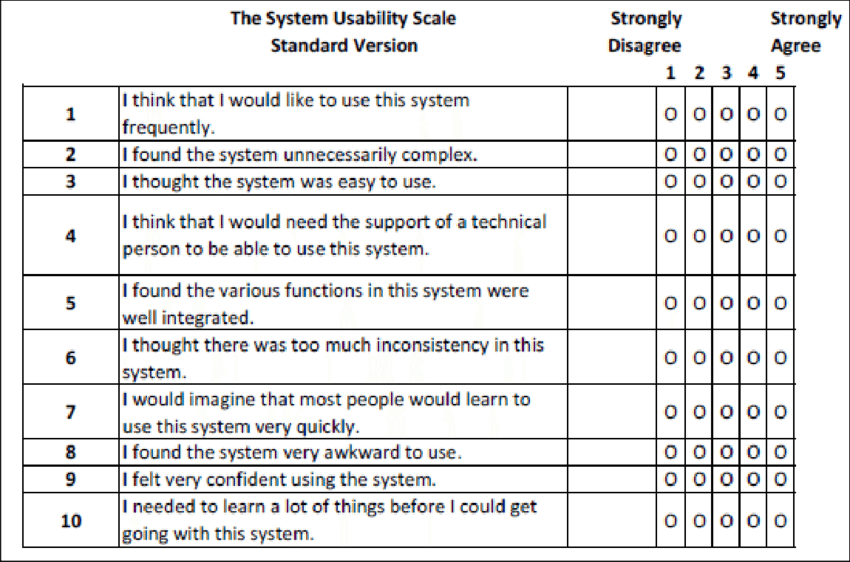

User Testing

Guides from the Nielson Norman Group:

System Usability Scale (SUS)

- SUS by John Brooke 1986

Usability of machine tools

- combination of HCI and hardware

- Human Factors Ergonomics (HFE) and HCI need to be considered

- Consider the users you are designing the machines for (UX design)

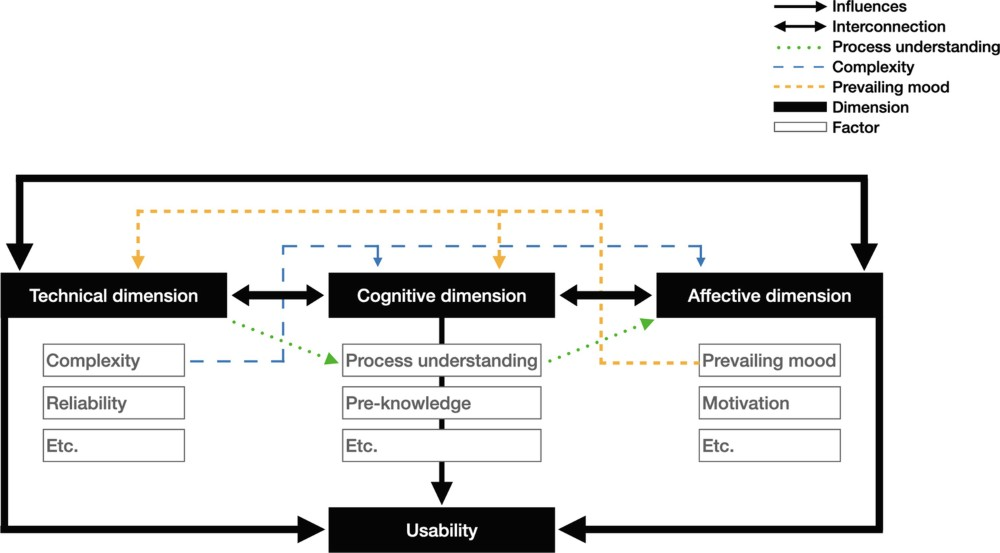

Physical, Cognitive and Affective Impacts

Usability of open source machine tools, Lange et al. (2024)

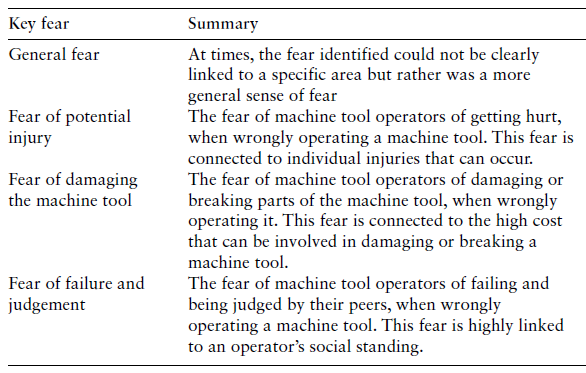

Anxiety and fear of machine tools

Further research on anxiety and fear

Social cognitive theory Albert Bandura 1999

Consumer orinetation through Kansei engineering

Kansei Eingineering for machine tools

Whirlwind History of HCI (Human-Computer Interaction)

(from 2021 lecture)

1953:

As We May Think It, Vaneever Bush

1960:

Man-Computer Symbiosis, J. C. R. Licklider

1963: Sketchpad, Ivan Sutherland

Ivan Sutherland's PhD Thesis for which he later recieved the Turing Award and the Kyoto Prize. It was the first program with a complete graphical user interface and the first CAD program.

