Week 9: Output Devices

This week's task was to add an output device to a microcontoller board we have designed and program it to do something.

1. Introduction & Overview

This project is an automated vertical linear actuator designed to precisely control the height of an LED grow light panel for an indoor garden system. The primary goal is to maximize the amount of plants that the light handle and optimize light distribution. The system employs a dual NEMA 17 stepper motor configuration, controlled by an ESP32 microcontroller, allowing for an extended range of motion and fine-tuned positioning.

The development followed a spiral methodology, incrementally building and testing functionality from basic motor control to coordinated multi-axis movement.

2. System Design & Components

The actuator is designed with two stepper motors working in tandem along a single vertical axis.

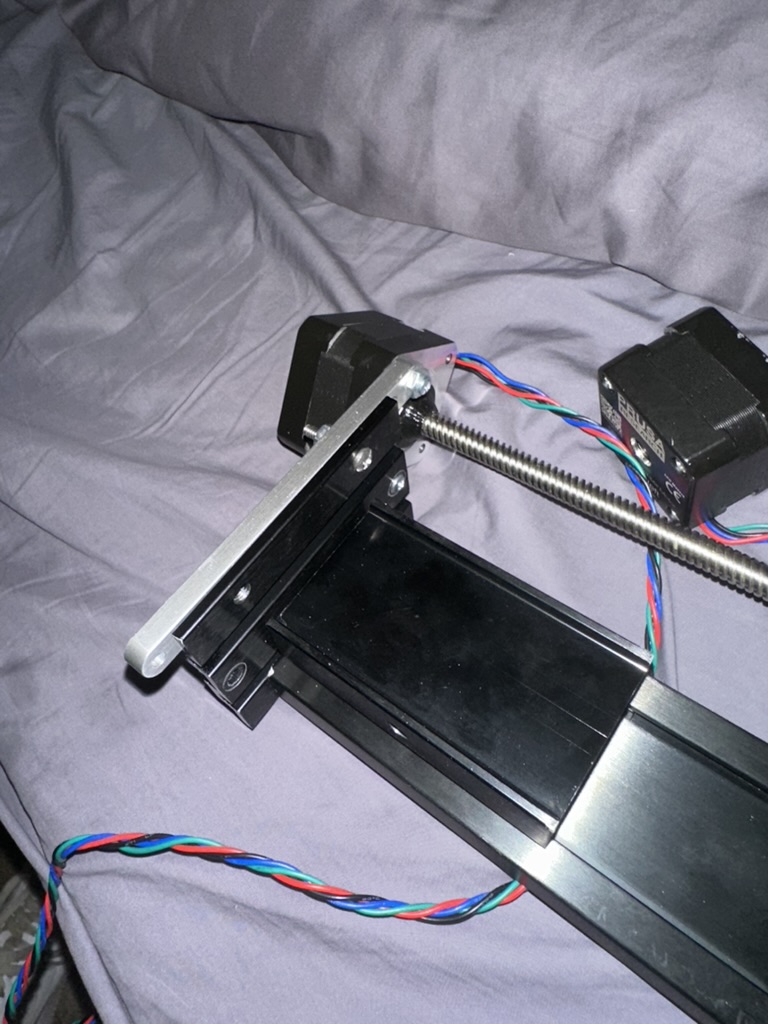

2.1. Mechanical Design

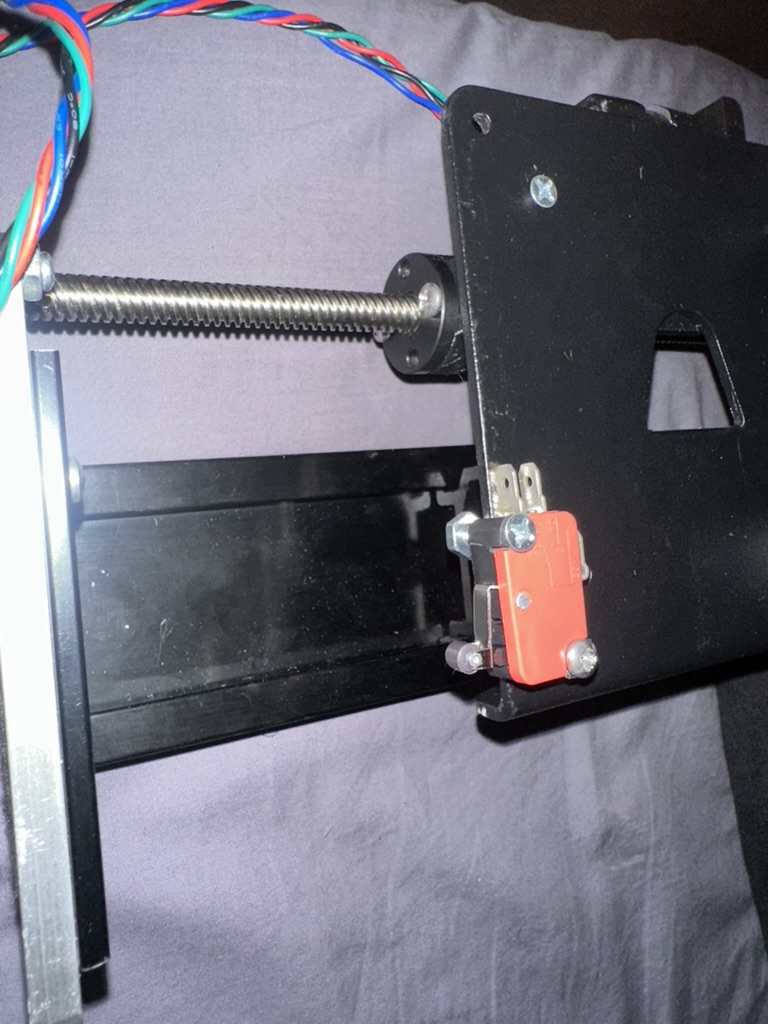

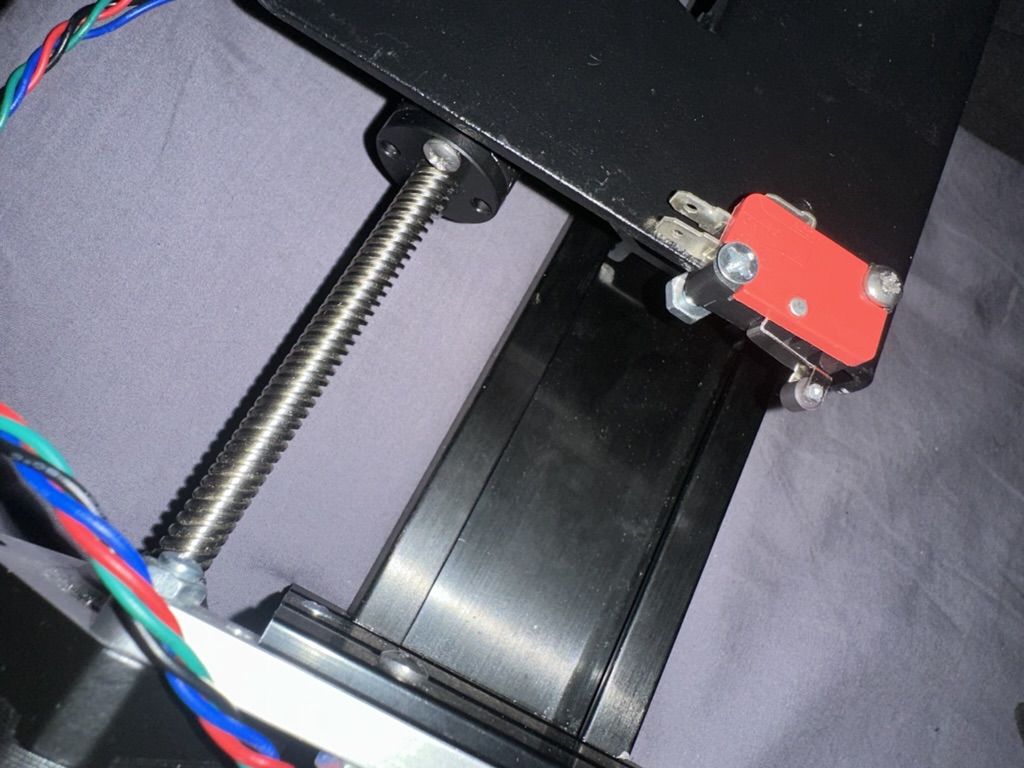

Dual-Stepper Configuration:

- Motor 1 (M1 - Coarse/Main Lift): This lower motor is responsible for the primary vertical movement of the entire upper assembly. It carries the load of Motor 2, its mounting hardware, and the LED panel.

