Week 15: Final Project Development

Overview

The 15th assignment of the semester was to document the update plans and the current progress of out final project. For my final project, I am making HACHIKO, which is would become my best robotic buddy.HACHIKO is inspired by the famous Japanese dog, Hachi, which was legendary loyal dog. What if you had a robotic buddy that acted like a well trained dog, and helped you do something, or fetched something for you? So I decided to make one.

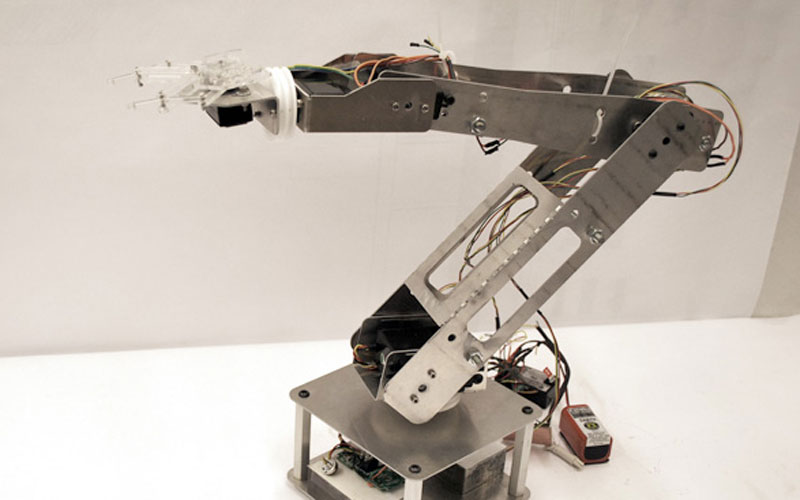

HACHIKO is a robot that has a mechanical arm. Like a dog, it would follow you, and listen to your orders. It also has a replacable attachment. You can attach the claw attachment to make it fetch something, you can attach the stiffness sensor to make it poke something and probe the stiffness of an object, or you can make your own! For the following the master, I am thinking of implementing a control framework based on IR sensing. The master would wear some kind of a IR emitting device and the robot would be steered in a way that would follow the IR beam.

Prior Work

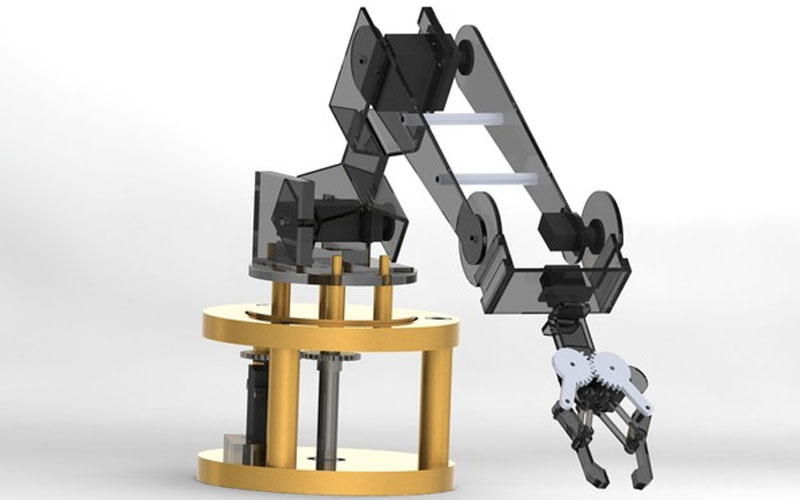

In terms of robotic arms, there are tons of examples that could be referenced. Some are big, some are small. Some are extremely expensive, while others are cheap and super easy to make. I decided to make a simple struncture with two flexible angles, actuated by servo motors. I have also decided to have a rotating base, actuated the stepper motor. I found a nice initial design in GrabCAD to start with. I also looked at Masoud Akbarzadeh's final project from 2010.Tasks

So far, I have completed the following tasks.- Initial ideation (week 1)

- Design and assemble the stiffness sensor module (week 9)

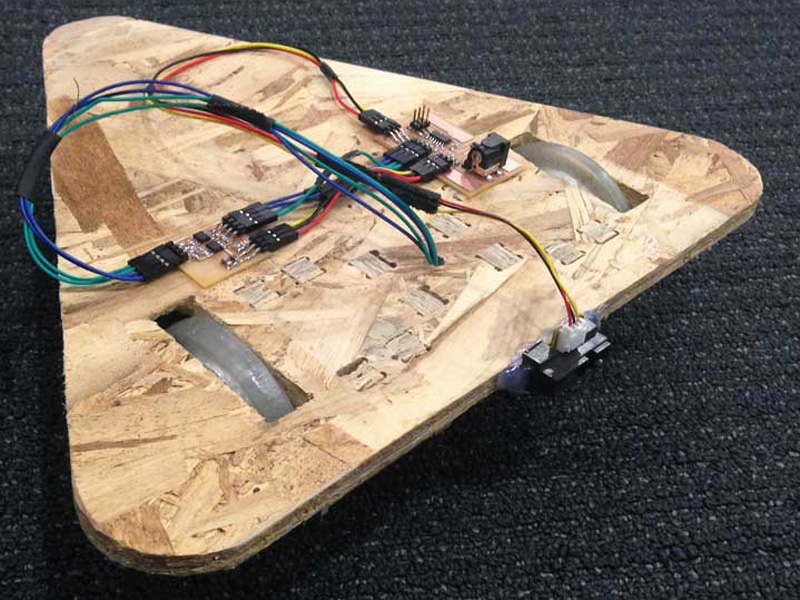

- Design and assemble of the base (week 11)

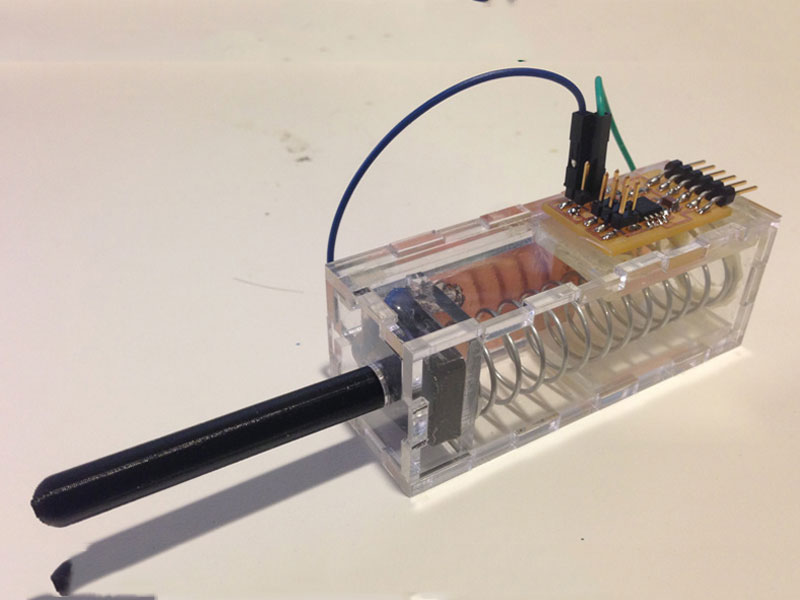

- Making a radio transreceiver for remote control (week 13)