1968:

Mother of All Demos, Douglas Engelbart

Presentation of oN-Line System (NLS) which was inspired by Sketchpad. Demonstrated windows, hypertext, graphics, efficient navigation, command input, video conferencing, the computer mouse, word processing, dynamic file linking, revision control, and collaborative real-time editing. Basically everything that became the modern personal computer.

1971: Design for The Real World

“There are professions more harmful than industrial design, but only a few of them. And possibly only one profession is phonier. Advertising design, in persuading people to buy things they don’t need, with money they don’t have, in order to impress other who don’t care……Never before in history have grown men sat down and seriously designed electric hairbrushes, rhinestone-covered file boxes, and mink carpeting for bathrooms, and then drawn up elaborate plans to make and sell these gadgets to millions of people.”

- Methods: The interaction of tools, processes, and materials. An honest and optimal use of materials. Example: Dow Chemical’s ‘self-generating’ Styrofoam dome.

- Use: ‘Does it work?’ Example: A vitamin bottle should dispense pills singly.

- Need: Much design has satisfied only evanescent wants and desires while the genuine needs of man have often been neglected by the designers. The economic, psychological, spiritual, technological, and intellectual needs of a human being are usually more difficult and less profitable to satisfy than the carefully engineered and manipulated ‘wants’ inculcated by fad and fashion. Example: To prevent food from perishing in Third World countries.

- Thesis: ‘The deliberate, purposeful utilization of the processes of nature and society to obtain particular goals’. The content of a design must reflect the times and conditions that have given rise to it, and must fit in with the general human socio-economic order in which it is to operate. Example: Americans who try to couple a Japanese interior with an American living experience in their search for exotica find that many elements cannot be ripped out of their context.

- Association: Our psychological conditioning, often going back to earliest childhood memories, comes into play and provides us with antipathy against a given value. Example: what shape is most appropriate to a vitamin bottle: a candy jar, a perfume bottle or a style salt shaker?

- Aesthetics: A tool that helps in shaping design. However, there is no yardstick for the analysis of aesthetics. Thus, it is simply considered to be a personal expression fraught with mystery and surrounded with nonsense.

1980:

Do Artifacts Have Politics?, Langdon Winner

Yes he says and he suggests two considerations:

"yes or no" on whether to adopt a new technology and

"special features in the design or arrangement of a technical system" for which the answer to the first choice was "yes." The most important thing to recognize about these choices is that they often go far being pragmatic concerns about what tool would be best or most cost-effective for a given job. Many amount to the selection of "forms of life," since they embody certain possibilities more than others. The "greatest latitude of choice exists the very first time a particular instrument, system, or technique is introduced," so "the same careful attention that one would give to the rules, roles, and relationships of politics must also be given" to such technological choices.

1983:

Psychology of Human-Computer Interaction, Stuart Card, Thomas P. Moran, Alan Newell

1983:

Visual Display of Quantitative Information, Edward Tufte

Seminal text on information visualization.

1983:

Direct Manipulation: A Step Beyond Programming Languages, Ben Shneiderman

- continuous representation of the objects and actions

- rapid, incremental, and reversible actions

- physical actions and gestures to replace typed commands, which enabled designers to craft more effective graphical user interfaces

The Eight Golden Rules of Interface Design

-

Strive for consistency. Consistent sequences of actions should be required in similar situations; identical terminology should be used in prompts, menus, and help screens; and consistent color, layout, capitalization, fonts, and so on, should be employed throughout. Exceptions, such as required confirmation of the delete command or no echoing of passwords, should be comprehensible and limited in number.

-

Seek universal usability. Recognize the needs of diverse users and design for plasticity, facilitating transformation of content. Novice to expert differences, age ranges, disabilities, international variations, and technological diversity each enrich the spectrum of requirements that guides design. Adding features for novices, such as explanations, and features for experts, such as shortcuts and faster pacing, enriches the interface design and improves perceived quality.

-

Offer informative feedback. For every user action, there should be an interface feedback. For frequent and minor actions, the response can be modest, whereas for infrequent and major actions, the response should be more substantial. Visual presentation of the objects of interest provides a convenient environment for showing changes explicitly.

-

Design dialogs to yield closure. Sequences of actions should be organized into groups with a beginning, middle, and end. Informative feedback at the completion of a group of actions gives users the satisfaction of accomplishment, a sense of relief, a signal to drop contingency plans from their minds, and an indicator to prepare for the next group of actions. For example, e-commerce websites move users from selecting products to the checkout, ending with a clear confirmation page that completes the transaction.

-

Prevent errors. As much as possible, design the interface so that users cannot make serious errors; for example, gray out menu items that are not appropriate and do not allow alphabetic characters in numeric entry fields. If users make an error, the interface should offer simple, constructive, and specific instructions for recovery. For example, users should not have to retype an entire name-address form if they enter an invalid zip code but rather should be guided to repair only the faulty part. Erroneous actions should leave the interface state unchanged, or the interface should give instructions about restoring the state.

-

Permit easy reversal of actions. As much as possible, actions should be reversible. This feature relieves anxiety, since users know that errors can be undone, and encourages exploration of unfamiliar options. The units of reversibility may be a single action, a data-entry task, or a complete group of actions, such as entry of a name-address block.

-

Keep users in control. Experienced users strongly desire the sense that they are in charge of the interface and that the interface responds to their actions. They don’t want surprises or changes in familiar behavior, and they are annoyed by tedious data-entry sequences, difficulty in obtaining necessary information, and inability to produce their desired result.

