Prototyping Mechanisms

This week , we were challenged to design, model, and protoypte the operation of a mechanism of our machine. I used the opportunity to deeply analyze the future direction of Fab in a box and to do some research in existing capabilities. Below you can follow my development and the lessons learned in prototyping the assembly and disassembly of Fab in a box.

Researching and Drafting Potential Directions

I used this week to make a decision about the direction of the future of Fab in a box:

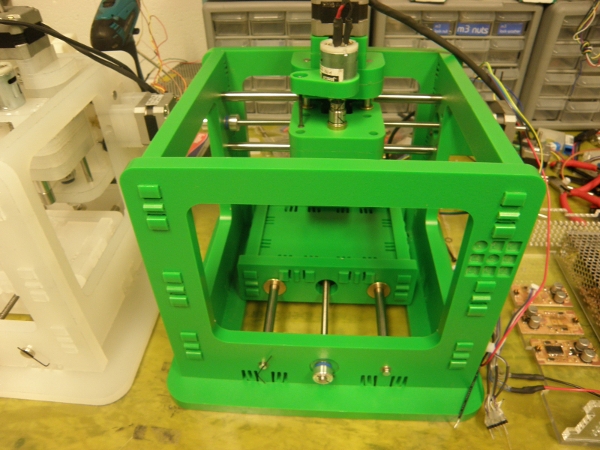

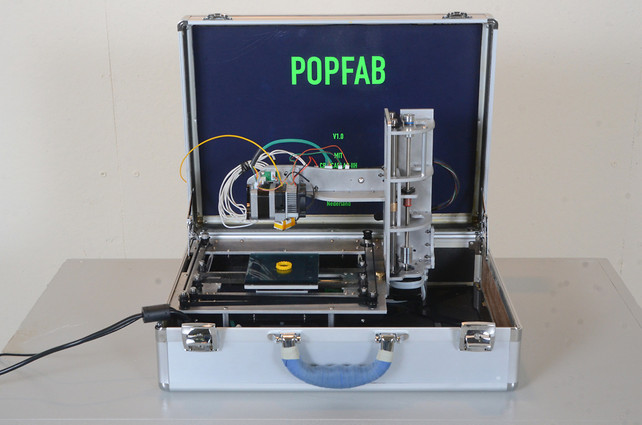

One of the proven types of structures for a Fabinabox-like machine is that of the MTM Snaps, pictured left, famous for its hackiness in assembly as a machine that can be snapped together. The other rival in this game is Popfab, pictured left, that takes a briefcase shell and fits a machine inside of it.

While there are benefits to both, I decided that choosing the Popfab direction would leverage the technology developed by people that are already making that their living, and would allow me more room to focus on maximizing the machine design and bed plate.

