this page exists as a void to throw all of my unfiltered thoughts, ramblings, ideas, feelings and frustrations into as i go through the design and prototyping process. for a more concise documentation of my project, visit my final project page.

entries are listed in reverse chronological order.

after getting my prototype running I spent a couple days playing with mapping and noise maxing in max and eventually scrapped it. and then i had to take a big step back to catch up on all my other work.

now the other work is done and it is time to properly dive into my final build! i am going to document the final process of all of it as i go on my main final project page, so there may not be more posted here.

so much happened this week. i have a shitty prototype running, so that's a big deal. check out my week 12 assignment to see it! excited to see where it goes, i think

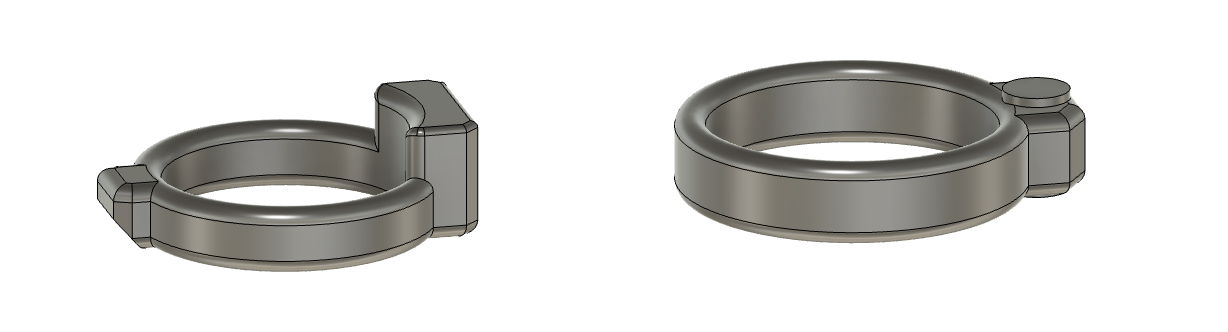

yesterday i printed the "shell" rings I designed over the weekend and made a new (smaller) hall PCB to go inside. it took a bit of modification to fit everything together, but it worked, and now i have my best prototype so far!!! as we speak, the modified version of the design is printing- but this time sized for my middle finger. the new set of designs is all parametric for easy resizing, which will be great for fabrication efficiency once i have a final design.

this is gonna be a loooong one so buckle up. it's been a BUSY week so there's a lot to cover...

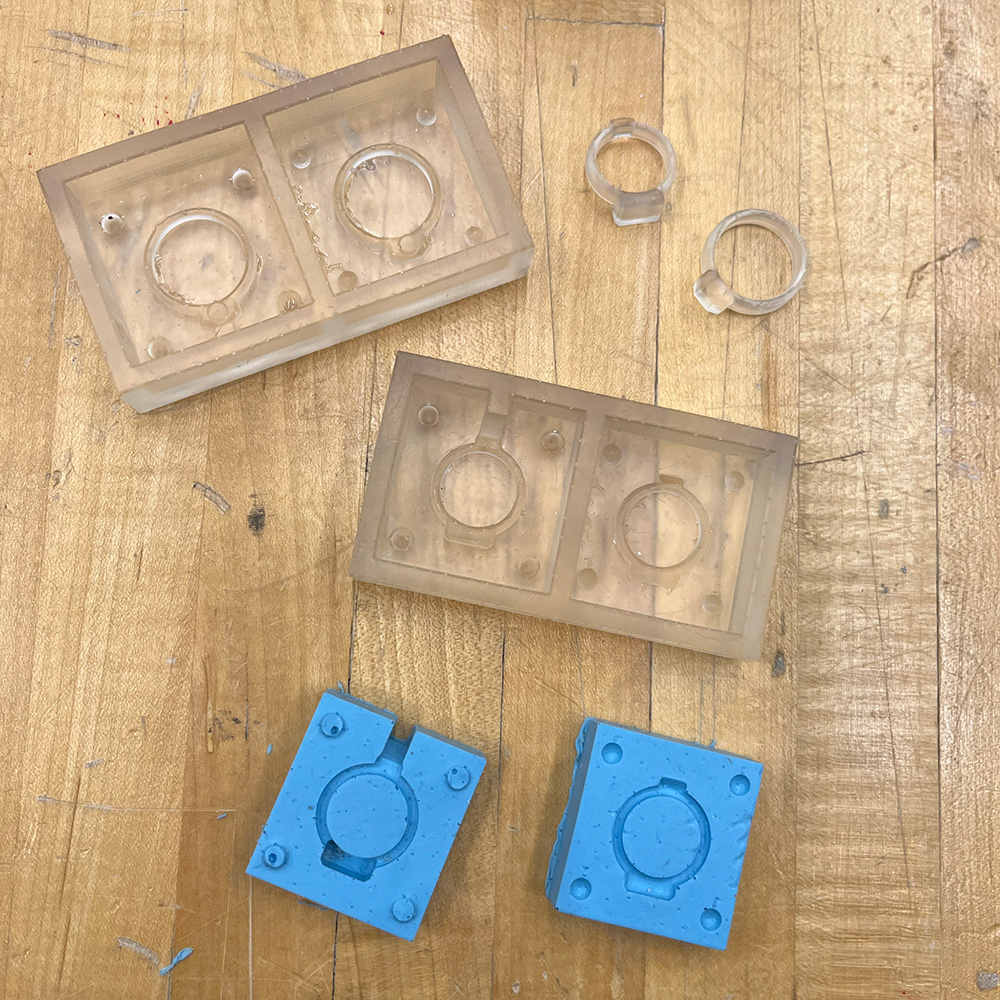

starting with: last sunday. i went into the shop to help with the group project. after that i had some time to kill and started asking around about the SLA printer. wedyan was there and taught me how to use it so i printed the molds i designed last week.