- Motor 2 (M2 - Fine/Extension Lift): Mounted on M1's moving carriage, M2 provides additional vertical travel for the LED panel itself, relative to M1's position. This allows for either an extended total range or finer adjustments within a smaller range.

Linear Motion: Both motors drive lead screws (e.g., repurposed Prusa MK3 Z-axis TR8*8 lead screws) to convert rotational motion into linear motion. The entire assembly slides along a rigid linear rail to ensure stability and smooth travel.

Payload: A sideways-mounted LED grow light panel.

Cable Management: A critical consideration due to M2 and the LED panel moving with M1. A flexible drag chain or a carefully managed service loop is necessary to protect wiring.

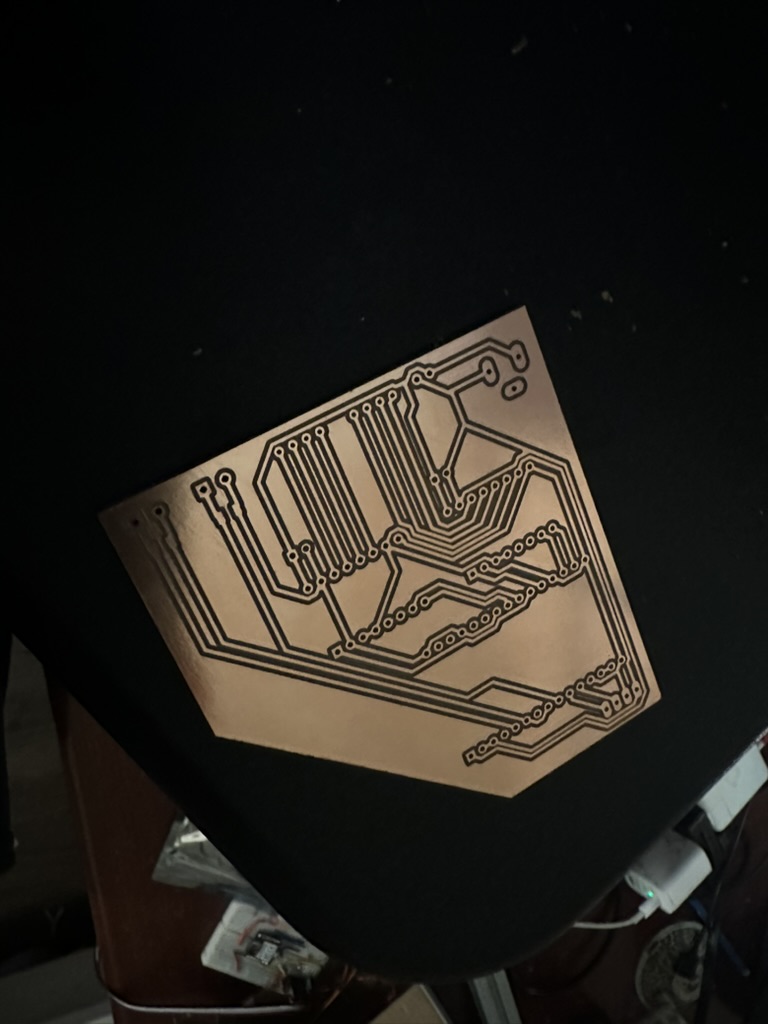

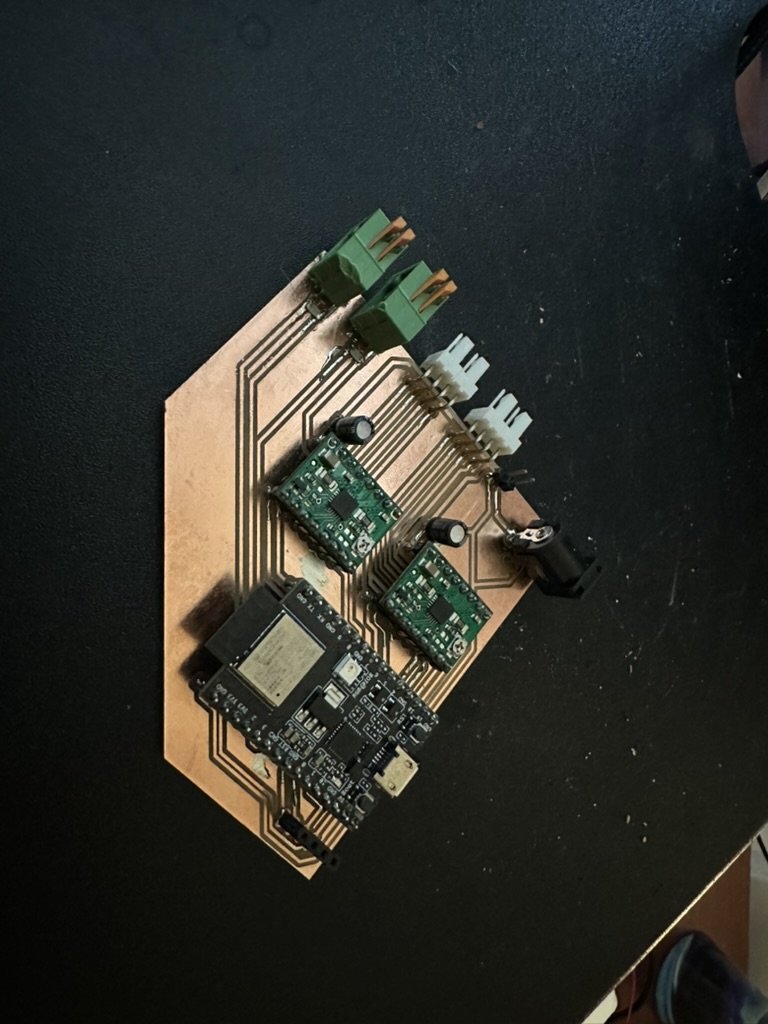

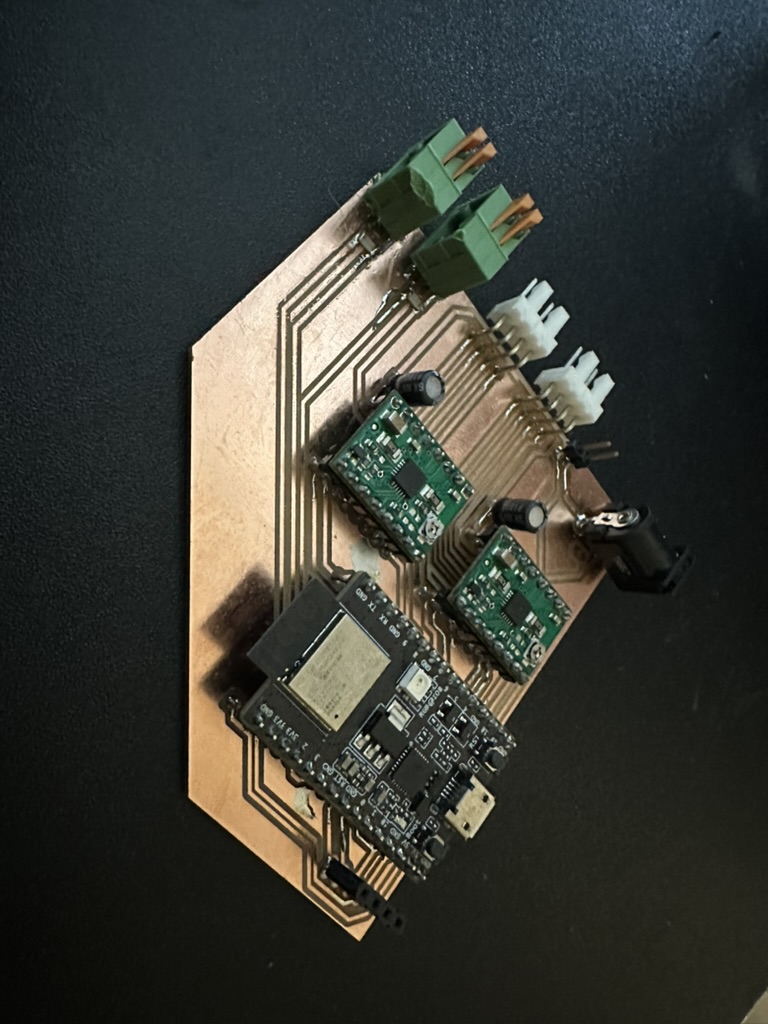

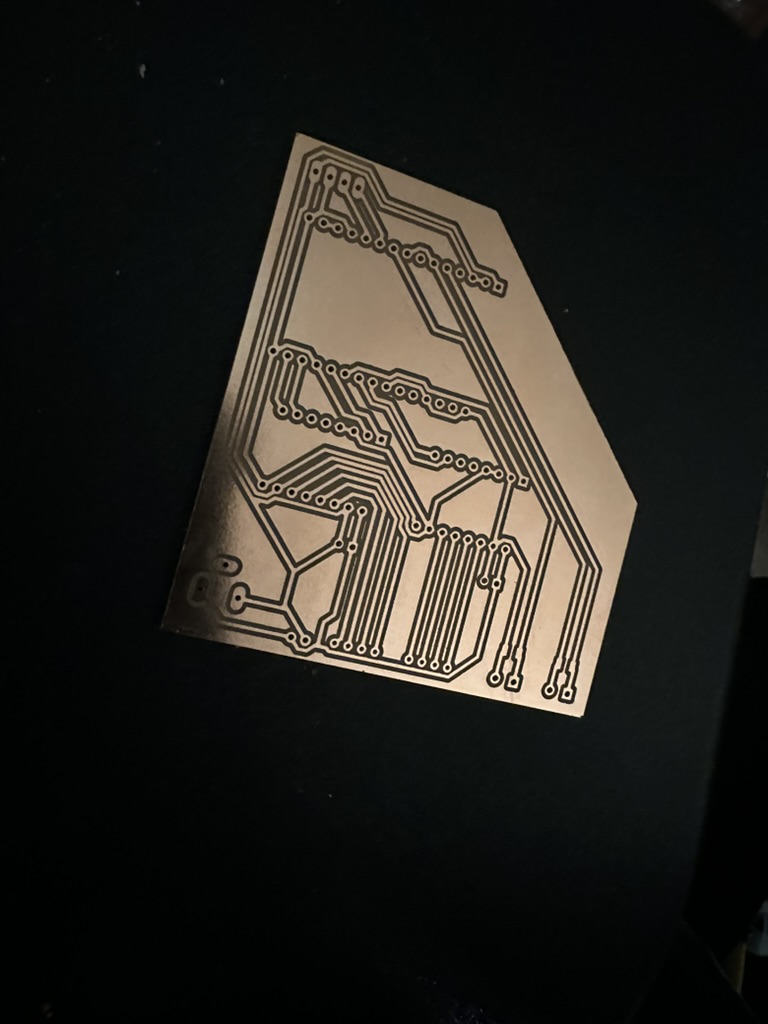

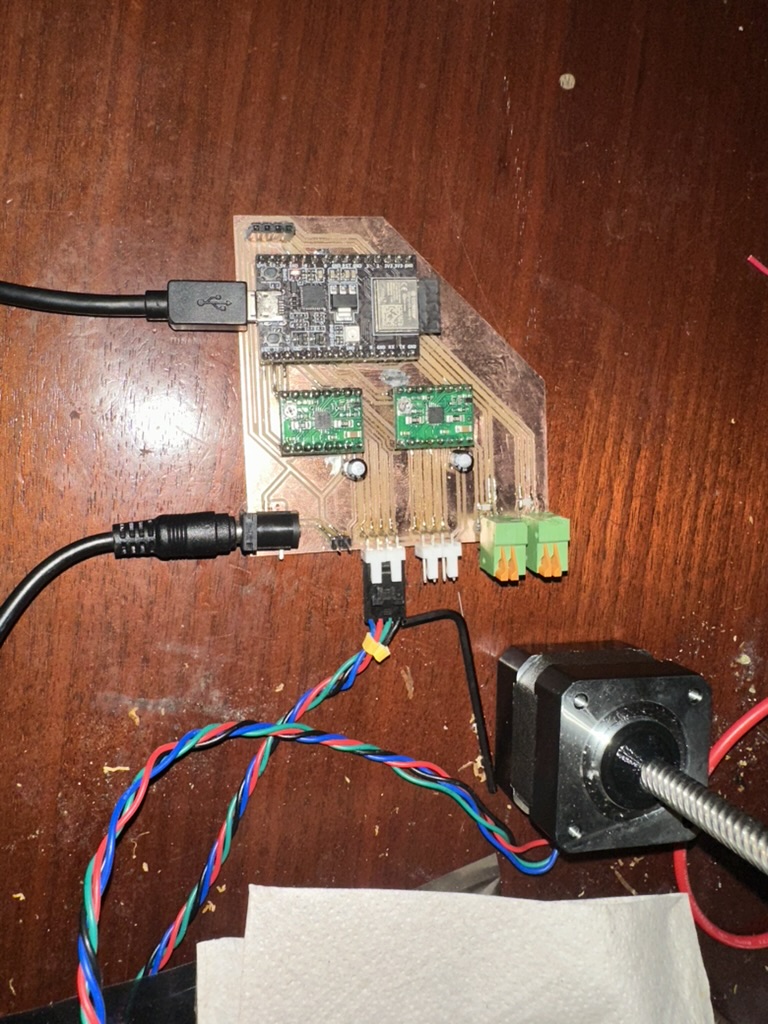

2.2. Electronics Hardware

