3D Printing

For this week's assignment, we had to design a 3D model, print it, and get our hands dirty with 3D scanning.

In terms of 3D scanning, we used the Sense 3D scanner, which was super finicky when it came to 3D scanning objects, but scanned human faces (and bodies) fairly well. Even though a turn table to turn the object agains a stationary 3D scanner to get a 360 degrees view of it, tracking would be lost very frequently. I speculate that tracking might work better if scanning was done against a monochromatic baakground!

So after several attempts to 3D scan my lovely cat pencilcase, Elliot helped me 3D scan my face, and I helped him do his :)

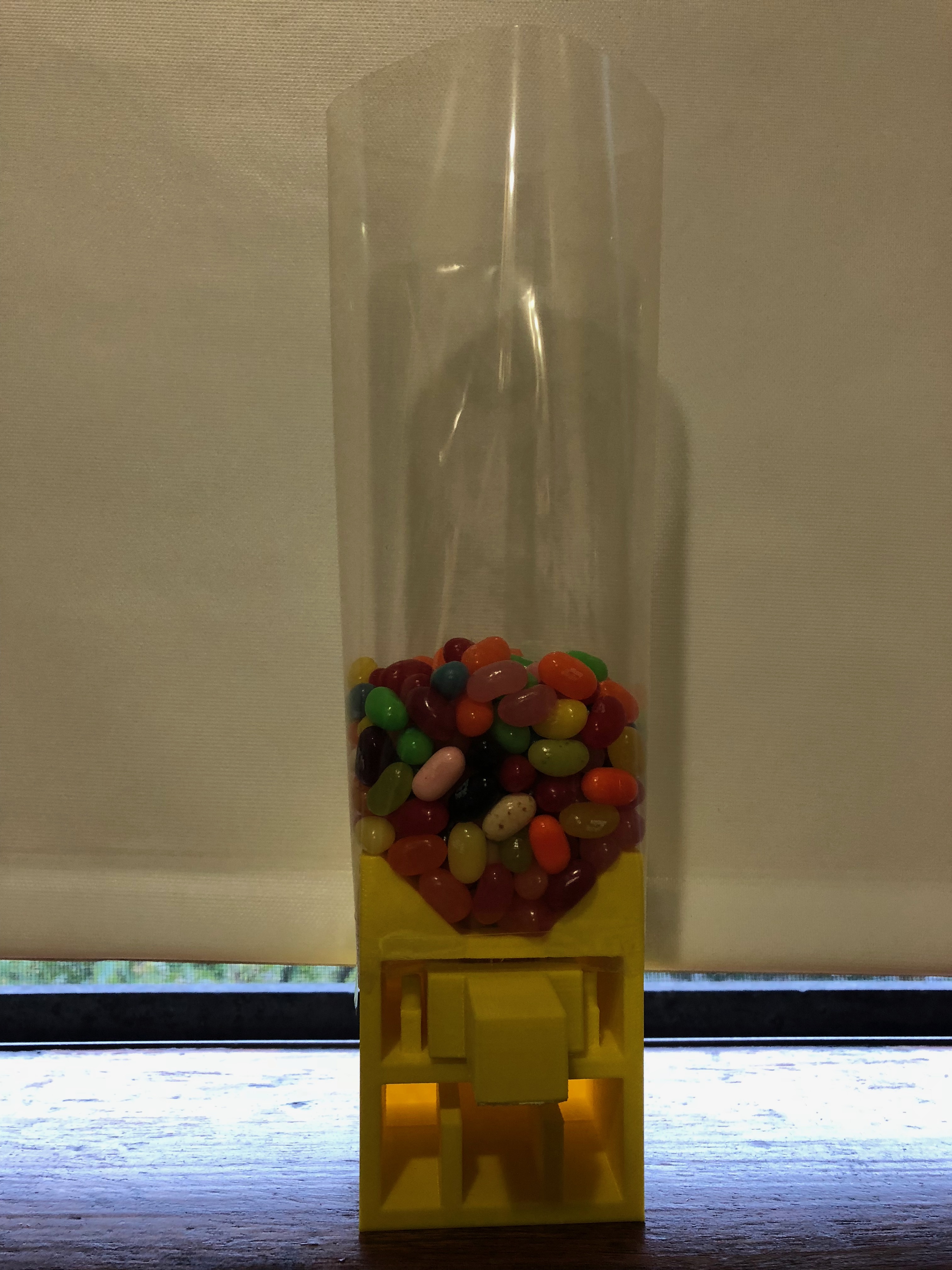

As for the 3D modelling segment of the assignment, I wanted to make something fun. So, I thought I would make a candy dispenser. I modelled my design such that it would work for spherical jawbreakers, but unfortunately they weren't avaliable in store when I went to purchase the candy, so the candy dispenser didn't work as well for Jelly beans (which I bought as a substitute) as I had anticipated it to do. In addition, when left out for a long time, the jelly beans lumped together (because of heat) and got stuck through the dispensing mechanism

