Swivelling Couplers

This week, I focused (more) on the prototyping of my end effector's progress on its way to being a Tangential Oscillating Cutter. I worked on designing and sourcing multiple couplers so that my knife could swivel through the material, and ultimately machined my own coupler.

Sketching Coupler Designs

Below are some designs Gwyn and Jack from D-Lab helped me sketch up.

Below are the final three designs I took to Pat, the Edgerton machinist in Area 51 (N51). We realized that for design 2 and three, we would need to make a special tool to then make the part. In the interest of time (and for solid feasibility analysis anyway, I pursued the slot design (originally Jack's idea!) and machined it for a should screw insert to couple the top half motion with the swivelling bottom half motion.

Machining the Slot Design: Turning on the Lathe

Machining the Slot Design: Milling on the CNC Machine

Used a collet block to hold my piece down.

After machining my first prototype, I took some measurements and made some edits on a second iteration: thicker stock for more support, smaller height for a smaller assembly.

Machining the Slot Design v2

Processing for Assembly Integration

Tapping the coupler. Also had to make a new shaft collar for the new design with a shoulder screw on the hinge rotation.

Made some more edits to fit a third holder for the top half of the coupler. Next, these holes will have bearings press-fit inside.

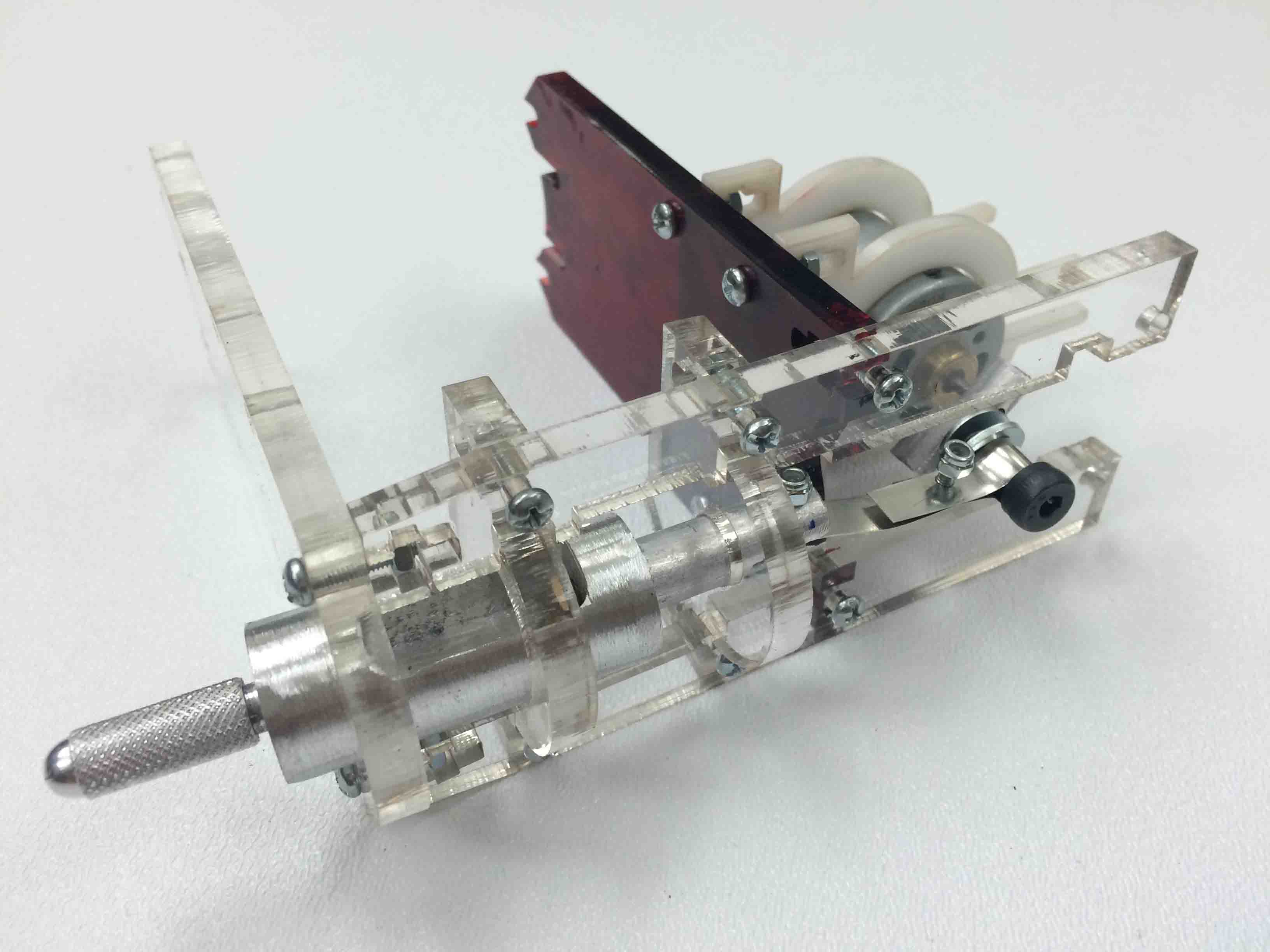

Final Assembly

Here's a video of everything working!

The second after this video was taken, I put the assembly down and got ready to mount it to Fabinabox to test its cutting force, but the acrylic exploded because, in the words of Jack, "acrylic hates being acrylic." Future iterations will give more tolerances to the acrylic, and better alignment.