-

Reduce short-term memory load. Humans’ limited capacity for information processing in short-term memory (the rule of thumb is that people can remember “seven plus or minus two chunks” of information) requires that designers avoid interfaces in which users must remember information from one display and then use that information on another display. It means that cellphones should not require reentry of phone numbers, website locations should remain visible, and lengthy forms should be compacted to fit a single display.

These underlying principles must be interpreted, refined, and extended for each environment. They have their limitations, but they provide a good starting point for mobile, desktop, and web designers. The principles presented in the ensuing sections focus on increasing users’ productivity by providing simplified data-entry procedures, comprehensible displays, and rapid informative feedback to increase feelings of competence, mastery, and control over the system.

1988:

Design of Everyday Things, Don Norman

7 principals of design:

-

Discoverability. It is possible to determine what actions are possible and the current state of the device.

-

Feedback. There is full and continuous information about the results of actions and the current state of the product or service. After an action has been executed, it is easy to determine the new state.

-

Conceptual model. The design projects all the information needed to create a good conceptual model of the system, leading to understanding and a feeling of control. The conceptual model enhances both discoverability and evaluation of results.

-

Affordances. The proper affordances exist to make the desired actions possible. The object suggests its use.

-

Signifiers. A signifier communicates where an action should take place. Effective use of signifiers ensures discoverability and that the feedback is well communicated and intelligible.

-

Mappings. The relationship between controls and their actions follows the principles of good mapping, enhanced as much as possible through spatial layout and temporal contiguity.

-

Constraints. Providing physical, logical, semantic, and cultural constraints guides actions and eases interpretation.

1997:

Towards Accessible Human-Computer Interaction, Johnson Bergman

"Providing accessibility means removing barriers that prevent people with disabilities from participating in substantial life activities, including the use of services, products, and information."

2000:

Tools for Thought, Howard Rheingold

Exploring where "mind-amplifying technology" comes from.