on monday i went in to pick up the molds and had to go through the finishing process for the UV resin printer. i made a mess with the resin and smelled like a dentist's office all day because i didn't totally know what i was toing but it worked out fine- well sort of. the

supports on my print left a bumpy mess, the mold i made from it turned out like shit and i didn't even bother casting it or making a mold from the large ring mold because at that point i was like yeah this isn't working i need to go with the wax after all. i did, however, make a set of the rings (without sensors) with the

SLA printer just to see the shape and fit and those turned out awesome, i was wearing them around all week.

also on monday, i had my midterm review with quentin. i brought in my sla molds, discussed my woes, and he gave me some smaller endmills so i could maybe make this work with wax after all.

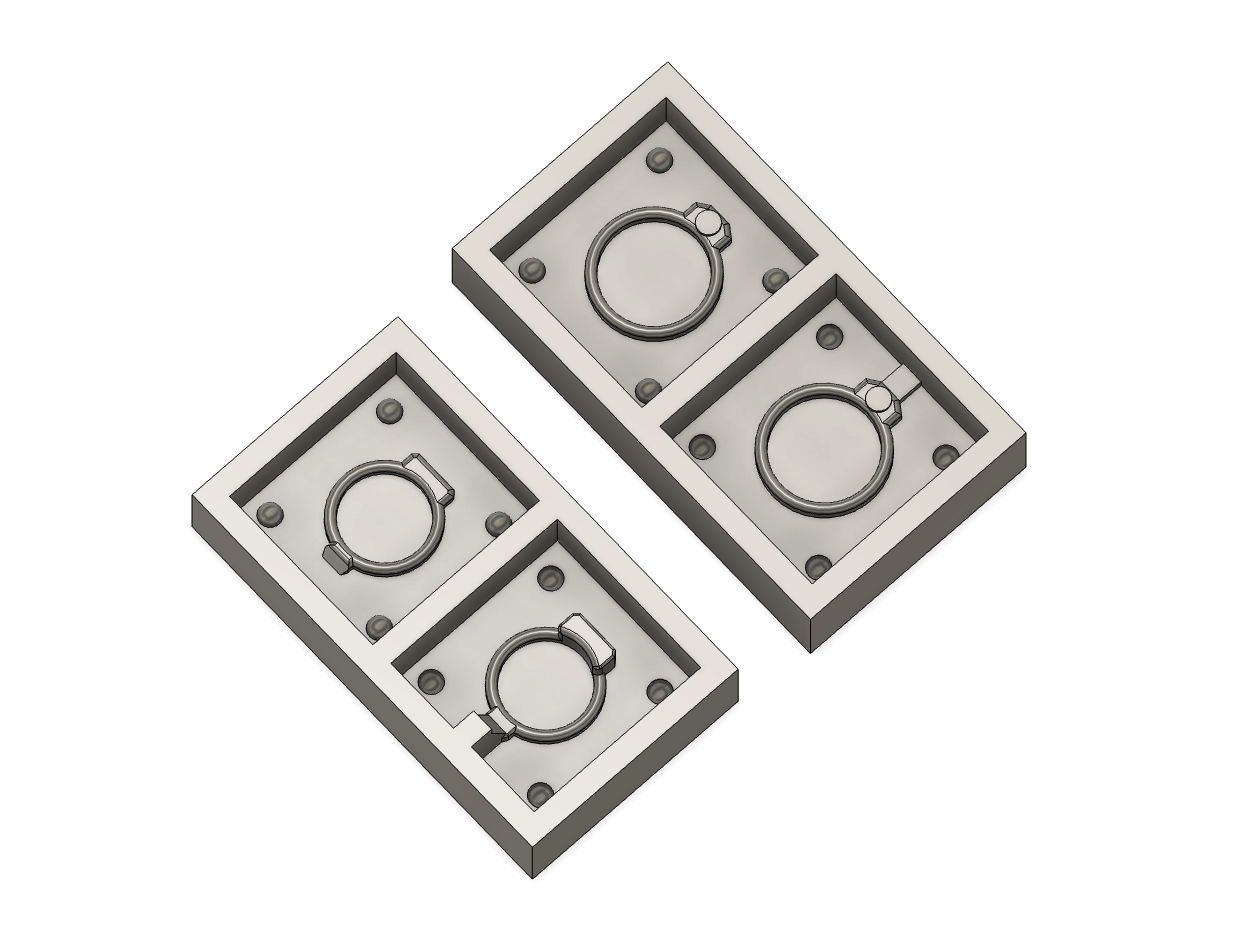

on tuesday i put a lot of work into redesigning all my shit so i could make the wax molds. and on wednesday i went in and made the wax molds. this took so much work for so many reasons.

1. i had to make new tools in fusion for the endmills which was a little confusing but i figured it out.

2. i spent so. much. time. on tuesday and wednesday going back and forth between machine processes trying to optimize which endmill to use and then making my design work with that and it is a very detailed design and i made a lot of little adjustments so yeah it was a lot of work.