CAD Modeling

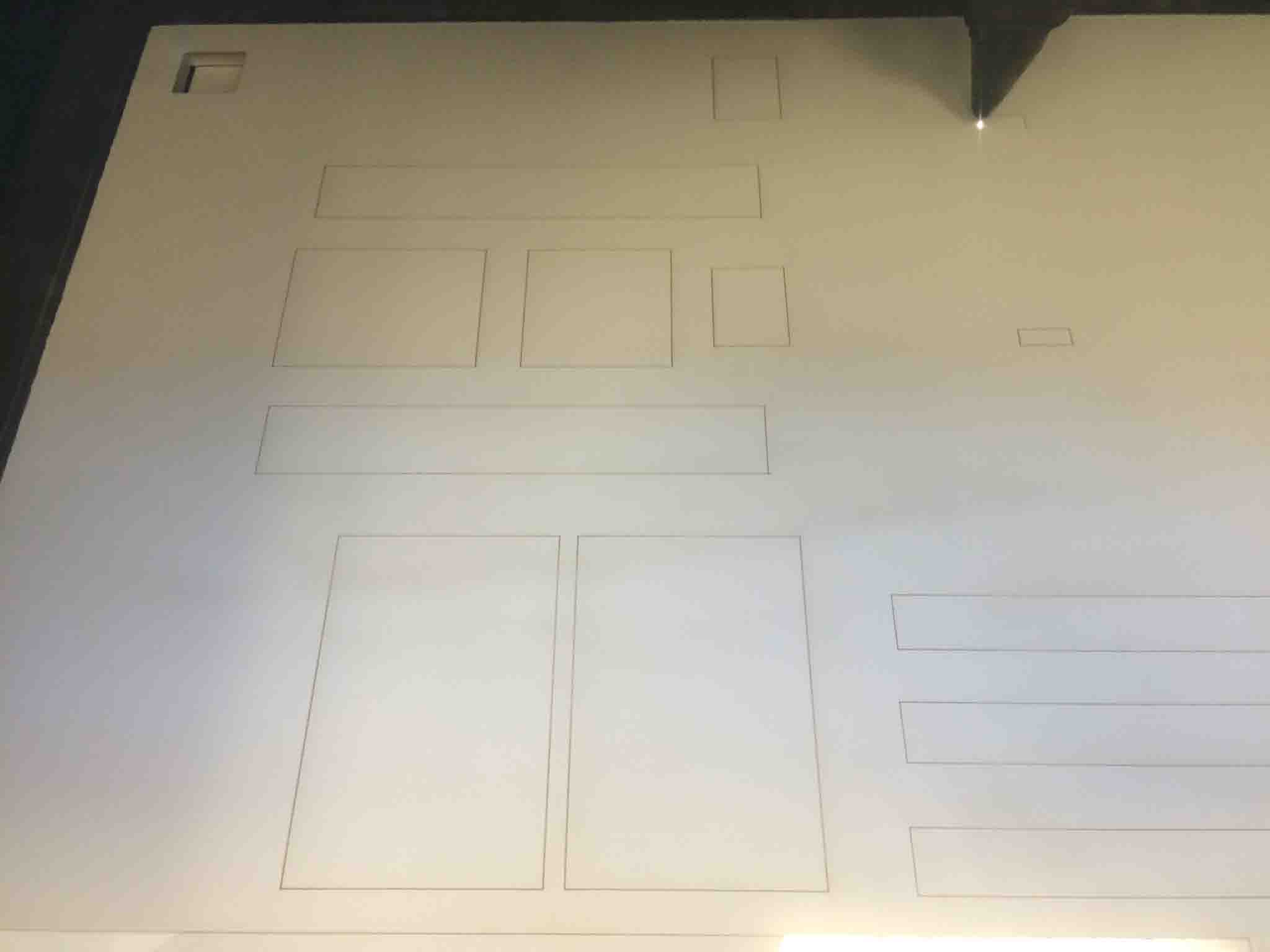

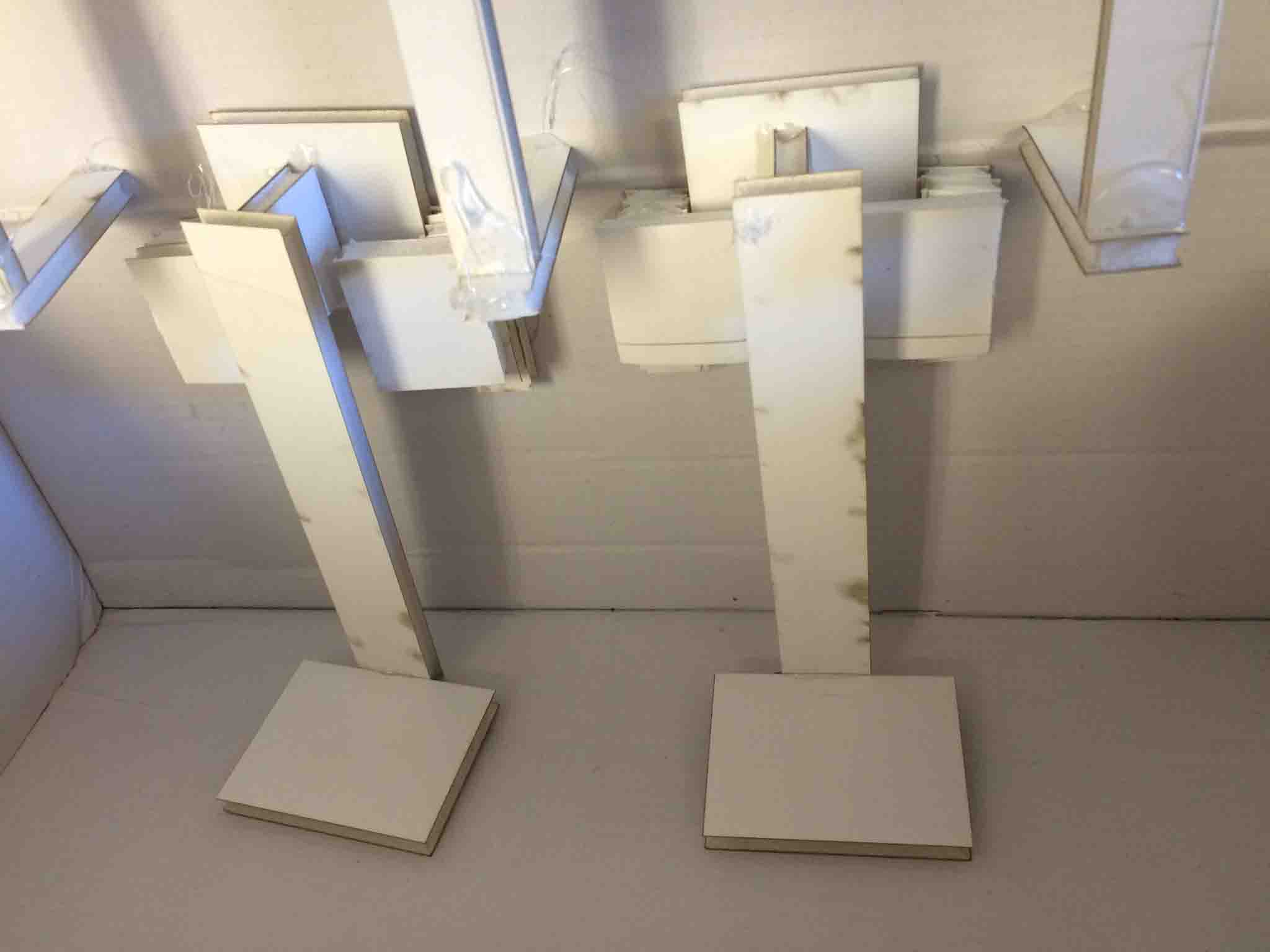

Made as a first prototype to hold the top part of the briefcase from flapping in:

The assembly, in the order it's meant to be assembled:

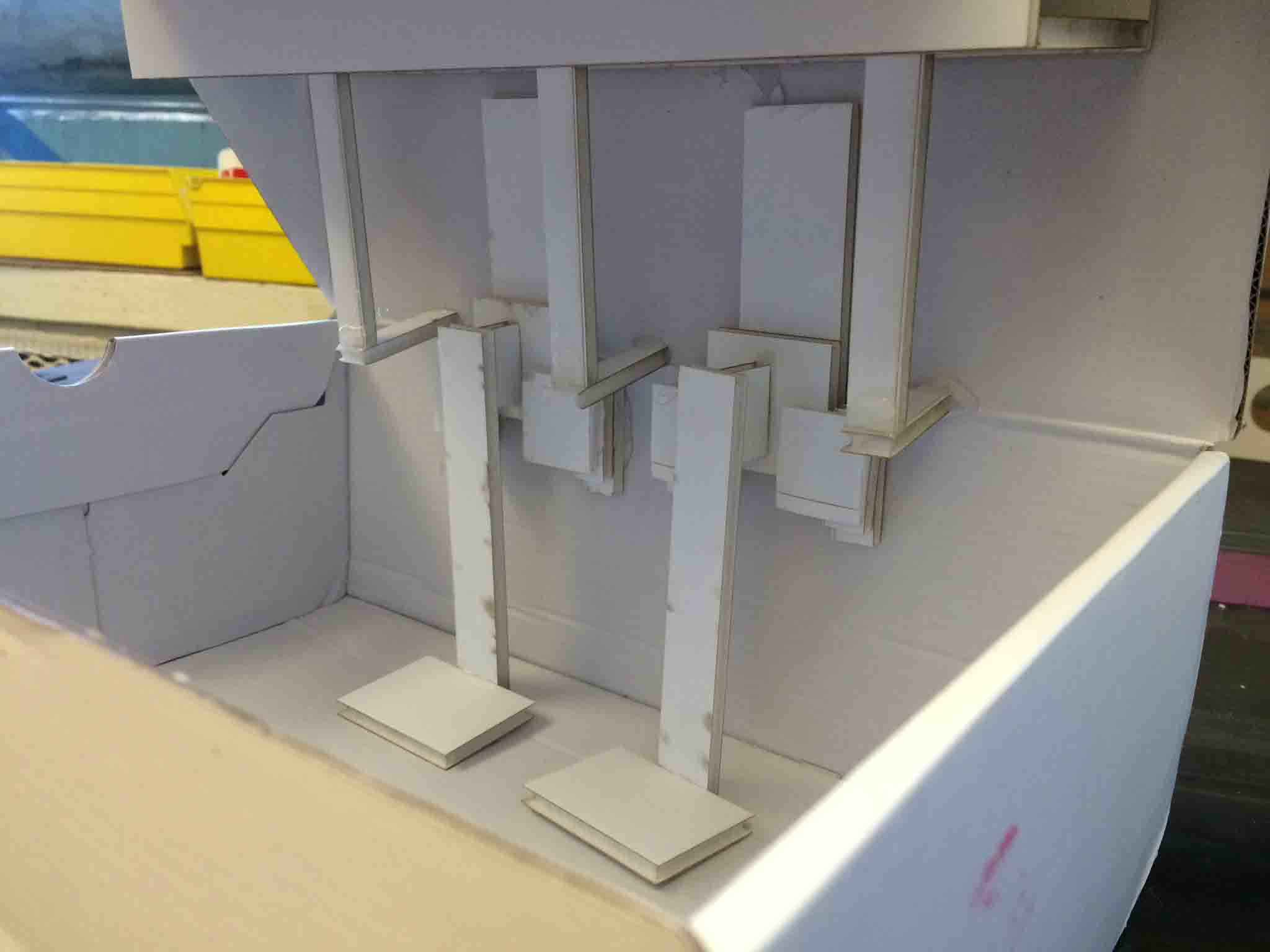

Prototyping in Foamcore

One modification to attach the L-brackets to the briefcase:

And now...a la PopFab style: