Making Something Big - ShopBot

I decided to make a set of unusual nesting tables on the ShopBot.

I made the design in Adobe Illustrator, and imported the .ai file into PartWorks to creat a toolpath. Pockets were generated as holders for the table legs, which I made of 1" birch dowel.

On the ShopBot, we initially placed screws at each corner to hold down the board, and set the Z-zero in the center of the board (roughly X = 0 and Y = 1/2 Ymax). The board was slightly bowed, and this led to the measured Z=0 being higher than the surface of the board at the edges.

Note the gap in the cut. The first pass didn't touch the wood for the region where the surface was lower than Z=0.

As such, the 0.45" cut depth (for the 0.4375" thick wood) failed to cut through.

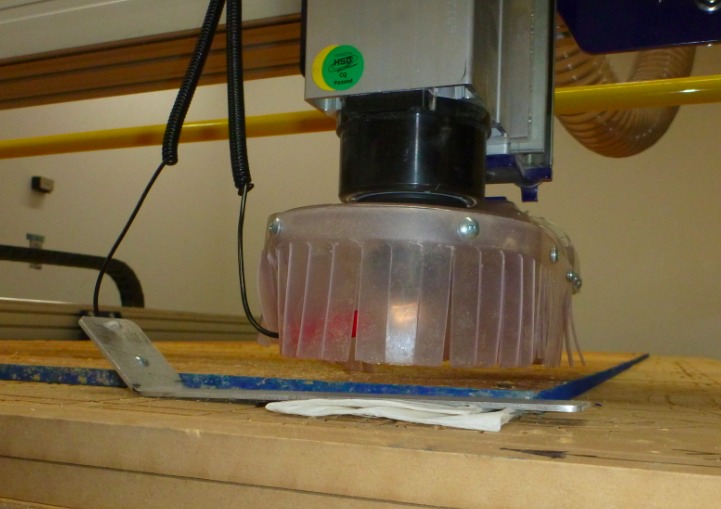

In order to complete the cuts, we re-zeroed the Z at the level of the groove already cut, in order to eliminate the need for recutting the air in the groove prior to actually cutting through the material with the deeper toolpath cut we needed.

Zeroing Z at the level of the first pass groove depth.

This worked well and cut efficiently. However, for one of the transitions between pieces, the endmill dragged through the board, rather than above it, leaving a gouge.

I cut the dowel with a jigsaw and fit the legs into the pockets on the underside of the tables.

Completed tables.

I found this project extremely fun. I will definitely be exploring further uses of the ShopBot!

Thanks to Costanzo for giving up his Sunday morning to train me on the machine, to Jen for giving us access to the room, and to Emma for being an awesome ShopBot partner!