3. FINAlly on wednesday i had the gcode ready but the genmitsu was not set up so i spent a while figuring that out and literally reversed engineered the setup by looking at other students' documentation from molding and casting week that showed the machine so i could figure out how the clamps were set up and how the spindle was connected to the power supply but

i figured it out!!!

4. triumphantly i started the roughing operation. yeah, that job that was supposed to take 22 min according to the fusion simulation? oh, it took an hour 20 minutes!

5. it was so damn late and i desperately wanted to go home but damnit i was not gonna stop in the middle of things so i started the finishing operation (estimated 29 min, it took over an hour and a half to get 75% of the way thru). so i actually went in and made a new finishing operation for the last 25% that cut out some less necessary things, stopped it mid job, And

ran that instead to save time.

okay, now you must be thinking: well, nina, you did the thing! why was this a fail? well uhh, the final thing was not at ALL worth the time it took and there were aspects of the design that made the oh so long awaited and worked for molds a pain to use

the first round of silicone molds i made from the wax were shit. like bubbles in all the worst places. so i made a second round (which came out much better!!) but decided to practice casting on the first ones just so i'd hopefully do a better job with the sensor ones.

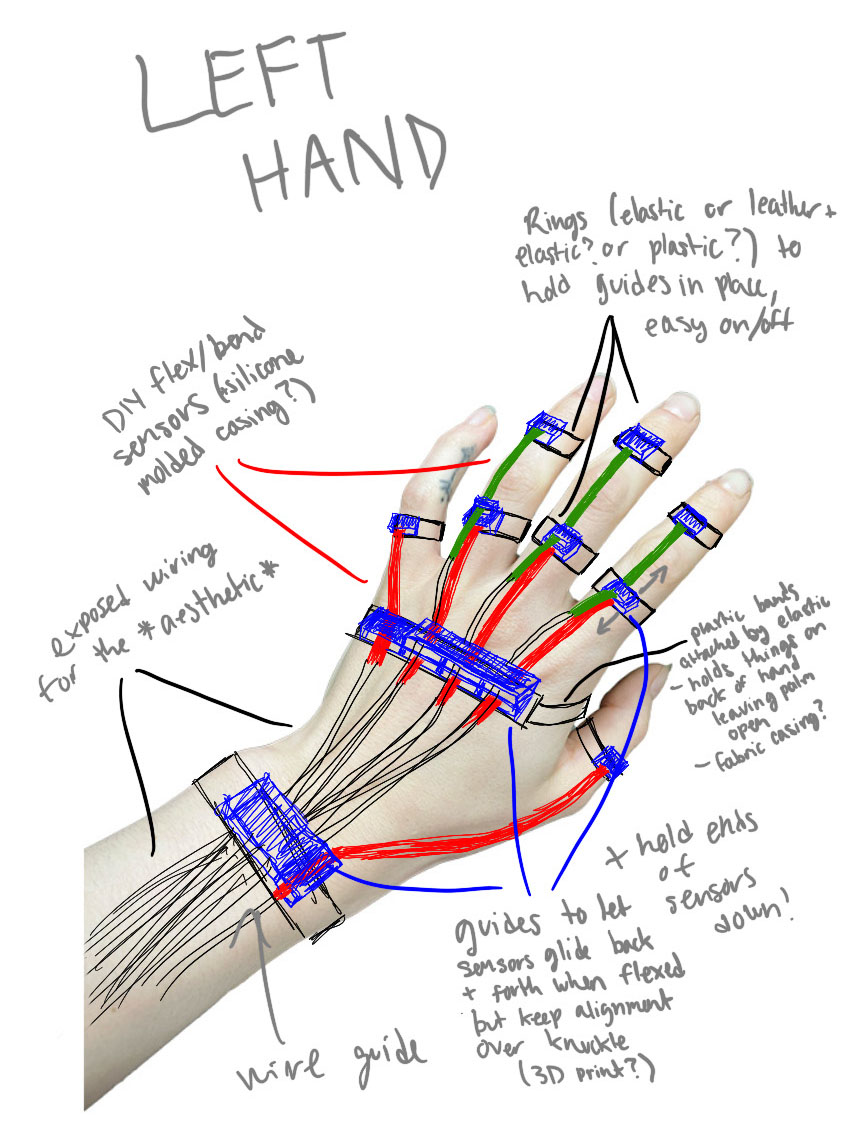

yet another day in bed working on this because there's not much else i can do right now. yesterday i thought a lot about the wrist cuff design, looked into battery options, downloaded the slicer for the SLA printer and got my

designs ready to print, ordered some materials, and tried designing a new PCB to go with my wrist cuff design. today i made progress on that design and made an updated sketch/diagram of it for my final project page. fun stuff!

i want to think about how to actually make the wrist cuff look more interesting/ give it a cooler aesthetic and personality. but i think for me that is gonna be less a pre-designed thing and more following the inspiration of hands-on work

once i have the materials in front of me.

spent a long time today working on new ring designs + molds for them. good distraction from being sick!

Over the past few weeks I had been playing with ring mold design a lot to make something out of wax but I want to try making a 3D printed mold instead because I think it will be better for this and it is

less of a hassle. Making a more specific to-do for myself to mentally organize

- learn how to use SLA printer for mold making

- learn about other material options (resin) for casting?// figure out who to ask...

- new ring molds

- decision on where to put IMU...

- order wire

I am sick and working from home today so I'm just going to try and get a lot done on this, let's see what happens.

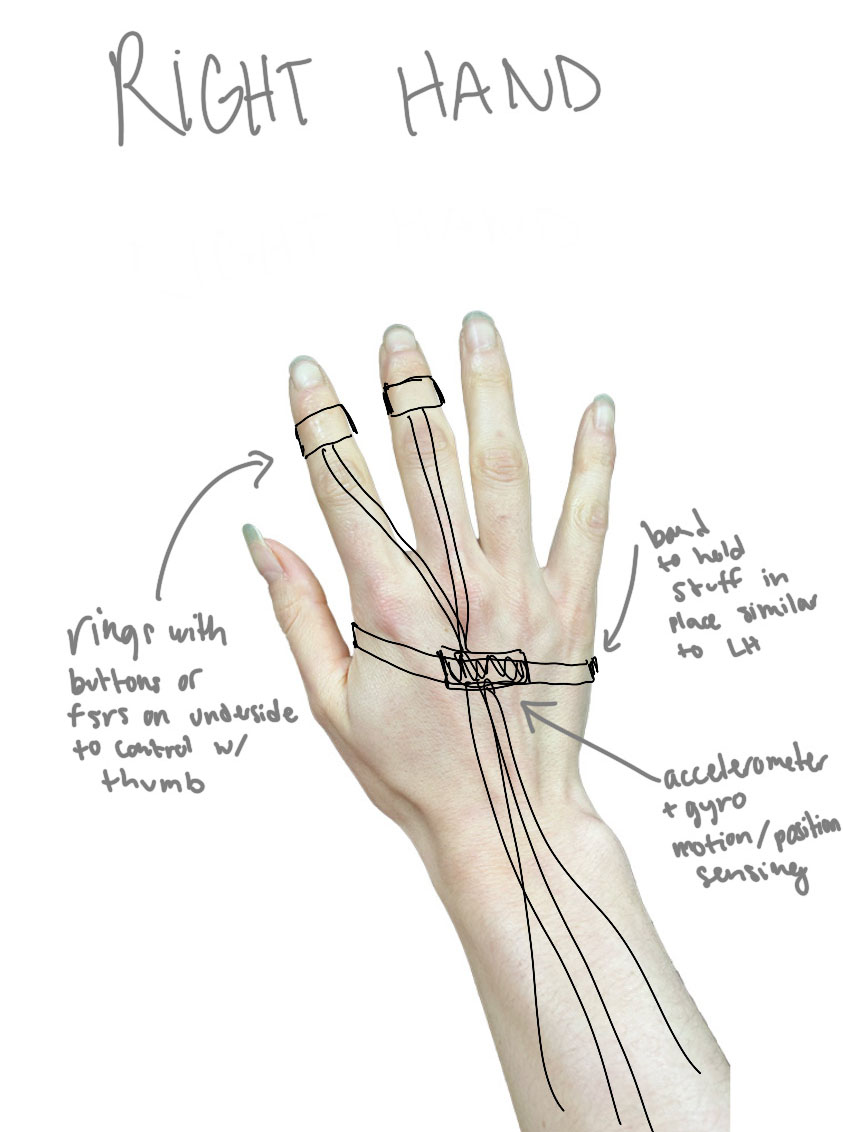

i've been looking into different styles of palm cuff jewelry to think about how to attach the IMU to my hand in a minimally invasive way. worst case, i stick it on my wrist. but want it on my hand because wrist motion is so expressive!

as for the wrist cuff design, i have some ideas brewing but nothing easily communicable. i need to start playing with materials. that's about it for this week so far...

okay, overview of the past few weeks. in general, i have been doing a lot of thinking, many scattered bits of research, prototyping, design, pondering, and the pieces are coming together a little bit.

i made the sensor rings during molding and casting week. i was really excited about the lig. in class neil told me to try step response and i decided not to but in thinking about it/researching it, i decided to give hall sensors another shot. they work great, better than i expected.

and it's not perfect but i think the form factor is just better suited to what i want to do than the lig right now? sad because the lig is super fun and cool but relieving because it is tough work and would need a lot of prototyping time that i can now spend honing in other things.

also had good success with the bno085. and leds from last week.

I feel like i've put so much time and work into this project already and there is still soooo much to do but at least i am gradually moving away from ideation/experimentation and towards actual implementation. for what it's worth i have a clearer idea of implementation/final design that i'm going to sketch out soon.

earlier this week i designed a new mold for making rings to hold the hall sensors/magnets. i didn't get around to making it. as well as some teeny tiny hall pcbs to fit in the ring.

casting the sensors into the rings in a prototype-y way is easy. making it nicer is going to be harder because i should probably do a 2 part mold but i uh. making that work so i can get the sensors in there seems tough. i think i might try 3d printing instead of wax milling. maybe this weekend i'll cad something for that.

i'm worried about the sensors moving around too much with that method. hm. i also want to make a set of sizer rings!!! sosososo much to do... but there is time for it i'd like to think

have not updated much because my past couple assignments have been final proj focused anyways but this week has been SUPER EXCITING read about it here. I have struck new inspiration and am pivoting a bit yet again. Will write more about it later...

i have spent a lot of time staring at my hands on the T over the past feew weeks, probably enough to look pretty suspicious.

thinking about the mechanics of how they move for one, but also how gestures feel.

expressivity is really important to me and is a value i want to keep at the foundation of what i do. this week has been a bit of an exhausting clusterfuck and it's making me step back and consider what i actually want out of this project...

i think something that's tough here is the many challenging parameters i am tackling at once and i'm realizing it would be wise to narrow down my real needs/ desires and simplify things around that.

i think the first thing is: so why am i really bothering with trying to sense multiple knuckles per finger? why don't i just do one. and i think a few weeks ago i wouldve passionately fought that, but i'm realizing my initial approach is

a. unnecessary and b. more of a pain in the ass than it is worth.

following that revelation-- the reason that i wanted to make the 2 hands so different in the first place was because it would be too damn complicated to make 2 of the whole thing in different sizes, but if i simplify things, it actually makes a hell of a lot

more sense to match them anyways!

and then going off of that- i can use one xiao esp32s3 per side and then bam, my life just got a hell of a lot easier. and wow!!! increased modularity!!!