Now (>2010): Bret Victor

The Humane Representation of Thought

Accessibility in low resource contexts

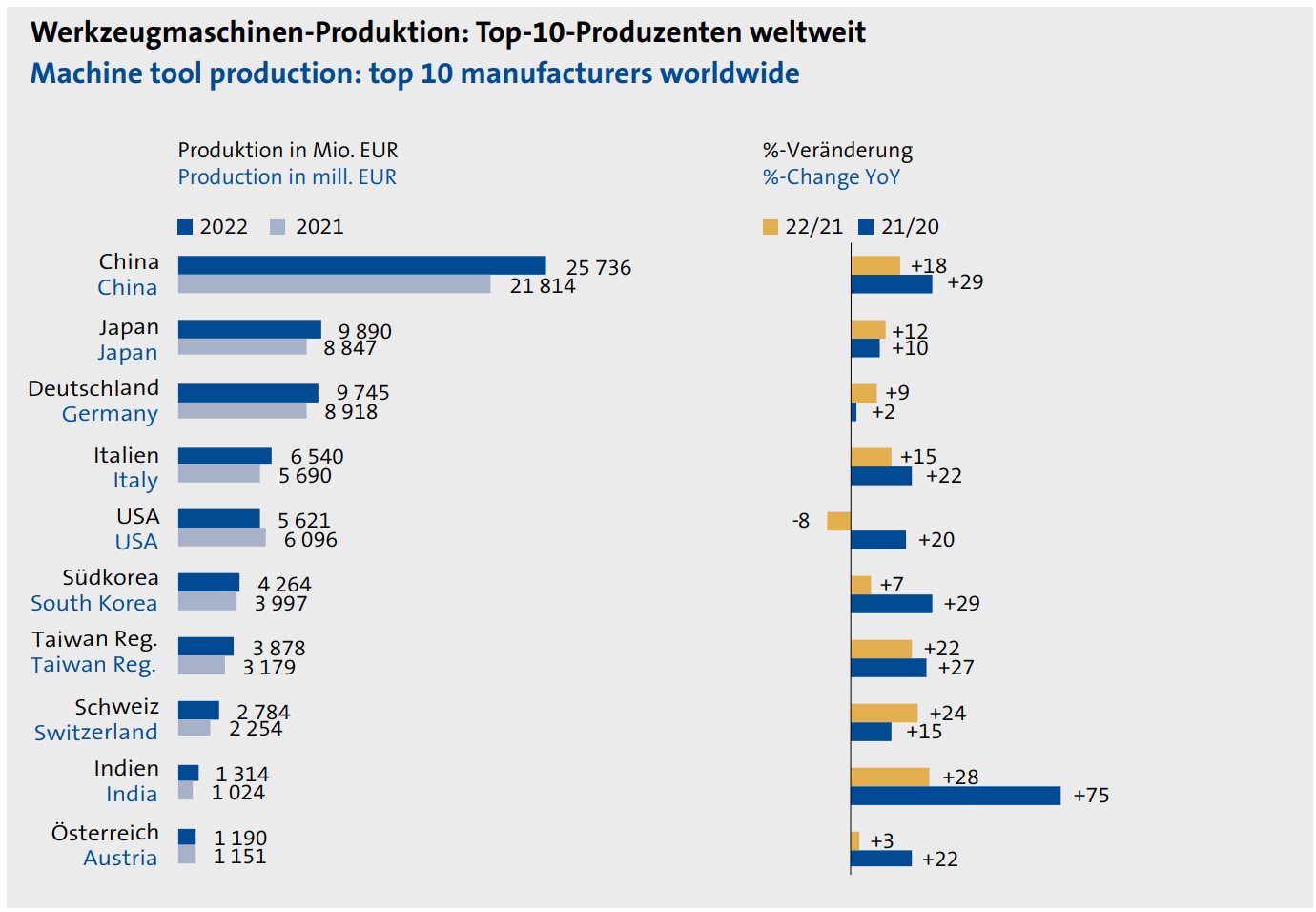

Importance of Manufacturing in Economic Development

- Manufacturing is a key driver for sustainable transformation

- Machine tools - also known as mother machines are the key enablers of manufacturing

- Technological developments in the manufacturing sector have spillover effects in various other industries

- Can directly contribute to SDG goals 8 Decent Work and Economic Growth and 9 Industry, Innovation and Infrastructure

- Creating jobs and income, directly contribute to reducing poverty, reducing inequalities and several others.

The Accessibility Problem

- Machine tools and more specifically 'digital fabrication machines' are generally produced in a select few industrialized countries like the USA, Germany, China, Japan etc.

- Most developing countries do not produce any machine tools and therefore have to import them

- These machines are usually way too expensive for small microenterprises to purchase. Shipping costs and taxes further increase these costs along with increased adminstrative and beaurocratic complexity.

- With used machine tools being more affordable, they are still expensive for typical users in developing countries due to such machines still costing several thousand USD

- Lack of research capacities and human capital to invent machine tools

- Commercial machine tool technology hidden behind IPs and patents

The Open Source DIY movement: Hedonic vs Utilitarian

- Open source economics as an alternative bottom up approach

- Majority of users in the makerscene are generally categorized as white, male, middle-class with a degree in engineering or computer science.

- Most open source machine projects also originate from users based in the global north which are inevitably also catered to the needs, resources and backgrounds of users from similar demographics

- Digital fabrication in global north is often for hobbyist related purposes with motivations often being self-fulfillment,reputation, learning new skills, building reputation, being part of a community etc.

- In global south - DIY projects are more utilitarian i.e. with a focus on income generation or solving real world problems where they are often also cosidered frugal innovations, famously known in hindi as Jugaad.

Open source machine tools (OSMT)

- Open source machine tools (OSMT) i.e. a distinct subset of open source hardware (OSH) have been proposed as a solution to the problem

- The blueprints to reproduce OSMT are freely available for anyone to use, modify and sell.

- Example project: Fabulaser mini

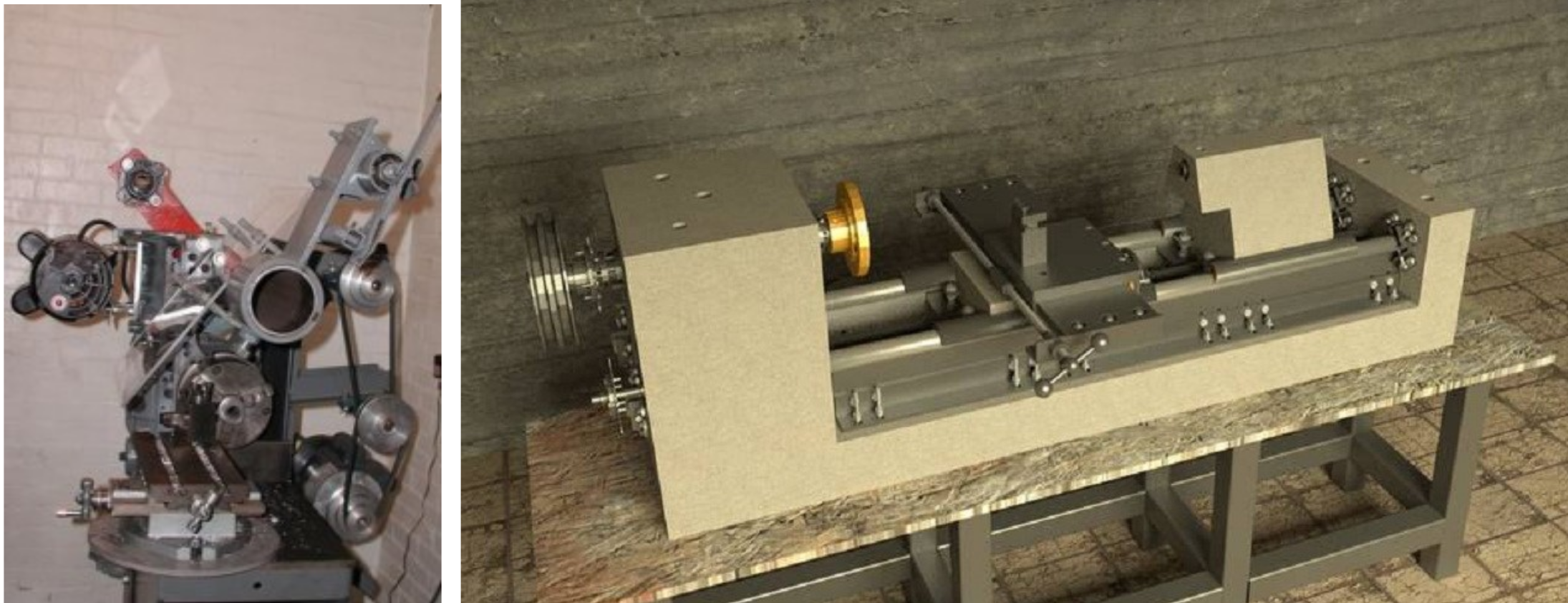

Pat Delaney's Open Source Machine Tools Project

Left: Multimachine, Right: Concrete lathe

Left: Multimachine, Right: Concrete lathe

-

Pat Delaney's Open source machine tools project was basically a set of instructions to build manual machine tools from scratch from early 2000

