This week my inital intent was to create two molds for ceramic/slip cast coffee mugs. I've been working on this project for the last few weeks to get ahead on HTMAA. However, critically, my work on my ceramic castings didnt fufill this weeks goal of using/leaning CAM - Computer Aided Manufactoring. Please see my reference PDF for detailed instructions on CAM.

This is a bit of a brain teaser. I need a finished mug made out of silicone, to make this I needed a plaster mold. Therefore, I needed a silicone mold to mold a plaster mold. Finally, I needed to 3D print an object to mold in silicone. With slip cast, there is no need to form an inner plaster mold. The plaster 'cures' the ceramic slip from the outside in to create wall thickness.

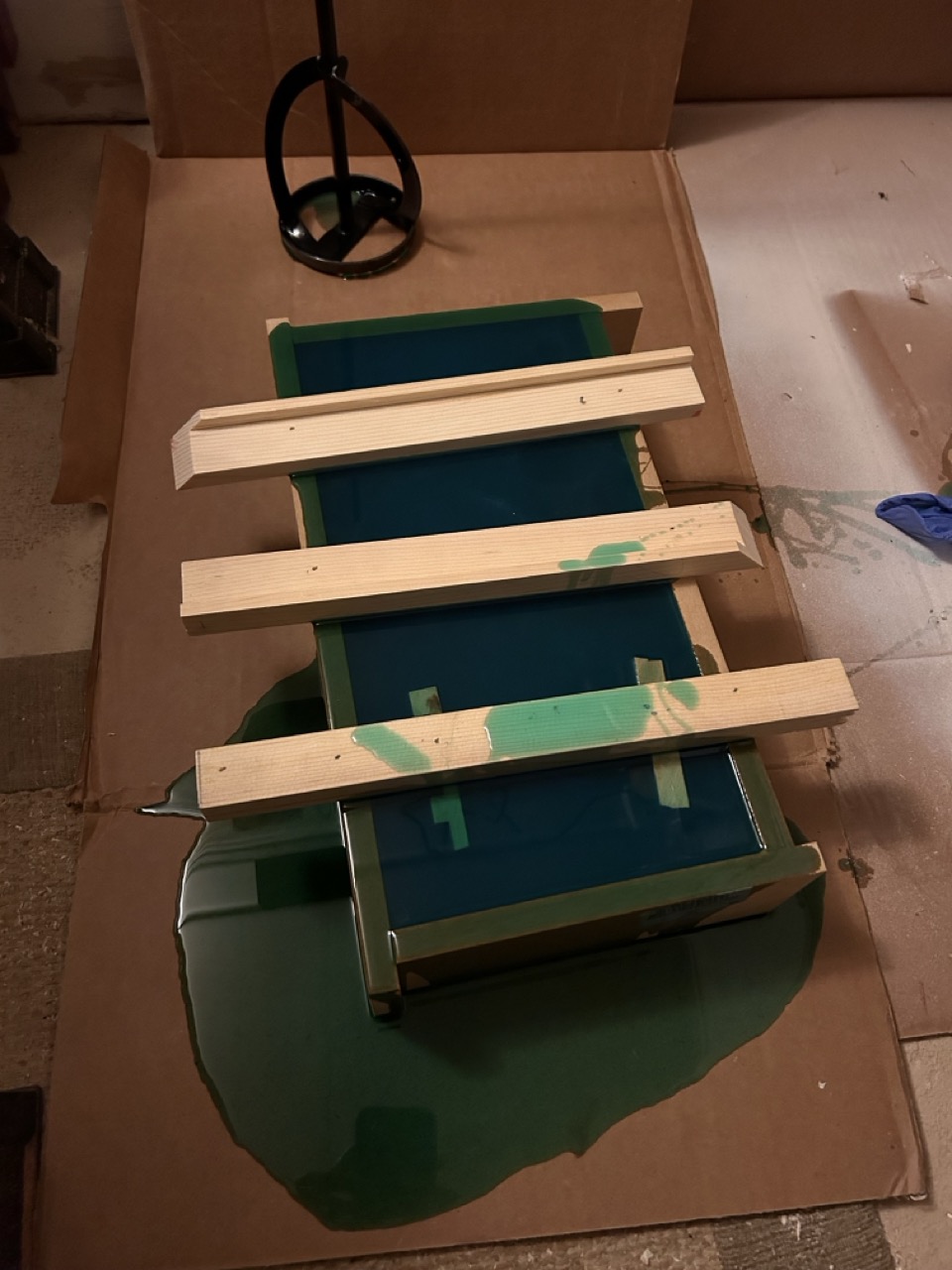

Above you can see the final, 3D print - this is the final shape I need *in plaster*. I forgot to machine the indexing keys so they weren't a perfect CAD fit. I resigned myself to do that in post processing - Plaster is easy to machine with hand tools. I made a mold with MDF (melamine is WAYY better, but I had MDF on hand) and stuck the prints to the bottom with double stick tape. BAD IDEA.

