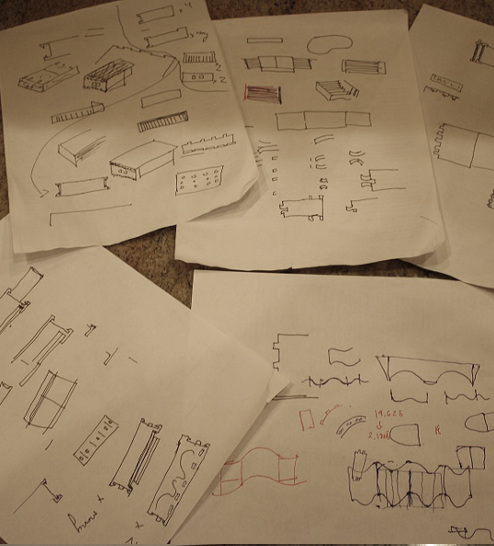

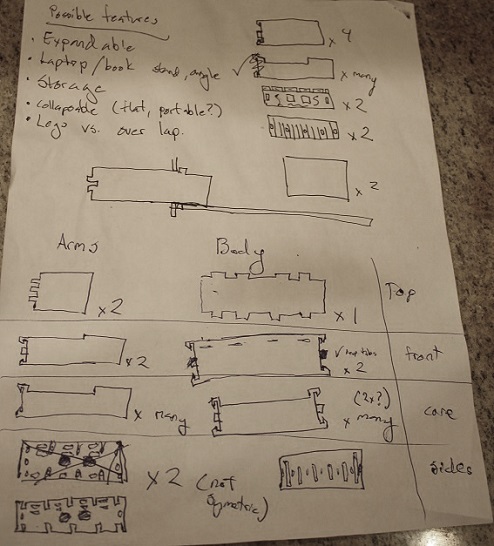

For our first substantive assignment, our task was to design a "press-fit construction kit", using corrugated fiberboard (aka "cardboard"), or other materials such as acryllic sheets, if we chose. The computer controoled cutting aspect would be accomplished by a laser-cutter, using a design we created in CAD or illustration software (since we are designing flat pieces, a vector graphic made in Inkscape or Illustrator would be sufficient for the cutter to use.)

A key aspect of this assignment is designing something to be "press-fit"; that is, held entirely together by tabs, joints, and tension in the material without using glue or adhesives to hold pieces together. In class we were shown several ways of creating press-fit joints using Antimony modeling software, using various designs for tabs, teeth, and slots to secure materials together. A key necessity for the complex designs was flexibility in the material to allow it to bend out when inserting and then spring back to secure the joint. These designs were interesting, but they did not seem like likely candidates for the relatively rigid corrugated fiberboard.

An additional tool we had access to was the vinyl cutter. This could not really make pieces for the press-fit assignment, but it used the same principles for computer-controlled cutting that we would use with the laser, and would be useful for designing custom decals, or printing flexible circuit boards from copper coated vinyl.