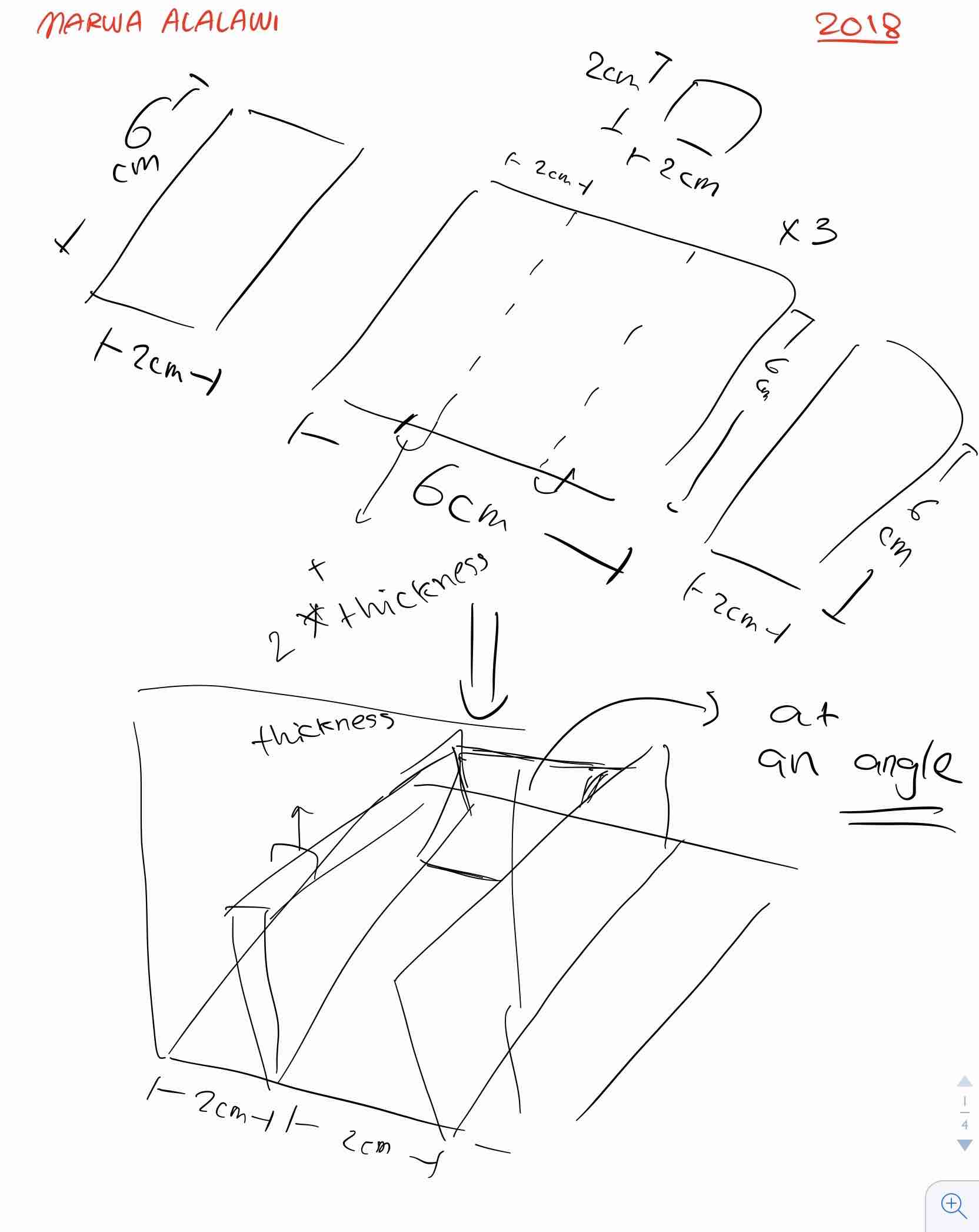

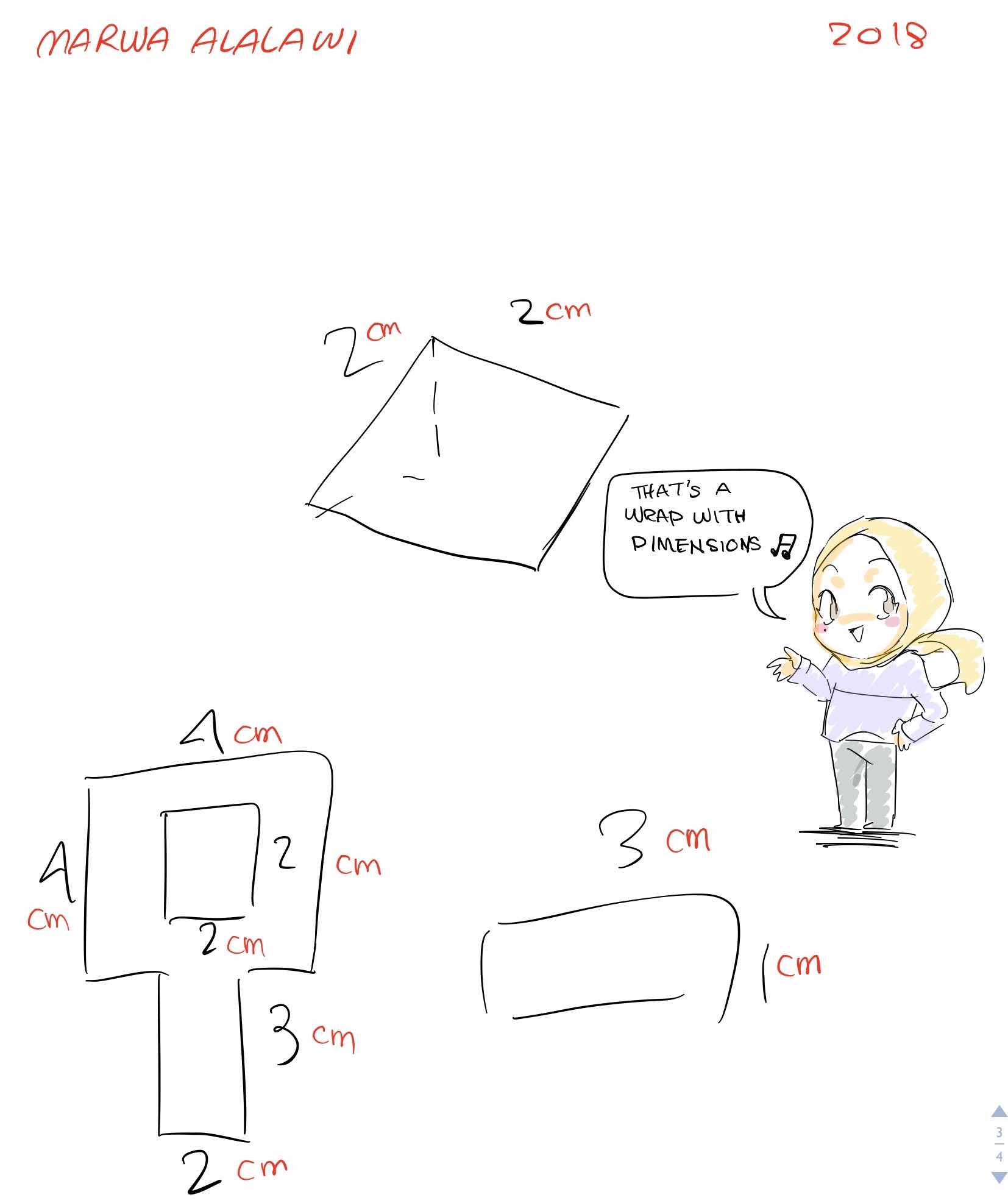

I used Solidworks for modelling, but before modelling, I had already determined the dimensions I would be working with. After that, I used a thin plastic layer to act as a glass enclosing. I plan to update the dispneser by cutting vinyl stickers to decorate the dispenser.

