Topics for the semester

Topics for the semester

introduction introduction

|

|||||

assignments assignments

|

|||||

readings readings

|

|||||

projects projects

|

|||||

pictures pictures

|

Assignment 1 : Introduce yourself with three "something's" that you would wish to build : 16 Feb 2004

Pocket Milling machine

The idea behind this proposal is to be able to shrink down a milling machine down to the size where it could fit in your pocket. With better metrology and deterministic machine design, machine tools are reaching sub-micron limits in resolution and accuracy. The idea is to build a small-stroke (2cm by 2cm by 2cm milling volume), very high resolution (sub-micron) milling machine. With a smaller stroke lengths it is possible to design a compliant mechanism based machining stages which provide very high resolution and repeatability. With possibilities of FIB (Focused Ion Beam) machined Tools it would be possible to explore usage of such a machine in prototyping MEMS based true 3 dimensional structures.Applications

1. Milling microfluidic circuits - advantages - deeper channels (~ 1 mm ), various materials can be milled, 3D surface profile for channels

2. Milling tools for dentists - should be able to make 3D prototypes of tooths rapidly - with very high resolution - 6 axis machining.

Design Specifications

1.

Error Budget for Modela MDX 15 , (coming up)

Error Budget for Modela MDX 15 , (coming up)

2.

FRADPARC for Pocket Milling Machine

FRADPARC for Pocket Milling Machine

3. Analysis and control of a parallel kinematic mechanism for a XY theata stage.

References

1. Electrochemical Machining , Philippe Allongue et al. Science Vol 289 July 2000

2. FIB shaped microtools , Picard Precision Engineering 27(2003), 59-69

3. Construction and testing of nanomachining instrument, Gao et al. Precision Engineering 24(2000) 320-328

4. Tool geometry study in micromachining, F Z Fang et al., J. Micromech. Microeng. 13(2003) 726-731

Image a credited to [3], Image b credited to [2], Image c credited to [4] Images above have been used without permission.

