Closed-Loop Controls

1. Starting with a Stepper Motor

Last Fall I designed and made a stepper motor board that worked. I wanted to build off of this, since research was pointing me towards using a stepper motor.

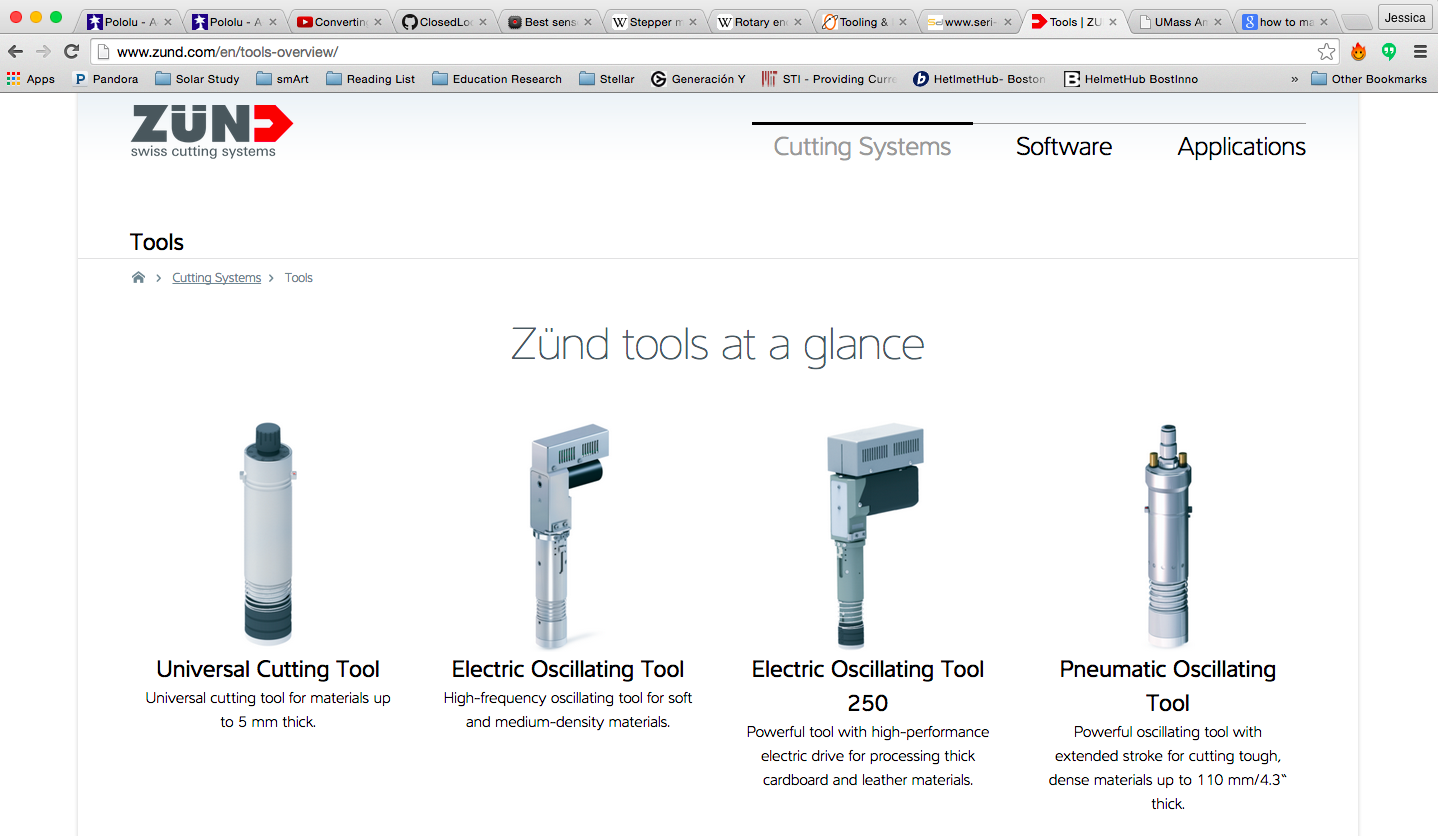

2. Researching Tangential Oscillating Knife Featers

Spent a lot of time thinking about how to design my end effector, again, and it looks like most have some kind of linaer and some kind of rotary actuator:

Took lots of sketches on these:

Once I figured out I needed a rotating actuator, I got stuck between choosing a servo or a stepper motor and then I got stuck convincing myself that I needed an econder on the stepper motor. Then I found myself conflicted between an acceleromter and finding examples of how to hook up a potentiometer. Then it was too late and we went to IHOP. More updates once this is all figured out to come, soon.