-

Notably the multimachine and the concrete lathe (a more recent instructable of the concrete lathe build)

-

The multimachine cleverly reused scavenged automotive car engines to create a coombined milling and lathe machine. Engines already have precisely machined surfaces and therefore avoids the need to machine flat surfaces (difficult with no access to large industrial machine tools).

-

The project was specifically aimed at developing countries with a lack of precision manufacturing facilities and access to specilized components

-

However the project died out due to several reasons such as much too complicated instructions, complex modifications, need to source specifc types of engines etc.

Open Source Ecology's 'Civilization Starter Kit'

- Set of 50 machines that could be used for self-sufficinecy from macnufacturing and agricultural to baking machines.

- Several CNC cable machines among the list of machines developed such as a CNC oxyfuel cutter, 3D printer etc.

- Being developed in the US, still hard to translate 1:1 to other contexts with different resources and manufacturing capabilities

- Slow progress - Due to reasons such as lack of similar incentives for designers as seen in conventional industry projects, design and development done in free time, lack of resources etc.

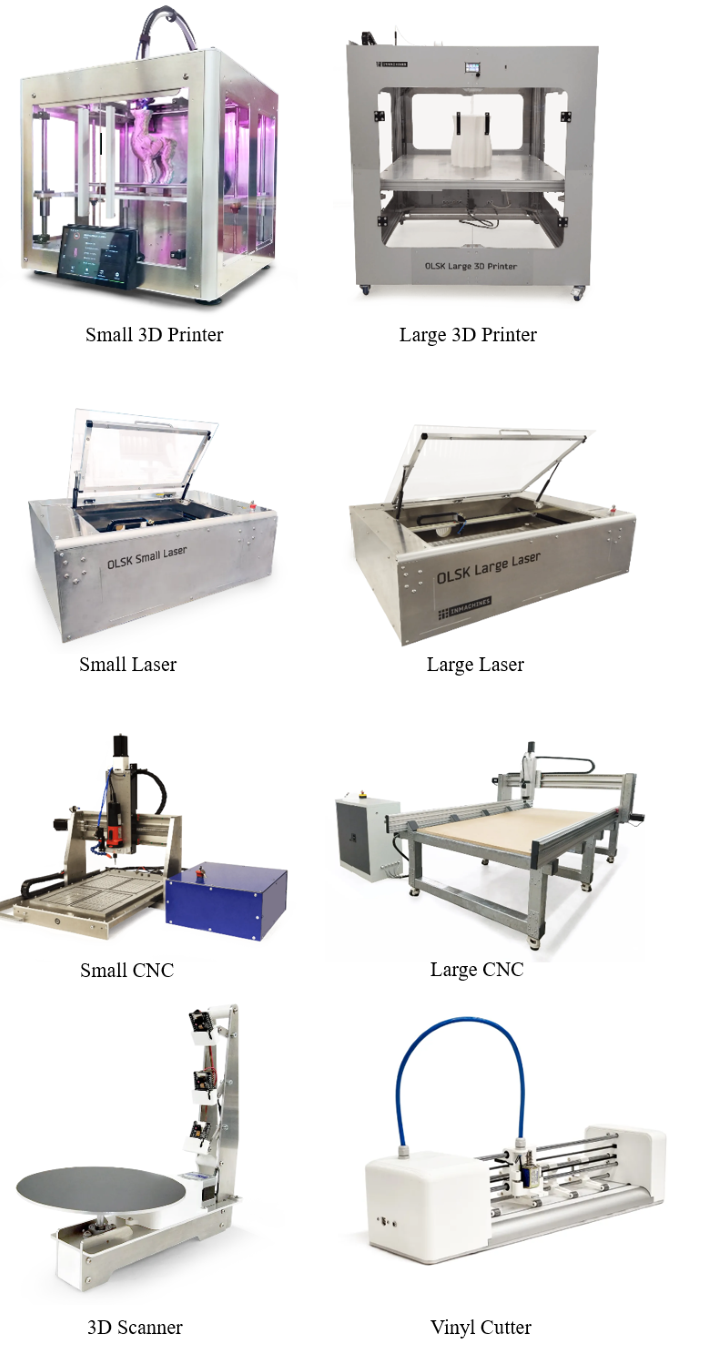

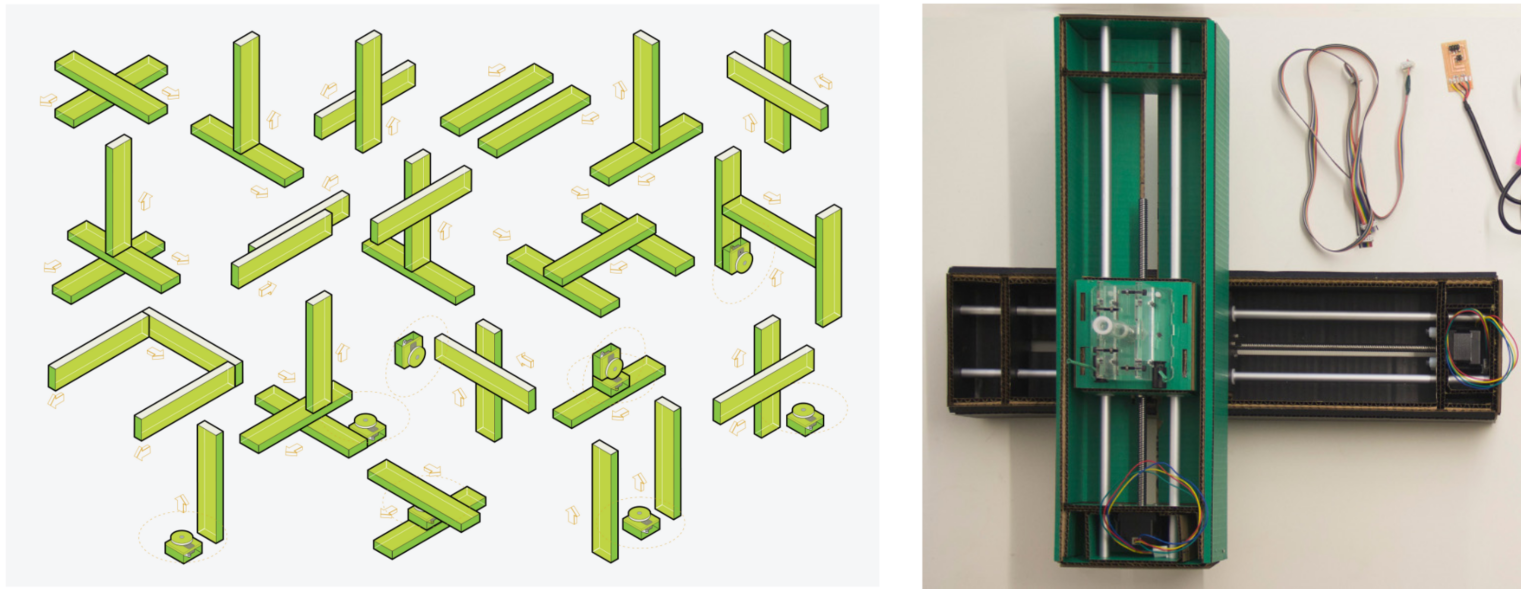

Open Lab Starter Kit (OLSK)

The 8 open source alternatives to the Fablab Inventory

- The OLSK project is an open source alternative to the commercial fablab machines

- Set of 8 open source machines - 3D printers, laser cutters, vinyl cutters and a 3D scanner.

- Focus on replicability by enabling the fabrication of the machines by conventional fab lab machinery

- Focus on Documentation to resemble pictorial documentation guides like LEGO and IKEA.

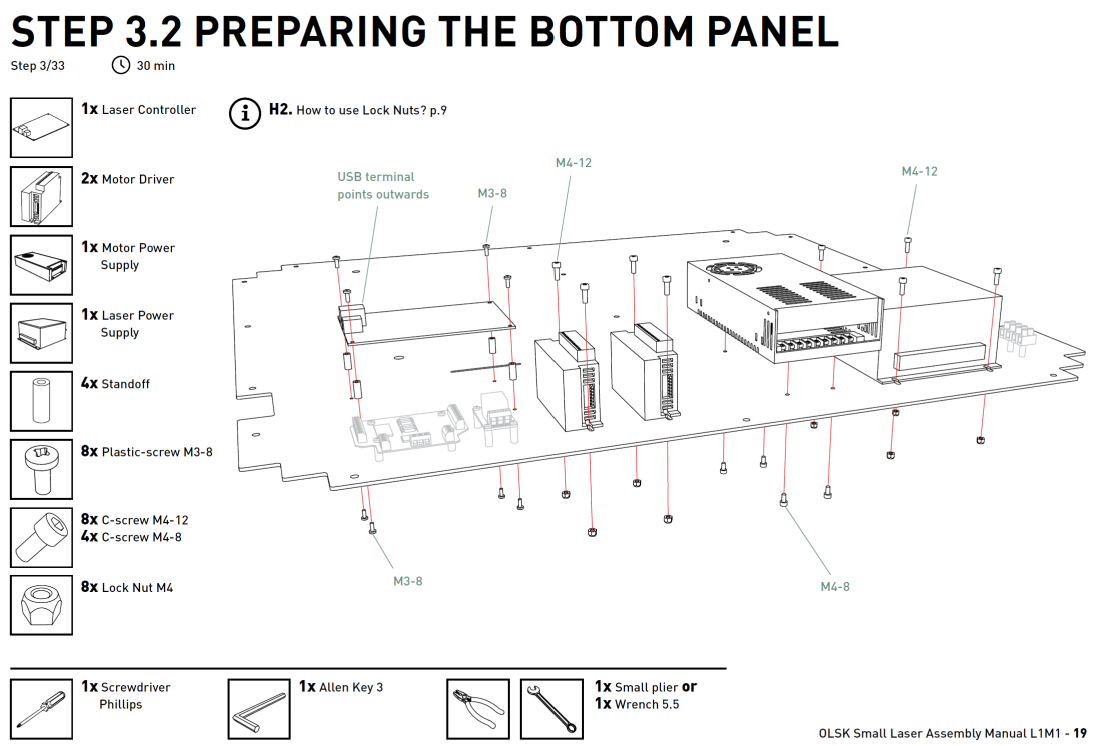

Snapshot of build manual for the OLSK laser cutter design

- Iterative design with each machine undergoing 3 major design iterations supported by user feedback from build workshops and continued usage

- Focus on several aspects such as design for manufacturing, design for assembly, design for usability, design for affordability etc.

