Computer-Controlled Machining

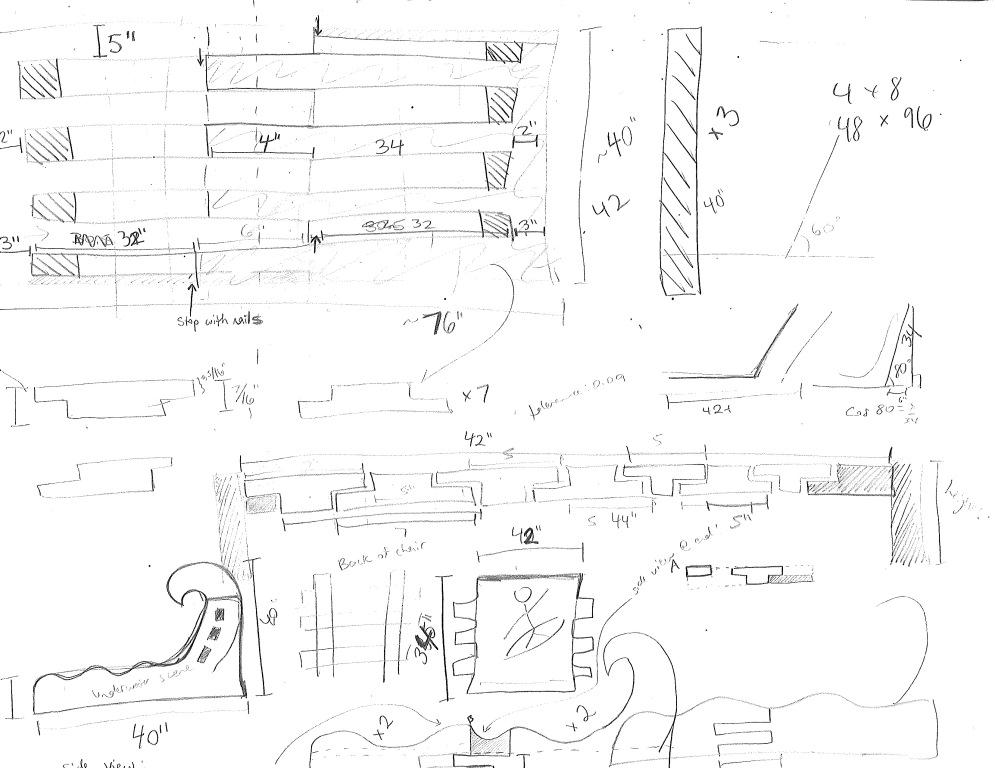

This week's task was to make something BIG. I wanted to make myself a convertible futon frame that can be either a chair or a bed, because my futon mattress currently sits directly on my floor. I thought it would be fun to make the sides of the frame shaped like a wave. I drew up a few designs by hand and showed them to the TA, Tiffany, and Brian at the Hobby Shop, but they thought making structurally sound convertible furniture would require more than one week.

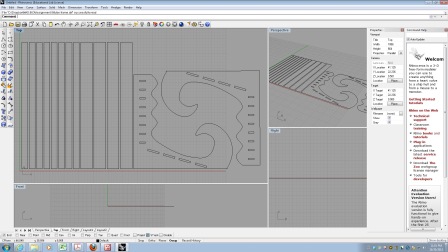

I dropped the idea of a convertible frame and designed a chair frame for when my futon is folded (I will still have to put it on the floor if I want to use it as a bed). I drew the 2-D cut outs in Rhino this week, because I wanted to learn another CAD program other than Solidworks. Though I initially had some trouble adjusting to the new program, I liked that I was able to draw using commands.

I converted my .dxf file from Rhino into a g-code .NC file using MasterCam on the Hobby Shop computer. I had to add a few notches to the ends of my press fit holes in order to ensure a better fit. While I was making changes anyway, and I knew I had more wood available, I decided to also draw a "squatty potty" (to be discussed below).

First I cut out a test slot and piece to make adjustments for my press fit holes. The piece fit perfectly into the slot, so I went ahead and cut my design using the large milling machine.

The pieces came out fine and I spent a few hours sanding them. I thought everything was going well, until it was time to actually press-fit the components together. Only one side of the beams fit into the side wall; the other was too wide, and despite additional sanding, I could not get the other side to fit into the other wall. Apparently, the thickness of the wood was not the same throughout, and I had cut my test pieces from the thinner side. At this point, I did not have any more time to sand, file, or even cut it down with the bandsaw. I will have to continue this project another time, or maybe I will commit more time and make the frame convertible, as I had originally wanted.

Luckily, I had quickly designed my squatty potty, so I do have a finished product for this week. What is a squatty potty? It's a little stool that you rest your feet on while you use the toilet in order to force your knees up to simulate squatting. Humans were designed for squatting, after all, and a sit-down toilet is a recent invention. Squatting straightens out your colon and helps you poop more easily and healthily! Don't believe me? Watch this video:

I did not make the toilet stool press-fit, so I glued the legs to the top, using clamps to hold the pieces in place, and then I drilled in screws for reinforcement.

When the toilet stool was finished, I needed to test it out. As you can see in the photos below, you can easily store the stool by tucking it under the toilet, and you can pull it out when you need to use it.

The results of my test were successful! But I think next time I would make the stool a little taller.

Files