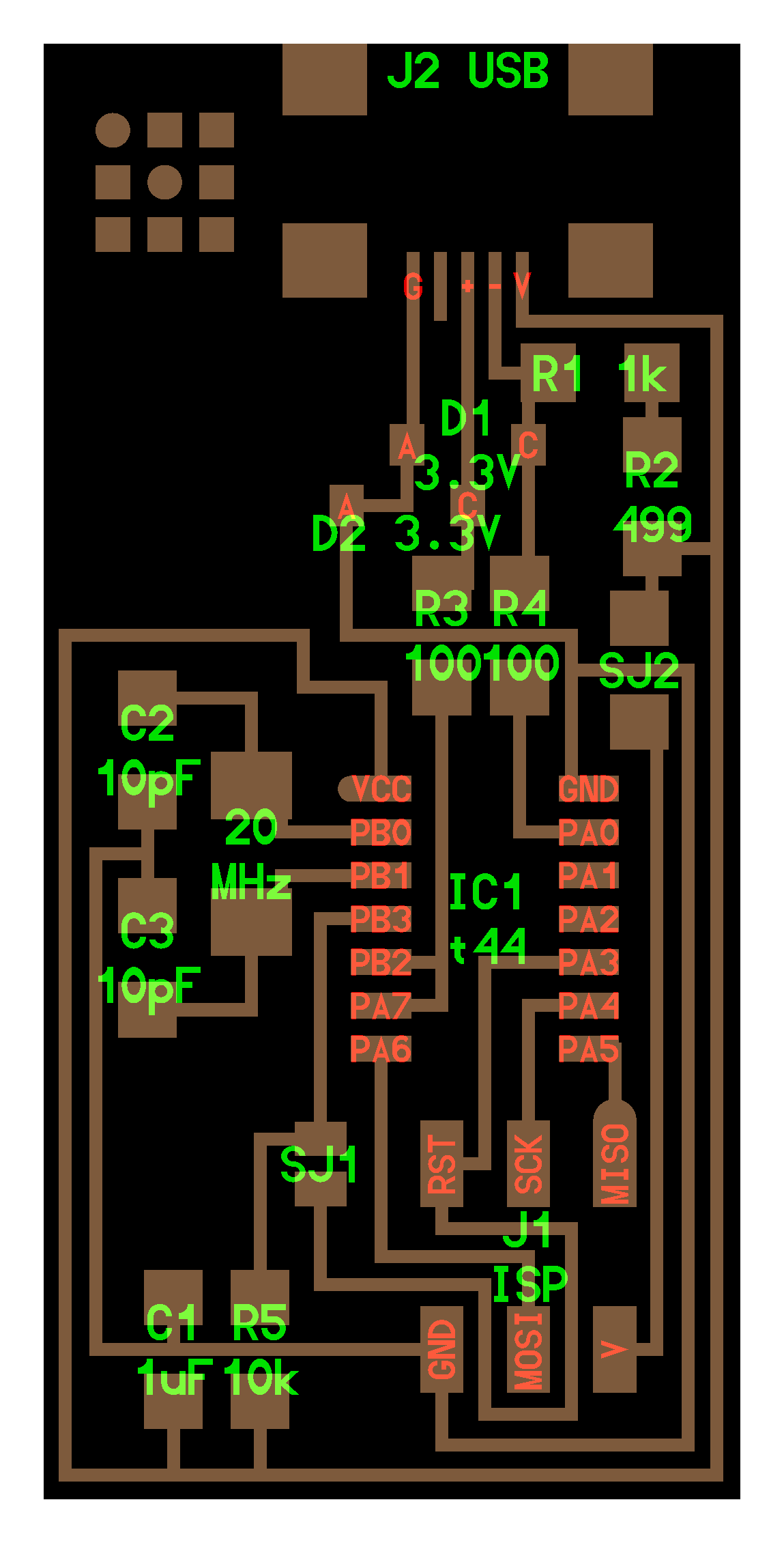

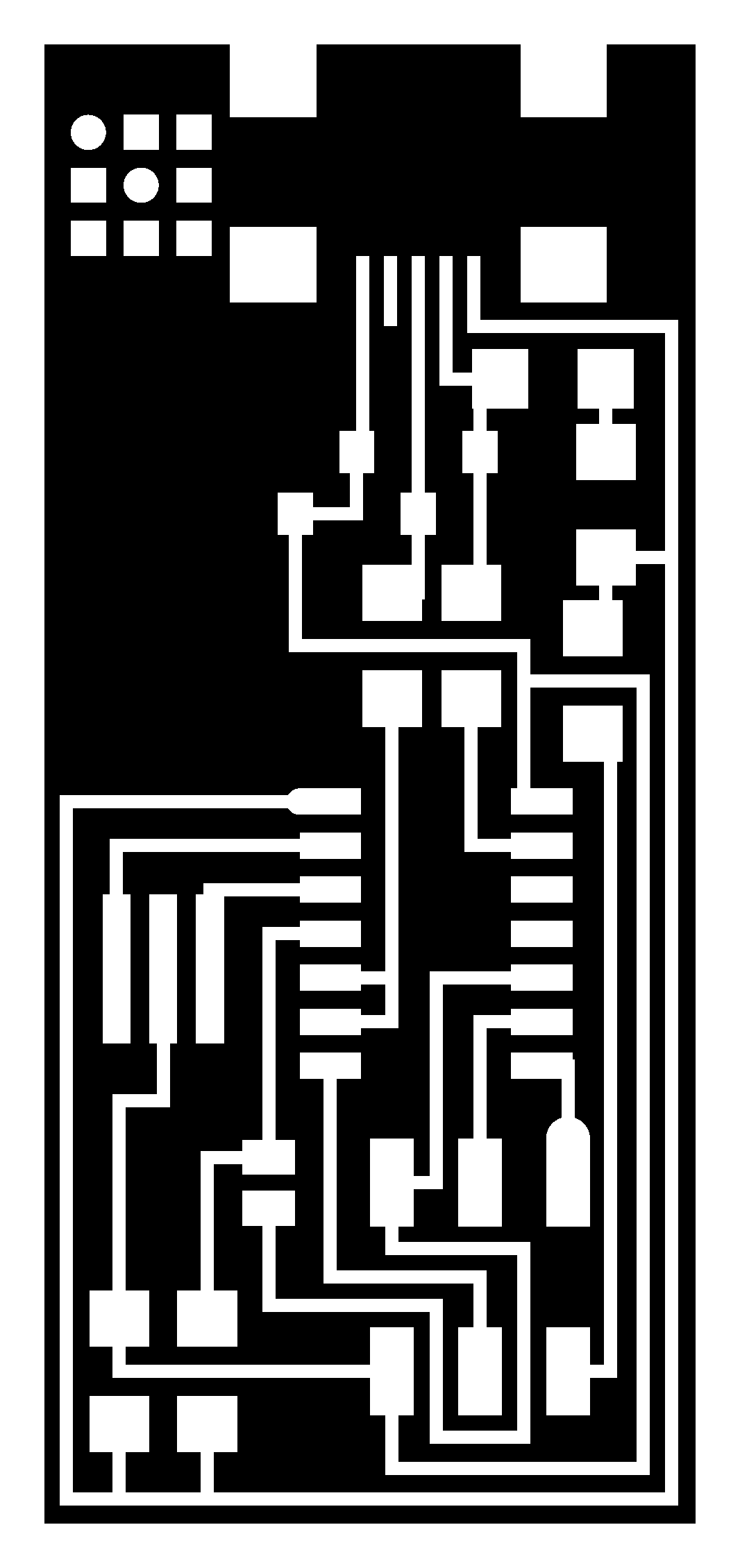

Make the FabISP in-circuit programmer.

Milling the board was pretty straight-forward and to be expected, using the 1/64 and 1/32 endmills on the Modela. The only issue that stumped me for a few minutes was changing the send command to "rtscts" as it did not pop up that way.

After loading the fab modules, milling the board really only took about 15 minutes. Soldering the board however, took about four hours. The soldering iron I was using wasn't evenly distributing heat, and Thras ended up replacing the tip. The most difficult part to solder was the USB. I ended up flooding the prongs with solder and then wicking away the excess with copper braid.

Soldering is about as theraputic as it gets. I am a big fan of the lead solder, so switched to that with my second board because it is easier to manage and doesn't seem to lose flux as quickly.

So unfortunately, my first board was pretty unhappy. At first I had decided to use the flux pen and heat gun to see if I could get the solder to cooperate, but once I realized I had reversed one of my diodes and microcontroller, I decided to just get a clean start.

With my second design I chose to use the FabISP with the crystal resonator instead because it was easier to solder.

Once Will and I plugged in my second board there were surprisingly few problems. I had missed soldering the end of one of the resistors, but after a quick fix, my board was recognized as a USB and I removed the jumpers. I then made an IDC ISP cable, and ran the programmer.

Success: