2:30am on a tuesday night.

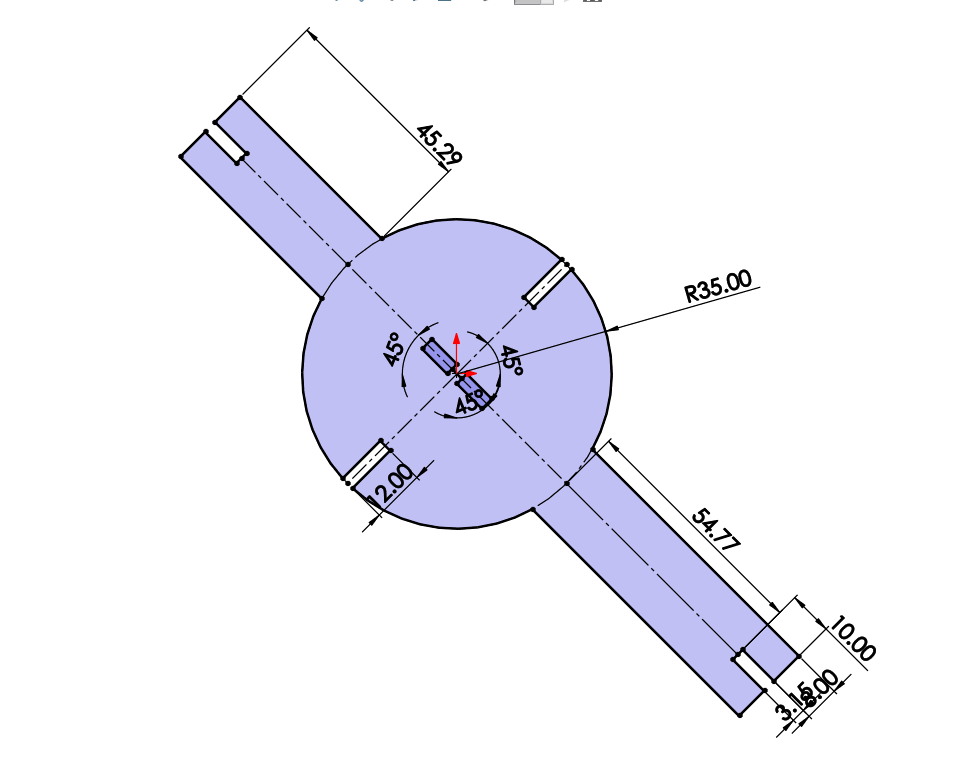

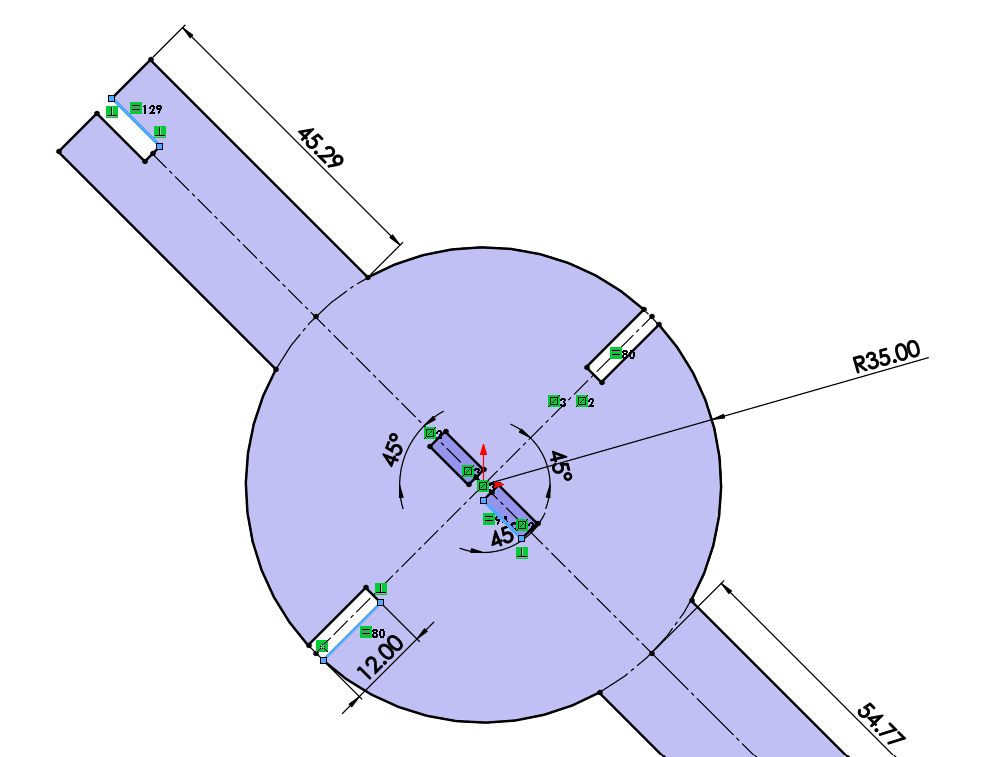

For the laser cut project, I was interested in exploring an asymmetrical construction assembly to see what kind of assemblies I can make. I launched my favorite CAD program solidworks to design a module. It started off trying to make a Q shaped module, but as I progressed it kind of deviated from the initial design. I added relations that would make the assembly process more interesting.