- Project completion Q4 2024

Challenges to design for Low Resource Contexts

Migrant-run Steel fabrication workshops in Oman

- Constrained resources

- Limited access to financing

- Limited access to advanced manufacturing capabilities

- Lack of infrastructure

- Machines when present, often analog and substandard in quality/ worn out > difficult to fabricate to tight tolerances

- Deficient access to international markets

- Low digital, technological and general literacy levels - A key barrier

- Source: Exploring the Potential of Open Source Machine Tools for Sustainable Industrial Development in Low Resource Contexts - A Case Study of Migrant-Run Microenterprises in Oman

Design principles for low resource contexts

- Appropriate design - Designed to be contextually appropriate, that takes local resources, needs, preferences and capabilities into account.

- Frugal Design > Focus on key components

- User centered design or Co-design

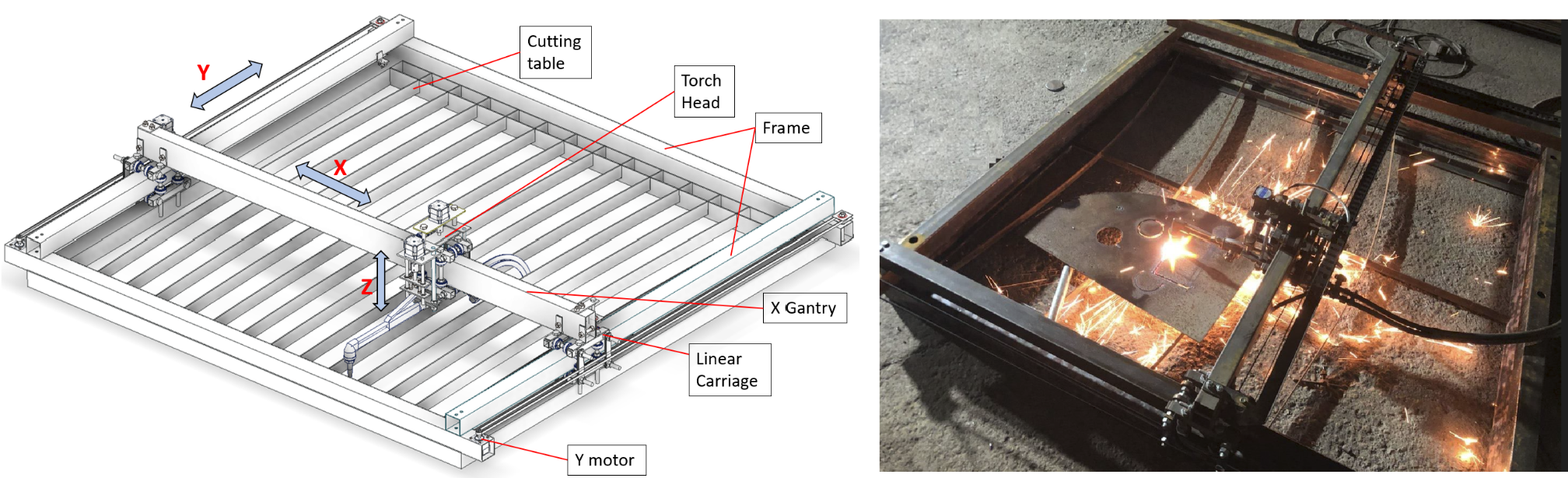

- Example of frugal automation of an oxyfuel cutter

An handheld oxyfuel cutter was automated with a user centered design using local materials and basic 3d printer parts like nema17 motors and an arduino ramps board.

