Amon Millner

|

|

||||

| Weekly Assignments | ||||

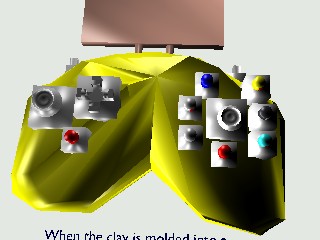

| Final Project - The "Claytroller" |

"The Claytroller Goal: I wanted to provide simple connectable building blocks that make complex computer/console interfaces accessible to novices. |

|

||

| Week 10 - |

"Displays"

Tools: Camm vinyl cutter or Modela mini-mill or Chemical etcher, soldering iron, Eagle, cam.py Media: LCD displays Goal: make boards that displays a text messages on LCD screens or TVs |

|

||

| Week 9 - |

"Micro machining"

Tools: Resonetics UV Excimer Laser Media: metal Goal: make something really small |

|

||

| Week 8 - |

"Communication / Internet 0"

Tools: Camm vinyl cutter or Modela mini-mill or Chemical etcher, soldering iron, Eagle, cam.py, C-to-AVR stuff Media: copper adhesive tape, epoxy film, phenolin sheet or CEM PCB Goal: create a project using Internet 0 style "click" communication |

|

||

| Week 7 - |

"Motor Control"

Tools: Camm vinyl cutter or Modela mini-mill, soldering iron, Eagle, cam.py Media: stepper motors, electronic components, copper adhesive tape, epoxy film, phenolin sheet or CEM PCB board, a battery pack or wall adapter Goal: drive stepper motors using the kinds of circuit boards used in week2 and week4. |

|

||

| Week 6 - |

"Injected Plastic Parts"

Tools: injection mold machine, vacuum forming machine Media: ABS plastic, pet-G thermal plastic Goal: make a model of something by injecting ABS plastic into an aluminum mold |

|

||

| Week 5 - |

"Milled Button Mold"

Tools: Feature Cam 2004, Hass CNC super mini-mill and appropriate drill bits Media: aluminum block Goal: operate a powerful CNC mill to create a mold of a shape that will be used an injection mold machine |

|

||

| Week 4 - |

"Chimp Sensor"

Tools: Camm vinyl cutter, soldering iron, Eagle, cam.py Media: copper adhesive tape, epoxy film, phenolin sheet Goal: use a vinyl cutter to cut traces of a circuit board. The traces can then be transferred to another surface such as epoxy. The circuit on the epoxy can be stuck to any surface and withstand the heat of a soldering iron when electronic components are being placed on the board. The board that can be programmed (through a custom parallel port cable) to sense capacitance and resistance of items near the board. The sensed values can be sent to a computer to control things that happen on the screen. |

|

||

| Week 3 - 3D! |

"Phony Bone"

Tools: GeoMagic, Minolta Laser Scanner w/ turntable, ZCorp 3D printer, ZCorp 3D printer software Media: plastic toy bone to scan, plaster dust to build replica from Goal: scan and print an object |

|

||

|

Week 2 - Basic Electronics

Microcontrollers |

"Hello board"

Tools: Modela mini-mill, soldering iron, Eagle, cam.py Media: CEM PCB, surface-mount electronic components Goal: stuff a small surface- mount circuit board that can be programmed (through a custom parallel port cable) to send text messages to a computer monitor (through custom serial cable) |

|

||

|

Week 1 - Cutting press-fit objects Make a structure that holds itself together without adhesives |

"Magic Maracas"

Tools: laser cutter, sDraw, cam.py Media: acrylic Goal: make a hand-scale press-fit object more complex than a cube but not impossible for youth to make |

|

||

|

Week 0 - 3D Modeling

Model a potential final project |

"Claytroller"

Tools: Blender Goal: customizable computer input device |

|

||

|

|

||||