I dont know if any of this makes any damn sense but it does in my head, i promise (and i have ideas to show for it that i will better formulate and communicate... later)...

i met with wedyan on thursday to talk about the diy lig flex sensors and it went so so well!!!! for one she is really passionate about the technology and was happy to teach me about it, so i learned a lot and asked many questions.

she also understood my goals and aesthetic considerations and was in support of my pursuit to do something against the grain even though it introduces more challenges-- which was both technically helpful and creatively validating in a much needed way.

we talked about lots of different sensors in determining whether the lig sensors are right for me and it seems like they are but the biggest thing she stressed was that the customizability is what makes them worth using, so i should really try to capitalize on that

in my design. we are going to meet on friday and she is going to walk me through making some sensors.

after that i went home and started eating dinner then a few bites in decided to say fuck it and run to the craft store before it closed to get some prototyping materials.

i got some flat/wide aluminum wire, a multi-gague pack of round wire, and a cheap plastic mandrel. came home and immediately began mocking up a bunch of rings and hinges. these were my favorites:

i thought a lot about how sensors would actually integrate into the design and used some of the beat up old flex sensors i had on hand to test out possible configurations. it would be really nice to have the sensor to the side of the finger as part of the hinge, because that way it doesn't need to slide to bend over the knuckle, it can just be fixed in place. then also just because it'd look way cooler. however there really isn't a lot of space to play with to the side of the finger like that so i don't know how feasible that truly is (though the lig sensors could be made far narrower than the ones i am playing with here)

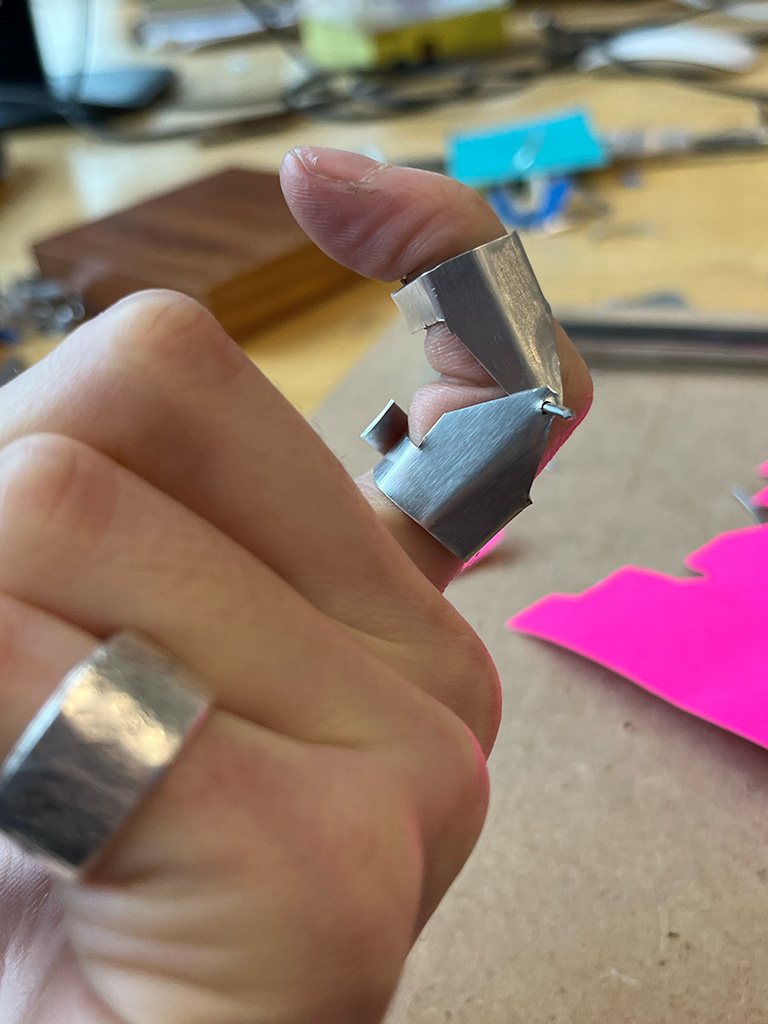

lastly, i played with wrapping the sensors in wire and folding the end of the metal band over the sensor either to clamp it in place or create a channel for it to slide through, just to see how it looked/felt:

maybe in an unnecessarily cynical mood because i want to go home and eat dinner and sleep but need to wait on my 3d print thing so i am working on this to pass the time.

anyway, made progress yesterday on a mix of things. new prototype similar to the ones below but shaped like the etsy one. slight improvement. using rivets for this sucks but i don't yet know how to make a better hinge,

and am considering abandoning the hinge idea altogether..

i also talked to alfonso (the TA) in office hours about possible options and he said he could help me spot weld/ that would probably be necessary here. so that is exciting, but i am still feeling a bit stuck. i think figuring out the sensor situation will make this easier. but also i am just finding it hard to know where to look for ideas/inspiration or even just basic info regarding what i want to do when it comes to working with metal.

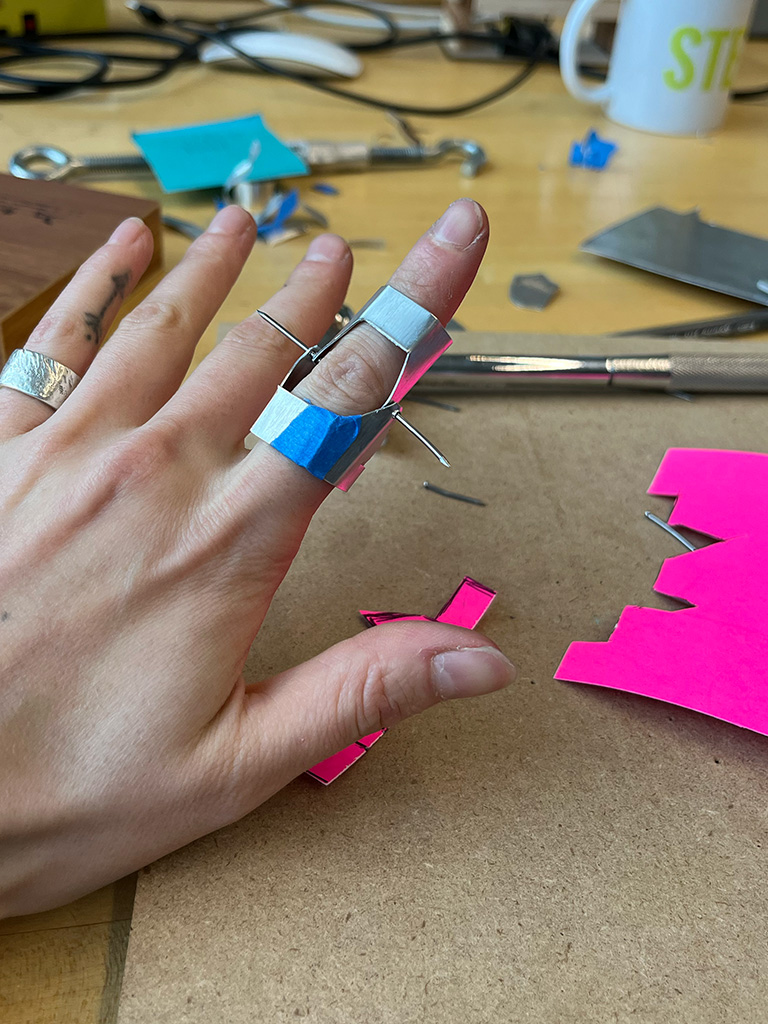

friday was eventful-- i made a better prototype following the pattern concept from the 3d print glove previously mentioned. i used actual rivets instead of nails (took some troubleshooting to figure out because i'd never used rivets before). i had to step away from working on it for my 3d printer training but brought the

metal wih me to drill rivet holes while in the shop-- conveniently the TA running the training (alfonso) is doing his phd in printing molds to fold sheet metal and i got to talking to him about it and he strongly recommended i try it for this project! i'm going to his office hours on monday to talk to him about it!

anyways after the training i went back to assemble the ring. it worked well however i did realize that having the metal bend over the hinge is really not conducive to it moving smoothly (i was skeptical of this initially but wanted to follow the pattern and i didn't notice the issue in round 1, likely because the pieces

could slide around on the nail more and weren't so pressed together). anyways here's how that went:

after that i went home and on the way there (and for a while afterwards) did a lot of pondering, brainstorming, google searching. looked into various jewelry rings with a similar hinge concept and found this simple one that i really liked:

something about the minimalist shape made me realize while armor is super cool, my ideal vibe for this isn't directly that but an adjacent aesthetic. industrial with a hint of futurism. mechanical. gothic elegance meets punk diy. so rather than think about this as armor i really do like the idea of a more jewelry-inspired approach.

landing on that realization/ idea felt really good, like i am moving further in the direction of what i actually want and refining my artistic vision and voice. i think it also feels good in that this is starting to feel more personal, or maybe just more uniquely mine. as in- i started with looking at familiar approaches to this flavor of wearable

and through a lot of thought and some experimentation have moved away from that in a direction that is fairly distinct from other projects i've encountered in my research. which is great in that it feels more artistically fulfilling. challenging in that i'm moving further away from the existing map of how to tackle certain design challenges.

but that's a good thing still-- a creative problem solving opportunity i will gladly embrace.

i want to make a new prototype with a different shape when i'm back in the lab on moday. in the meantime next step might just be to make new concept drawings and draft up some plans.

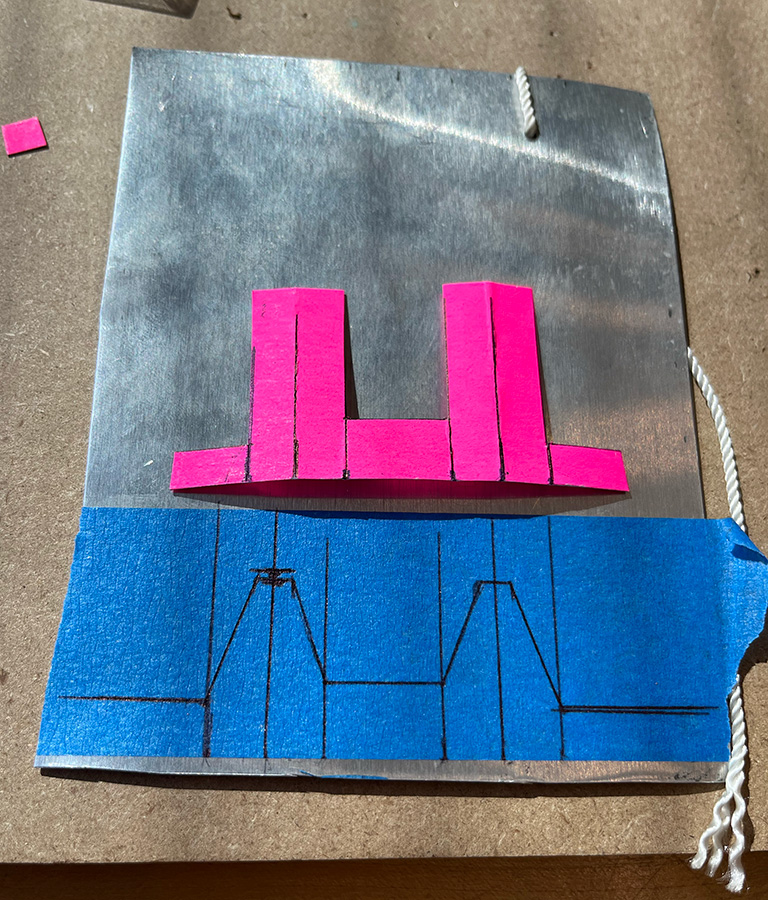

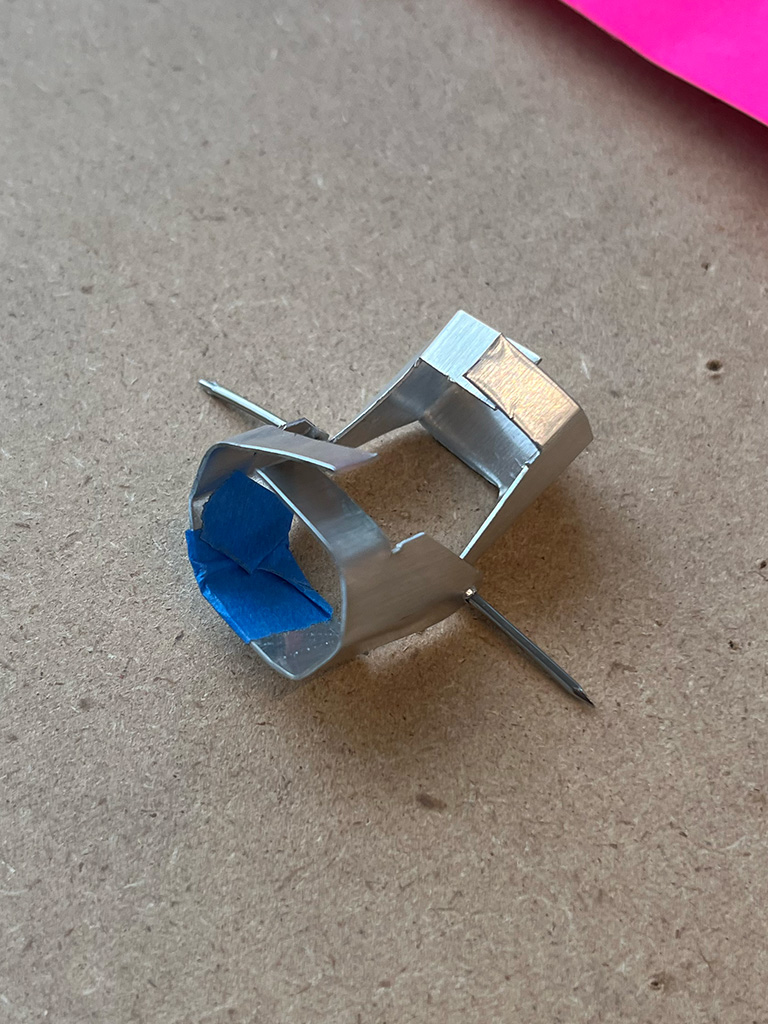

yesterday i got the chance to sit down for a few minutes and make a sheet metal "prototype" just to see how the material felt and test whether i liked having the different knuckle seconds attach with a hinge. i made a cardstock paper pattern roughly inspired by the shapes from this project and adjusted it then used that to draw something out and cut out the sheet metal. i didn't have any rivets so the hinges are just 2 nails sticking out. i also accidentally broke one of the pieces when hammering in the nail so i had to tape it back together. but it works!!! and i actually adore the tactile feel of it. i definitely want to proceed with this direction for things. note: the pictures look real janky but i promise it feels nice and moves surprisingly smoothly!!

on monday, in talking to other students and doing some searching in the class archive, i found that wedyan, one of our TAs this year did some really cool work making DIY flex sensors using Laser-Induced Graphene.

i emailed her and haven't heard back yet but i'm excited to hopefully ask her about it because i could see this method working well for what i'm hoping to do!

yesterday (tuesday) during lecture for another class, in the page opposite my notes, i was scribbling tons of ideas for designs for this and letting my mind run. mostly thinking about materials, shapes, how to attach the sensors, and quickly iterating through many ideas and variations of these things.

