Week 5 - Make Something Big

How to Make (Almost) Anything - Manolis Zampetakis

Design

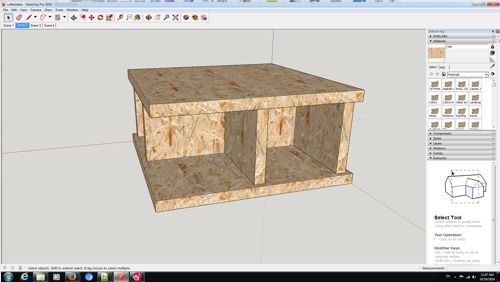

For this week we decided to fabricate a coffee table. To do so we first designed it in Sketch Up as shown in the next picture.

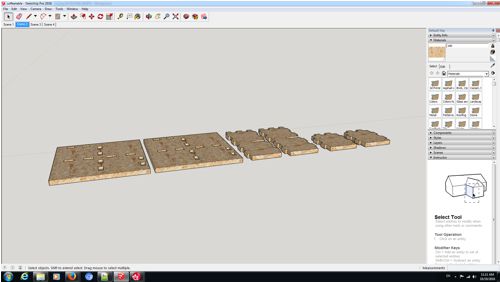

Then we found the sketch of each of the pieces.

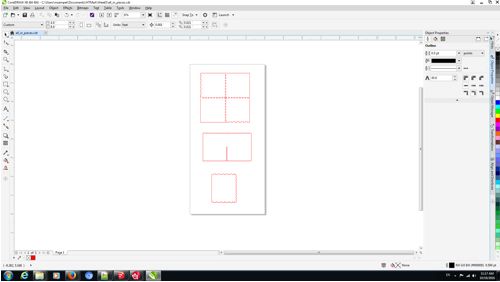

We then exported the sketches as DXF files to be able to open it with VCarve to produce the tool path for the CNC machine.

Then we where ready to put it to the CNC machine for cutting.

Cutting

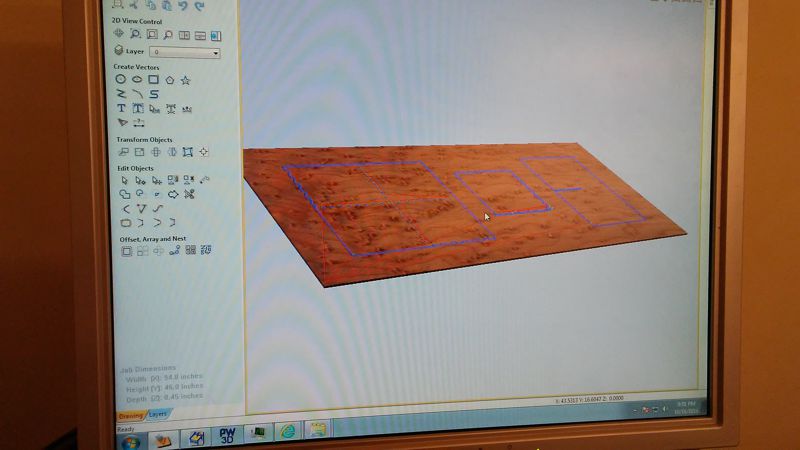

We first imported the DXF files to VCarve to control the settings for the cutting and produce the wanted tool path.

Then we started the cutting proccess.

|

|

|

|

Assemply

During the assemply proccess we had a lot of problems because the cutting wasn't perfect. First the side parts of the table were cutted in the wrong way!

|

|

This was very strange, but we found out that this was because the DXF file for this part had more that one pieces and some of them were cutted from the exterior and some from the interior. So we decided not to use the side parts.

Another problem was that the VCarve wasn't careful when producing the tool path and the connections had a smoothed curly shape. This way it was impossible to connect the part together and this is why we decided to fixed the connections by hand as shown in the next pictures.

Before the fix |

After the fix |

|

|

Lessons Learned

i. Be careful every closed curve should be one piece in DXF so VCarve will use the same settings for cutting all the perimeter of it.

ii. Be careful with the route of the tool that might produce curly corners.

iii. Always be prepared to fix some stuff by hand! :)