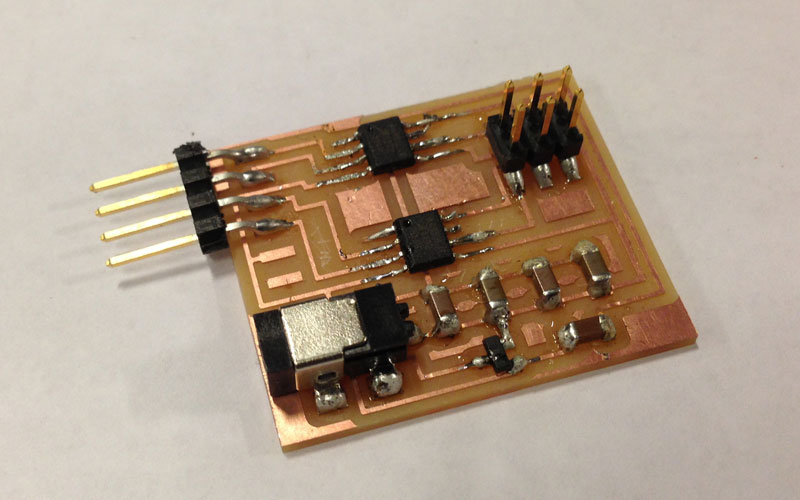

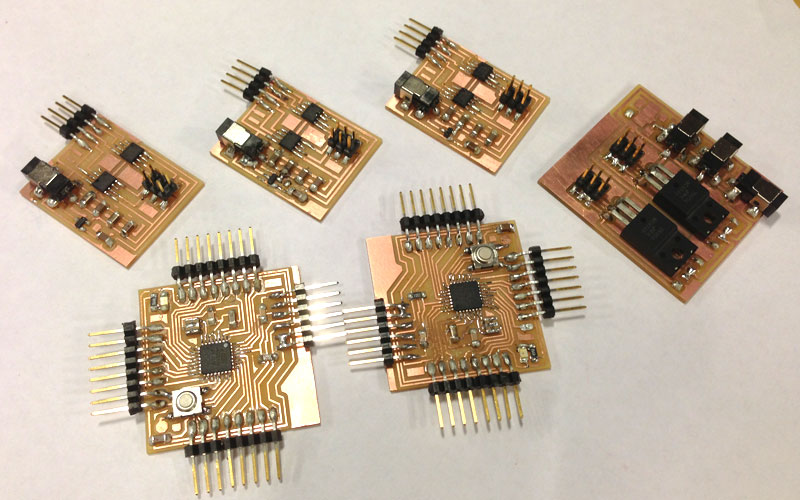

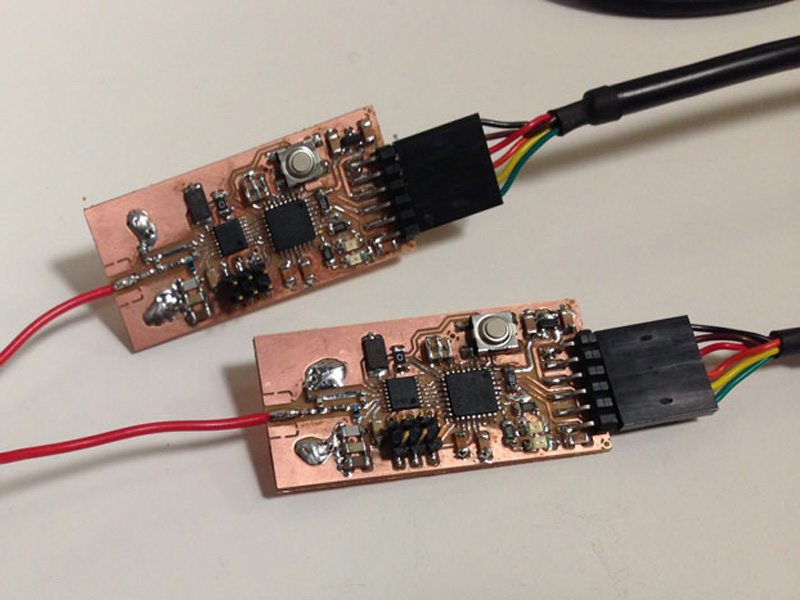

- Make the Fabduino for the main processor (this week)

- Design and make the motor driver for the stepper motor (this week)

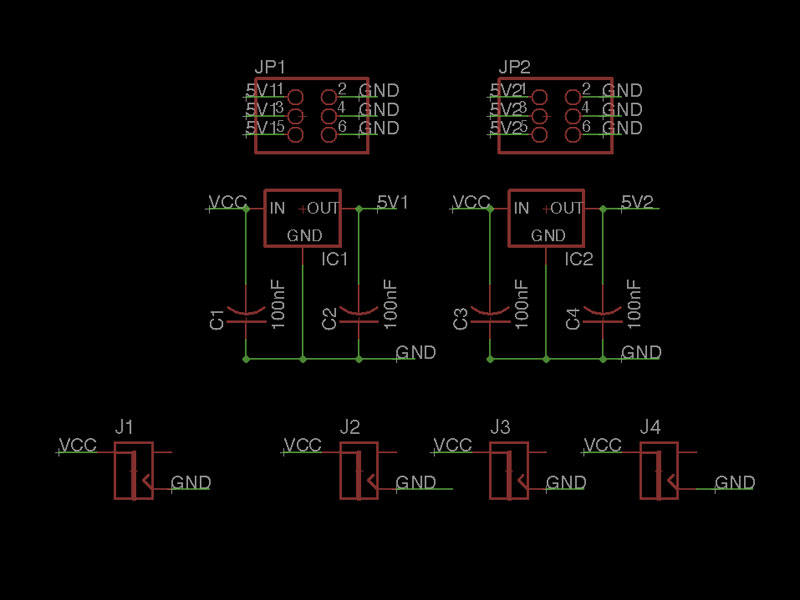

- Design and make a power supply to serve 5 V and 12 V current (this week)

|

|

|

|

In the remaining 6 days, I need to do the following.

- Detailed design of the mechanical arm

- Fabrication of the mechanical arm using acrylic material and aluminum

- Design and fabrication of the claw module

- Programming the control mechanism

- Design and fabrication of the remote controller

This Week's Progress

For this week, I mainly focused on electronics design and fabrication. As described in the page for week 14, I designed a motor controller for a bipolar stepper motor.I also design a power supply board. It is a simple board with a 12 V input, two 12 V outputs, and six 5 V outputs. For providing the 5 V current, I used two 7805 voltage regulators.

|

|

I've done quite a few board fabrication and soldering this week. Now that I have all the electronics, so the next week would be more focused on the mechanical design and assembly.