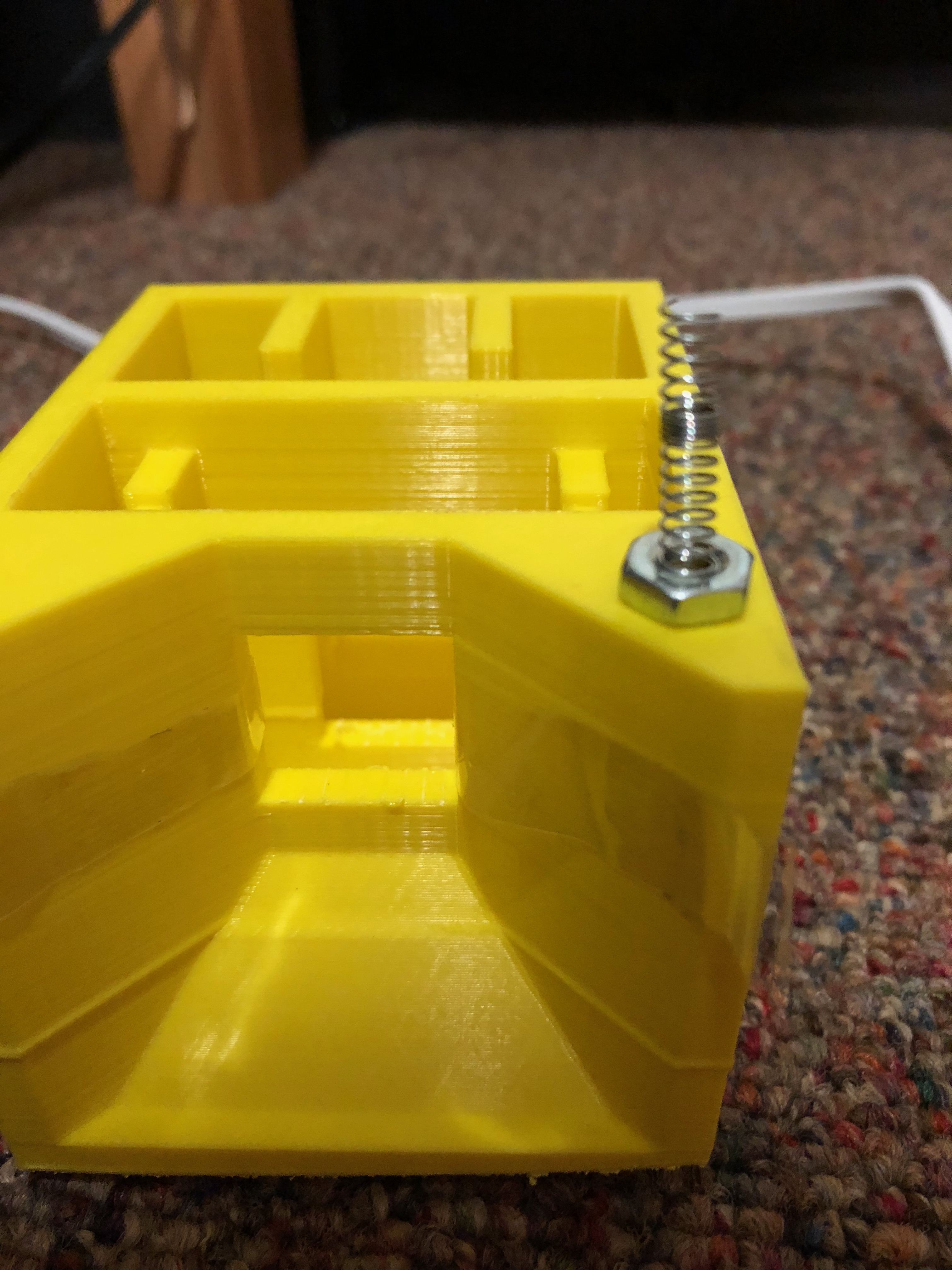

After 3D printing,I worked on the inner mecahnics of the dispenser. At first, I wanted to use rubber bands to have an automatic recoiling mechanism. But that proved hard, so I used springs instead. I mounted the springs on nuts, and used Epoxy glue to attach them to the inner segment of the dispenser.

The dispenser works overall, but is not optimal for the jelly beans. The jelly beans, due to their irregular shape, get stuck inside, and some force is required to get them out.

Download Dispenser Base

Download Dispenser Inner Mechanism

.