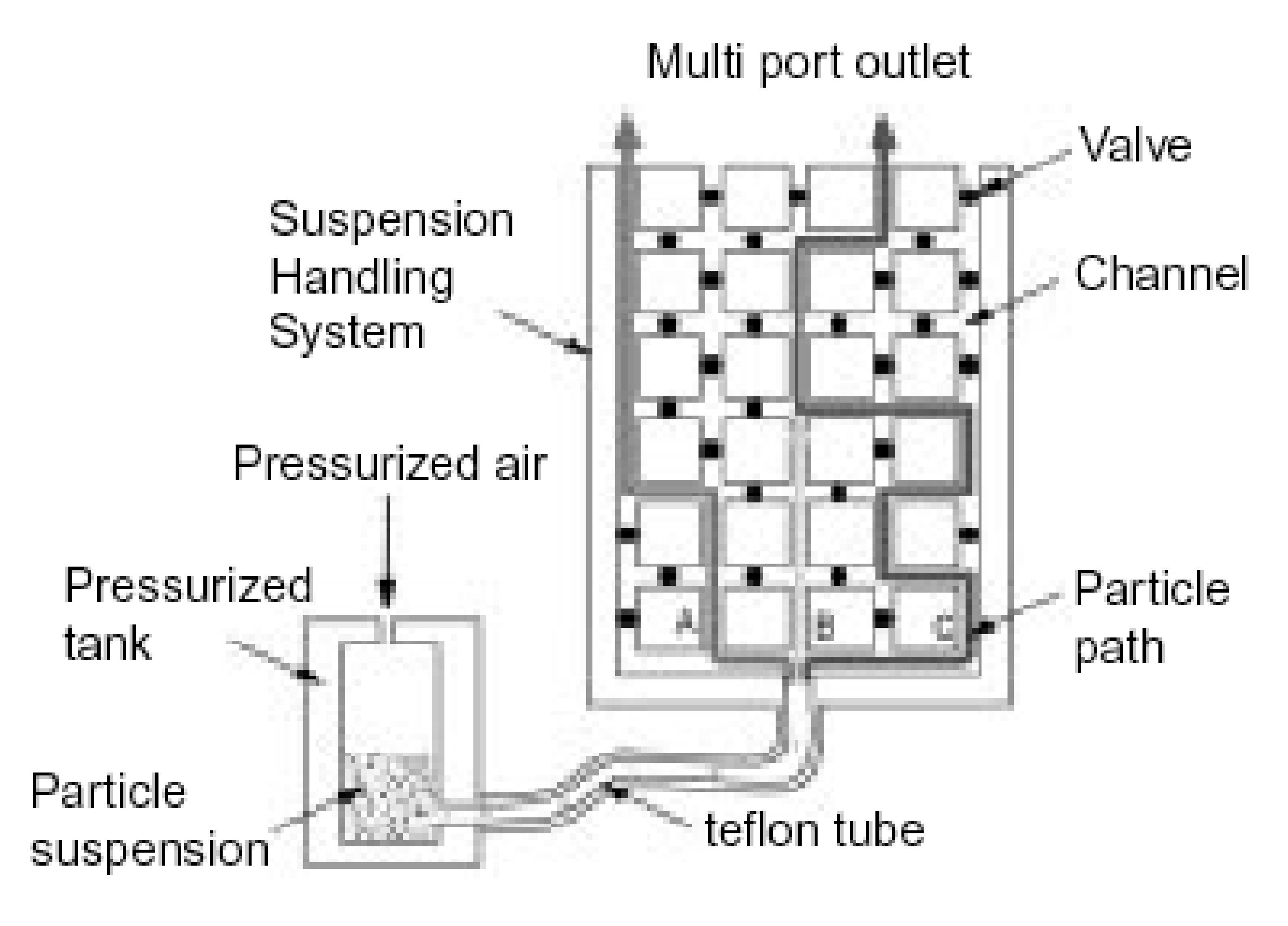

Microfluidic Assembly Lines for complete 3D micro assembly

Assembly lines for macroscale parts is a very well known technique in the industry. The idea for this project is to shrink down the assembly line on to a microfluidic based chip. The goal of the project is to acheive complex 3 dimensional assembly of multiple micro/meso scale parts based on interactions of the parts controlled by the flow fields (could be due to fluid flow, electric, magnetic fields) generated. The geometry of the channels ensure the right binding sites meet for corresponding parts. Also the assembly sequence for a particular assembly is encoded in the geometry of the microfluidic track.Applications

1. Assembly of complex mems parts - higher througput integration of optical, mechanical and electrical parts.

2. Digital fabrication

Analysis

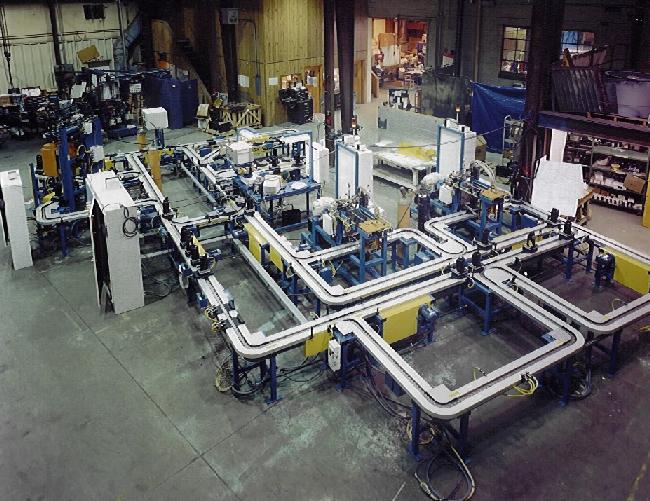

Pipe Screen saver model based rapid prototyping machine

(with Saul Griffith)All of you have seen the 3D "crazy pipe screen saver". The goal is to use a pipe constructing algorithm to build 3D objects in physical space, in a rapid prototyping setting. We think it is a very optimised solution since it is space saving and thus shall use less material per cubic volume. Thus a CNC machine will be built which can join together, cut and form pipes to form any arbitrary shape.

Gene-fab : On demand DNA synthesis on microfluidic chip

(with Peter Carr)Building a Two-photon absorption-polymerization for 3D microfabrication from a confocal microscope.

Reference1. Fabrication and metallization of three-dimensional microstructures, T. Baldacchini et al. MRS 2004 , Boston.