After building out the module, I used the assembly mode in solidworks to quickly check what kind of configurations I would be able to build. Trying it virtually allows me to make quick changes that would give assembling more possibilities.

| characterization | measurements |

|---|---|

| focus | N/A |

| power | 40% |

| speed | 10 |

| rate | PPI 250 |

| kerf | 0.5MM |

| joint clearance | 0.15MM |

| types | 4MM corrugated cardboard |

Initial test was done on the laser cutter to see what would be a good tolerance. Our group used kai's design to figure out the best fit and kerf cut.

Proceeded to cut out the modules, kept the long side of the corrugated cardboard for strength in this linear design.

I tried assembling the modules in different ways. I would say this design is limited in terms of what kind of complete assembly it can make, but is very fun and puzzly to assemble and play with.

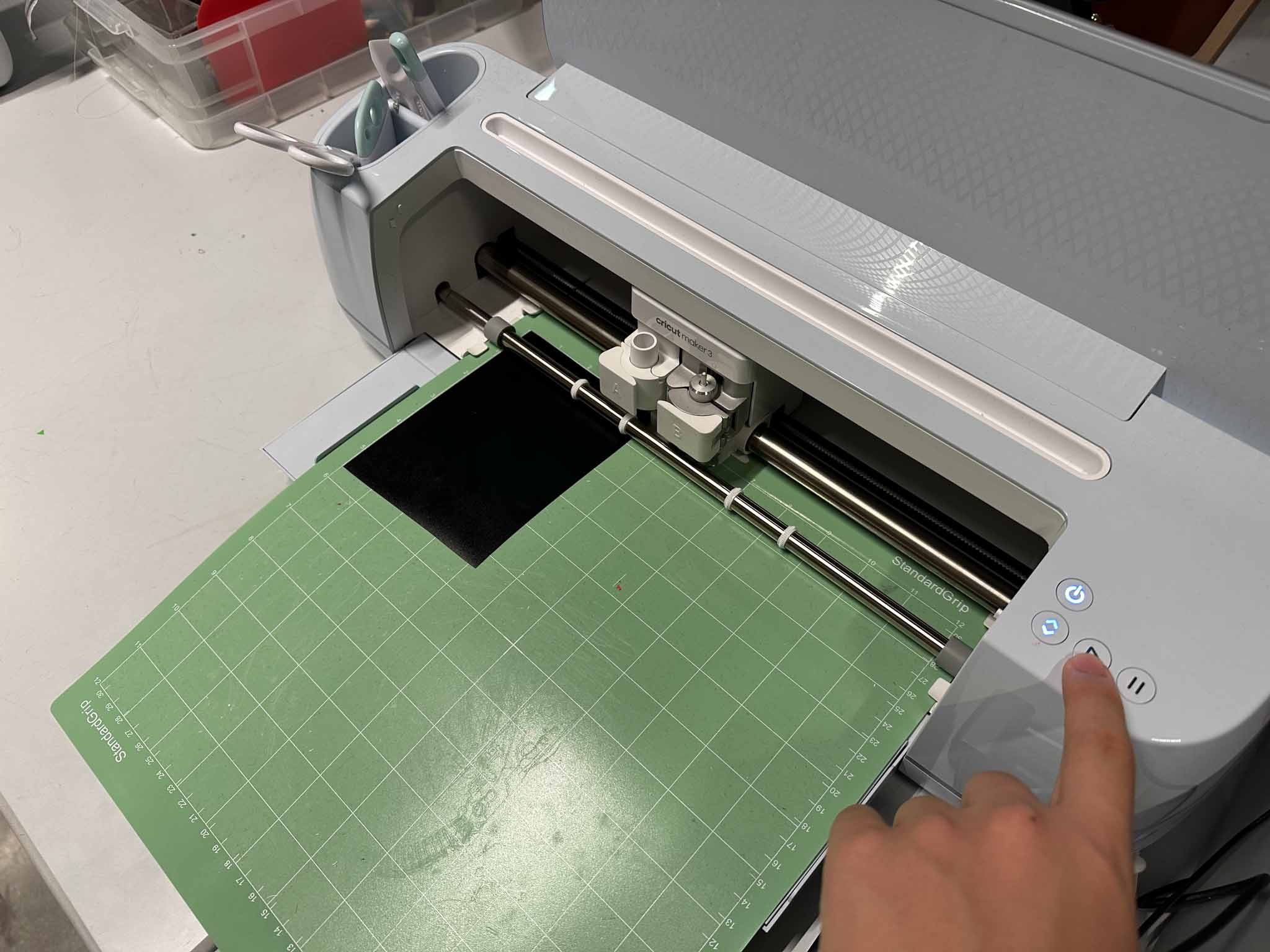

For the vinyl cut assignment, I made a vinyl cut laptop sticker using the graphics from a previous project.

The Circuit is very intuitive and easy to use, it was able to recognize different parts from a svg file and can even convert jpegs. Load the material and the machine starts cutting.

I then used transfer tape to move the final cut on to my computer, since I have some very thin cut outs.

Here is the final result on my computer.