Some other notes, unformatted, again:

"Direction, working speed and rotation is controled with dedicated processor. It can be mount to wide variety of 3D milling machines. Oscillation range is 300 - 3000 oscillations per minute, Fluency rotation is settable to 10000 pulses per revolution.” https://www.youtube.com/watch?v=5irxBCBFoOY

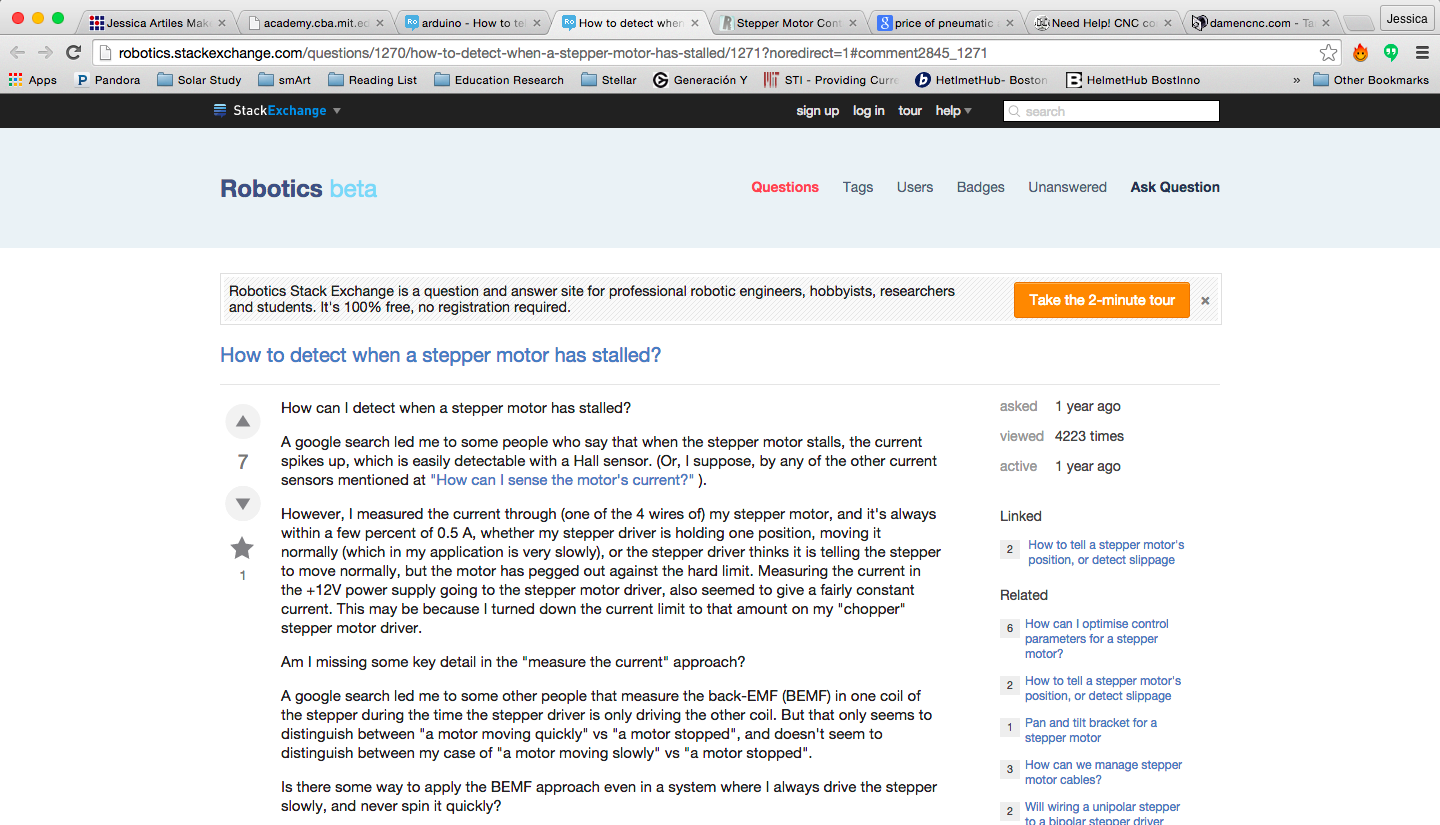

To sense position around stepper motor:

Specs for German knife:

Supply voltage control electronics: 12V =

Oscillation voltage: 12 - 24V =

Oscillation: about 3500-7000 strokes / minute, depending on the stroke (1.0 / 2.0 / 3.0 / 4.0 / 5.0 mm)

Dimensions: 86 x 58 x 220mm

http://www.cnc-step.co.za/tangential-oscillating-knife/

Very helpful in understanding the space: http://www.robotshop.com/blog/en/how-to-make-a-robot-lesson-3-actuators-2-3703

Saying that servo motor are cheaper and lighter and already come with encoder, but stepper motor can do higher torque against

Arduino Closed-loop stepper motor Pt. 2, but he uses an optical encoder: https://www.youtube.com/watch?v=Z6OMT1fIQnU

Want to make a closed-loop stepper motor with a potentiometer.

measuring distance: http://www.ahmetozkurt.net/MEC515/week2_%20displacement.pdf

Really beautiful explanations of why an oscillating cutter is so useful: http://www.zund.com/en/pneumatic-oscillating-tool

Using this potentiometer: http://www.digikey.com/product-detail/en/PVZ2A103C04R00/490-6999-1-ND/3846196

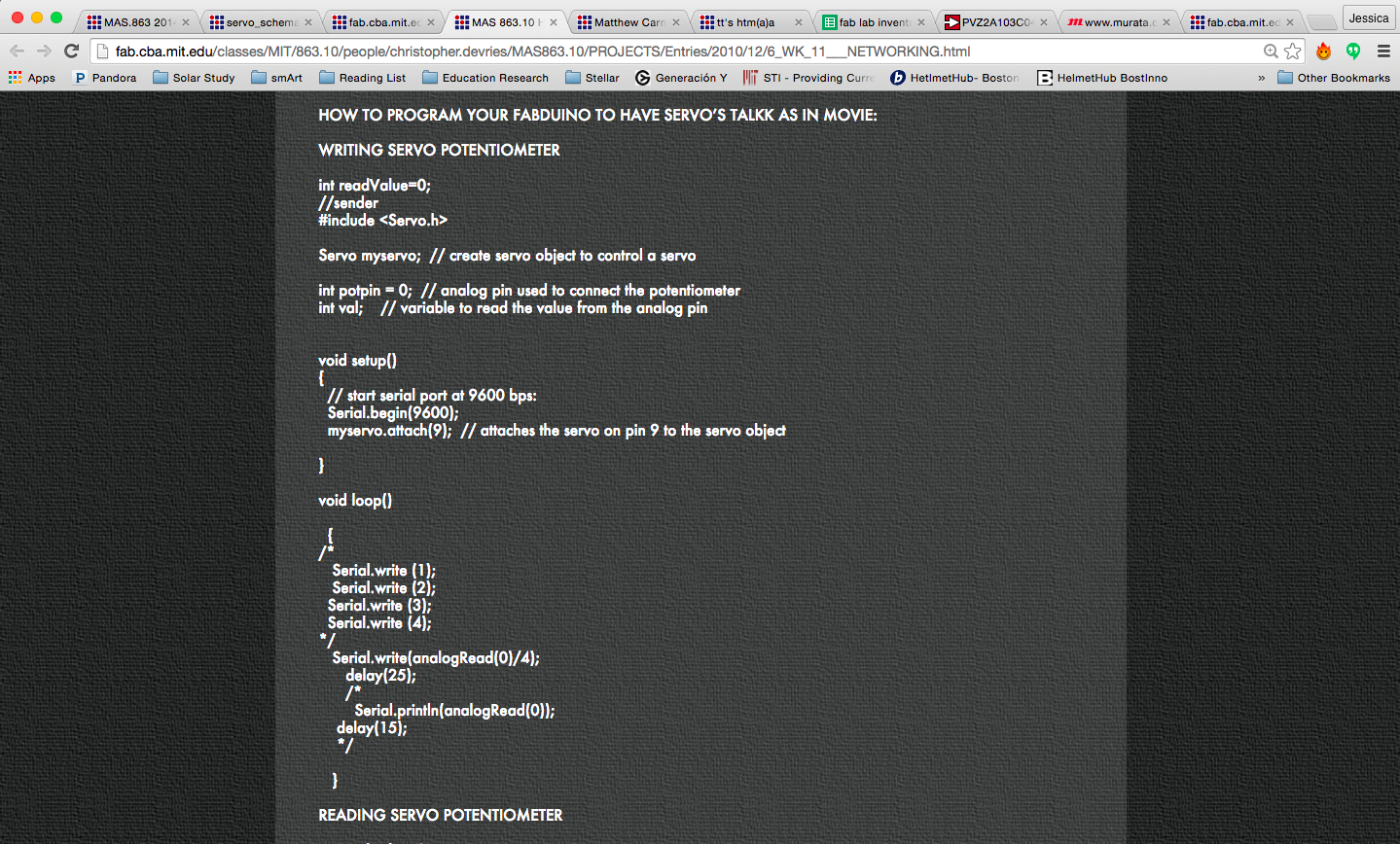

Want to follow in Matt Carney’s steps and implement reading the potentiometer: http://fab.cba.mit.edu/classes/4.140/people/carney/p10/p10.html

Then Close the loop