i wish i had more time and materials to prototype with so i could try everything.

anyways, during that class the instructor was talking about prototyping and had brought some sheet metal to tell us how easy it is to work with, and that really caught my attention!! on my way out of class i asked him if i could take a piece and i ended up using it to play around with making rings later in the day

and i really liked the tactile feel of it. that got me thinking about how cool it would be to take artistic inspiration from medieval armor. here's a picture of the sheet metal rings i made to experiment with (and my pinky ring for reference, which i did not make)

now i am sitting in lecture (for this class) and thinking about how to design something armor-reminiscent. directions i want to research for inspiration are actual medeival armor but also things like this

* interrupting myself because neil is talking about IMUs and has a datasheet for the BNO08X pulled up and is talking about data fusion for position sensing-- things which I should look into later**

anyways re: the 3d-printed glove thing i linked is an example of some glove designs i have seen which take a sort of exoskeleton approach. looking through this page, the designer showed a sheet metal version made during the prototyping phase and it

looks SO COOL and also like something i could replicate!!!! at least to prototype with

i sketched up some designs:

initial goals/constraints/considerations:

- exposed wiring because i love that aesthetically, but make it robust enough to withstand the demands of live performance and

long-term repeated use

- form factor which provides tactile feedback and feels like an electronic device, not like clothing. not too bulky, mimimize skin covered, but

make something sturdy enough to hold itself in place while i move

- designing for human hands is hard because they move at so many weird angles and finger size varies with temperature and other things. i don't want

to make something that fits one day and is too loose to stay in place or too tight to put on the next (the challenge of using rings)

. i have like a million aspects of this i want to think about more so i'm gonna tackle a few things here

1. DIY flex sensors, silicone flex sensors

- DIY flex sensors can be made using velostat and copper tape. I know i can cut copper tape with the cricut. I'm not sure about velostat though because it is a really finicky material and

[in my experience] surprisingly hard to hand cut with an exacto knife because it stretches and folds. TO DO (maybe?): cad up patterns and test cutting. bring in copper tape + velostat. figure out necessary cricut settings

- ok after looking into it a bit, i think i will be choosing between a DIY sensor using the velostat method or molding something with silicone and conductive fabric like this

or this

- i still want to explore the possibility of making a sensor as described in the first bullet point and using silicone to hold everything together (like perhaps mold in silicone after laminating in tape?)

2. What to do with many many wires/ analog inputs

- for wires, want exposed wiring but not all way up to main board because that is an unreasonable amount of wire. wires either bundle at some point or go to some chip

meant to handle all the analog inputs

- need to talk to TAs or something, figure out ideal microcontroller for this among other things...

okay, i'm not gonna say that my initial final project "idea" was terrible or that I wasn't briefly like-actually-very-excited about it. but i did make that page just to satisfy the assignment, thinking i'd let my *actual* project idea come to me over the course of the semester. which in theory like yeah sure good idea but that is so not the ideal way to go about this class, i am now realizing. so, a few days ago it properly hit me that i needed to come up with something for real and since then i have been spinning my wheels in my own little personal creative cage feeling unfortunately out of touch with myself and what i really want as an artist, a student, a researcher, etc etc etc...

in racking my brain to figure that out, i knew that my turmoil was indeed a result of self-imposed constraint, like this feeling that i have to be bold and innovative and intersting and impactful. and that is really tough to face in the context of my interest in wearable instruments, especially wearable hand gesture tracking form factors because it is something that many people have done some variant of before, cooler and/or better than i would probably.

and after a lot of back and forth i was able to reason with myself a bit. because here's the thing. this concept of wearable, hand movement tracking controllers, and even the technical building blocks people generally rely on to create them--- those things are not new, and i can't really avoid all of it because some of it just makes sense. and i don't need to be innovative on all fronts for my work to be valid. as neil said in class, we are meant to stand on the shoulders, not the feet of giants (aka the work of those who came before us). and there is still plenty of space for individuality and innovation in a project which builds upon or holds similarity to previous work.

Now to step back on a necessary tangent: here's the point where i should explain a bit of background. My interest in wearable instruments began in undergrad when i took a digital instrument design course and scrapped together this instrument for my final project. Due to my limited resources and fabrication knowledge, the whole project was designed out of scrap materials and held together mostly by hot glue. There's a lot i could say about it, but i wont get too carried away. point is, for some time after that i did a ton of thiking (and even some shitty prototyping) on making a new custom wearable for myself. the ideas i am developing now are informed by years of brainstorimng, tinkering, researching, planning and giving up. it's a new design intended to rely upon a number of skills i'll be learning in the class which are new to me, and it's also subject to change along the way.

okay now back to the 'innovation' side of things. i have a lot of very strong opinions on musical instruments. i have respect for midi controllers and commercialized musical interfaces made for a broad user base, etc. but i do not want to make those things. i'm interested in designing things that are highly custom (not customizable), experimental, and aesthetically specific (visually and musically). you cannot mention glove based musical controllers without someone bringing up mi.mu and i am not at trying to recreate that, but it is helpful to look at, along with the other dataglove type interfaces out there, because designing for the human hand is an odd challenge with tough constraints that existing devices have found reasonable ways around.

i have more to explain but i think the intitial need to ramble through my ideas has been satisfied so i'm just gonna start laying out what i want and what my design ideas are. actually no, i'm gonna go home and deal with that later because my dog is growling at me and it is 7:30 pm on a friday