- Microcontroller: ESP32-C3-DevKitM-1 – chosen for its processing power, Wi-Fi capabilities (for potential future IoT integration), and sufficient GPIO.

- Stepper Motors: 2x NEMA 17 bipolar stepper motors.

- Stepper Motor Drivers: 2x stepper motor driver modules (e.g., STSPIN820, A4988, DRV8825) capable of microstepping (configured for 1/128th microsteps for smooth motion).

- Limit Switches: 2x mechanical limit switches, used for homing M1 and M2 to their respective bottom positions. Configured as Normally Closed (NC) switches connected to GND and a GPIO pin with an internal pull-up.

- Power Supply: A DC power supply appropriately rated for the ESP32, both stepper motors (voltage and current), and the LED panel.

2.3. Software Design (Control System)

The control software is written in C++ using the Arduino framework for the ESP32.

Development Approach: A spiral development model was used to incrementally build features:

- Iteration 0-1: Basic independent motor control, then homing for M1 and position tracking.

- Iteration 2: Homing for M2, steps-per-mm calibration, mm-based position reporting, and handling inverted direction logic for one of the motors.

- Iteration 3: Software end-stops for safe travel limits, and coordinated absolute panel positioning logic.

- Iteration 4: Persisting continuous sliding

Key Features:

- Independent and coordinated control of two stepper motors.

- Precise homing routine for both axes.

- Position tracking in both steps and millimeters.

- Software-configurable steps-per-millimeter for accurate calibration.

- Software-defined travel limits (end-stops).

- Command to move the LED panel to an absolute vertical height.

- Serial command interface for control and diagnostics.

Communication: USB Serial for commands and feedback.

3. Key Software Functionality & Control

The system is controlled via serial commands sent to the ESP32.

3.1. Homing (home 1, home 2, home_all)

A critical function to establish a known reference point (zero position) for each motor.

- M1 homes first by moving physically DOWN until its bottom limit switch is triggered.

- M2 then homes by moving physically DOWN (relative to M1's carriage) until its limit switch is triggered.

- After hitting a switch, the motor backs off a small, defined distance to release the switch.

- The homed position (at the switch activation point) is defined as 0 steps for that motor. Position values increase as the motor moves physically UP.

3.2. Position Control

Direction (dir <motor> <0|1>): Sets the intended physical direction of movement (0 for UP, 1 for DOWN). The software handles any necessary inversion of the DIR pin logic for specific motors.

Relative Moves (steps <motor> <count> <period_us>): Moves the specified motor by a relative number of steps at a given step period.

Continuous Moves (speed <motor> <period_us>): Runs the specified motor continuously at a given step period until a stop command.