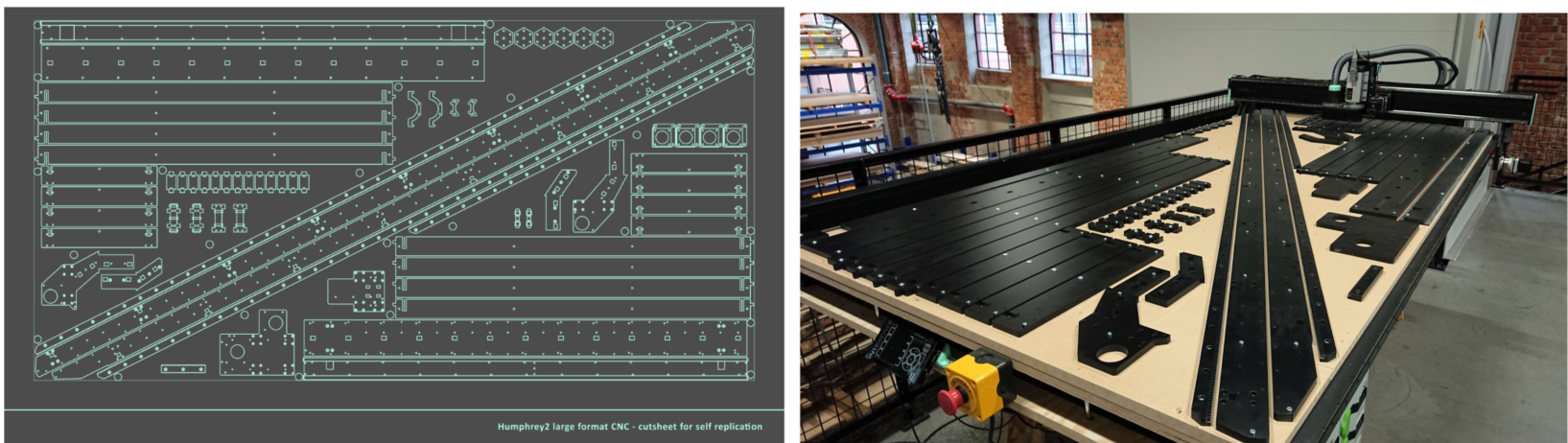

Use of digital fabrication technologies

- Focuses on CNC 2d fabrication methods for the fabrication and manufacturing of machine parts

- Avoids the need for user to be highly dextrous or experienced with mechanical precision builds, preventing assembly and fabrication errors

- Example: Humprey 2 from Jens Dyvik's fabricatable machines, where almost the entire machine structure can be machined from a single sheet of POM

Modularity and parametric design

- Each machine tool subsystem is designed as an individual module that is independent of other modules - eg. linear stages, frame, spindle unit etc.

- Design can be scaled to user spatial requirements, or to save costs

Accessibility (New Modalities, Multimodal approaches and Natural Interactions)

Alternative CAD/CAM Methods for people without technical background

Making Gestures

- The research focuses on a multimodal body-centric approach to interactive fabrication, utilizing a gesture language as the primary mode of communication between the user and the machine.

- The framework aims to democratize robotics among designers by providing tools with a low barrier to entry, making advanced technology more accessible.

- Overcoming operational and representational limitations by facilitating conversation and interaction with machines.

- Start 1:22

Gesture Recognition for Feedback Based Mixed Reality and Robotic Fabrication

- Enables direct manipulation of digital information through natural hand movements, making the interaction with robotic arms more intuitive

- Allows uses to identify nonstandard cut stock in 3D and set robotic toolpaths using gestures .

- Provides immediate visual feedback in the MR interface as users interact with physical objects, allowing for seamless adjustments

- Start 0:17

Computer Aided Design in AR/VR

- The system is designed to be accessible by non-expert users, enabling participation in the design process through an MR user interface that manages module properties and connectivity.

- 3D modeling like move objects, instead of using commands or gumball tool

- The custom MR environment facilitates on-site collaborative design, making the technology more accessible to users in the actual construction setting

- Start 0:7

Active bending in physics based mixed reality (video)

Accessibility (Making machines accessible to everyone)

Who has access?

3d printed elephant in the room

- the mainstream maker movement lacks diversity and representation of people of color

Digital Fabrication Practices for the Education of Visually Impaired or Blind Youth

- Digital fabrication tools in the education of visually impaired or blind youth, highlighting the adoption of laser cutting over 3D printing and the need for better coordination

Do-It-Yourself Empowerment as Experienced by Novice Makers with Disabilities

- A study on Do-It-Yourself Empowerment for novice makers with disabilities, exploring the empowering potential of making through online videos, fieldwork at makerspaces, and workshops called DIY-Abilities.

Designing makerspaces for accessibility

- Design Process used to enhance the Accessibility of a university-based makerspace for individuals with disabilities, involving a tour, design activity, and brainstorming session.

Accessible platforms/machines

Sharing platforms as a way in which work, ideas, making, becomes more inclusive and accessible.

OpenStructures is an open modular construction project where anyone designs for everyone on the shared basis of a grid. Designs on OpenStructures as well as parts that can be reproduced are shared and evolved through use, redesign, and resharing. These parts are meant to be reproducible in the efforts of personal fabrication/dispersed manufacturing.

They also host workshops and products can be anything from furniture to low tech home appliances, and flexible tools.

Jesse Howard - transparent tools

Similarly are also projects by Jesse Howard, who has a few projects on relatively simple machines/home appliances since they while not complicated, they are often inaccessible to the average user. Furthermore, repair or recycling is essentially impossible with these machines, as when these products cease to function they are essentially disposable.

Appropriate technologies

CACITA - Autonomous Center for Inter-Cultural Creation of Appropriate Technology

Example: Solar Charged Lawnmower

Appropriate technologies collaborative

Appropriate Technologies Collaborative

Cost

Rob Thompson Manufacturing Guides

Inclusion

Shirin Voussoughi

Nation of Makers

Narratives of Being a “Maker”

Dale Dougherty - We Are Makers

The Entrepreneurial Narrative

Debbie Chachra

Mistakenly Only Considering Access

Asking the right questions and reframing

Visibility/Representation

Megan Smith - Shift 7

Equity in media: images matter

Cracking the code (study with USC)

Leah Buechley