Aijia Yao

MIT EECS • HTMAA 2025

Week 6 – Electronics Production

October 2025

This week was mainly about PCB production.

What I Did

- Follow this link to the group assignment.

- Learning design tools for PCB production, particularly milling copper board.

PCB Design

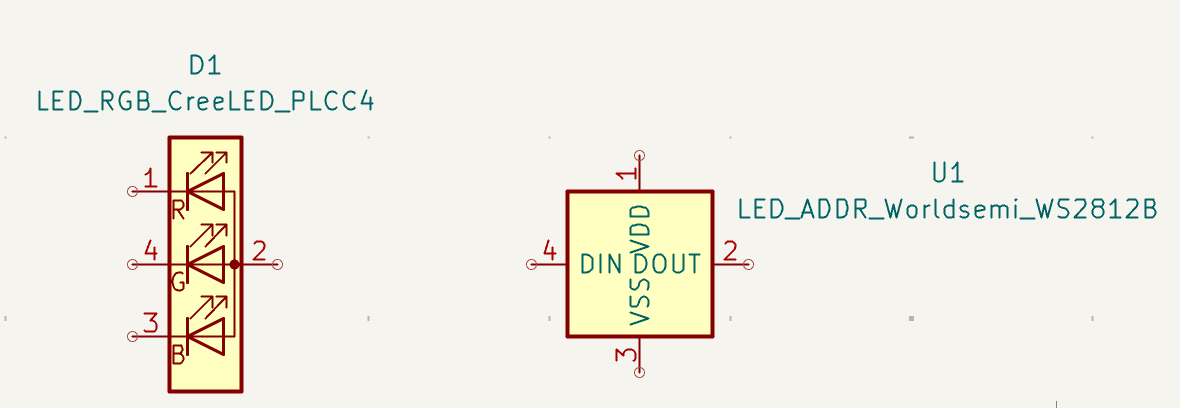

- Before milling the PCB, I reviewed my design from last week of a simple PCB with XIAO-RP2040 microcontroller and RGB LEDs.

| Component | Specification |

|---|---|

| Microcontroller | XIAO-ESP32-S3(simulation);XIAO-RP2040(real design) |

| LED | NeoPixel Compatible LED (WS2812B, see datasheet) |

| Button | Tactile switch (TS04-66-43-BK-260-SMT, see datasheet) |

PCB Milling

Then I milled the PCB using Bantam Othermill. The process is quite straightforward.

- First, I secured the copper board on the milling bed with double-sided tape.

- Next, I loaded the .gbr file into the software and set the origin point.

- After that, I just needed to press "Start" and change the milling tool if necessary, then just wait for it to finish.

- (The whole process took around 10 minutes)

Other Notes

- The gerber files for copper layer is here and the edge cuts is here.

- After debugging with a multimeter, I confirmed that all connections were correct and the circuit was functioning as intended. The full play around with this PCB is discussed in Output Device Week.