Position Querying:

get_pos_steps <1|2>: Returns the current position of the specified motor in microsteps from its home.get_pos_mm <1|2|all>: Returns the current position of the motor(s) in millimeters from home.

Absolute Panel Positioning (move_panel_to <target_abs_mm>): This command moves the LED panel to a specific absolute vertical height from the base of the system.

The absolute panel position is calculated as: PanelPos_mm = (M1_currentPositionSteps / M1_steps_per_mm) + (M2_currentPositionSteps / M2_steps_per_mm)

The control logic determines the necessary movements for M1 and M2 to achieve this target, respecting individual motor software limits. Motors are moved sequentially.

Panel Position Query (get_panel_pos_mm): (Should be get_panel_pos_mm or similar, if get_pos_mm all doesn't give the combined value). This command would report the calculated absolute height of the LED panel.

3.3. Calibration & Safety

Steps per Millimeter (set_steps_per_mm <motor> <value>): Allows calibration of how many microsteps correspond to 1mm of linear travel for each motor. This is crucial for accurate positioning in real-world units. Depends on lead screw pitch and microstepping settings.

Example Calculation: For a TR8*8 lead screw (8mm travel per revolution) and a 1.8° NEMA 17 motor (200 full steps/revolution) with 1/128 microstepping: Steps_per_mm = (200 full_steps/rev * 128 microsteps/full_step) / 8 mm/rev = 3200 microsteps/mm

Software End-Stops (Iteration 3): Constants like M1_MAX_TRAVEL_MM and M2_MAX_TRAVEL_MM define the maximum permissible travel for each motor from its home position. Movement commands check against these limits (if the motor is homed) to prevent over-travel and potential mechanical damage.

3.4. Motion Smoothing (Iteration 4)

To prevent missed steps, reduce mechanical stress, and achieve smoother operation, especially when moving the significant mass of M2 and the LED panel, acceleration and deceleration (ramping) are implemented. This involves gradually changing the step period at the beginning and end of moves, rather than instantly starting/stopping at full speed.

(Describe your chosen method briefly: e.g., Linear Ramp or AccelStepper library integration).

4. Challenges & Learning

(This is a section for you to personalize heavily! Here are some potential points you might have encountered or learned from):

- Mechanical Alignment: Ensuring the linear rail, lead screws, and motor shafts are perfectly aligned to prevent binding and ensure smooth motion.

- Cable Management: Designing a robust solution for the moving cables to M2 and the LED panel to prevent snagging and wear.

- Software Complexity: Managing the states of two motors, their homing sequences, coordinate systems, and direction logic requires careful planning and debugging.

- Motor Tuning: Finding the right balance for stepper motor current, speed, and acceleration to achieve reliable movement without overheating or stalling.

- Limit Switch Precision: Ensuring limit switches trigger consistently and that the back-off distance is appropriate.

- Debugging Serial Communication: Effectively using serial prints for debugging state variables and command parsing.

- Iterative Development: Experiencing the benefits of the spiral development model by building and testing features incrementally.

5. Future Work & Potential Improvements

Advanced Coordinated Motion: Implement more sophisticated algorithms for distributing movement between M1 and M2 when move_panel_to is called (e.g., to minimize wear, maximize speed, or keep M2 in a preferred part of its range). Potentially simultaneous movement of M1 and M2 if using a library like AccelStepper.

- Sensor Integration: Add a plant height sensor (e.g., ultrasonic, ToF LiDAR) to enable fully autonomous height adjustment based on actual plant growth. Temperature/humidity sensors for environmental monitoring.

- User Interface: Develop a web interface (using the ESP32's Wi-Fi) or a dedicated physical interface (buttons, LCD) for easier control instead of relying solely on serial commands.

- Persistent Settings: Store calibration values (steps_per_mm, max travel) in the ESP32's non-volatile memory (EEPROM or LittleFS) so they persist across power cycles.

- Error Detection & Recovery: More robust error handling (e.g., detecting stalls if using TMC drivers with StallGuard, or if homing fails repeatedly).

6. Code & Visuals

The complete Arduino sketch for the ESP32 controller can be found here: [Link to your Git repository or code file]

(Embed key code snippets here if desired, e.g., the homeMotor function or the move_panel_to logic).

Visuals