[introduction] cad/cam, modeling, software

[press fit structure] laser cutter, vinyl cutter, plasma cutter/router

[printed circuit boards] pcb fabrication, board stuffing -

[cables] making molex<->serial and soic8<->parallel cables

[hello world] microcontroller programming

[coffee or tea] 3d scanning and printing

[input devices] sensors, instrumentation, light, sound, temperature, position, proximity-

[flexures] waterjet cutter, CNC milling and turning

[output devices] LEDs, OLDEs, LCDs, video, speakers, motors

[pdms] molding, forming, and casting

[internet zero] communications and networking

[manu] laser micromachining, confocal microscopy

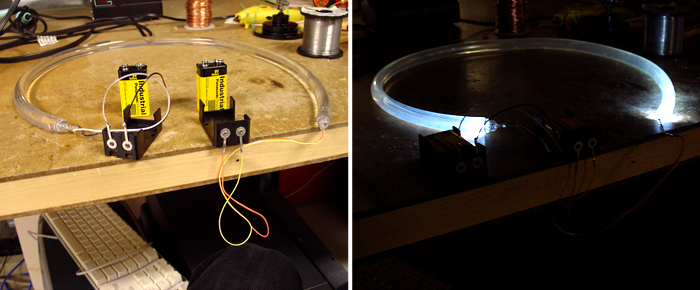

[fab lounge] final project - product

| _intro | _product |

The execution of the fab lounge prototype included the following materials:

|

download the VIDEO of the Fab Lounge during testing & construction here, 5mb