This was a disaster. The air filled 3D prints floated to the top. Luckily I had gloves, batton strips, and a brad nailer handy in my basement.

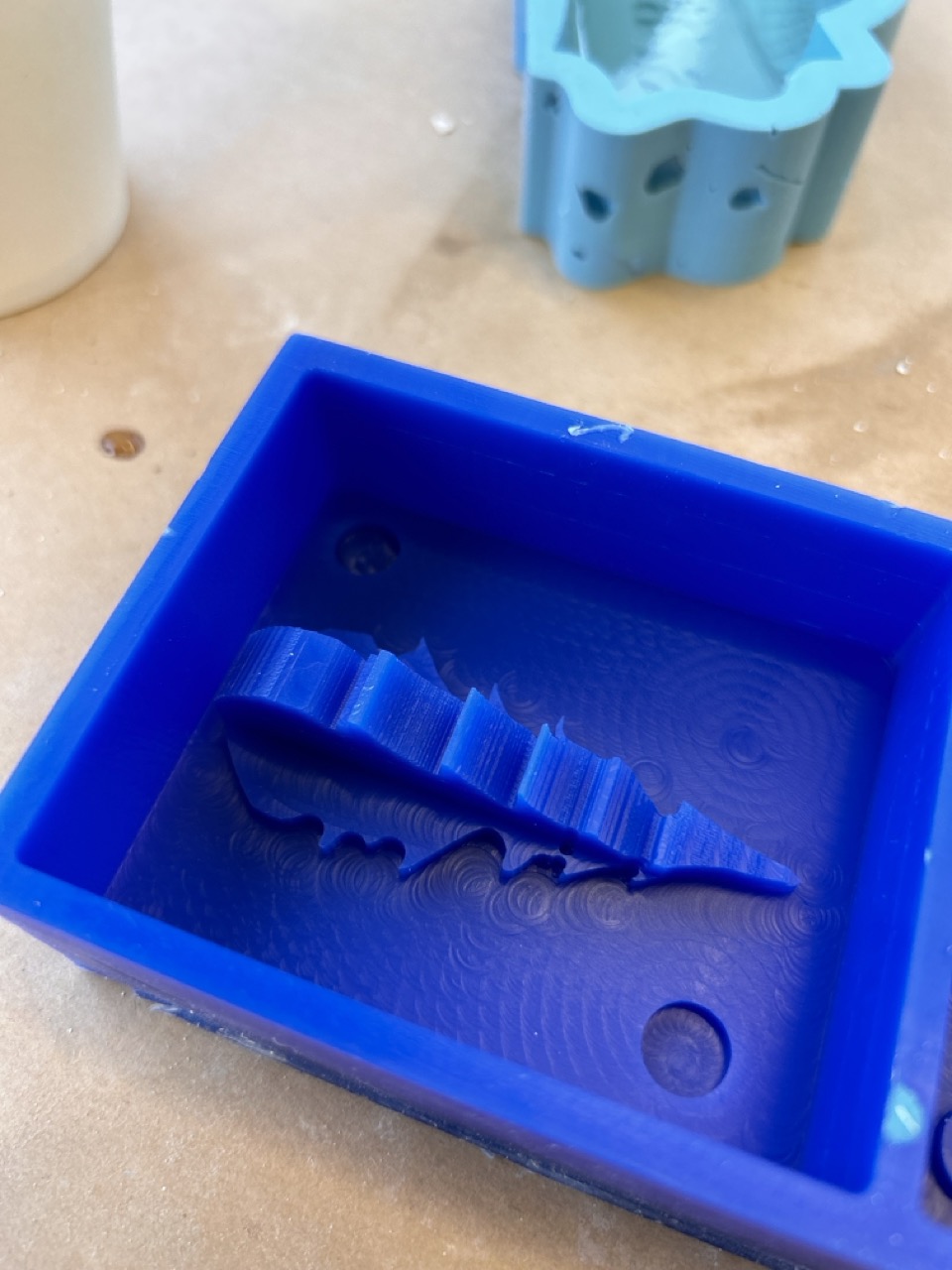

These are the final results of the silicone molds. The Anchor Mold looks terrible but yields decent plaster results, while the mountain mold turned out really good!

Above is a picture of plaster drying. By the rules you're really supposed to be pretty precise in the plaster/water weights... but I kinda winged it. Plaster is really cheap and I can make a lot of molds.

While I cracked a bunch of plaster molds. Some of them turned out really good!

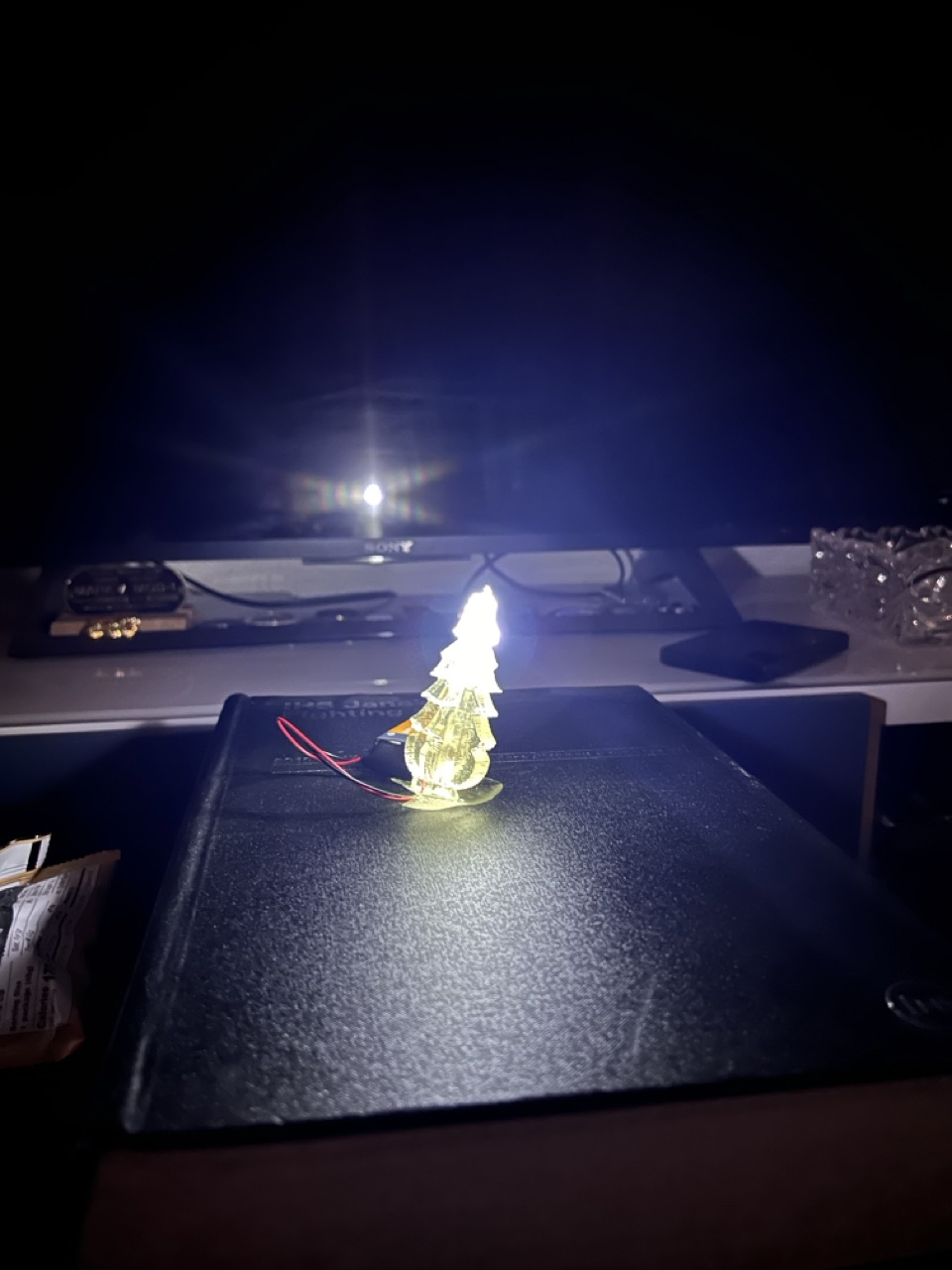

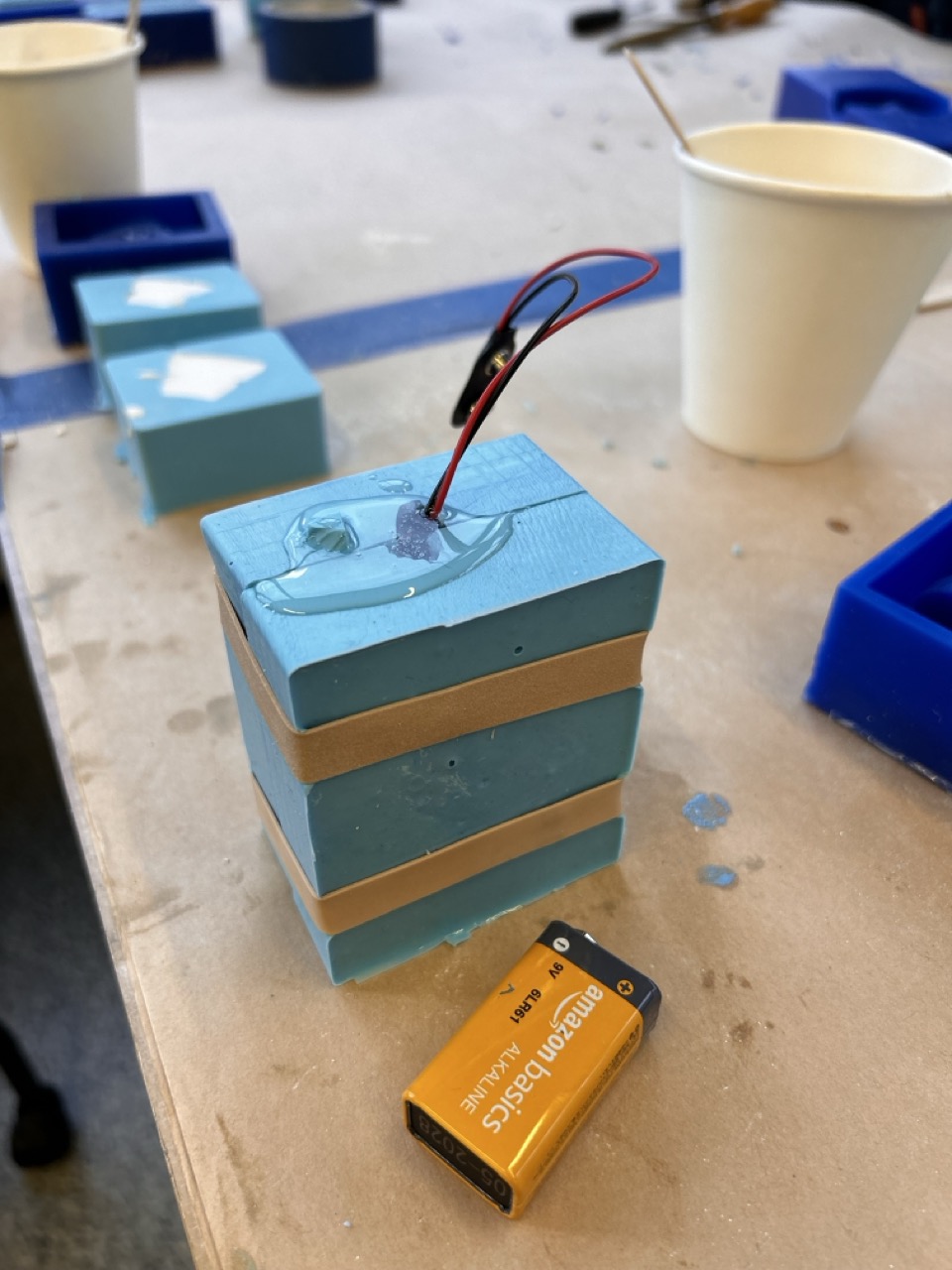

For this week, I also needed to learn CAM. I decided to model a Simon Pearce Glass Tree in Epoxy. I did a rough CAD of the tree and worked on the CAM following the tutorial that Anthony put on the HTMAA site. I took a screen video of Anthony helping me through the CAM, so I could do it again by myself.

I used the supplied silicone compound to mold in my wax. This was a 1:1 two part mix by volume. I then cast the tree in epoxy. I embedded a 9V Battery, 800 Ohm Resistor, and White LED in series in the tree.